方案详情文

智能文字提取功能测试中

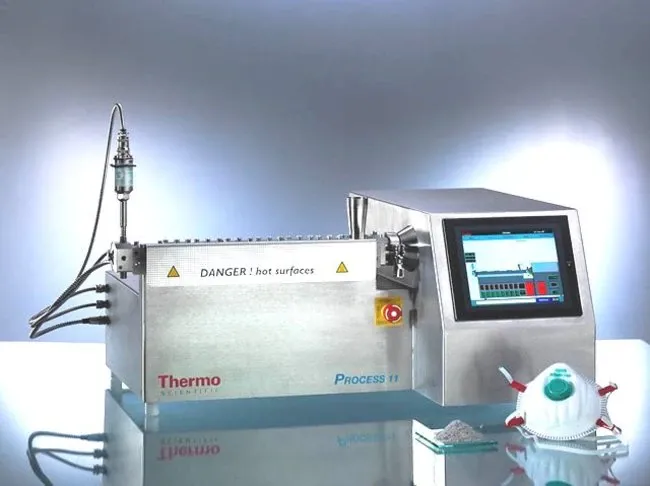

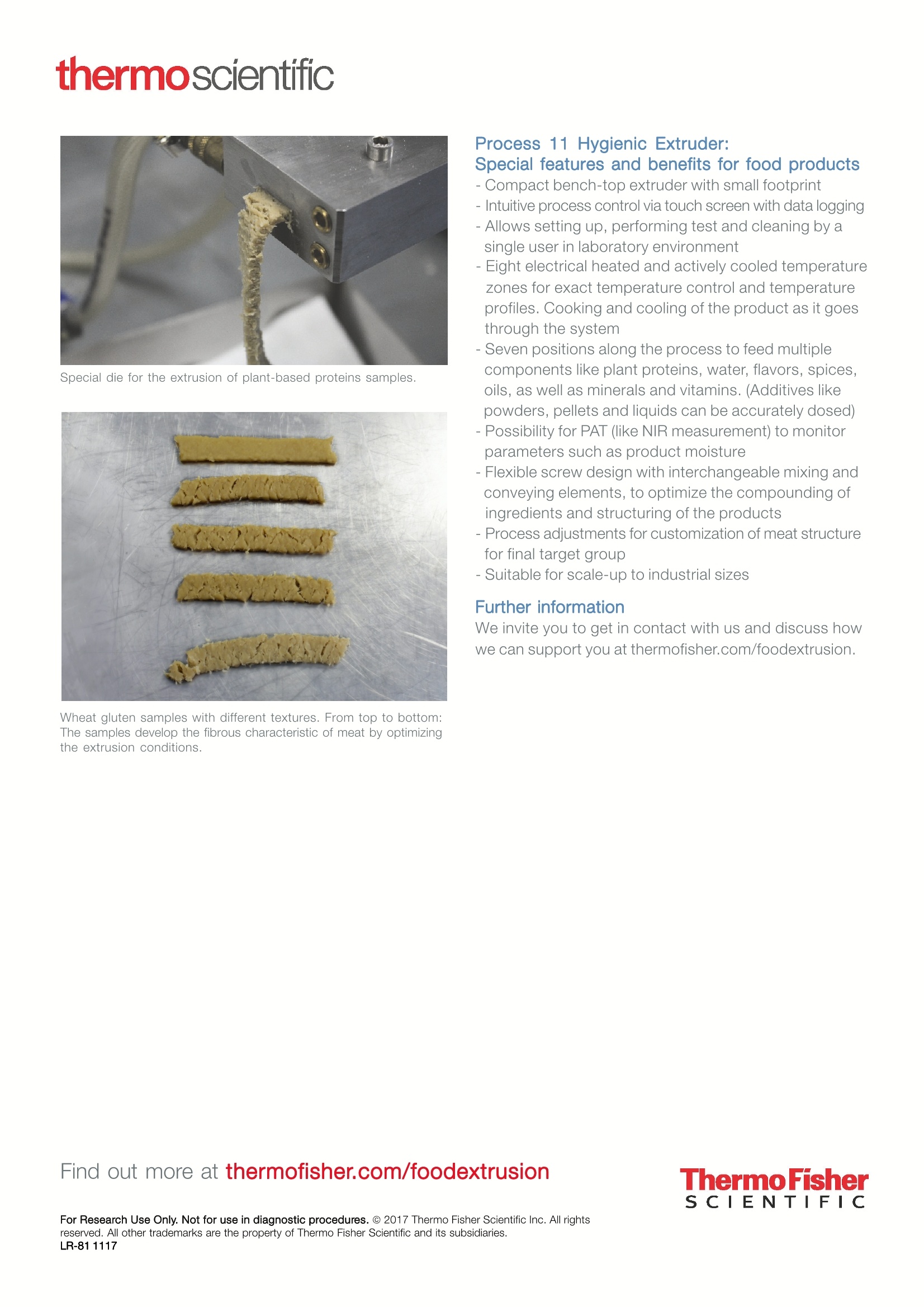

thermoscientific APPLICATION NOTE Extrusion solution for meat analogues Matthias JahrlingThermo Fisher Scientific, Karlsruhe, Germany Executive summary Reducing the carbon footprint by producing“meat-like"structures from vegetal proteins has been a processingchallenge until now. Taste, flavor and structure are allthree needed to mimic the“meat-like" characteristicsof analogue meat. With Thermo ScientificTM compounding solutions combinedwith a new cooled sheet die for meat analogues, fibrous“meat-like" structures can be successfully made fromvegetable proteins. The compact design of the Thermo ScientificM Process 11Hygienic extruder allows you to optimize the process anddevelop new meat analogue formulations on a lab scale,with significantly reduced test time, sample size andwaste. The challenge with meat analogues The increasing population and development in the worldhas caused a growing demand for meat. The resultingincreased meat production from animal proteins has a.significantly high impact on the carbon footprint (i.e., pro-ducing 1 kg of beef produces about the same amount ofCO2 emission as driving 100 km or over 63 miles in a car) It also takes about 15 kg of vegetable feed to producejust 1 kg of animal protein. That means plant-basedproteins are an essential component in feeding the earth'sgrowing population and reducing the carbon footprint atthe same time. Thermo Scientific Process 11 Hygienic Extruder with cooled slit die. To get consumers to accept meat analogues based onvegetable proteins, it is necessary to improve the mouth-feel of such products. Meat analogues need to have acertain texture and appearance to feel like real meat inthe mouth, and to ensure a similar eating experience. Challenge solved The ideal solution for the mouth-feel challenge is a twin-screw extruder process combined with a special die headthat can cool the extruded protein down in a long flowchannel to generate a fibrous, structure similar to realmeat. Special die for the extrusion of plant-based proteins samples. Wheat gluten samples with different textures. From top to bottom:The samples develop the fibrous characteristic of meat by optimizingthe extrusion conditions. Process 11 Hygienic Extruder: Special features and benefits for food products-Compact bench-top extruder with small footprint - Intuitive process control via touch screen with data logging- Allows setting up, performing test and cleaning by a single user in laboratory environment 一- Eight electrical heated and actively cooled temperaturezones for exact temperature control and temperatureprofiles. Cooking and cooling of the product as it goesthrough the system - Seven positions along the process to feed multiplecomponents like plant proteins, water, flavors, spices,oils, as well as minerals and vitamins. (Additives likepowders, pellets and liquids can be accurately dosed) - Possibility for PAT (like NIR measurement) to monitorparameters such as product moisture - Flexible screw design with interchangeable mixing andconveying elements, to optimize the compounding ofingredients and structuring of the products - Process adjustments for customization of meat structurefor final target group -Suitable for scale-up to industrial sizes Further information We invite you to get in contact with us and discuss howwe can support you at thermofisher.com/foodextrusion. Find out more at thermofisher.com/foodextrusion ( For Research Use Only. Not for use in dia g nostic proc e dures. o 2017 T h ermo Fisher Scientific Inc. All ri g htsreserved. All other trademarks are the property of Thermo Fisher Scientific and its s ubsidiaries. LR-81 1117 ) Thermo FisherSCIENTIFIC Reducing the carbon footprint by producing “meat-like“structures from vegetal proteins has been a processingchallenge until now. Taste, flavor and structure are allthree needed to mimic the “meat-like“ characteristicsof analogue meat.

关闭-

1/2

-

2/2

产品配置单

上海珩泽科技有限公司为您提供《肉类中挤出检测方案(挤出机)》,该方案主要用于肉制品中其他检测,参考标准《暂无》,《肉类中挤出检测方案(挤出机)》用到的仪器有Process 11 平行双螺杆挤出机。

我要纠错