方案详情文

智能文字提取功能测试中

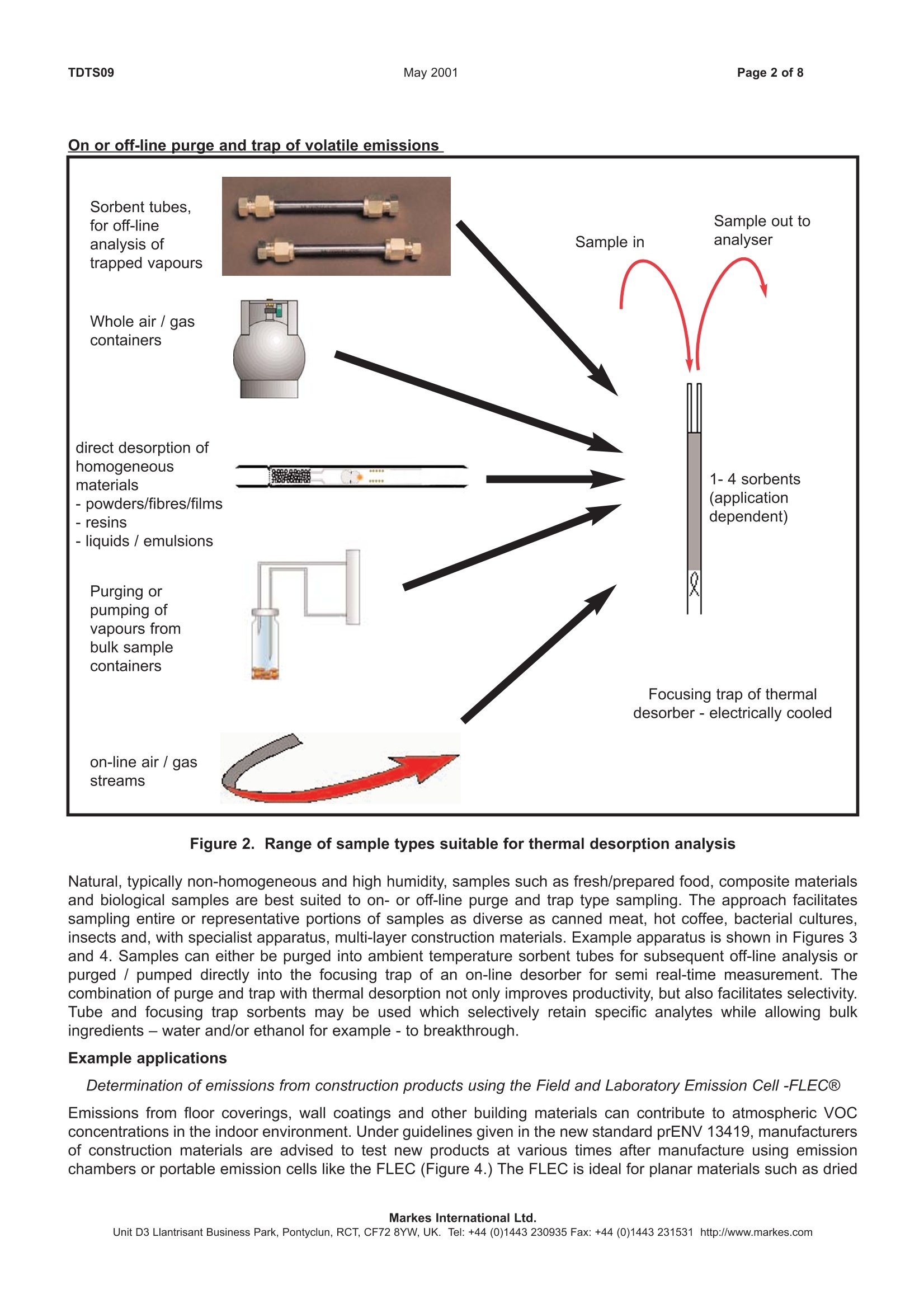

Unit D3 Llantrisant Business Park PontyclunRCT CF72 8YW United KingdomTel: +44 (0) 1443 230 935 Fax: +44 (0) 1443 231 531http://www.markes.comMARKESinternationalL M ED May 2001TDTS09Page 2 of 8 Thermal Desorption Technical Support Note 9:Monitoring Materials and Processes for VOCs at High and TraceLevels Thermal desorption has long had a place as a high sensitivity alternative to solvent extraction forthe determination of volatile organic compounds (VOCs) in environmental health and safetyapplications. Recent developments have extended its application to routine quality assurance andquality control testing. Whatever the nature of the product or raw material containing the VOCs -solid, liquid, gas, emulsion, resin, etc. - thermal desorption can provide an efficient, readily-validated and cost-effective alternative to conventional laboratory sample preparation methods. What is thermal desorption? Strictly speaking, thermal desorption (TD) is the process of extraction/desorption of volatile and semi-volatile organicanalytes from a sorbent or sample matrix using heat and a flow of inert gas rather than solvent. In practice it isinvariably a multi-step procedure -automating much more than the extraction process - The latest technology nowcombines versatile on-line or off-line sampling with solvent-free extraction, analyte concentration and automatictransfer of analytes to the measurement system in a concentrated ‘slug’of vapour. It can be used to facilitate themeasurement of VOCs in almost any sample that, for one reason or another, cannot be introduced directly to astandard laboratory gas chromatograph (GC.) Thermal desorption offers many advantages versus conventional solvent-based sample preparation methods -liquid extraction, solvent exchange, steam distillation, etc.. Figure 1. ULTRA-UNITY automatedthermal desorber Application range Thermal desorption can be used to automate or drastically reduce the number and complexity of sample preparationsteps required for a wide range of quality assurance / quality control applications. Depending on the nature of thematerial under test, solid or liquid samples may either be weighed into empty thermal desorption tubes / tube linersfor direct desorption, or purged (on-line or off-line) into sorbent tubes/traps. This is known as purge and trap.Gas phase samples can be collected on sorbent tubes for subsequent off-line analysis or monitored in real-timeusing discontinuous on-stream analysers. The range of sample types is illustrated in Figure 2. Figure 2. Range of sample types suitable for thermal desorption analysis Natural, typically non-homogeneous and high humidity, samples such as fresh/prepared food, composite materialsand biological samples are best suited to on- or off-line purge and trap type sampling. The approach facilitatessampling entire or representative portions of samples as diverse as canned meat, hot coffee, bacterial cultures,insects and, with specialist apparatus, multi-layer construction materials. Example apparatus is shown in Figures 3and 4. Samples can either be purged into ambient temperature sorbent tubes for subsequent off-line analysis orpurged/ pumped directly into the focusing trap of an on-line desorber for semi real-time measurement. Thecombination of purge and trap with thermal desorption not only improves productivity, but also facilitates selectivity.Tube and focusing trap sorbents may be used which selectively retain specific analytes while allowing bulkingredients - water and/or ethanol for example-to breakthrough. Example applications Determination of emissions from construction products using the Field and Laboratory Emission Cell -FLECQ Emissions from floor coverings, wall coatings and other building materials can contribute to atmospheric VOCconcentrations in the indoor environment. Under guidelines given in the new standard prENV 13419, manufacturersof construction materials are advised to test new products at various times after manufacture using emissionchambers or portable emission cells like the FLEC (Figure 4.) The FLEC is ideal for planar materials such as dried paints/coatings, flooring materials or wood products and is simply placed onto a sample of the test material. Pure Figure 3. Direct pump/ purge sampling ofvapours from non-homogeneous materials Figure 4. FLEC cell for sampling gaseousemissions from construction materials.. humidified air is then passed over the material inside the FLEC cell to simulate real-world environmental conditions.The exhaust gases are collected either onto sorbent tubes for off-line analysis (Figure 5) or pumped directly into thefocusing trap of an on-line thermal desorber for monitoring rapid changes in the emission profile. Shelf-life of fresh or prepared foods: As foods age, the processes of oxidation or decomposition generate indicative and often malodorous organicvolatiles. The presence of these compounds in the headspace vapour immediately above a sample of food is oneof the first indications that a product has past its sell-by date’. A simple thermal desorption-based laboratoryprocedure can be developed for objectively evaluating the freshness of natural ingredients or products: Fresh or prepared food samples - pizza, canned meat, breaded fish, etc- are simply placed in a suitable glassvessel and incubated at ambient or elevated storage temperatures under a flow of pure air. Samples of effluent airfrom the purge vessel are either collected intermittently onto conditioned tubes packed with one or more sorbent orcan be passed directly into the cold trap of the UNITY thermal desorber on a semi-continuous basis using a DirectInlet accessory in pumped mode (see Figure 3 and brochure Mi BINLET,available from Markes International). Tubeand focusing trap sorbents are selected to retain target analytes while allowing water, ethanol and otherinterferences to purge to vent. One or a combination of hydrophobic sorbents - e.g. TenaxTM TA or graphitisedcarbon- may be used for quantitative retention of organics ranging in volatility from pentane while allowing the bulkof water / ethanol to pass through unretained. Complete flavour profiles are more typically collected using two oreven three sorbents in series. Excessive quantities of decomposition/oxidation compounds or deviations from the normal odour/flavour profile canthen be quantitatively assessed from the subsequent thermal desorption -GC(-MS) analysis and used as reliable,objective indicators of product quality and stability. Semi-continuous, direct sampling into the UNITY thermaldesorber using the Direct Inlet accessory allows changes in odour/flavour profile to be monitored in real time. Potable spirits C4 to C6 ethyl esters make excellent markers for the maturity of potable spirits such as whisky. Simply pumping orpurging a given volume of whisky headspace vapour into a conditioned Tenax tube or focusing trap allows selectiveconcentration of higher boiling flavour components, including ethyl esters, while water and the more volatilealcohols, aldehydes, etc., pass through the tube unretained. This procedure simplifies the subsequent GC analysisfacilitating detection of ethyl esters and other higher boiling indicators of spirit maturity while at the same timeeliminating water and the large ethanol peak which would otherwise mask most of the chromatogram. The methodis ideal for quality control of spirits to be used as ingredients in products such as cream liqueurs. Identification and life-cycle studies on natural species Biologists use another variant of purge-and-trap/ thermal desorption technology to identify plant, animal or microbialspecies, map life-cycle changes and characterise the origins of hybrids and cultivars of scented plants1. Specimensare placed in glass containers or special nylon bags in a sampling method derived from that used by forensicscientists to analyze fire debris for residual accelerants in cases of suspected arson. Samples are incubated orpurged as required before pumping an aliquot of the headspace vapour into a sorbent tube or on-line TD system.The fragrance profile obtained from subsequent TD-GC(-MS) analysis acts as a fingerprint helping to characterisethe sample under the test conditions and allowing it to be compared to other related or control samples. Direct desorption Dry or homogeneous materials - for example; therapeutic drugs, packaging materials, resins, spices,ointments/creams, polymers, water-based paints, edible fats, etc., can be weighed into empty tubes or tube linersand desorbed directly (Figures 6 and 7.) In this case, sample preparation is essentially reduced to zero and theassociated risk of error introduction is eliminated. This has to be one of the most straightforward and cost effectivesampling procedures for otherwise difficult materials. As above with the combination of purge and trap and thermaldesorption, the actual thermal desorption procedure can be tailored to meet analytical requirements - either acharacteristic ‘odour profile'or complete, quantitative extraction of specific target analytes can be achieved. Themethod facilitates analysis of the most challenging materials - combining sample cleanup, analyte extraction andsample injection/introduction into one simple, automated operation. Figure 6. Dry, homogeneous material weighed directly into an empty tube for direct desorption Optional sorbent bed to prevent Glass Wool Liquid Resin or Creamhigh boiling compounds or matrix Plug sample sample artifacts migrating into the flow path Figure 7. Liquid or resinous materials measured into a PTFE liner, and placed inside an empty tube, fordirect desorption Direct thermal desorption is compatible with a wide range of different material types -Salt/sugar solutions,suspensions, resins, creams and plain solids. The only rules for success are as follows: Ensure solid materials have a high surface area-powders, granules (particle size <1 mm3), fibers or films.Bulk solids should be ground with a coolant such as solid carbon dioxide before the material is weighed intosample tubes. The gas flow path must not be blocked with sample. Thermal desorption is a dynamic process and gas mustbe allowed to pass through the sample tube unrestricted. Ensure that the sample is placed inside the sample tube such that it is well within the heated zone of thethermal desorber used. Direct thermal desorption is only appropriate if the desired extraction takes place at a temperature below thedecomposition point of other materials in the sample matrix and provided the relatively small sample size that canbe measured into a thermal desorption tube is representative of the sample as a whole. Most samples are bestweighed into a tube insert or liner, rather than being weighed directly into a glass or steel desorption tube. (Linersare typically constructed of heat shrink PTFE tubing with a reduced diameter at one end - see Figure 7. A smallsample tubes and eliminates risk of degradation from samples coming into contact with metal tube surfaces. Within these limitations thermal desorption provides automatic on-line extraction / preparation system for everythingfrom water based paints to dried soups, from drugs to printed packaging film and from to toothpaste to epoxy resin. Example applications ‘Off-odour’or taint' By eliminating most or all of the sample preparation steps typicallyinvolved in trouble shooting something assubjective as taint in soap flakes or off-odour in edible fat, thermal desorption can speed up and simplifyidentification of impurities and hence pinpoint the source of many quality problems. Both these materials have been real-world success stories for thermal desorption.... (1) In the case of the edible fat, samples of control and ‘problem' material were weighed into PTFE sample linerspacked with clean glass wool and inserted behind a short bed of conditioned Tenax sorbent. After 10 minutesdesorption at moderate temperatures, the profile of volatiles obtained from the tainted sample could be comparedwith that from the control sample. The fat constituents and other solids were retained by the glass wool and Tenaxand did not interfere with the analysis. Used liners were disposed of. (2) After a week of trying various extraction solvents in combination with GC and high resolution MS technology, thecause of malodour / taint in a batch of soap flakes had not been successfully identified. Once received by thethermal desorption lab, a small sample of soap flakes (~100 mg) was simply weighed into a PTFE liner and held inposition with clean glass wool plugs. The liner was inserted into an empty desorption tube and a TD-capillary GC-MS method was established using moderate desorption conditions - Desorption: ~100℃ for 10 minutes. Using TD-GC and bench top MS technology, one analysis of the tainted soap and one of a control (less than 2 hours work intotal) was enough to demonstrate that a homologous series of pyrazoles was causing the taint problem. [Note that there is no need for complete extraction of volatiles during a qualitative investigation. Obtaining arepresentative profile of the odour is more important. IModerate desorption temperatures are therefore generallyrecommended when monitoring for unknowns.] Organic Volatile Impurities in Drugs The analysis of volatiles in drugs is complicated both by the fact that many are difficult to dissolve in common/safesolvents and because many of the residual solvents in question actually form part of the crystal structure. Completedissolution or breakdown of the crystal structure is therefore required before an accurate determination of organicvolatile impurities can be made. Thermal desorption provides a quick and simple alternative to solvent extraction provided a drug melts at atemperature below its decomposition point. Complete extraction can typically be achieved in 2-3 minutes. PTFEliners are again recommended to minimize risk of drug degradation (see TDTS No. 41 for more information). Residual epichlorohydrin in epoxy resin Epichlorohydrin, the toxic volatile monomer used in epoxy resin production, is typically present at low PPMconcentrations in samples of epoxy-based adhesives. Around 40 mg of resin is simply smeared around the innerwall of a PTFE tube liner plugged with glass wool as described above. Provided care is taken to maintain a cleargas flow path through the middle of the liner, and that the sample of resin is positioned well within the heated zoneof the desorber, approximately 95% extraction efficiency is achieved in a single 10 minute desorption at atemperature (typically~175℃) well below that of polymer degradation. Savings achieved using this method versusconventional solvent extraction procedures are such that the production facility responsible for method developmentrecouped the cost of their automated thermal desorption equipment within one month of operation. Quality control of dried spices Spices and essential oils represent the high-priced ‘designer’sector of the food business. Rigorous quality controlis required to ensure ingredients meet the standards required and that the most expensive materials are notsubstituted or diluted by cheap imitations. For spices, spice mixtures, even complex dried sauce preparations, acombination of gentle desorption (for example 10 minutes at just under 100°℃) with high resolution capillary gaschromatography provides an interference free and extremely reproducible flavour profile. The reproducibility is suchthat even slight deviations in the composition of a mixture and/or variations in product quality can be readily andobjectively identified. Water-based paints Modern atmospheric emission regulations require control of the volatile and semi-volatile organic content of allpaints and coatings. However, some of these materials present a significant challenge regards monitoring andanalysis. In water based paints, for example, the presence of relatively large masses of water compromises capillaryGC performance and the exceptionally high solid content (above 80% in some cases) is guaranteed to plug up anysyringe as soon as it is inserted into a hot GC injector. Direct thermal desorption of small aliquots (~5 ml) of paint introduced onto a secondary glass wool plug inside aconventional PTFE tube insert overcomes both of these limitations and eliminates any requirement for pre-analysispreparation of paint samples. During the thermal desorption process, solids from the paint remain safely on the glasswool plug while volatile and semivolatile materials are purged into the instrument flow path. (Note that a fresh glasswool plug should be used for each new sample.) Provided a suitable two stage desorber is in use; i.e. one offeringappropriate electronic control of a small sorbent focusing trap such as that in UNITY-see Figure 2), a combinationof focusing temperatures and sorbents can be selected such that all the organics of interest are retained while waterpasses through to vent. When the focusing trap is subsequently desorbed, an interference-free chromatogram isproduced. Water and artefacts from the paint solids have all been safely eliminated prior to analysis. Therapeutic creams This example is a ‘piece de resistance’ for thermal desorption. The extraction of essential oils and other organicvolatiles - methyl salicilate, camphor, etc, - from a petroleum jelly or similar organic matrix is extremely challengingby conventional methods. Solvents do not differentiate sufficiently between target analytes and matrix materials andanalysts resort to lengthy steam distillation techniques to prepare samples. Even then results are disappointing anda significant fraction of the petroleum jelly distills over into the sample extract precluding both capillarychromatography and automatic injection. For thermal desorption however, 20-50 mg samples of the cream are simply smeared inside a short PTFE tube linercontaining a plug of clean glass wool in an analogous manner to the epoxy resin example detailed above. This isthen pushed into a conditioned desorption tube packed with 5-10 mm Tenax TA and backed up with unsilanisedglass wool. Provided the PTFE tube insert is not reused and provided the desorption conditions selected are theminimum required for complete extraction, the same Tenax bed may be reused multiple times. The Tenax tube should be repacked and reconditioned as soon as artifacts begin to appear in the chromatogram. Trace impurities in process/industrial air and gases Thermal desorption is also the technique of choice for on- or off-line determination of trace level volatiles in air andgas streams. Compatible sample types include: · Pressurised gas streams ● Process vents ·Ambient/workplace air at atmospheric or sub-atmospheric pressure Sealed containers of gas or air- e.g. canisters, TedlarTM bags, cylinders, etc. Thermal desorption systems incorporating an electrically-cooled focusing trap can be installed on-plant or in fieldlaboratories to operate round-the-clock with minimal operator intervention. Key functions such as sampling flowsand analytical desorption parameters are typically all incorporated into one PC-controlled method and monitoredcontinually. Even basic systems should feature automatic interchange between sample, zero and calibration gasstreams at a user defined frequency. Analytes must be vapour phase and typically range in volatility from acetyleneto n-C14/16. Cycle times range from 4 minutes to 3 hours depending upon application requirements and the choiceof analyser. An ideal operating sequence is as follows: -User-determined volumes of gas are pumped or drawn into theelectrically-cooled focusing trap at controlled flow rates ranging from 5-50 ml/minute. Only inert, non-emittingcomponents are allowed to come into contact with the sample and the flow path is purged with carrier gas betweensamples to ensure against carryover. After the sampling period, the focusing trap is heated rapidly in a flow of inertgas to transfer or ‘inject' the retained analytes into the analyser in a concentrated ‘plug’of vapour. The speed ofdesorption from the focusing trap is such that analytes are efficiently transferred to the analytical system with flowsas low as 2-2.5 ml/min. This facilitates splitless transfer and optimum sensitivity with high resolution capillaryGC/GC-MS. Desorption volumes may also be adjusted to suit alternative direct-read-out measurement systemssuch as enose sensors (see TDTS No & UniSense brochure) or process MS (see TDTS No ). Detection limits inthe order of low parts per trillion of individual organic compounds are possible depending on the samplingparameters and detector sensitivitv. Analysis is automatically initiated by the desorber when the focusing trap begins to heat. Collection of the nextsample can begin within 1-5 minutes -as soon as the trap has re-equilibrated at its focusing temperature. Example applications Applications range from kinetic studies of organic emissions to process control of industrial gas purity (Figure 8) andfrom continuous ambient air monitoring (Figure 9) to demilitarisation. Figure 8. Process measurement of trace levelbenzene and other organics in carbon dioxide forthe carbonated drinks industry Figure 9. TD analysis of on-line air sample,comparison with bottled nitrogen Summary The above series of brief examples is presented to illustrate the considerable labour-saving benefits that can berealised using thermal desorption. The technique offers the versatility and automation to improve productivity andreduce costs for most quality control tests involving the measurement of VOCs. Some of the applications presentedas examples above could not beachieved without the sensitivity and flexibility of thermal desorption.7. Could thermal desorption improve throughput and reduce costs in your lab?- For labsfrom polymers to foods, frompharmaceuticals to paints, from regulatory to routineindustrial- the answer is YES. ( References: ) ( 1. Chemotaxonomy of plant species u s ing h e adspace sa m pling, th e rmal de s orption and ca p illary GC. J o f HRC,14, pp 637-639, 1991. ) Registered in England No. AT Registration Markes International Ltd.Unit D Llantrisant Business Park, Pontyclun, RCT, CFW, UK. Tel: +()Fax: +()http://www.markes.com

关闭-

1/8

-

2/8

还剩6页未读,是否继续阅读?

继续免费阅读全文产品配置单

磐合科仪(上海磐合科学仪器股份有限公司)为您提供《检测材料中痕量级挥发性有机气体》,该方案主要用于包装中null检测,参考标准《暂无》,《检测材料中痕量级挥发性有机气体》用到的仪器有null。

我要纠错

相关方案

咨询

咨询