方案详情文

智能文字提取功能测试中

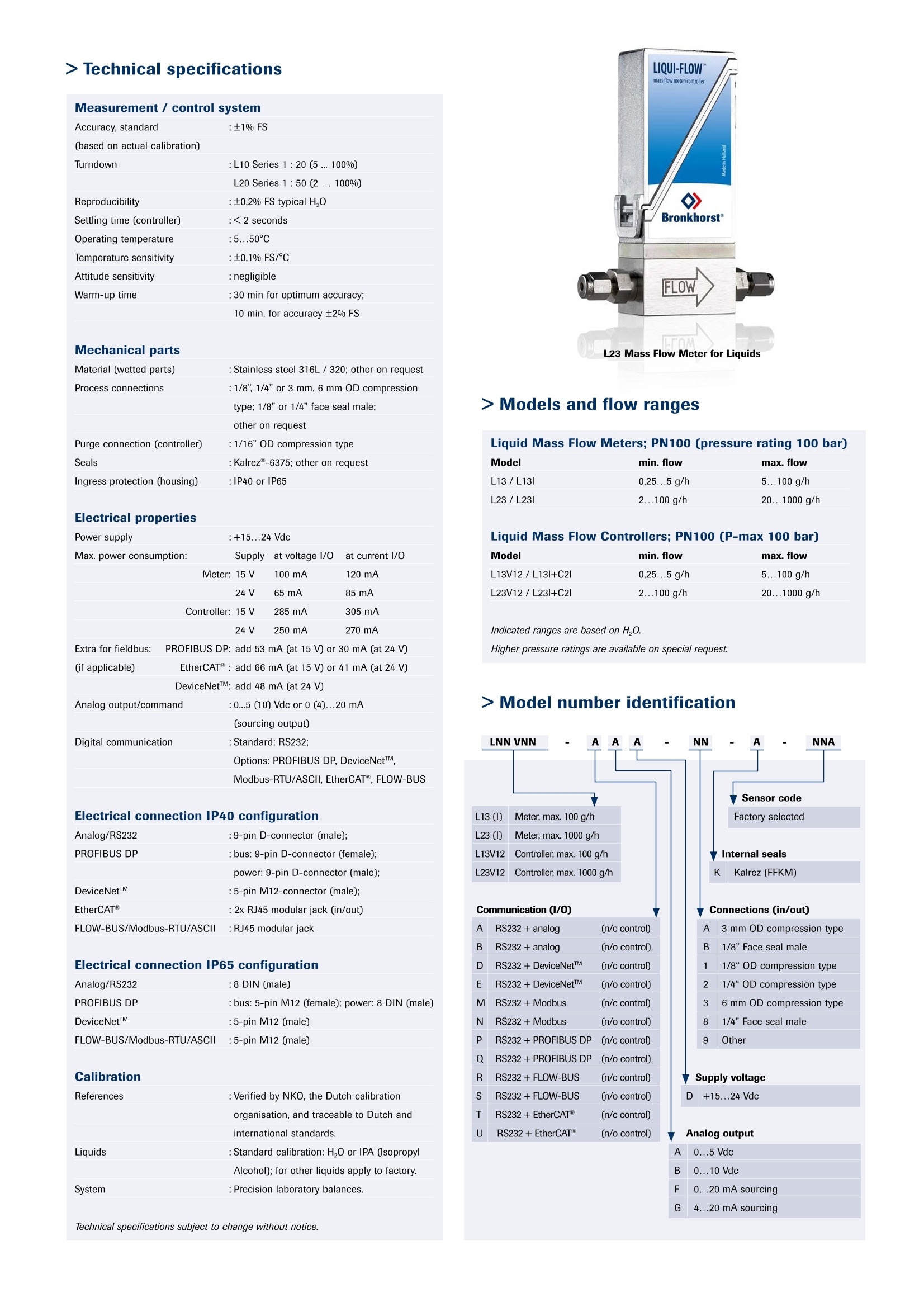

T +31(0)573 45 88 00 F +31(0)573 45 88 08 I www.bronkhorst.com E info@bronkhorst.com LIQU-FLOWIM Series L10 / L20 Digital Mass Flow Meters / Controllers for Liquids > Introduction Bronkhorst High-Tech B.V., the European market leader in thermalMass Flow Meters/Controllers and Electronic Pressure Controllers,has many years experience in designing and manufacturing preciseand reliable measurement and control devices. With a wide rangeof instruments, Bronkhorst offers innovative solutions for manydifferent applications in many different markets. The instruments aremade to customers' specification, in various styles, suitable for usein laboratory, industrial environment, hazardous areas, semiconductorprocessing or analytical equipment. >LIQUI-FLOWTM series L10 / L20 Bronkhorst has been the pioneer in the field of micro to low flowliquid metering instruments based on a thermal measuring principle.The digital LIQUI-FLOWTM Mass Flow Meter was designed to coverthe range between 5 and 1000 g/h (Full Scale) in a compactinstrument with a fast response. The Flow Meter is basically astainless steel tube without any moving parts or built-in obstructions.The heater/sensor assembly is arranged around the tube and, byfollowing the anemometric principle: a constant difference intemperature (AT) is created and the energy required to maintainthe AT is dependent of the mass flow rate. Due to the benefits ofthe unique patented sensor, the fluid will be warmed to a maximumof 5℃, thereby making the L10/L20 series suitable for fluids withlow boiling points. > Liquid flow control Flow control is achieved by integrating a control valve onto thebody of the Liquid Flow Meter, or by mounting it as a separatecomponent [in IP65 configuration). This control valve has a purgeconnection on top of the sleeve that enables easy elimination of airor gas when starting up the system. The electronic control functionforms part of the normal circuitry in the liquid flow meter, so theneed for an external controller is eliminated. > Multi-Bus technology Bronkhorst developed their latest digital instruments according tothe “multi-bus” principle. The basic pc-board on the instrumentcontains all of the general functions needed for measurement and control. It has analog I/O-signals and also an RS23 connection asa standard feature. In addition there is the possibility of integrating aninterface board with DeviceNetTM, PROFIBUS DP, Modbus, EtherCATor FLOW-BUS protocol. > General LIQUI-FLOWTM features ◆fast and accurate measuring signal ●iinsensitive to mounting position ◆ very small internal volume ◆ suitable for liquids with low boiling points ◆ for laboratory and OEM applications ◆also available for industrial applications, with IP65 housing,ATEX Cat.3, Zone 2 > Digital features ◆D[eviceNet M, PROFIBUS DP, Modbus-RTU/ASCII, EtherCATor FLOW-BUS slave ◆ RS232 interface ◆ alarm and counter functions >Fields of application ◆SSemiconductor industry ◆ HPLC applications Chemical industry Food & Pharmaceutical industry ◆ Analytical laboratories > Dimensions and weights Model A B C H K Weight (kg) L13 (1/8”OD) 47 98 47 118 25 0,4 L23 (1/4”OD) 47 102 47 121 25 0,4 Mass Flow Controller IP65 Mass Flow Meter Model A B C H K L Weight (kg) L13I (1/8"OD) 47 98 74 125 25 36 0,9 L23I (1/4”OD) 47 102 74 128 25 36 0,9 Dimensions in mm Model A B C H K L Weight (kg) L13I+C2I (1/8”OD) 127 178 74 125 29 36 1,4 L23I+C2I (1/4”OD) 127 178 74 128 29 36 1,4 > Industrial style LIQUI-FLOWTM series The LIQUI-FLOWTM series L10I/L20I digital Liquid Flow Meters /Controllers for low flow ranges are equipped with a rugged‘industrial style'(IP65) pc-board housing for use in industrialenvironments or even Zone 2 hazardous areas, due to theirATEX category 3 approval. The instruments operate on a thermal,thru-flow measuring principle. The flow meter can be connectedto a control valve to form a closed control loop. The standarddirect acting valve (model C2l) is normally closed, has a pressurecapability of 100 bar (1500 psi) and a purge connection for easyelimination of air or gas. L13I Mass Flow Meter,IP65 configuration IP65 Mass Flow Meter with close-coupled Control Valve > Application examples Verifying pumps LIQUI-FLOWIM flow meters are used in analytical applications incombination with HPLC pumps, verifying the pump performance oreven, as shown in this example, close-coupled with a gear pump.Using the integrated PID controller, the setpoint signal continuouslyadjusts the rotation speed of the pump. GMP validation in food & pharma filling processes In food and pharmaceutical applications critical filling processesmust be very accurately and, above all traceably documented. LIQUI-FLOWIM Series L10/L20 are particularly suitable for this task. Themain features of these digital instruments are: high precision, fastresponse, compact design and a very small internal volume. Bronkhorst High-Tech B.V. Nijverheidsstraat 1a, NL-7261 AK Ruurlo Netherlands Liquid Delivery with Vapour Control The CEM-System (Controlled Evaporation and Mixing) is aninnovative Liquid Delivery System (LDS] that can be applied foratmospheric or vacuum processes. The vapour generation systemconsists of a liquid flow controller,an MFC for carrier gas anda temperature controlled mixing and evaporation device.The system is suitable for mixing liquid flows of 0,25-1200 g/hresulting in saturated vapour flows of 50 ml,/min up to 100 l,/min.This vaporizer system can replace bubblers. New opportunitiescreated with the CEM-system: mixtures can be evaporated andeven solids, dissolved in solvents can be vaporised successfully. Features ◆ Accurately controlled gas/liquid mixture (mass flow) ◆ Fast response ◆ High reproducibility ◆ Handles water, solvents, liquid mixtures ◆ Very stable vapour flow ◆ Flexible selection of gas/liquid ratio ◆ Lower working temperature than conventional system Vapour delivery applications ◆ CCVD (Chemical Vapour Deposition), e.g. for hardening,thin film coating or planarization processes ◆Testing/calibration of analyzers with reference gasvapor concentrations ◆ T Toxic gas effects on protective clothing ◆ Analyzers with reference H,0 vapour concentrations ◆Humidification of fuels ◆ Anaesthetics 巧克力糖果业本周咱们来聊一聊不断增长的巧克力糖果行业及其调味使用的趋势。调查显示,75%的女人和68%的男人沉迷于巧克力。 巧克力。。。1000亿美元蓬勃发展的全球市场,曾始于牛奶、黑巧克力或白巧克力之间简单的选择。如今,由于调味配方的不同,其选择的变化也是巨大的。 巧克力作为季节性的礼物倍受欢迎。节假日前后,人们倾向于购买更多的巧克力。出人意料的是,在西方,巧克力的畅销季并非在情人节,而是在复活节。除了款待自己,增添节日气氛也是销售量上涨的一个热门原因,特别是年轻的成年人。大多数巧克力买家(特别是在美国)都在寻找混搭的选择,而不是平淡无奇的品类。风味和质感全球巧克力市场在风味和质感方面已经有了相当大的创新。新产品的开发一直具有非凡的想象力,除了传统的甜味之外,还有更多口味和质感的探索。然而,消费者群体往往比较保守,因为目前最流行的口味是榛子、焦糖、杏仁和橙子。 年长一些的消费者对巧克力的偏爱程度往往较低。对巧克力缺乏兴趣,这反映了他们渴望健康饮食。为了重新获得这一类消费人群,公司已经转向诸如使用酒精口味、有机配方和优质定位的策略,例如柠檬酒黑巧克力与甜利口酒巧克力。健康的生活方式健康的生活方式,全球主要趋势之一,也是巧克力市场大幅增长的原因,虽然这可能会令人吃惊,但并非毫无根据。巧克力,特别是含量超过85%可可的黑巧克力,提供有益于身体的健康元素,例如:富含纤维、铁、镁、铜、锰和其他矿物质强力的抗氧化剂来源预防心血管疾病 人们越来越意识到纯巧克力和黑巧克力对健康的益处,是巧克力消费量增加的原因。随着黑巧克力的日益普及,其他风味的巧克力销售额也在增加。人们正在寻求其他“健康”的变化,例如无糖、无麸质、犹太洁食或公平贸易巧克力。由于这些道德声明,该行业已经出现了巨大的变化。 为了增强巧克力的健康形象,功能性成分例如纤维、蛋白质、微量元素、快速能量(瓜拉纳提取物)、绿茶提取物或奇异子越来越多地被添加到巧克力中。 可可 、不断增长的巧克力需求也有其不利之处。每年消耗约300万吨可可豆,其中超过70%来自西非四个国家:科特迪瓦、加纳、尼日利亚和喀麦隆。可可是一种精致的作物,25年前种植的树木已经达到产值高峰,而且它们种植的土地不像以前那样肥沃。为了防止作物生产的损失,必须大量修复土地和树木。气候变化也正在造成损失。这导致可可生产国的原材料成本高昂,经济状况不稳定。为了防止供应短缺,一些著名的巧克力生产公司决定投资修复栖息地的土地和树木,以确保将来有可可这种作物可用。 在此之前,中国、印度和俄罗斯等发展中国家的巧克力销量预计将增长30%。质量流量计和巧克力由于使用香料和功能性成分,为巧克力的多样性带来了巨大的增长,质量流量计和控制器顺势进入糖果行业。由于高精准和超稳定的特点,特别是当它们与泵结合使用时,基于科里奥利原理的低速质量流量计和控制器非常适合配制口味和功能性配料这项工作。 Bronkhorst 科里奥利仪表直接测量质量流量,并且不受流体特性影响,这意味着可在数秒内更改设定值,无需拆卸泵,并无需重新校准安装。这是一个巨大的优势,可以节省大量时间,并使流程更加灵活。 使用科里奥利仪表进行添加剂配料可以减短批次间的停机时间、实现成分可追溯性以及更高的产品一致性和质量。

关闭-

1/4

-

2/4

还剩2页未读,是否继续阅读?

继续免费阅读全文产品配置单

布琅轲锶特(上海)测量设备贸易有限公司为您提供《巧克力中质量流量检测方案(液体流量计)》,该方案主要用于巧克力及制品中理化分析检测,参考标准《暂无》,《巧克力中质量流量检测方案(液体流量计)》用到的仪器有mini CORI-FLOW™系列 科里奥利质量流量计/控制器。

我要纠错

相关方案

咨询

咨询