方案详情文

智能文字提取功能测试中

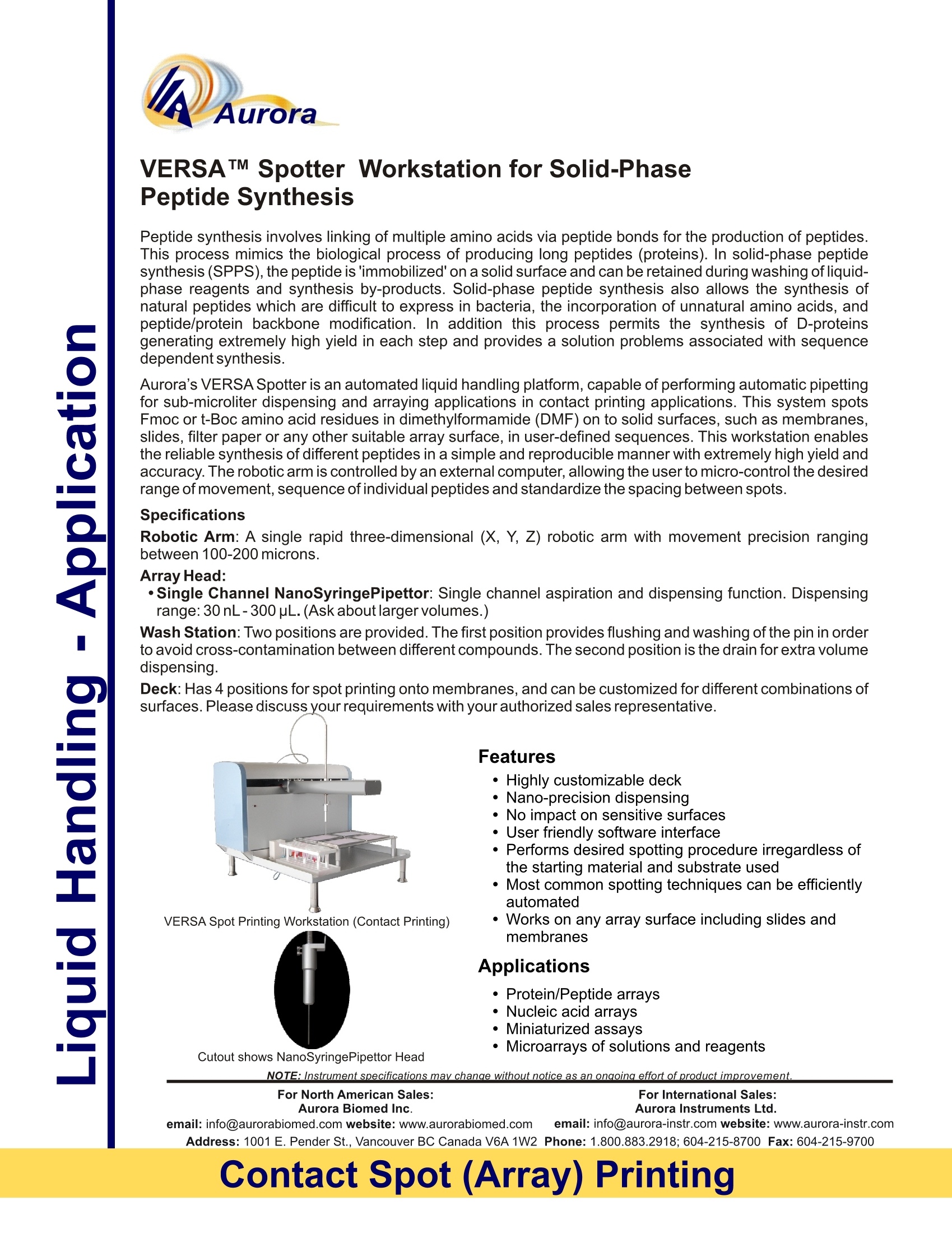

Contact Spot (Array) Printing VERSATM Spotter Workstation for Solid-PhasePeptide Synthesis Peptide synthesis involves linking of multiple amino acids via peptide bonds for the production of peptides.This process mimics the biological process of producing long peptides (proteins). In solid-phase peptidesynthesis (SPPS), the peptide is 'immobilized' on a solid surface and can be retained during washing ofliquid-phase reagents and synthesis by-products. Solid-phase peptide synthesis also allows the synthesis ofnatural peptides which are difficult to express in bacteria, the incorporation of unnatural amino acids, andpeptide/protein backbone modification. In addition this process permits the synthesis of D-proteinsgenerating extremely high yield in each step and provides a solution problems associated with sequencedependent synthesis. Aurora's VERSA Spotter is an automated liquid handling platform, capable of performing automatic pipettingfor sub-microliter dispensing and arraying applications in contact printing applications. This system spotsFmoc or t-Boc amino aci(PMd residues in dimethylformamide (DMF) on to solid surfaces, such as membranes,slides, filter paper or any other suitable array surface, in user-defined sequences. This workstation enablesthe reliable synthesis of different peptides in a simple and reproducible manner with extremely high yield andaccuracy. The robotic arm is controlled by an external computer, allowing the user to micro-control the desiredrange of movement, sequence of individual peptides and standardize the spacing between spots. Specifications Robotic Arm: A single rapid three-dimensional (X,Y, Z) robotic arm with movement precision rangingbetween 100-200 microns. Array Head: ·Single Channel NanoSyringePipettor: Single channel aspiration and dispensing function. Dispensingrange:30 nL-300 pL. (Ask about larger volumes.) Wash Station: Two positions are provided. The first position provides flushing and washing of the pin in orderto avoid cross-contamination between different compounds. The second position is the drain for extravolumedispensing. Deck: Has 4 positions for spot printing onto membranes, and can be customized for different combinations ofsurfaces. Please discuss your requirements with your authorized sales representative. Features ·Highly customizable deck ·Nano-precision dispensing · No impact on sensitive surfaces ·User friendly software interface ·Performs desired spotting procedure irregardless ofthe starting material and substrate used · Most common spotting techniques can be efficientlyautomated ·Works on any array surface including slides andmembranes Applications ·Protein/Peptide arrays ·Nucleic acid arrays ·Miniaturized assays ·Microarrays of solutions and reagents email: info@aurorabiomed.com website: www.aurorabiomed.com email:info@aurora-instr.com website: www.aurora-instr.com Address: 1001 E. Pender St., Vancouver BC Canada V6A 1W2 Phone: 1.800.883.2918;604-215-8700 Fax: 604-215-9700 自动固相多肽合成–VERSA™ 点样仪自动固相多肽合成涉及通过肽键连接多个氨基酸以生产多肽。这个过程模拟了产生长肽(蛋白质)的生物过程。在固相多肽合成(SPPS)中,肽被“固定”在固体表面上,并可在液相试剂的洗涤和合成副产物时保留。固相多肽合成还允许合成难以在细菌中表达的天然肽,加入非天然氨基酸,以及肽/蛋白质骨架修饰。此外,这一过程允许在每个步骤中合成产生极高产率的D-蛋白,并提供与序列依赖性合成相关的解决方案。Aurora的VERSA微阵列打印机 是一个用于进行自动固相肽合成的液体处理平台。它能够用于接触式喷印应用中的亚微升分配和接触式阵列喷印应用的自动移液,系统将二甲基甲酰胺(DMF)中的Fmoc或t-Boc氨基酸残基按用户定义的顺序定位于固体表面,如膜、载玻片、滤纸或任何其他合适的阵列表面。该工作站以简单、可重复的方式自动化固相多肽合成,具有极高的产率和准确度。机械臂由外部计算机控制,允许用户对所需的运动范围、单个肽序列进行微控制,并标准化点之间的间距。特征定制化的盘面纳米级分液对敏感表面无影响用户友好的软件界面执行所需的定位程序,不考虑所用的起始材料和基底高效自动化平时的定位技术在任何阵列表面,包括载玻片和膜应用固相多肽合成蛋白质/多肽微阵列核酸阵列微型分析溶液和试剂的微阵列获取更多VERSA自动固相多肽合成工作站的信息:请向我们提供有利于我们更好协助您的信息。http://www.aurorabiomed.com.cn/liquid-handling-apps/solidphasepeptidesynthesis/

关闭-

1/1

产品配置单

加拿大欧罗拉生物科技有限公司为您提供《自动固相多肽合成》,该方案主要用于其他中前处理检测,参考标准《暂无》,《自动固相多肽合成》用到的仪器有多肽合成微阵列点样工作站 多肽阵列制作点样应用、多肽合成微阵列点样系统 抗菌性活性多肽合成仪器 多肽药物研发、多肽药物研究微阵列点样系统 抗肿瘤多肽芯片合成、固相合成多肽点样工作站 生物阵列工作站多肽合成移液系统、多肽芯片点样仪 欧罗拉微阵列喷印移液工作站 、多肽微阵列打点 多肽打点应用阵列喷印移液工作站。

我要纠错

推荐专场

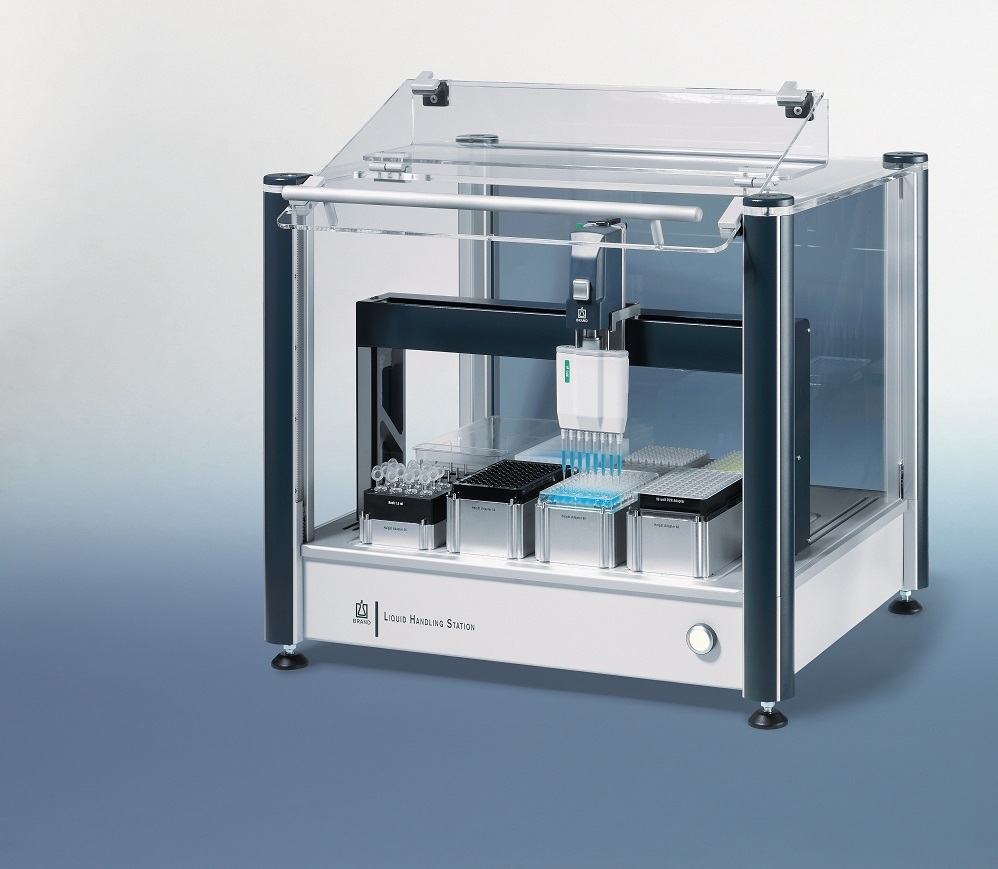

液体处理工作站(移液工作站)

更多相关方案

咨询

咨询