方案详情文

智能文字提取功能测试中

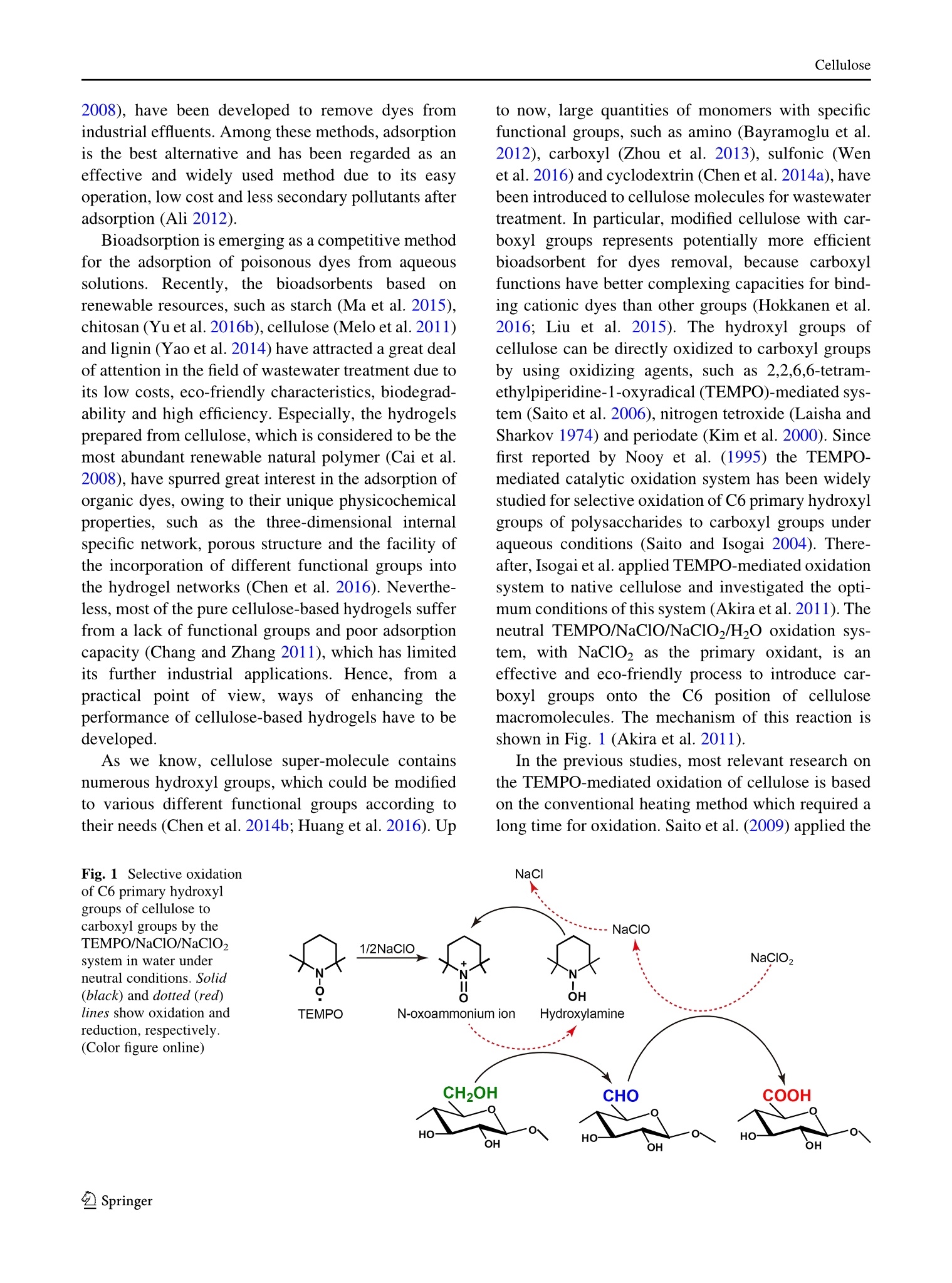

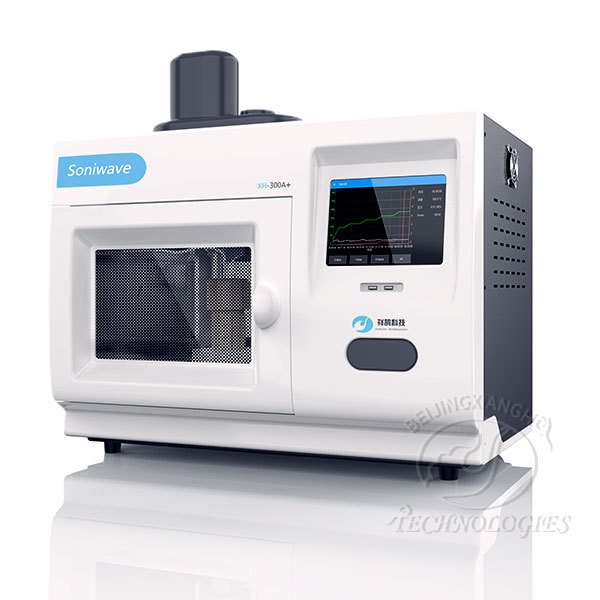

CelluloseCrossMarkDOI 10.1007/s10570-017-1473-9ORIGINALPAPER Cellulose Microwave-assisted facile synthesis of TEMPO-oxidizedcellulose beads with high adsorption capacity for organicdyes Fengcai Lin· Yuzhe You· Xuan Yang· Xin Jiang· Qilin Lu· Ting Wang·Biao Huang· Beili LuD Abstract A facile, green and efficient microwave-assisted method was developed to oxidize cellulosehydrogel1beads with neutral 2,2,6,6-tetram-ethylpiperidinyl-1-oxyl radical (TEMPO)-mediatedsystem. Resulting cellulose beads were investigatedby scanning electron microscopy, solid-state13c-NMR spectra, and X-ray diffraction. The patterns of13C-NMRspectra 1indicated tthat:the oxidationoccurred only at C6 primary hydroxyl carbon, andthe carboxyl groups amounted to 1.28 mmol/g in thecellulose beads.TheeTEMPO-oxidized cellulosebeads showed highly porous structures consisting ofnano-sized fibrils with retention of original sphericalshapes, and the crystallinity index of the cellulose IIalmost unchanged after oxidation. The maximumadsorption capacity of rhodamine B, auramine O,malachite green and methylene blue on the TEMPO-oxidized cellulose beads was found to be 609,537,740and 873 mg/g, respectively, and the adsorption pro-cess waswell described by pseudo-second-order F. Lin· Y. You· X. Yang· X. Jiang·Q. Lu· ( B. Huang ()·B. Lu (区) ) College of Material Engineering, Fujian Agriculture andForestry University, Minhou 350108, Fujian, China e-mail: bhuang @fafu.edu.cn ( B. Lu ) e-mail: lubl@fafu.edu.cn ( T. Wang ) ( Guangxi Key Laboratory of Chemistry and Engineering ofForest Products, Nanning 5 30006, Guangxi, China ) kinetics. In addition, desorption tests showed thatTEMPO-oxidized cellulose beads could be regener-ated by acid treatment and used repeatedly. Thus,TEMPO-oxidized cellulose beads prepared by micro-wave irradiation can be potentially used for theremoval of organic dyes from industrial wastewater. KeywordsMicrowave· Cellulose beads ·TEMPO-mediated oxidation· Dye removal·Bioadsorbent Introduction Dyes are widely used by various industries, such astextiles, leather, printing, plastics and dyeing, to colortheir products, and thus the wastewater of theseindustries tend to contain a variety of dyes in largequantities (Gupta and Suhas 2009). Dyes are consid-ered as a toxic pollutant because they can impart colorto water resulting in the decrease of water transmit-tance and the destruction of biological metabolismprocesses in ecosystem (Peng et al. 2015). Further-more, some dyes and their biotransformation productslike aromatic amines may cause serious health prob-lems to human beings as well as other animals (Zhouet al. 2014). Thus, it is necessary and urgent to removehazardous dyes from waste waters. To tackle thischallenge, various techniques, such as flocculation(Wang et al. 2012), oxidation (Turgay et al. 2011),adsorption (Yu et al. 2016a), photocatalytic degrada-tion (Zhanget al. 2010) and ion exchange (Wu et al. 2008), have been developed to remove dyes fromindustrial effluents. Among these methods, adsorptionis the best alternative and has been regarded as aneffective and widely used method due to its easyoperation, low cost and less secondary pollutants afteradsorption (Ali 2012) Bioadsorption is emerging as a competitive methodfor the adsorption of poisonous dyes from aqueoussolutions. Recently, the bioadsorbentsbasedonrenewable resources, such as starch (Ma et al. 2015),chitosan (Yu et al. 2016b), cellulose (Melo et al. 2011)and lignin (Yao et al. 2014) have attracted a great dealof attention in the field of wastewater treatment due toits low costs, eco-friendly characteristics, biodegrad-ability and high efficiency. Especially, the hydrogelsprepared from cellulose, which is considered to be themost abundant renewable natural polymer (Cai et al.2008), have spurred great interest in the adsorption oforganic dyes, owing to their unique physicochemicalproperties, such as the three-dimensional internalspecific network, porous structure and the facility ofthe incorporation of different functional groups intothe hydrogel networks (Chen et al. 2016). Neverthe-less, most of the pure cellulose-based hydrogels sufferfrom a lack of functional groups and poor adsorptioncapacity (Chang and Zhang 2011), which has limitedits further industrial applications. Hence, from apractical point of view, ways of enhancing theperformance of cellulose-based hydrogels have to bedeveloped. As we know, cellulose super-molecule containsnumerous hydroxyl groups, which could be modifiedto various different functional groups according totheir needs (Chen et al. 2014b; Huang et al. 2016). Up to now, large quantities of monomers with specificfunctional groups, such as amino (Bayramoglu et al.2012), carboxyl (Zhou et al. 2013), sulfonic (Wenet al. 2016) and cyclodextrin (Chen et al. 2014a), havebeen introduced to cellulose molecules for wastewatertreatment. In particular, modified cellulose with car-boxyl groups represents potentially more efficientbioadsorbent for dyes removal, because carboxylfunctions have better complexing capacities for bind-ing cationic dyes than other groups (Hokkanen et al.2016; Liu et al. 2015). The hydroxyl groups ofcellulose can be directly oxidized to carboxyl groupsby using oxidizing agents, such as 2,2,6,6-tetram-ethylpiperidine-1-oxyradical (TEMPO)-mediated sys-tem (Saito et al. 2006), nitrogen tetroxide (Laisha andSharkov 1974) and periodate (Kim et al. 2000). Sincefirst reported by Nooy et al. (1995) the TEMPO-mediated catalytic oxidation system has been widelystudied for selective oxidation of C6 primary hydroxylgroups of polysaccharides to carboxyl groups underaqueous conditions (Saito and Isogai 2004). There-after, Isogai et al. applied TEMPO-mediated oxidationsystem to native cellulose and investigated the opti-mum conditions of this system (Akira et al. 2011). Theneutral TEMPO/NaClO/NaClO2/H2O oxidation sys-tem, with NaClo as the primary oxidant, iss aneffective and eco-friendly process to introduce car-boxyl groups onto the C6 position of cellulosemacromolecules. The mechanism of this reaction isshown in Fig. (Akira et al. 2011). In the previous studies, most relevant research onthe TEMPO-mediated oxidation of cellulose is basedon the conventional heating method which required along time for oxidation. Saito et al. (2009) applied the Fig. 1 Selective oxidationof C6 primary hydroxylgroups of cellulose tocarboxyl groups by theTEMPO/NaClO/NaClO,system in water underneutral conditions. Solid(black) and dotted (red). lines show oxidation andreduction, respectively.(Color figure online) neutral TEMPO/NaClO/NaClO2 oxidation system tohardwood cellulose in water bath at 60 °C. Thecarboxyl content of the modified cellulose vWasapproximate to 0.8 mmol/g, however, the reactiontime was up to 55 h. Recently, the microwave-assistedmethod has been received as a promising technologyin various transformations because of its close relationto the postulates of green chemistry. Compared withthe conventional method, microwave irradiation hasthe unique characteristics of short reaction time, rapidvolumetric heating, high reaction selectivity, acceler-ated reaction rate and less energy loss (Razzaq andKappe 2008). Besides, microwave irradiation is adielectric heating process that thermal energy can beintroduced into reaction mixture through dielectricheating without any contact (Gabhane et al. 2011).Owing to the electromagnetic nature of microwave,itholds electric and magnetic fields which are perpen-dicular to each other (Khandanlou et al.2016).Theelectric field of microwave causes heating throughdipolar rotation and ionic conduction (Beatrice andPhilippe 2002), which leads to selectively heating ofthe polar (lossy) part and generates a “hot spot”in theinhomogeneous materials (Hu and Wen 2008; Penget al. 2014). Thus, the molecular polarity is a primaryparameter in microwave-enhanced chemistry. Due tothe polarity of water molecules, the use of aqueousmedium, which can absorb microwaves and convertthem into heat energy to accelerate the reaction rates,is advantageous in microwave reaction (Gan et al.2014). In cellulose modification processes, the dipolerotation of microwave irradiation disrupts the weakhydrogen bonds and ultra-structure within cellulosefiber, leading to the improved accessibility of cellulose(Shaveta et al.2014; Xu et al. 2017). Several studieshave been carried out on the microwave-assistedsynthesis of cellulose derivatives or cellulose-based(nano)composites (Jia et al. 2010; Lin et al.2010), butto our knowledge, the efficiency of microwavetechnology in the TEMPO-mediated oxidation ofcellulose under neutral conditions has not yet beenevaluated. In this study, a facile microwave-assisted oxidationreaction was explored to produce modified cellulosehydrogelbeadsunder neutral TEMPO/NaClO/NaClO2 system. In this way, only 6 h oxidation timewas needed, and up toD1.28 mmol/g carboxylatecontent could be achieved. The obtained oxidizedcellulose beads were characterizedbyscanning electron microscopy, solid-state 13c-NMR spectraand X-ray diffraction. Subsequently, four organic dyes(rhodamin B, auramine O, malachite green andmethylene blue) were used as model water pollutantsto evaluate the adsorption characteristics of cellulosebeads after microwave-assisted oxidation. The adsorp-tion behaviors and kinetics, as well as recyclability ofoxidized cellulose beads, were investigated to verifythe utility of our method to prepare cellulose-basedadsorbents with high adsorption capacity and goodrecyclability. Experimental Materials Bamboo pulp (o-cellulose content >95%) provided byNanping Paper Co.,Ltd. (Nanping,Fujian, China) wascut into pieces and beaten to form powdered cellulose.Sodium hydroxide (NaOH), urea, hydrochloric acid(HCl), calcium chloride (CaCl2), sodium chlorite(NaClO2) and 10%NaClO solution were purchasedfrom Sinopharm Chemical Reagent Co., Ltd (Beijing,China) and used without further purification. 2,2,6,6-tetramethylpiperidinyl-1-oxyl radical (TEMPO) wasobtained from Aladdin Industrial Corporation (Shang-hai, China). All reagents used in this work were ofanalytical grade and deionized water was used for thepreparation of aqueous solutions. For adsorption experiments, rhodamin B (RB),auramineO (AO), malachite green (MG) and methyleneblue (MB) were of analytical grade and used withoutfurther purification. Chemical structure and someproperties of organic dyes were tabulated in Table 1. Preparation ofcellulose hydrogel beads Cellulose solution with the concentration of 4.0 wt%was prepared according to procedures reported in theliterature (Chang et al. 2010). In brief, an aqueoussolution of NaOH/urea/H20 with a weight ratio of7:12:81 was used as solvent of cellulose.96 g portionof the solvent was pre-cooled to -23°C for 24 h.4.0 g (oven dried weight) of cellulose was added andstirred vigorously at 3500 rpm for 10 min to obtain atransparent cellulose solution. The solution was sub-jected to centrifugation at 5000 rpm for 8 min toremove air bubbles before further use. The beadlike Table 1 Chemical structure and some properties of organic dyes Dyes Chemical formula Molar mass (g/mol) 八max (nm) Rhodamin B (RB) OH 479.01 554 CI Auramine O (AO) C| 303.84 430 H3C LCH CH Malachite Green (MG) 364.92 618 H3 .CH CI Methylene Blue (MB) 373.90 667 H3C CH3 CH. CH3 hydrogel was prepared by dropwise addition of thecellulose solution to the magnetically stirred coagula-tion solution (comprising 5.0 wt% of HCl and5.0 wt% of CaCl2; stirring speed of 30 rpm) with a5 mL glass syring at the dropping rate of 3 mL/min.Spherical cellulose hydrogel beads wwere formedinstantaneously and allowed to stir in coagulationsolution for 4 h for hardening. Then the hydrogelbeadss were filtered out and immersed in excessdeionized water for 3 days, with the water changedtwiceevery day toIremove non-participatedingredients. Microwave-assisted TEMPO-oxidationof cellulose hydrogel beads TEMPO-mediated oxidation of cellulose beads wascarried out in a microwave catalytic synthesis/extrac-tion apparatus (XH-300A, Beijing Xianghu Technol-ogy Development Co. Ltd., China). The microwavepower was 600 W, and the system was equipped withsealed flat-bottomed glass flask (250 mL), an internaltemperature sensor and a magnetic stirrer (set at 30%).Wet cellulose beads corresponding to 1.0 g dry weightwere placed in a flat-bottomed flask, and 0.1 M acetatebuffer solution1((100mL))at pH 6.86 containingTEMPO (98%, 0.096 g, 0.45 mmol)and sodium chlo-rite (98%, 1.85 g, 15 mmol) was added to the bottle, with the addition of 10 wt% NaClO solution (0.93 mL,15 mmol) at one step to the suspension. The flask wasimmediately stoppered, and the suspension reacted inthe microwave catalytic synthesis/extraction apparatusat a temperature of 60 ℃ for a designated time (0-9 h).Oxidation was quenched by adding an excess amount ofethanol. The oxidized cellulose beads were washedthoroughly with deionized water by filtration, and thenstored at 4C without drying. In the present study, theoxidation of cellulose beads for 1, 3 and 6 h weredesignated as CB-1h, CB-3h and CB-6h, respectively,while the original one was designed as CB-0h. As a control, TEMPO-mediated oxidationl wascarried out at 60°C in a water bath. The ratio ofcellulose beads/TEMPO oxidation system and subse-quent processing after reaction was the same asmentioned above. Weight recovery ratio and swelling ratiomeasurement The TEMPO-oxidized cellulose beads were weighedwith a glass weighing bottle, followed by freeze-dryingto obtain dry weights. The weight recovery ratio (RE)was obtained from the average of three runs ofmeasurements and calculated according to the Eq. 1. where Mo (g) is the mass of dried TEMPO-oxidizedcellulose beads and M (g) is the dry weight of theoriginal cellulose beads. The swelling ratio of TEMPO-oxidized cellulosebeads was measured by immersing samples into thedeionizedl water at 25 °C, the swollen TEMPO-oxidizedbeads were removed from water andweighted with a glass weighing bottle, followed byfreeze-drying to obtain dry weights. The swelling ratio(SR) was obtained from the average of three runs ofmeasurements and calculated according to the Eq. 2. where Mi (g) is the mass of swollen TEMPO-oxidizedcellulose beads and M2 (g) is the weight of the driedTEMPO-oxidized beads. Carboxylate content measurement The carboxylate content of the cellulose beads wasdetermined by the electric conductivity titrationmethod. The TEMPO-oxidized cellulose beads werefreeze-dried and ground into fine powder beforemeasurement. Water (55 mL) and 0.01 M sodiumchloride solutions (5mL) were added to a driedpowder (0.3 g), and the mixture was sufficientlystirred to prepare a well-dispersed slurry. Afterwards,0.1 M HCl was added to the suspension to set the pHvalue in the range of 2.5-3.0. Then the suspensionswere titrated with 0.1 M NaOH at the rate of 0.1 mL/min and titration curves were generated. The carboxy-late content was calculated according to the Eq. 3(Zhou et al.2013). where CcooH isthe carboxylate content of thecellulose beads; C is the NaOH concentration (mol/L); Vi and V2 are the amount of NaOH (L); M is theweight of freeze-dried sample (g). Adsorption of organic dyes Adsorption of organic dyes on cellulose beads (CB-0h,CB-3h and CB-6h) was carried out via batch adsorp-tion experiments on a thermostatic shaker (SHA-C,Kaihang Instrument Company,China) with a constant speed (150 rpm) at 25 °C. An accurate amount of theCB-0h, CB-3h and CB-6h (wet beads corresponding to0.02 g dry weight) was dispersed in 100 mL dyesolution (400 mg/L) for 48 h to ensure equilibrium.The concentration of organic dye was determined byusing a UV spectrometer (Agilent8453, Agilent tech-nologies, USA) at appropriate wavelengths corre-sponding to the maximum absorbance of each dye,554, 430, 618 and 667 nm for RB,AO, MG and MB,respectively. To study the adsorption kinetics, anamount of CB-6h (wet beads corresponding to 0.02 gdry weight) was soaked in 100 mL of 400 mg/mL dyesolution and then shaken at 25 ℃. At the specifiedtime intervals, 1 mL of suspension was collected andanalyzed by UV spectrometer. The adsorption capac-ity (qe, Eq. 4) and amount of dye adsorbed on CB-6h(q, Eq.5) at preset time were calculated as follows(Wang and Li 2013; Sun et al. 2016): where qe is the adsorption capacity of the cellulosebeads (mg/g);Co and Ce are the initial and equilibriumconcentrations of dye in solution (mg/L),respectively;Ct is the dye concentration at preset time t (min); m isthe dry weight of the adsorbent (g); and V is thevolume of the solution (L). Reuse of oxidized cellulose hydrogel beads Reusability of TEMPO-oxidized cellulose beads (CB-6h) was measured as follows. An accurate amount ofthe CB-6h (corresponding to 0.02 g dry weight) wasdispersed in 100 mL dye solution (400 mg/L)at 25℃for 48 h to ensure equilibrium. After the adsorption oforganic dyes, the cellulose beads were regenerated byhydrochloric acid solution to remove the adsorbeddyes. Firstly, the cellulose beadswere added to150 mL of 0.2 M HCl solution in a thermostatic waterbath shaker at 25 °C for 12 h, then the cellulose beadswere washed with deionized water for several timesand subjected to the next cycle. In order to test thereusability of the cellulose beads, the adsorption/desorption cycle was repeated five times and theconcentration of dyes was measured at each cycle byUV spectrometer as described above. Field emission scanning electron microscopy (FE-SEM) and nitrogen adsorption measurement The cellulose beads were freeze-dried and coated withgold for field emission scanning electron microscopy(FE-SEM) analysis. Allthe samples were pho-tographed by SU8010 FE-SEM (Hitachi, Japan) atan accelerating voltage of 1.0 kV. Nitrogen adsorption analysis was performed onTEMPO-oxidized cellulose beadsdS(freeze-drying)using a Micromeritics AsAp2020 (USA), and Bru-nauer-Emmett-Teller (BET) and Barrett-Joyner-Halendar (BJH) analyses were done by software.The BET analysis was performed for relative vaporpressure of 0.05-0.3 at 77 K. The BJH analysis wascarriedout from the desorption branch of theisotherms. Nuclear magnetic resonance spectroscopy(NMR)and Fourier transform infrared spectroscopy(FTIR) The TEMPO-oxidized cellulose beads were freeze-dried and ground into fine powder before measurementof NMR. Solid-state 13C-NMR spectra of the TEMPO-oxidized cellulose beads were recorded on a BrukerAVANCEIII 400 (C frequency =100.0 MHz) atcross-polarization and magic angle spinning under thefollowing conditions: spinning rate 6.0 kHz, pulsedelay 5.0 s and contact time 5.0 ms. Infrared spectra of the samples were recorded atroom temperature on a Nicolet 380 FTIR spectrometer(Thermo Electron Instruments Co., Ltd.,USA) tocharacterize TEMPO-oxidized cellulose beads beforeand after adsorption of organic dyes. Freeze-driedsample powders were analyzed as KBr pellets in thefrequency range of 4000-400 cm. X-ray diffraction (XRD) analysis The crystallinity index (CrI) of TEMPO-oxidizedcellulose beads in comparison with original cellulosebeads was investigated by X-ray diffraction analysis.Wide-angle X-ray diffraction measurement was per-formed on anXRD diffractometer (Philips-FEI,Netherlands) by using Cu Ko radiation at 40 kV and40 mA. Diffractograms were collected in the 20 rangefrom 5° to 60°at scanning rate of 0.02°s. The CrIwas calculated according to the Eq. 6. where I101 is the diffraction intensity of (101) plane at20=20.0-21.0° and Iam is the diffraction intensity at20=15.0°. Results and discussion Preparation of oxidized cellulose hydrogel beads The preparation procedure of TEMPO-oxidized cel-lulose hydrogel beads with high adsorption capacity isschematically shown in Fig. 2. Transparent cellulosesolution (4.0 wt%) was prepared by dissolving cellu-lose in an aqueous NaOH/urea solution. The obtainedcellulose solution was added dropwise into the coag-ulation solution (containing 5.0 wt% of HCl and5.0 wt% of CaCl2) and the cellulose hydrogel beadswere immediately formed. After that, cellulose beadswere suspended into TEMPO-mediated oxidationsystem at pH 6.86, and the oxidation of cellulosebeads was carried out in the microwave catalyticsynthesis/extraction apparatus at a temperature of60 °C. Carboxylate groups were introduced in thecellulose beads by the selective oxidation of C6primary hydroxyl groups of cellulose without obviousexternal morphological changes. Additionally, theTEMPO-oxidized hydrogel beadswere used toremove various organic dyes. The significant colorchanges after adsorption revealed the high adsorptioncapacity of the hydrogel beads for RB, AO, MG andMB. Determination ofcarboxylate content Figure 3 shows the relationship between reaction timeand carboxyl group content or weight recovery ratio ofoxidized cellulose beads under microwave heating andconventional water bath heating conditions, respec-tively. As for the method assisted by microwave, thecarboxylate content increased sharply to 1.28 mmol/gwith the reaction time increasing to 6 h and thenreached a plateau level, and the weight recovery ratiowasmore than 96.0%. However, the carboxylatecontent of cellulose beads via the water bath heatingincreased slowly to 1.23 mmol/g with the extension ofoxidation time to 24 h and then reached 1.27 mmol/g Fig. 2 Schematicillustration for thefabrication of TEMPO-oxidized cellulose hydrogelbeads by microwave heatingand its organic dyesadsorption Fig. 3 Carboxylate content and weight recovery ratio ofcellulose hydrogel beads oxidized by the neutral TEMPOsystem with microwave heating and conventional water bathheating at 60°℃ after oxidation for 36 h, with the significant decreaseof weight recovery ratio to 85.4%. These resultsindicate that, compared to the water bath heating,process underr microwave heatingsignificantly cellulose at the C6 position) and external mechanicalimpact force (magnetic stirrer bar was used), resultingin partial dissolution of cellulose beads during thereaction (Isogai and Kato 1998; Hirota et al. 2009). Physical properties of TEMPO-oxidized cellulosebeads As can be seen in Fig. 4 and Table 2, the TEMPO-oxidized cellulose beads retained their original spher-ical shapes and the average diameter was almostunchanged even after 6 h irradiation at 60 ℃ in theneutral TEMPO/NaClO/NaClO2 system, indicatingthat TEMPO oxidation reaction via microwave heat-ing did not destroy the appearance of cellulose beads.The carboxylate content increased linearly with theextension of irradiation time, revealing that thecontent of introduced carboxylate can be controlledby changing the reaction time. Due to the highhydrophilicity of carboxylate groups, the swellingratio and water content of TEMPO-oxidized cellulosebeads increased along with the carboxylate content. Inaddition, after 6 h reaction, the specific surface area ofcellulose beads increased from 59.29 to 132.37 m/g,and the average pore diameter decreased from 19.33 to11.69 nm. These results indicated that microwaveirradiation and TEMPO-mediated system had an Fig. 4 Photographs of the original cellulose beads (CB-0h) and TEMPO-oxidized cellulose beads (CB-1h, CB-3h, CB-6h) obvious influence on the microstructure of the cellu-lose beads. Morphology analysis As can be seen in Fig. 5a, the surface of originalcellulose hydrogel beads presents a relatively smoothtexture and there is no obvious pore in the microstruc-ture. After 1 h TEMPO oxidation via microwaveirradiation, the surface structure of the cellulose beads(Fig. 5b) became coarser and some pores began toform. As shown in the Fig. 5c, d, after 3 or 6 hoxidation, the fibril began to appear on the surface ofcellulose beads and the diameter of fibril graduallyreduced from hundreds of nanometers to tens ofnanometers. At the same time, more poresi withincreasing average pore size was also observed inthe SEM images of CB-3h and CB-6h. However, asshown in the Fig. 5e-h, none of the cross-section SEMmicrographs of the original or TEMPO-oxidizedcellulose beads show much difference. This clearlyindicates that only the surface of the cellulose beadswas oxidized. In the surface region, all of the abovemorphologic changes were possibly caused by thepartial dissolution of carboxylated cellulose beads,which contained the water-soluble polyglucuronicacid (carboxylated cellulose at the C6 position) after Table 2 Properties of original and TEMPO-oxidized cellulose beads CB-0h CB-1h CB-3h CB-6h Average diameter (mm)" 2.87 2.89 2.87 2.91 Carboxylate content (mmol/g) 0.03 0.45 0.96 1.27 Swelling ratio (g/g) 11.81 14.08 16.67 20.74 Specific surface area (m /g) 59.25 100.59 111.76 132.37 Average pore diameter (nm) 19.33 10.84 10.56 11.69 "Data obtained from photographs of the beads with image analysis software (Image J) Data obtained from BET with a relative vapor pressure of 0.05-0.3 of desorption branch Data from BJH desorption branch Fig. 5 SEM micrographs of surface (a-d) and cross-section (e-h) of original cellulose beads (CB-0h) and TEMPO-oxidized cellulosebeads (CB-1h, CB-3h, CB-6h) TEMPO oxidation (Isogai and Kato 1998). Suchhighly specific porous network with thinner fibrilscreated abundant adsorption sites of cellulose beads,facilitating the high adsorption for the organic dyes. cNMR spectra analysis The investigation of chemical structure changes in theTEMPO-oxidized cellulose beads was carried outthrough solid-state 13C-NMR analysis. Figure 6 showsthe solid-state 13c-NMR. spectra of the originalcellulose beads (CB-0h)aanddTEMPO-oxidized cellulose beads (CB-1h, CB-3h and CB-6h). In thespectra, original cellulose beads (CB-0h) exhibit sometypical signals at 105.8 (C1), 88.4 and 85.1 (C4), 75.3(C2, C3 and C5) and 63.7 ppm (C6) (Chang et al.2009). Compared with this, a new peak was observedin the spectra of oxidized cellulose beads (CB-1h,CB-3h and CB-6h) at 175.7 ppm, which was assigned tothe carbon of the carboxylategroup (Saito et al. 2005).Meanwhile, in the spectra of CB-Oh, the signal at63.7 ppm corresponding to the C6 primary hydroxylgroup decreased after oxidation. These results indi-cated that the oxidation of C6 primary hydroxylgroups of cellulose beads to carboxylate groups could Fig. 6 Solid-state 13c-NMR spectra of CB-0h, CB-1h, CB-3hand CB-6h be achieved efficiently via microwave irradiation(Saito et al. 2005, 2009). Moreover, the signal at175.7ppm becarameeSstronger withreaction1 timeextended, indicating the increased carboxylate contentof oxidized cellulose beads. This result is also in goodagreement with the conductivity titration measure-ment as shown in Fig. 3. On the other hand, the signalsat 105.8, 175.3.),88.4andd 885.1 ppm remainedunchanged after the TEMPO-mediated oxidation for6 h, definitely confirming that the oxidation occurredonly at C6 primary hydroxyl group and the macro-molecular structure of cellulose was not destroyed. X-ray diffraction analysis The X-ray diffraction patterns of original cellulosebeads (CB-0h) and TEMPO-oxidized cellulose beads(CB-3h and CB-6h) are shown in Fig. 7. It can beobserved that the XRD patterns of all the samplesexhibit three diffraction peaks at20=12.2°,20.3°and21.6°, which are assigned to cellulose II (Liu and Hu2008). Thus, the crystalline type of cellulose remainedintact during the microwave-assisted process in thisstudy.The crystallinity index ofCB-0h, CB-3h and CB-6h are calculated as 52.39, 52.25 and 52.21%, respec-tively. Compared with CB-0h, the crystallinity index ofCB-3h and CB-6h almost unchanged after oxidation,suggesting that the oxidation occurred essentially at theC6 primary hydroxyl groups exposed on the fibrilsurfaces (Saito et al. 2009). Fig.7 Powder X-ray diffraction patterns of CB-0h, CB-3h andCB-6h Organic dye adsorption behavior of TEMPO-oxidized cellulose hydrogel beads The effect of carboxylate content on cellulose beadsadsorption According to the results discussed above, TEMPO-oxidized cellulose beads possessed abundant hydroxyland carboxylate groups as well as unique microstruc-tures,leading to efficient adsorption of dyes by variouskinds of interactions. In this study, the originalcellulose beads (CB-0h) and TEMPO-oxidized cellu-lose beads (CB-3h and CB-6h) with carboxylatecontents of 0.003, 0.97 and 1.28 mmol/g were usedfor removing cationic dyes (400 mg/L) from aqueoussolution at 25℃. As shown in Fig. 8a, the originalcellulose beads (CB-0h) can absorb about 69, 48, 71and 86 mg/g of RB, AO, MG and MB, respectively.This is possibly due to the great abundance ofhydroxyl groups on the hydrogel beads, which havean affinity for organic dyes through hydrogen bondinginteractions (Luo and Zhang 2009). However, with theincrease of carboxylate content of cellulose beadsfrom 0.003 mmol/g (CB-0h) to 1.28 mmol/g (CB-6h),a sharp increase in the organic dyes adsorption can beobserved. The maximum adsorption capacity of CB-6h for RB, AO, MG and MB is found to be 609, 537,740 and 873 mg/g, respectively. This has been clearlyvisualized in the photograph of the dye-adsorbedcellulose beads shown in Fig. 8b. With the increase ofcarboxylate content, the color of the beads became Fig. 8 a Adsorption property of original cellulose beads (CB-Oh) and TEMPO-oxidized cellulose beads (CB-3h and CB-6h)for RB, AO, MG and MB with a concentration of 400 mg/L, darker, indicating that the adsorption capacity ofcellulose beads was improved significantly aftermicrowave-assisted oxidation. This phenomenon canbe explained in terms of the presence of carboxylategroups and porous microstructure of oxidized cellu-lose beads, thus promoting the electrostatic interac-tions between dyes and adsorbents. Figure 8c showsthe possible interactions between methylene blue andoxidized cellulose beads. b photographs of the color change of cellulose beads afteradsorption, c schematic drawing for the interactions betweenMB and TEMPO-oxidized cellulose beads Adsorption mechanism The possible interaction between organic dyes andTEMPO-oxidized cellulose beads was confirmed byFTIR spectra analysis. Figure 9 shows the FTIR spectraof thee TEMPO-oxidized cellulose beads (CB-6h)before and after adsorption for organic dyes. In theFTIR spectra of CB-6h (Fig. 9e), the characteristicpeaks are appeared at 3449 cm-(O-H vibration Fig. 9 FTIR spectra of TEMPO-oxidized cellulose beads (CB-6h) before and after adsorption for organic dyes: a afteradsorption for RB, b after adsorption for MB, c after adsorptionfor AO, d after adsorption for MG,e before adsorption stretching), 2899 cm-(C-H symmetric stretchingvibration), 1611 cm(carboxylate groups (-COO-)一1stretching), 1363 cm-(antisymmetric deformation of-CHs groups), 1161 cm(an antisymmetric C-O-Cglycoside), and 1064 cm-(C-O stretching vibration)(Lin et al. 2012;Zhao et al. 2016). After adsorption, thepeaks of O-Hvibration stretching of CB-6h broadenedand shifted from 3449 to 3435 cm-(adsorption forMG), 3442 cm(adsorption for AO), 3438 cm-(adsorption for MB) and 3434 cm- (adsorption forRB). Meanwhile, the bands of carboxylate groups (-Coo-) at 1611 cm-shifted to 1594 cm-(adsorptionfor MG), 1602 cm(adsorption for AO), 1628 cm-(adsorption for MB) and 1632 cm (adsorption forRB), and the intensity of which decreased. Thesechanges probably due to the interaction of organic dyeswith -OH groups and -Coo groups of CB-6h viahydrogen and electrostatic bonding during the adsorp-tion process (as show in Fig. 8c) (Liu et al. 2015). Inaddition, the intensity and position change of bands at2899,1363 and 1064 cm- was also due to theadsorption of organic dyes on CB-6h (Fig. 9a-d).Therefore, all of the above FTIR spectra changes couldbe regarded as the evidence for the interaction betweenTEMPO-oxidized cellulose beads and organic dyes. Adsorption kinetics In order to better understand the adsorption properties,the adsorption kinetics of organic dyes for CB-6h was performed and the results were shown in Fig. 10a. Asillustrated in Fig. 10a, the adsorption curves oforganic dyes for CB-6h can be divided into twostages: an initial rapid adsorption processes within ashort time and a subsequent slow adsorption stage. Theadsorption rates of organic dyes were fast for CB-6h inthe first 100 min and then the rates decreased gradu-ally. At around 300 min, the adsorption equilibriumwas achieved, and the equilibrium adsorption capacityof CB-6h for RB, AO, MG and MB reached up to 601,530, 732 and 862 mg/g,respectively. Owing to thenumerous active sites of CB-6h, the adsorption oforganic dyes showed a fast rate in the initial period.With the extension of contact time, the active siteswere gradually occupied by the organic dyes and theadsorption rates slowed down. Finally, by furtherextending the adsorption time, the amount of dyesadsorbed could not increase anymore because therewas strong repulsive force existing between theadsorbed organic dyes (Tian et al. 2014), and theadsorption equilibrium occurred at this moment. To gain further insight into the mechanism andcharacteristics of organic dyes adsorption behavior,the following pseudo-first-order (Eq.7) and pseudo-second-order (Eq. 8) kinetic models are used to testthe experimental data (Liu et al. 2015). where qe and qt(mg/g) are the adsorption capacities ofCB-6h at equilibrium and at time t (min), and k(min-) and k2 (g/(mg min)) are the rate constants ofpseudo-first-order and pseudo-second-order adsorp-tion kinetics, respectively. The fitting curves areshown1 in Fig. 10b, c and corresponding kineticparameters and correlation coefficients (R2) from bothmodels are listed in Table 3. It can be seen that thetheoretical qe values obtained from the pseudo-first-order kinetic model did not agree well with theexperimental values, whereas the pseudo-second-order kinetic model for the adsorption of organic dyeson CB-6h showed perfect straight lines (Fig. 10c) andbetter correlation coefficients (R²=0.9994-0.9998).These results suggested that the adsorption kinetics oforganic dyes on the TEMPO-oxidized cellulose beadscould be well described by the pseudo-second-ordermodel, which indicated that the overall rate of the Time (min) Fig. 10 a Adsorption kinetic curves for the adsorption of organic dyes (400 mg/mL) on CB-6h at 25 ℃, b Pseudo-first-order kineticmodel, and c Pseudo-second-order kinetic model for adsorption of RB, AO, MG and MB, respectively Table 3 Parameters ofkinetics studies for dyesadsorption onto CB-6h Adsorbate Pseudo-first-order Pseudo-second-order 9e, exp k(min~) ge (mg/g) R k2 (g/(mg min)) ge (mg/g) R2 (mg/g) RB 0.00419 183.66 0.8821 0.0413 617.28 0.9998 601.21 AO 0.00436 157.58 0.8833 0.0425 546.45 0.9994 530.89 MG 0.00452 263.68 0.9236 0.0347 757.58 0.9998 732.43 MB 0.00448 290.89 0.9134 0.0370 892.86 0.9998 861.84 adsorption process was controlled by chemisorption(Peng et al. 2015). The main interaction force of dyesadsorption on oxidized cellulose beads is throughelectrostatic interactions (see Fig. 8c). Reusability of TEMPO-oxidized cellulose beads From practical point of view, reusability isanimportant index for the applicability of adsorbents. Fig. 11 The performance of TEMPO-oxidized cellulose beads(CB-6h) by multiplecycles of regeneration In the present work, in order to evaluate the reusabilityof TEMPO-oxidized cellulose beads (CB-6h) as anbioadsorbent, the 0.2 mol/L HCl solution was selectedas a desorption agent for the organic dyes desorptionexperiment. The adsorption/desorption cyclewasrepeated five times and the results were shown inFig. 11. It was found that the organic dyes could besuccessfully desorbed from CB-6h by acid solution.However, the adsorption capacity of CB-6h fororganic dyes decreased as the cycles proceeded (e.g.methylene blue: from 862 to 264 mg/g). The reasonfor this phenomenon is attributed to the transformationof carboxyl group from sodium carboxylate (-COONa ) to carboxylic acid (-COO-H+) on CB-6h afteracidic treatment, leading to the decrease in theelectrostatic repulsive force and the aggregation toform hydrogen bond with neighboring hydroxylgroups (Astrini et al. 2015; Isobe et al. 2013). Thus,the number of active sites available for organic dyesadsorption decreased after HCl solution treatment.Nevertheless, the CB-6h after fiveadsorption/desorp-tion cycles had more than twice as high an adsorptioncapacity as the original cellulose beads (CB-0h).Therefore, it can be said that the TEMPO-oxidizedcellulose beads could be recovered with acid treatmentand repeatedly used for organic dyes adsorption inindustrial wastewater. Conclusions In summary, an effective microwave-assisted methodis presented to oxidize C6 primary hydroxyl groups of cellulose beads to carboxyl groups by using TEMPOoxidation system at pH 6.86. The carboxylate contenton the cellulose beads reached up to 1.28 mmol/g bymicrowave heating for only 6 h, however, 36 h ofreaction time was required with the conventionalwater bath heating conditions, indicating that thereaction time for cellulose beads oxidationwassignificantly shortened by microwave heating. TheTEMPO-oxidized cellulose beadssshowed highlyporous structures consisting of nano-sized fibrils withretention of original spherical shapes, and the celluloseII crystal structure of cellulose beads remained almostunchanged. Theporousnetwork structures ofTEMPO-oxidized hydrogel beads associated with thepresence of carboxyl groups on the surface of thinnerfibrils were found to effectively increase its adsorptionsites, resulting in excellent dye adsorption capacity.The maximum adsorption capacity of RB, AO, MGand MB were 609, 537, 740 and 873 mg/g,respec-tively, and the adsorption behavior was well describedby pseudo-second-order kinetics. In the adsorption-desorption experiments, the TEMPO-oxidized cellu-lose beads showed more than twice as high anadsorption capacity as the original cellulose beadsafter five cycles. Thus, the technically feasible, cost-effective, and highly efficient cellulose-based bioad-sorbent has been successfully prepared with greatpotential for organic dyes adsorption from industrialwastewater. Further study is needed to excavate thepotential of TEMPO-oxidized cellulose beads forheavy metal ions adsorption. AcknowledgmentsWe acknowledge the generous financialsupport of the State Forestry Administration 948 project (No2014-4-30), National Natural Science Foundation of China (No.21402027,31370560), the Natural Science Foundation of FujianProvince (No. 2015J05046), open fund of Guangxi KeyLaboratory of Chemistry and Engineering of Forest Products(No. GXFC 14-03) and Chemicals and Science Foundation forDistinguished Young Scholars of Fujian Agriculture andForestry University (No. xjq201503). References Akira I, Tsuguyuki S, Hayaka F (2011) TEMPO-oxidized cel-lulose nanofibers.Nanoscale 3:71-85 Ali I (2012) New generation adsorbents for water treatment.Chem Rev 112:5073-5091 Astrini N, Anah L, Haryadi HR (2015) Adsorption of heavymetal ion from aqueous solution by using cellulose basedhydrogel composite. Macromol Symp 353:191-197 ( Bayramoglu G, Altintas B, Arica MY ( 2 012) Synthesis a nd characterization of magnetic beads c o ntaining aminatedfibrous surfaces for removal o f r eactive g reen 19 dye: kinetics and thermodynamic parameters. J Chem TechnolBiot 87:705-713 ) Beatrice K, Philippe C (2002) Recent extraction techniques fornatural products: microwave-assisted extraction and pres-surised solvent extraction. Phytochem Anal 13:105-113 Cai J, Kimura S, Wada M, Kuga S, Zhang L (2008) Celluloseaerogels from aqueous alkali hydroxide-urea solution.ChemSusChem 1:149-154 Chang C, Zhang L (2011) Cellulose-based hydrogels: presentstatus andla2pplication prospects. Carbohydr Polym84:40-53 Chang C, Duan B, Zhang L (2009) Fabrication and characteri-zation of novel macroporous cellulose-alginate hydrogels.Polymer 50:5467-5473 Chang C Zhang L, Zhou J, Zhang L, Kennedy JF (2010)Structure and properties of hydrogels prepared from cel-lulose in NaOH/urea aqueous solutions. Carbohydr Polym82:122-127 Chen L, Berry RM, Tam KC (2014a) Synthesis of -cy-clodextrin-modified cellulose nanocrystals (CNCs)@Fe.O4@SiO2 superparamagnetic nanorods. Acs Sustain ChemEng 2:951-958 Chen W, Li Q,Wang Y, YiX, Zeng J, Yu H, Liu Y, Li J (2014b)Comparative study of aerogels obtained from differentlyprepared nanocellulose fibers. ChemSusChem 7:154-161 Chen X, Zhou S, Zhang L, You T, Xu F (2016) Adsorption ofheavy metals by graphene oxide/cellulose hydrogel preparedfrom NaOH/urea aqueous solution. Materials 9:582-596 Ching TW, Haritos V, Tanksale A (2017) Microwave assistedconversion of microcrystalline cellulose into value addedchemicals using dilute acid catalyst. Carbohydr Polym157:1794-1800 Gabhane J, William SPMP, Vaidya AN, Mahapatra K, Chak-rabarti T (2011) Influence of heating source on the efficacyof lignocellulosic pretreatment—a cellulosic ethanol per-spective. Biomass Bioenerg 35:96-102 Gan S, Zakaria S, Chia CH, Kaco H, Padzil FN (2014) Synthesisof kenaf cellulose carbamate using microwave irradiationfor preparation of cellulose membrane. Carbohydr Polym106:160-165 Gupta VK, Suhas (2009) Application of low-cost adsorbents fordye removal-a review.J Environ Manage 90:2313-2342 Hirota M, Tamura N, Saito T, Isogai A (2009) Surface car-boxylation of porous regenerated cellulose beads by 4-ac-etamide-TEMPO/NaClO/NaClO2 system. Cellulose16:841-851 Hokkanen S, Bhatnagar A, Sillanpaa M (2016) A review onmodification methods to cellulose-based adsorbents toimprove adsorption capacity. Water Res 91:156-173 ( Hu ZH, Wen ZY (20 0 8) Enh a ncing enzymatic digestibility of switchgrass b y microwave-assisted al k a li pr e treatment. Biochem Eng J 38:369-378 ) Huang B, Lu Q, Tang L (2016) Research progress of nanocel-lulose manufacture and application. J For Eng 1:1-9 ( Isobe N, Chen X, K im UJ, Kimura S, Wada M, Saito T, Isogai A(2013) TEMPO-oxidized cellulose hydrogel as a high-ca-pacity and reusable h eavy m e tal i o n a d sorbent. J H a zard Mater 260:195-201 ) Isogai A, Kato Y (1998) Preparation of polyuronic acid fromcellulose byyTTEMPO-mediated oxidation. Cellulose5:153-164 ( Jia N, Li SM, Zhu JF, Ma MG, Xu F, Wang B, Sun RC (2010)Microwave-assisted s y nthesis a n d characterization of cel- lulose-carbonated hydroxyapatite nanocomposites in NaOH-urea aqueous solution. Mater Lett 64:2223-2225 ) Khandanlou R, Ngoh GC, Wen TC (2016) Feasibility study andstructural analysis of cellulose isolated from rice husk:microwave irradiation, optimization, and treatment processscheme. Bioresour 11:5751-5766 Kim UJ, Kuga S, Wada M, Okano T, Konodo T (2000) Periodateoxidation of crystalline cellulose. Biomacromol 1:488-492 Laisha GM, Sharkov VI (1974) The kinetics of oxidation ofcelluloses by nitrogen tetroxide as a characteristic of theirsupermolecular structure. Polym Sci USSR 16:1971-1978 Lin C, Zhan H, Liu MH, Fu SY, Huang LH (2010) Rapidhomogeneous preparation of cellulose graft copolymer inBMIMCL under microwave irradiation. J Appl Polym Sci118:399-404 Lin N, Bruzzese C, Dufresne A (2012) TEMPO-oxidizednanocellulose participating as crosslinking aid for alginate-based sponges. ACS Appl Mater Interfaces 4:4948-4959 Liu Y, Hu H (2008) X-ray diffraction study of bamboo fiberstreated with NaOH. Fibers Polym 9:735-739 ( Liu L, Gao Z Y, Su XP, Chen X , J i ang L, Yao J M (2015)Adsorption removal of dyes from single a nd binary s olu-tions using a cellulose-based bioadsorbent. ACS Sustain Chem Eng 3 :432-442 ) Luo X, Zhang L (2009) High effective adsorption of organicdyes on magnetic cellulose beads entrapping activatedcarbon. J Hazard Mater 171:340-347 ( Ma X, Liu X, A nderson DP, Chang PR (2015)Modification ofporous starch f or the adsorption o f heavy metal i o ns from aqueous s olution. Food Chem 1 81:133-139 ) Melo JCP, Filho ECS, Santana SAA, Airoldi C (2011) Syn-thesized cellulose/succinic anhydride as an ion exchanger.Calorimetry of divalent cations in aqueous suspension.Thermochim Acta 524:29-34 Nooy AEJD, Besemer AC, Bekkum HV (1995) Highly selectivenitroxyl radical-mediated oxidation of primary alcoholgroups in water-soluble glucans. Carbohydr Res 269:89-98 ( Peng H , C hen H, Qu Y, Li H, Xu J ( 2014) Bioconversion ofdifferent s izes of m icrocrystalline cellulose p r etreated bymicrowave i r radiation with/without NaOH. A ppl Energy117:142-148 ) ( P eng Q, L iu M , Zheng J, Z hou C ( 2 015) A d sorption o f dyes in aqueous solutions by chitosan–halloysite nanotubescomposite h ydrogel beads.Microporous Mesoporous Mater 201:190-201 ) Razzaq T, Kappe CO (2008) On the energy efficiency ofmicrowave-assisted1 organic reactions. ChemSusChem1:123-132 Saito T, Isogai A (2004) TEMPO-mediated oxidation of nativecellulose. The effect of oxidation conditions on chemicaland crystal structures of the water-insoluble fractions.Biomacromol 5:1983-1989 ( Saito T, Shibata I, Isoga i A , Sugur i N , Sumikawa N (2005) Distribution of carboxylate groups i ntroduced into cotton linter s by the TEMPO-mediated o xidation. Carbohydr Polym 61:414-419 ) ( Saito T, Okita Y, Nge T T, S ugiyama J , I s ogai A (2006) TEMPO-mediated oxidation of native ce l lulose: m i cro- scopic analysis of fibrous f r actions i n t h e oxidized pr o d- ucts. Carbohydr Polym 65:435-440 ) ( Saito T, Hirota M, Tamura N, Kimura S, Fukuzumi H, Heux L,Isogai A (2009) Individualization of nano-sized pla n t cel - lulose fibrils by direc t surface carboxylation using TEMPO catalyst under neutral conditions . Biomacromol10:1992-1996 ) ( Shaveta Bansal N, Singh P (2014) F-/Cl- mediated m icrowaveassisted breakdown o f cellulose to glucose. Te t rahedronLett 55:2467-2470 ) ( Sun C, Huang Z, Wang J , R ao L, Z hang J, Yu J, Du J, Xu C (2016) Modification o f mi c rocrystalline ce l lulose with pyridone derivatives for removal of c a tionic dyes fr o m aqueous s olutions. Cellulose 23:2917-2927 ) ( Tian D, Zhang X, Lu C, Yuan G,Zhang W, Zhou Z (2014)Solvent-free s ynthesis o f c arboxylate-functionalized c el- lulose from w aste cotton fabrics for the removal of cationicdyes from aqueous solutions. Cellulose 21:473-484 ) ( Turgay O, E rsoz G , A talay S , Forss J, Welander U (2011) Thetreatment of a zo dyes found in textile i ndustry wastewater by a naerobic b iological method and chemical oxidation. Sep Purif Technol 79:26-33 ) ( Wang L , Li J ( 2013) A dsorption of C.I. Reactive Red 228 dye from aqueous solution b y modified ce l lulose from fl a x shive: kinetics, equilibrium, and t hermodynamics. I n d Crops Prod 42:153-158 ) ( Wang Y F, Gao B Y, Y ue QY, Wang Y , Y a ng Z L (2012) Removal o f acid a n d direct dye b y ep i chlorohydrin- dimethylamine: f locculation performance a nd f loc aggre- gation properties . Bioresou r Technol 113:265-27 1 ) Wen Y, Wei B, Cheng D, An X, Ni Y (2016) Stabilityenhancement of nanofibrillated cellulose in electrolytes ( through g rafting o f 2 -acrylamido-2-methylpropane su l - f onic acid . Cellulose 24:1-8 ) Wu JS, Liu CH, Chu KH, Suen SY (2008) Removal of cationicdye methyl violet 2B from water by cation exchangemembranes. J Membr Sci 309:239-245 ( Xu Y , Xu Y, Yue X (2017) Changes of hydrogen bonding andaggregation s t ructure of cellulose fiber due to microwave-assisted a lkali treatment and its impacts on the applicationas f luff pulp. Cellulose 24:967-976 ) ( Yao Q, Xie J, Liu J, Kang H, Liu Y (2014) A dsorption of leadions using a m odified lignin hydrogel . J Polym Res21:465-481 ) ( Yu M , Li J , Wang L (2016a) K OH-activated carbon a erogelsderived from s odium carboxymethyl cellulose for high- performance s upercapacitors and dye adsorption . ChemEng J310:300-306 ) ( Yu S, Xiao Y, Wang G, Luo W, Li X, Li u Y (2016b) Preparation of f lyash/chitosan composites and i t s application i n thewastewater of wood dyeing. J For Eng 1:29-33 ) ( Zhang Y, T ang Z R, F u X, X u Y J ( 2 010) TiO2-gr a phenenanocomposites f o r gas-phase photocatalytic degradation of v olatile aromatic p ollutant: is TiO2- g raphene tr u ly different from other TiO2- carbon composite materials? ACS Nano 4:7303-7314 ) ( Zhao D, Huang J, Zhong Y, Li K , Z h ang L, Cai J (2016) H i ghstrength and high toughness double cross linked cellulosehydrogels: a new strategy using sequential chemical and physical cross linking. Adv Funct Mater 2 6:6279-6287 ) ( Zhou Y, Zhang M, Hu X , W ang X, Niu J, Ma T (2013) Adsorption of c a tionic dyes o n a cellulose-based multi-carboxyl adsorbent. J Chem Eng Data 58:413-421 ) ( Zhou Y, W ang X , Zhang M , Jin Q , G a o B, Ma T ( 2014) R emoval o f P b (II) a nd malachite g reen f rom aqueous solution by modified cellulose. Cellulose 2 1: 2 797-2809 ) Published online: SeptemberSpringer Springer

关闭-

1/16

-

2/16

还剩14页未读,是否继续阅读?

继续免费阅读全文产品配置单

北京祥鹄科技发展有限公司为您提供《TEMPO氧化纤维素珠中有机染料的吸附能力检测方案(微波合成仪)》,该方案主要用于涂料中有机染料的吸附能力检测,参考标准《暂无》,《TEMPO氧化纤维素珠中有机染料的吸附能力检测方案(微波合成仪)》用到的仪器有电脑微波超声波组合合成萃取仪 Soniwave XH-300A+型 、微波消解工作站 Honeycomb、电脑微波超声波紫外光组合合成萃取仪。

我要纠错

推荐专场

相关方案

咨询

咨询