方案详情文

智能文字提取功能测试中

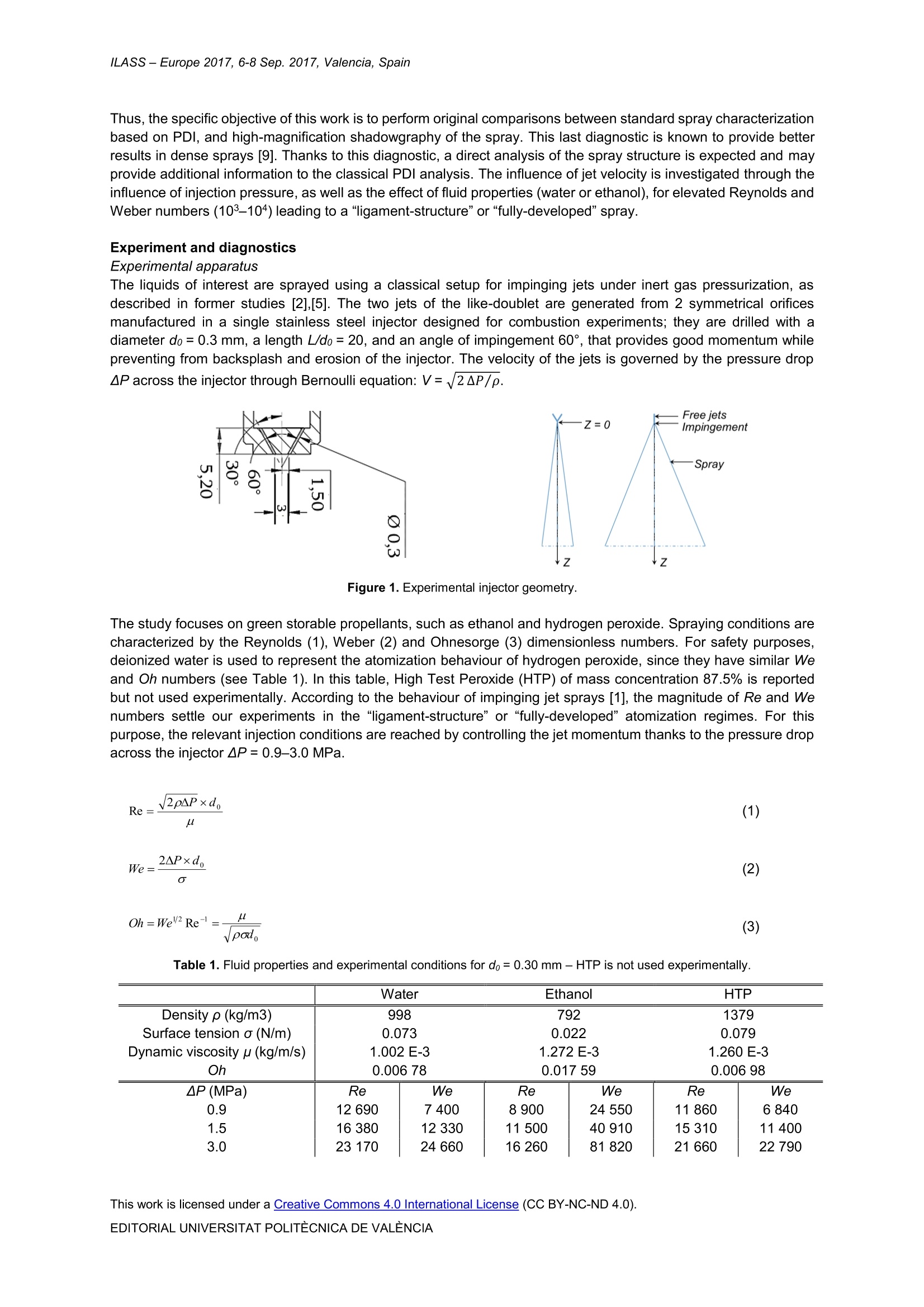

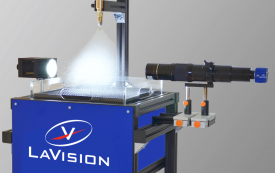

ILASS-Europe 2017, 28th Conference on Liquid Atomization and Spray Systems, 6-8 September 2017, Valencia, Spainhttp://dx.doi.org/10.4995/ILASS2017.2017.5001 ILASS-Europe 2017, 6-8 Sep. 2017, Valencia, Spain Characterization of Liquid Impinging Jet Injector Sprays for Bi-Propellant Space Propulsion: Comparison of PDI and High-Magnification Shadowgraphy Bastien Boust*1, Quentin Michalski1, Alain Claverie1, Clement Indiana1, Marc Bellenoue1 1Institut PPRIME, CNRS/ISAE-ENSMA/Universite de Poitiers, France *Corresponding author: bastien.boust@ensma.fr Abstract Impinging jet sprays are investigated in the reference case of like-doublet injector, for application to bi-propellantcombustion. Green propellants are considered, namely ethanol as a fuel and hydrogen peroxide as an oxidizer,that is well represented by water.This study reports original comparisons between standard spray characterization(PDI) and high-magnification shadowgraphy of the spray (2.5x3.2 mm, 2.5 um per pixel) based on short laserbacklight illumination (5 ns). Shadowgraphy images describe accurately the inner spray structure and provide thesize and velocity of droplets. This diagnostic is used to analyse the influence of jet momentum (driven by injectiorpressure) on impinging jet atomization, as well as the evolution of spray topology, drop size distribution and averagediameter along the spray centreline. The application of shadowgraphy to the dense region of water and ethanolsprays shows the different atomization behaviour of these two fluids with respect to their surface tension. Ellipticaldroplets are characterized inside the spray, which confirms the interest of a direct visualization of droplets in suchdense sprays. Keywords Liquid impinging jet injector, Atomization, Shadowgraphy,Droplet sizing. Introduction Impinging jet injectors are used in most storable bi-propellant space engines. Current storable propellants such ashydrazine and nitrogen tetroxide usually burn after hypergolic ignition, which is allowed by their chemical properties.However, these toxic propellants are to be replaced by “green” propellants, e.g. hydrogen peroxide and ethanolwhich atomization, ignition and combustion deserve additional knowledge. Particularly, compared to currentstorable propellants, the atomization of green propellants may be less prone: i. to generate small droplets due totheir surface tension, ii. to generate a gaseous phase to their low volatility (e.g. hydrogen peroxide), iii. to ignite andburn efficiently, as a result. Therefore, attention must be paid to the atomization process of these new “green”propellants, particularly in the physical conditions encountered in combustion chambers i.e. subcritical at higrtemperature and pressure. In practice, liquid propellants atomization is usually based on jet impingement, which is a common way to generatedroplets with moderate levels of pressure (e.g. a few MPa). In this study, the like-doublet configuration is consideredas a reference case, even though real engines injectors may also feature unlike jet impingement (e.g. fuel oroxidizer) such as doublets or triplets etc. In the literature, numerous studies already address this like-doubletconfiguration in the spraying regime related to engine conditions, i.e. at elevated Reynolds and Weber numbers(103-104) leading to ligaments and fully developed breakup; a review of such spray phenomena can be drawn fromdetailed experiments [1]. Like-impinging doublets are investigated through theoretical studies [2] and numericalsimulation [3]-[4], highlighting the dynamics of the liquid sheet breakup that generates wavy ligaments and thendroplets. However in this complex situation, the reference knowledge concerning the spray shape, the distributionof droplet size and velocity, is provided by experiments [5]-[8]; for this purpose, most studies are based on Phase-Doppler Interferometer (PDI) and direct visualization of the spray. In these fundamental experiments the dropletdistribution is well characterized downstream the dense part of the spray (i.e. downstream the liquid sheet), but inreal engine conditions the flame affects the spray even from the dense zone [8], so that the spray properties cannotbe inferred directly from inert condition measurements. This makes spray combustion all the more complex becausedrop size influences combustion performance and induction length, as an example. Moreover, the Sauter MeanDiameter (SMD) measured with PDI is found to increase with increasing distance from the impingement point [5]-[6], whereas it is found to decrease in another study combining experiment and simulation [3]. This contradictionshows that impinging jet sprays deserve a specific study, in order to discuss the methods used to analyse thestructure of such sprays. ( This work is licensed under a Creative Commons 4.0 Int e rnational License (CC BY-NC-ND 4.0). ) Thus, the specific objective of this work is to perform original comparisons between standard spray characterizatiorbased on PDI, and high-magnification shadowgraphy of the spray. This last diagnostic is known to provide betterresults in dense sprays [9]. Thanks to this diagnostic, a direct analysis of the spray structure is expected and mayprovide additional information to the classical PDI analysis. The influence of jet velocity is investigated through theinfluence of injection pressure, as well as the effect of fluid properties (water or ethanol), for elevated Reynolds ancWeber numbers (103-104) leading to a "ligament-structure”or "fully-developed"spray. Experiment and diagnostics Experimental apparatus The liquids of interest are sprayed using a classical setup for impinging jets under inert gas pressurization, asdescribed in former studies [2],[5]. The two jets of the like-doublet are generated from 2 symmetrical orificesmanufactured in a single stainless steel injector designed for combustion experiments; they are drilled with adiameter do=0.3 mm, a length L/do =20, and an angle of impingement 60°, that provides good momentum whilepreventing from backsplash and erosion of the injector. The velocity of the jets is governed by the pressure drop AP across the injector through Bernoulli equation: V=√2AP/p. Figure 1. Experimental injector geometry. The study focuses on green storable propellants,such as ethanol and hydrogen peroxide. Spraying conditions arecharacterized by the Reynolds (1), Weber (2) and Ohnesorge (3) dimensionless numbers. For safety purposesdeionized water is used to represent the atomization behaviour of hydrogen peroxide, since they have similar Weand Oh numbers (see Table 1). In this table, High Test Peroxide (HTP) of mass concentration 87.5% is reportedbut not used experimentally.According to the behaviour of impinging jet sprays [1], the magnitude of Re and Wenumbers settle our experiments in the “ligament-structure”or“fully-developed”atomization regimes. For thispurpose, the relevant injection conditions are reached by controlling the jet momentum thanks to the pressure dropacross the injector AP=0.9-3.0 MPa. Table 1. Fluid properties and experimental conditions for do=0.30 mm - HTP is not used experimentally. Water Ethanol HTP Density p(kg/m3) Surface tension a (N/m) Dynamic viscosity p (kg/m/s) Oh 998 792 1379 0.073 0.022 0.079 1.002 E-3 1.272 E-3 1.260 E-3 0.006 78 0.017 59 0.006 98 AP(MPa) 0.9 Re 1269016380 We 7 4001233024 660 Re 890011 500 16 260 We2455040 91081820 Re 1186015310 21660 We 684011400 22790 ( This work is licensed under a Creative Commons 4.0 International License (CC BY-NC-ND 4.0). ) Spray analysis based on Phase-Doppler Interferometer Following the initial development of Bachalo, the Phase-Doppler Interferometer (PDI) has proved to stand as apowerful standard laser-based diagnostic instrument for simultaneous and accurate measurements of the size andvelocity of individual spherical particles in polydisperse particle flow environment [2],[5]-[6]. A modular PDI system (Artium 200 MD) is used for the real-time, non-intrusive measurement of individual drop sizeand 2 velocity components in this application. The diode-pumped solid-state lasers used in the transmitter provide532 nm and 473 nm wavelengths. The distances from transmitter to probe volume, and from receiver to probevolume, are set to 500 mm allowing 4.33 um fringe spacing and a range of diameters between 1.5 pm and 160 pmwhen used with a light scattering angle set to 40°. The probe volume dimensions are characterized by a quasi-circular cross-section of diameter 0.34 mm, and a length of 5.6 mm. PDI data processing includes the classical“probe-volume correction”(PVC) that compensates for the effect of varying sample volume on drop size. Spray analysis based on high-magnification shadowgraphy High-magnification shadowgraphy is recorded with pulsed backlight illumination, that is independent of the shapeand material of the particles (either transparent or opaque) and allows for the investigation of drop size down to afew microns per pixel. Based on a PIV system, this technique is expected to provide information on the dropletsshape coupled with size distribution and velocity. As illustrated (see Figure 2), a double-pulse Nd:YAG laser (Continuum Minilite Il, 2*25 mJ/pulse) is combined witha double-frame camera (LaVision Flowmaster 3S, 1280 x1024 px, 6.35 pm/px) equipped with a long-distancemicroscope (Questar QM1) of 60 cm working distance. A diffusor optics with a wavelength shifting fluorescing plateis mounted to the laser beam outlet, which yields a homogenous speckle-free backlight illumination of wavelengtharound 590 nm. The measurement volume is defined by the focal plane and the depth of field of the imaging systemThe image size is 2.5x3.2 mm, and image pixel size is 2.5 pm. Given a f-number for the optics of 9.3, the effectivespatial resolution based on Rayleigh criterion is 5.6 pm. The short laser pulsewidth (between 3 and 5 ns) ensuresthe motion freezing of all imaged droplets. Conventional corrections are applied to the drop size distributions usingstatistical weighting functions, in order to compensate for the so-called“border”and“depth-of-field”effects [9]. Figure 2. Experimental setup for high-magnification shadowgraphy. lmages are analysed using commercial software (ParticleMaster Shadow, Lavision) that includes severalparameters for droplet detection (see Figure 3). The first one is the kernel width of a sliding maximum filter, whichis used to ensure background homogeneity for droplets detection prior to the first segmentation: it is set to 100 px(250 pm). The binarisation threshold for the first segmentation is a global threshold relative to the maximum intensityfound on the image: it is set to 50%. A second segmentation computes a droplet diameter based on an averagebetween the 40%- and 60%-threshold relative to the local maximum on the droplet. Blurry particles are rejectedbased on a minimum slope criterion, locally defined as the relative intensity decrease at the particle rim: it is set to20%. Given the intensity difference between small and large droplets, the admissible depth of field depends on dropsize. Based on the slope criterion, it is comprised between 50 pm for the smallest droplets, and 330 pm for thebiggest ones. Droplet velocity is computed from each doublet of images, provided the droplet is identified in bothframes. The identification is based on a diameter variation inferior to 15%, and to a vertical velocity comprisedbetween -10 and 50 m/s. For each condition, 20 doublets of images are recorded at 2 Hz with 2 us delay betweenframes, which yields up to 50 validated droplets per frame. Figure 3. Example of particle detection obtained by the software-Water spray, 0.9 MPa, Z/do=100. Even though shadowgraphy is far less sensitive to droplet shape for detection, it may detect overlapping dropletsor ligaments to which is attributed an elliptical cross-section (see Figure 4). In order to avoid such erroneousparticles, images are computed using a second exclusion criterion, based on the ratio between the ellipticalinterpolation perimeter and the perimeter of the actual droplet: an optimal value of 0.875 is found for this criterionThis method is especially useful to exclude the erroneous ligaments for which the large extrapolated diameter isnot representative of a real diameter. Figure 4. Example of particles excluded (red dots) or included (blue dots) in the statistics. Perimeter detected (green overlay),perimeter of the ellipse (blue overlay). In this case 63 particles are excluded (about 10%)-Water spray, 0.9 MPa, Z/do=50. The spray is studied in steady operation. Its wavy behaviour is reported in the literature [2],[6] (see Figure 5 forvisualization) and the ligament wavelength is less than 1.0 mm, hence a characteristic frequency about 10 kHz fora typical velocity of 10 m/s. Our diagnostics are compatible with these space and time scales: the shadowgraphyfield of view (2.5x3.2 mm) corresponds to several wavelengths of the spray (2-3 wavelengths), while PDI isperformed over a large number of time-periods (6 kHz in average during 1-2s). Thus both diagnostics allow acorrect sampling. Besides, the characteristic dimension of the PDI probe volume cross-section (0.34 mm) represents around 10-15%of the shadowgraphy field-of-view. Moreover, shadowgraphy provides uniform results (same drop size distributionand dropletnumber) whatever the investigation region.Therefore, shadowgraphy and PDI results can be comparedin these spray conditions. Results and discussion Topology of the spray The spray is investigated by high-magnification shadowgraphy in the conditions of interest (see Table 1), for waterand ethanol. For each spray condition, the measurement point is displaced from the impingement point of the jets,along the spray centreline coordinate Z (see Figure 5). The corresponding shadowgraphy pictures provide anoriginal view of the inner spray structure. Although the topology of such sprays has been thoroughly described in past studies, the present visualizations offer a detailed description of the primary atomization process (sheetbreakup from Z=3 do), and of the secondary atomization process (ligament breakup from Z=20 do). Thesebreakup lengths and wavelengths have been discussed in our previous work concerning like-doublets [6].Addit information is given by the shape of ligaments and droplets. The dynamics of ligaments has a wavybehaviour that generates elongate blobs and droplets from Z= 20-30 do, and these structures exhibit a relaxationprocess towards a stable shape (i.e. spherical). However, pictures at Z= 100-150 do show that small droplets reacha round shape, whereas the numerous big droplets that remain in the spray still have an elliptical or concave shape.As a result, the biggest droplets may be detected well by shadowgraphy, but hardly by PDI. Figure 5. Shadowgraphy of the spray from the impingement point-Water, AP=0.9 MPa,illumination 5 ns, 2.5 x3.2 mm. Drop size distributions of the sprays The above shadowgraphy pictures reveal the structure of the spray as a function of the operating conditions ancmeasurement location. Additional spray pictures highlight the influence of pressure(AP) that drives the Reynoldsand Weber numbers throughjet momentum. As APincreases, the spray generates smaller droplets because of thisincrease in impingement force, which is a common result in like-doublets sprays [2],[5],[7]: this effect is evidencedby PDI and shadowgraphy measurements performed on the same water spray (see Figure 6a). Both diagnostics show that the drop size distribution is mainly composed of small droplets (D<0.20 do); this is dueto the measurement location situated far from the impingement point (Z/do=100) i.e. after secondary breakup. Itshould be noticed that, in the case of shadowgraphy, the diameter of maximum probability decreases when APincreases, while in the case of PDI measurements this diameter is the same but with increasing probability. Thesame comparison is performed on ethanol spray for the same measurement location, Z/do = 100 (see Figure 6b):shadowgraphy and PDI lead to a similar drop size distribution mainly composed of smaller droplets (D<0.10 do)than water distribution. The drop size distribution is smaller for ethanol than for water mainly due to the lower surfacetension of ethanol, and subsequently to its higher Weber number (see Table 1). As a conclusion, PDI andshadowgraphy provide similar drop size distributions, with small quantitative differences. This result is in agreement with comparable work performed on a steady atomizer [9], that also led to quantitativedifferences between the PDI and shadowgraphy results.A difference was found in the PDF distribution of drop size(albeit normalized in that work [9]), and differences were also reported in the statistical diameters. a) b) Figure 6. PDF of drop size distribution comparison: a) shadowgraphy vs. PDI, with increasing momentum (water, do =0.30 mm,Z/do=100); b) shadowgraphy (do=0.30 mm) vs. PDI (do=0.51 mm)-Ethanol, Z/do=170, AP=0.9 MPa. Effect of distance from the impingement point The evolution of this distribution is investigated at different measurement locations by shadowgraphy (see Figure7a): as distance Z increases from the impingement point, the distribution exhibits droplets of smaller size(D<0.05 do). And yet, as Z increases, the characteristic diameter computed from the drop size distribution hasdistinct behaviours in other work: SMD increases [5]-[6] or decreases [3] with increasing distance from theimpingement point. Therefore, a characteristic diameter should be evaluated to quantify this effect. For this purpose,the average diameter D10 is chosen because it represents fairly the whole drop size distribution, taking care to thegeometrical drop size that is detected directly by shadowgraphy. The average diameter D10 is computed from PDI and shadowgraphy measurements on ethanol and water spraysat AP= 0.9 MPa (see Figure 7b). The D10 computed with shadowgraphy is roughly constant for water, and decreasesslightly with increasing distance Z in the case of ethanol. The D10 for water measured with PDIis higher, which isconsistent with the drop size distribution (see Figure 7a), and decreases slightly with increasing distance Z, whilethe validation rate of the PDI instrument increases up to 80%. In the meantime, the corresponding shadowgraphypictures (see Figure 5) demonstrate that water droplets turn overall from ligaments and concave droplets(Z/do=50), to convex droplets (Z/do=150) which cross-section is not perfectly circular. This may explain thedifference between the PDI measurement, that is based on the spherical assumption, and the shadowgraphymeasurement that encompasses any droplet shape. a) b) Figure 7. Effect of distance Z from the impingement point (do=0.30 mm, AP=0.9 MPa): a) PDF of ethanol drop sizedistribution by shadowgraphy; b) average diameter D10 computed from PDI or shadowgraphy. ( This work is licensed under a Creative Commons 4.0 International License (CC BY-NC-ND 4.0). ) Distribution of droplet shapes From the above comparison, we can assume that the shadowgraphy measurements are less restrictive than PDIas far as droplet shape is concerned. In order to confirm this assumption, the droplet shapes detected by the.abovementioned shadowgraphy method are further analysed. For this, the centricity distribution of elliptical dropletscross-section is reported for water and ethanol sprays at Z/do=50 and 150, AP=0.9 MPa (see Figure 8a); theellipse centricity is defined as the ratio of its short axis to long axis. For both fluids, the centricity distribution is closerto unity in the dilute spray region (Z/do = 150) than in the dense region (Z/do=50), thus confirming that some timeis required after breakup to generate round droplets. In contrast, the PDI diagnostic may detect only the droplets ofcentricity close to unity. This causes a bias in the spray characterization because droplets of centricity lower than0.80 still represent a significant part of the distribution in our case: 10-20% in the dilute spray (Z/do=150), but 30-40% in the dense region (Z/do=50). It is necessary to assess which class of diameter is affected by this bias. The centricity of maximum probability is reported for each class of diameter, for water and ethanol sprays atZ/do=150, AP= 0.9 MPa (see Figure 8b); the velocity associated to each droplet is also reported.Most sphericaldroplets (of centricity close to 1) can be found in the range of diameter 30-100 pm, while the other droplets are oflesser centricity. The smallest droplets (D<30 pm) are less spherical, and their velocity is much lower than bigger,droplets. This may be due to the effect of the aerodynamic drag, that affects significantly this class of small dropletsUnder this effect, the unstable droplet shape oscillates due to the surface tension that tends to restore its roundshape, hence a periodic, elliptic deformation [10]. The biggest, elongate elliptical droplets (D> 100 pm) mayproceed from ligament parts (see Figure 8a). These large elliptical droplets may be difficult to probe with PDIconsidering the stringent tolerance in the maximum phase difference between pairs of detectors, but they carry asignificant amount of liquid with poor evaporation surface. Consequently, they deserve appropriate diagnostics suchas shadowgraphy. Their importance is superior in the dense region (Z/do =50); downstream, in the dilute regior (Z/do=150), largest droplets seem to relax towards spherical shape. This effect is observed either on water or ethanol, but ethanol seems to produce more elliptical droplets. This isconsistent with its lower surface tension compared to water, hence a higher sensitivity to initial conditions (ligamentbreakup) and a lesser cohesion prone to the oscillating deformation of ethanol droplet. Figure 8. Centricity of elliptical droplets computed from shadowgraphy pictures of water and ethanol sprays (do=0.30 mm,AP=0.9 MPa):a) distribution of centricity; b) evolution of centricity and velocity vs. droplet diameter at Z/do=150. Conclusions This study demonstrates the interest of high-magnification shadowgraphy for the study of impinging jet injector.Itallows to visualize directly the atomization process, and proves to be particularly useful for direct measurements ofdrop size, velocity and shape inside dense sprays. Indeed, this atomization process generates various shapes ofdrops and ligaments, especially non-spherical droplets, most of which can be detected by an elliptical interpolationIt is noticeable that most of the largest droplets generated by this injector are characterized by an elliptical shapeand consequently may be rejected by PDI. In the present study, shadowgraphy provides original data concerning the spray topology, as well as dropletmorphology, diameter and velocity. The distribution of droplet size has been recorded along the spray centrelinehighlighting the effect of jet momentum (driven by injection pressure) and the evolution versus distance from theimpingement point. Overall, it is clear that ethanol is prone to generate quickly smaller droplets sprays than water(thus hydrogen peroxide), thanks to its lower surface tension. This effect is quantified clearly by the drop sizedistributions and mean droplet diameters. The fluids investigated in this work stand for green storable bi-propellants, such as ethanol (fuel) and hydrogerperoxide (represented by water). Experimental conditions led to ligament- or fully-developed breakup atomizatiorregimes, representative of some engine injector conditions. As far as engine combustion is concerned, the elevatedpressure and temperature conditions may modify the spray structure, and combustion may interact with the sprayso that the evaporation time allowed to the propellants is limited. In this context, the influence of large droplets isparamount and should be taken into account from the injector characterization. Acknowledgements The authors wish to acknowledge the support of CNES (French Space Agency). Nomenclature AP Pressure drop across the injector [MPa] Dynamic viscosity [kg/m/s] Liquid density [kg/m³] Surface tension ([N/m] Nozzle diameter [mm] Droplet diameter [pm] D10 Mean droplet diameter [um] Oh Ohnesorge number PDF Probability Density Function PDI Phase-DopplerInterferometer Re Reynolds number SMD Sauter Mean Diameter [um] V Liquid jet velocity [m/s] We Weber number Z Distance along the spray centreline [mm] References [1] Bailardi, G., Negri, M. and Ciezki, H. K.,“Several aspects of the atomization behavior of various newtonianfluids with a like-on-like impinging jet injector”, ILASS-Europe 2010, 23rd Annual Conference on Liquid Atomizationand Spray Systems, Brno, Czech Republic, 2010. [2] Ryan, H. M., Anderson, W. E. and Pal, S., “Atomization characteristics of impinging liquid jets”, J. of Propulsionand Power, 11 (1), pp. 135-145, 1995. [3] Zheng, G., Nie, W., Feng, S., Wu, G., "Numerical simulation of the atomization process of a like-doubletimpinging rocket injector", Procedia Engineering 99, pp. 930-938, 2015. [4] Chen, X.,Ma, D., Yang,V., Popinet, S., "High-fidelity simulations of impinging jet atomization", Atomization andSprays, 23 (12), pp. 1079-1101, 2013. [5] Sakisaka, R., Hayashi, J.,Daimon, Y, Yamanishi, N., Akamatsu, F.,"Experimental measurements of impingingjet atomization at the vicinity of liquid fan", ICLASS 2012, 12th Triennial International Conference on LiquicAtomization and Spray Systems, Sep. 2-6,2012. [6] Indiana, C., Bellenoue, M., Boust, B., "Experimental investigations of drop size distributions with impingingliquid jets using phase-Doppler anemometer", International Journal of Energetic Materials and Chemical Propulsion14 (3), pp.241-264,2015. [7] Ramamurthi, K., Nandakumar, K. and Patnaik, R. K., “Characteristics of sprays formed by impingement of apair of liquid jets", J. of Propulsion and Power, 20 (1), pp. 76-82, 2004. [8] Indiana, C., Bellenoue, M., Boust, B., Petitot, S., “Experimental combustion investigations from like-impingement sprays of green propellants”, 52nd AIAA/SAE/ASEE Joint Propulsion Conference, Salt Lake City(USA), 25-27 July 2016. [9] Berg, T., Deppe,J.,Michaelis, D., Voges, H., Wissel, S., "Comparison of particle size and velocity investigationsin sprays carried out by means of different measurement techniques", ICLASS 2006, International Conference onLiquid Atomization and Spray Systems, Aug.27 -Sep. 1,2006. [10] Suh, Y., Lee, C.,"A numerical method for the calculation of drag and lift of a deformable droplet in shear flow"Journal of Computational Physics 241 (15) pp. 35-57,2013. ( This work is licensed under a Creative Commons 4.0 International License (CC BY-NC-ND4.0). ) EDITORIAL UNIVERSITAT POLITECNICA DE VALENCIA EDITORIAL UNIVERSITAT POLITECNICA DE VALENCIA Impinging jet sprays are investigated in the reference case of like-doublet injector, for application to bi-propellant combustion. Green propellants are considered, namely ethanol as a fuel and hydrogen peroxide as an oxidizer, that is well represented by water. This study reports original comparisons between standard spray characterization (PDI) and high-magnification shadowgraphy of the spray (2.5 x 3.2 mm, 2.5 μm per pixel) based on short laser backlight illumination (5 ns). Shadowgraphy images describe accurately the inner spray structure and provide the size and velocity of droplets. This diagnostic is used to analyse the influence of jet momentum (driven by injection pressure) on impinging jet atomization, as well as the evolution of spray topology, drop size distribution and average diameter along the spray centreline. The application of shadowgraphy to the dense region of water and ethanol sprays shows the different atomization behaviour of these two fluids with respect to their surface tension. Elliptical droplets are characterized inside the spray, which confirms the interest of a direct visualization of droplets in such dense sprays.

关闭-

1/8

-

2/8

还剩6页未读,是否继续阅读?

继续免费阅读全文产品配置单

北京欧兰科技发展有限公司为您提供《液体冲击喷射喷注器中液滴速度和粒径检测方案(激光粒度仪)》,该方案主要用于航空中液滴速度和粒径检测,参考标准《暂无》,《液体冲击喷射喷注器中液滴速度和粒径检测方案(激光粒度仪)》用到的仪器有LaVision ParticleMaster-Shadow 粒径测量系统、激光相位多普勒干涉仪LDV,PDI,PDPA,PDA、LaVision DaVis 智能成像软件平台。

我要纠错

推荐专场

相关方案

咨询

咨询