方案详情文

智能文字提取功能测试中

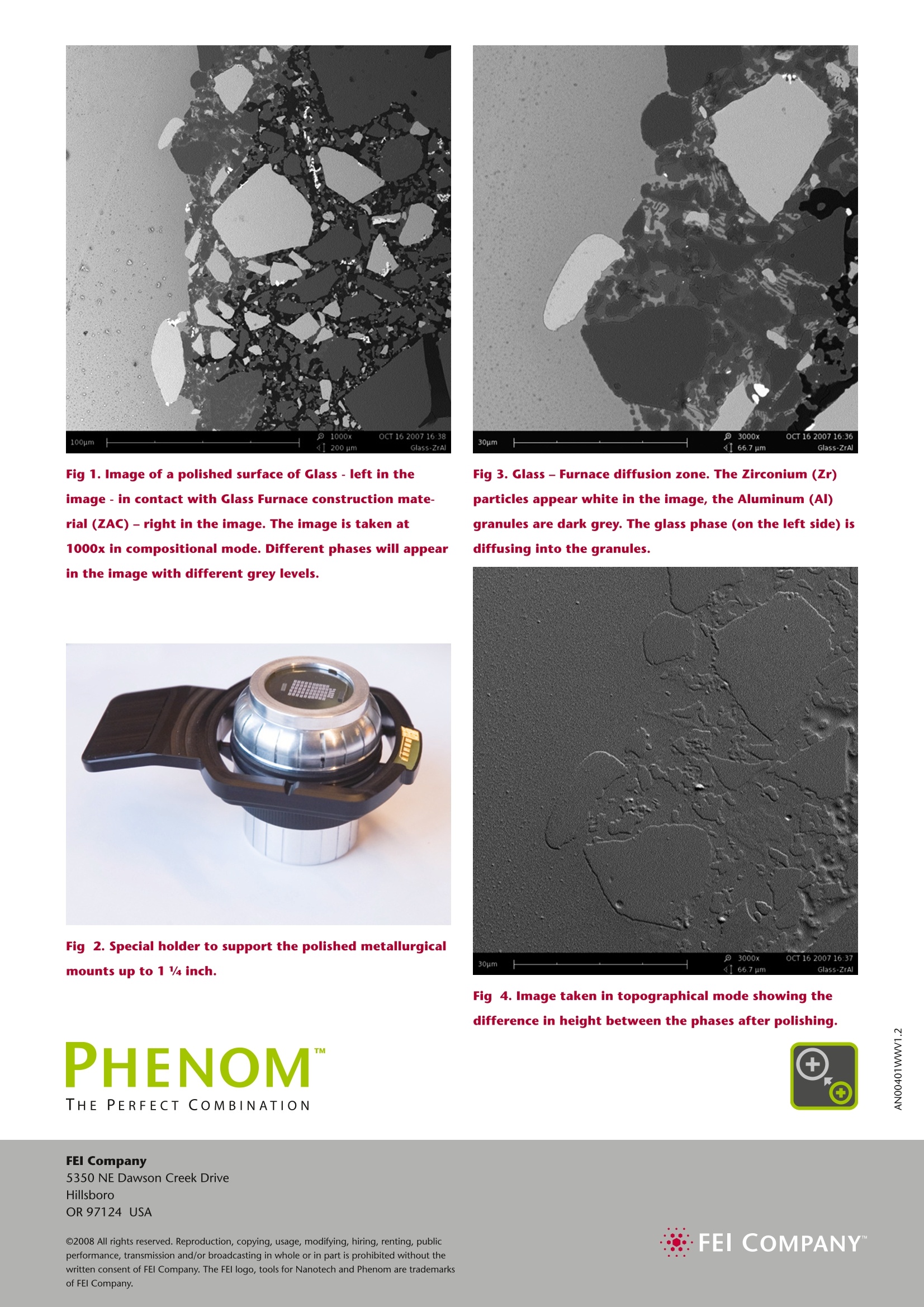

MICROSCOPIC INVESTIGATION OF AMETALLURGICAL MOUNT Embedding and polishing are common techniques used to create flat samples for microscopic investigation.Often the samples are embedded in a resin with a standard diameter of 1 inch. The Phenom offersa special metallurgical mount holder to support 1 14 inch (~32 mm) samples. The purpose of embedding is to protect fragile or coatedmaterials during preparation and to obtain good edgeretention. Embedding is also used to produce specimens of auniform size, like minerals, clay or other particles and can alsobe used to section a material and investigate its interior. Preparation Mechanical preparation is the most common method forpreparing materialographic/metallographicCSsamplesformicroscopic examination. Abrasive particles are used insuccessively finer steps to remove material from the surface,until the required result is reached. The preparation of materialographic/metallographic samplesfor examination by light microscopy or SEM for image analysisand hardness testing is often a specialist task. Increasingly,however, more fully automatic systems are available to makething easier. It can take a considerable time to section, grind,mount and polish a sample. Grinding and Polishing. Grinding removes saw marks and levels and cleans the surfaceof the specimen. Polishing eliminates the artifacts of grindingbut removes very little material. Grinding uses fixed abrasives- the abrasive particles are bonded to the paper or plates - forfast material removal. Polishing uses abrasive particles in aliquid which are suspended on a cloth. In summary, cutting the sample will take up to 1 hour,depending on the hardness. The grinding and polishing stepmay take approximately 2-2 12 hours. For ordering information; contact your local Phenom salesrepresentative (address can be found at the website). Fig 1. Image of a polished surface of Glass - left in theimage - in contact with Glass Furnace construction mate-rial (ZAC)- right in the image. The image is taken at1000x in compositional mode. Different phases will appearin the image with different grey levels. Fig 2. Special holder to support the polished metallurgicalmounts up to 1 V4 inch. Fig 3. Glass - Furnace diffusion zone. The Zirconium (Zr)particles appear white in the image, the Aluminum (Al)granules are dark grey. The glass phase (on the left side) isdiffusing into the granules. Fig 4. Image taken in topographical mode showing thedifference in height between the phases after polishing. APPLICATION NOTEFEI COMPANY" .FEI COMPANY

关闭-

1/2

-

2/2

产品配置单

复纳科学仪器(上海)有限公司为您提供《飞纳台式扫描电镜在金属金相领域的应用》,该方案主要用于纯金属中null检测,参考标准《暂无》,《飞纳台式扫描电镜在金属金相领域的应用》用到的仪器有飞纳台式扫描电子显微镜专业版Pro、飞纳台式扫描电子显微镜标准版 Pure、飞纳台式扫描电镜。

我要纠错

相关方案

咨询

咨询