方案详情文

智能文字提取功能测试中

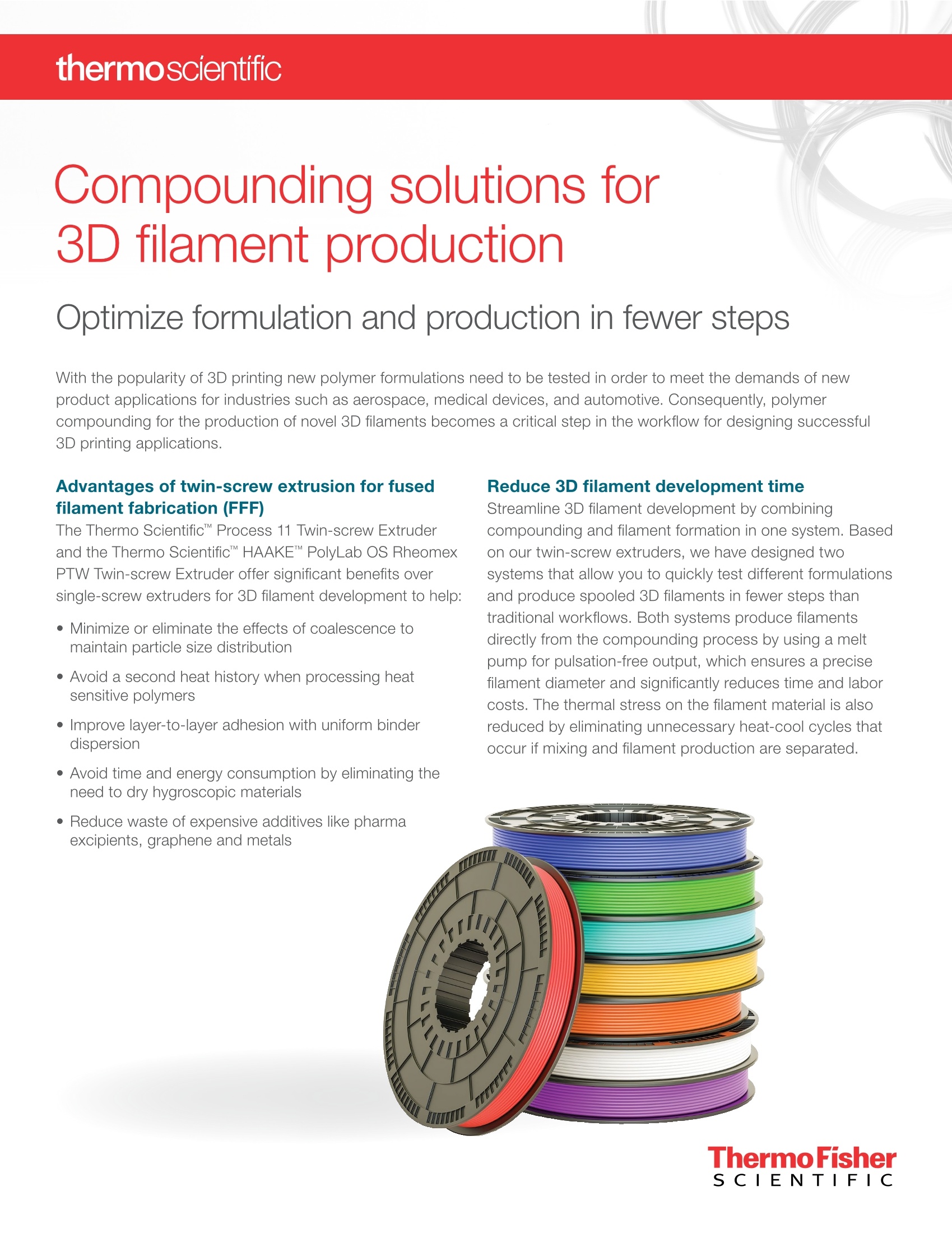

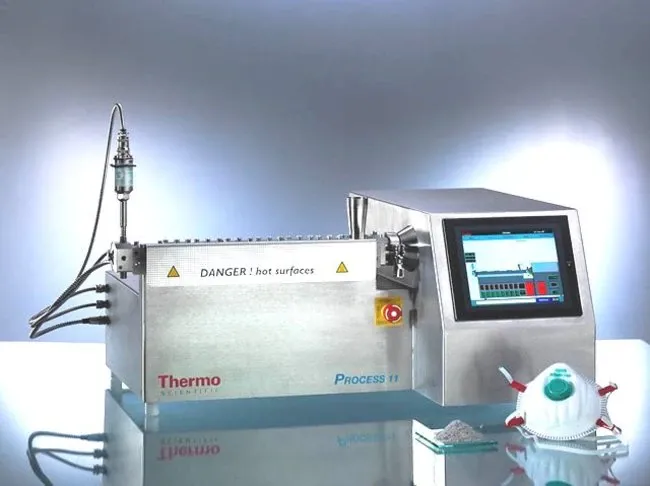

thermoscientific CompoundU川ing solutions for3D filament production Optimize formulation and production in fewer steps With the popularity of 3D printing new polymer formulations need to be tested in order to meet the demands of newproduct applications for industries such as aerospace, medical devices, and automotive. Consequently, polymercompounding for the production of novel 3D filaments becomes a critical step in the workflow for designing successful3D printing applications. Advantages of twin-screw extrusion for fusedfilament fabrication (FFF) The Thermo ScientificProcess 11 Twin-screw Extruderand the Thermo Scientific HAAKEM PolyLab OS RheomexPTW Twin-screw Extruder offer significant benefits oversingle-screw extruders for 3D filament development to help: ·Minimize or eliminate the effects of coalescence tomaintain particle size distribution ·Avoid a second heat history when processing heatsensitive polymers · Improve layer-to-layer adhesion with uniform binderdispersion · Avoid time and energy consumption by eliminating theneed to dry hygroscopic materials · Reduce waste of expensive additives like pharmaexcipients, graphene and metals Reduce 3D filament development time Streamline 3D filament development by combiningcompounding and filament formation in one system. Basedon our twin-screw extruders, we have designed twosystems that allow you to quickly test different formulationsand produce spooled 3D filaments in fewer steps thantraditional workflows. Both systems produce filamentsdirectly from the compounding process by using a meltpump for pulsation-free output, which ensures a precisefilament diameter and significantly reduces time and laborcosts. The thermal stress on the filament material is alsoreduced by eliminating unnecessary heat-cool cycles thatoccur if mixing and filament production are separated. Thermo Scientific Process 11 Lab-scale3D Filament Production System Use this compact benchtop solution for research-scaleformulation and process development. Figure 1 shows thissystem with: · Process 11 Twin-screw ExtruderThermo ScientificM Process 11 Melt Pump ·Filament spooler From 20 g/h up to 2 kg/h throughput, this system is idealfor development of new compounding processes. Easy tooperate this system provides process data that supportsthe scaling up of your 3D filament production process,while reducing the amount of expensive raw material duringformulation development. Thermo Scientific" HAAKE PolyLab Pilot-scale3D Filament Production System Use this system for lab-to-small scale process developmentand production. Figure 2 shows this system with: · HAAKE PolyLab OS Rheomex PTW Twin-screw Extruder · Thermo ScientificMelt Pump for the OS Rheomex Extruder · Filament spooler on a mobile bench Reach material throughputs of up to 5 kg/h with thissystem that includes the ability to characterize new materialcompounds with mixer tests and capillary rheology. Figure 1: Process 11 Lab-scale 3D Filament System with melt pump,water bath and spooler. Figure 2: HAAKE PolyLab Pilot-scale 3D Filament Production System. Already own one of our twin-screw extruders? Simply ask about our 3D accessories for twin-screw extruders, and build your own 3D filament production system forresearch and small-scale production. Find out more at thermofisher.com/3Dfilament For Research Use Only. Not for use in diagnostic procedures. O2019 Thermo Fisher Scientific Inc. Allrights reserved. All trademarks are the property of Thermo Fisher Scientific and its subsidiaries unless otherwisespecified. Specifications, terms and pricing are subject to change. Not all products are available in all countries. Please consult your local sales representative for details. FL53142_E 05/19M With the popularity of 3D printing new polymer formulations need to be tested in order to meet the demands of new product applications for industries such as aerospace, medical devices, and automotive. Consequently, polymer compounding for the production of novel 3D filaments becomes a critical step in the workflow for designing successful 3D printing applications.

关闭-

1/2

-

2/2

产品配置单

上海珩泽科技有限公司为您提供《灯丝中3D灯丝检测方案 》,该方案主要用于灯丝中3D灯丝检测,参考标准《暂无》,《灯丝中3D灯丝检测方案 》用到的仪器有Process 11 平行双螺杆挤出机。

我要纠错

推荐专场

相关方案

咨询

咨询