一种高效助催化剂N-掺杂碳点/大孔二氧化钛复合材料(N-CDs/TiO2)中构建合成方法检测方案(微波合成仪)

检测样品 金属材料基复合材料

检测项目 其他

白金会员

50 篇解决方案

白金会员

50 篇解决方案

方案详情文

智能文字提取功能测试中

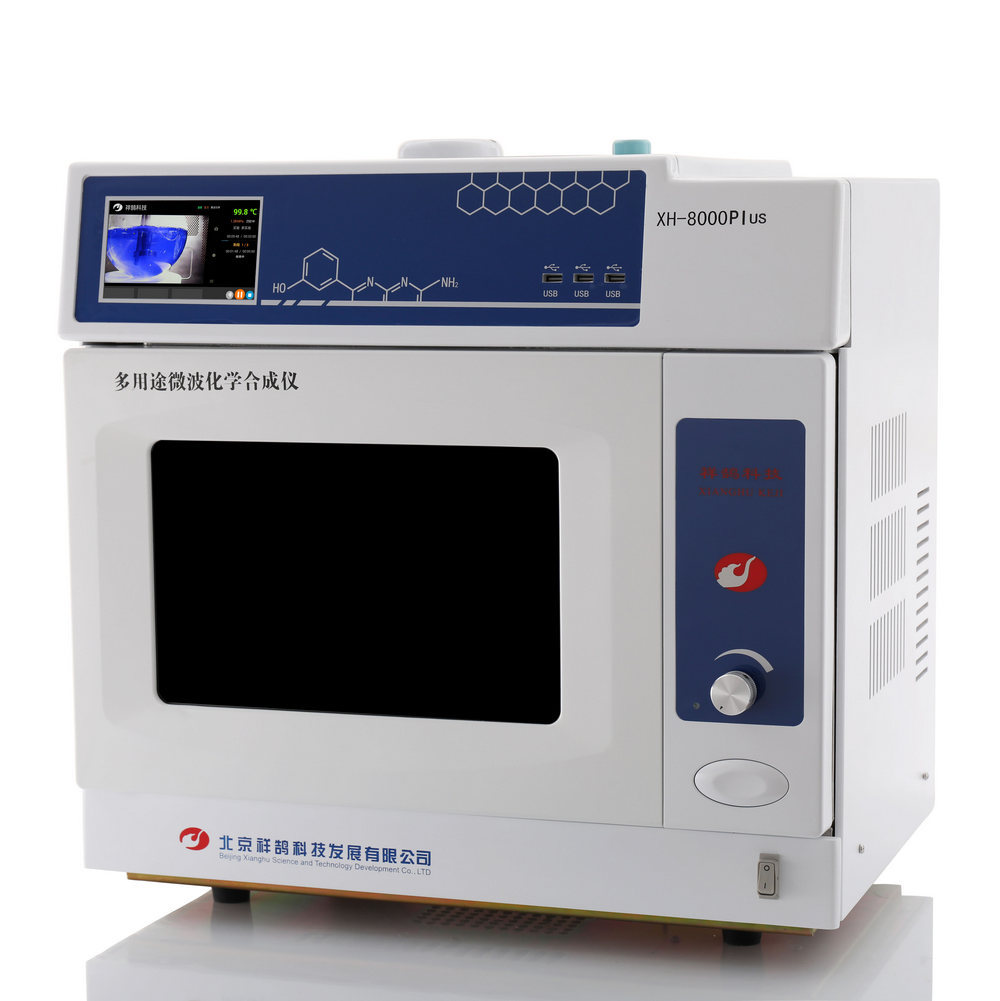

Article ArticleIndustrial & Engineering Chemistry Researchpubs.acs.org/IECR pubs.acs.org/IECR Construction of N-Doped Carbon Dots/Macroporous TiO,Composites (N-CDs/m-TiO2) with Dramatically EnhancedPhotocatalytic Activity Zhengting Zhang, Guiyun Yi,* Peng Li, Xiuxiu Zhang, Haiyang Fan, Xiaodong Wang,Chuanxiang Zhang, Yulong Zhang,* and Qi Sun Cite This: https://doi.org/10.1021/acs.iecr.1c02081 Read Online ACCESS| 山Metrics & More Article Recommendations ABSTRACT: Herein, a novel synergistic cocatalyst (N-CDs/m-TiO2)wasobtained by compounding m-TiO, with N-CDs for the first time. The e-2photocatalytic performance was investigated by employing methylene blue CO ·02(MB) as the simuN-CDslated pollutant. It was found that the unique 3Dinterconnected porous structure not only considerably increased the surfaceTiO, h* oHOHarea but also provided a high density of accessible active sites, which facilitated ·OH·OHthe mass and chaOrge transfer process. Furthermore, due to the excellent2·OH ·OHconversion luminescence property of N-CDs, the obtained N-CDs/m-TiO,3Macroporouspossessed significantly enhanced light absorption ability, simultaneously OH HO 200mmaccompanied by a greatly reduced energy band gap. The decolorization rateof MB by N-CDs/m-TiO2 was 99.59% after irradiation for 180 min, which faroutweighed that of TiO2 and m-TiOz. The remarkably enhanced photocatalytic performance was attributed to the synergistic effectbetween N-CDs sensitization and the unique porous structure, endowing it promising applications in practical wastewater INTRODUCTION Nowadays, environmental pollution and energy shortage aretwo major challenging issues faced by many countr1-4ies.Concerns are growing that the rapid growth of industrializationwill not only accelerate the energy consumption but also resultin the mass generation of toxic and refractory organicpollutants that pose a threat to the health of humankind.Thus, in the past decades, much effort has been devoted todeveloping advanced technologies for the treatment ofwastewater containing refractory organic pollutants. Thesemethods are mainly composed of electrochemical oxidation,5-8Fenton degradation,-12 btiodegradation, 3-15and photo-catalytic technology.16-20 In particular, photocatalytic technol-ogy has been considered as a promising way to degrade thosehazardous organic pollutants because solar energy as theenergy resource is inexhaustible and environmentally friendly.In general, the photocatalytic efficiency depends on the typesof photocatalysts that you choose as the photocatalytic activityof different photocatalysts exhibits a significant difference. Inrecent years, semiconductors as photocatalysts, including TiO2,CdS, ZnO, WO3, ZnS, etc., have become a research focus dueto their superior photocatalytic p-26erformance.-26Amongthem, TiO, has attracted significant research attention becauseof its high photocatalytic activity, nontoxicity, low cost, andexcellent stability. TiO, has been employed in a variety oftechnological fields, such as photocatalytic hydrogen evolution, photoelectric conversion, wastewater purification, and energystorage.7-34 The band gap of TiO, is wide at 3.2 eV, which correspondsto ultraviolet light at 387 nm, that is, only the small part ofsunlight can be effectively absorbed. As a result, the highlyactive electrons and holes are generated. In general, the holescan capture the electron from OH and HO, thus forming ahydroxyl radical (OH), while the electrons are capable ofabsorbing O, on the catalyst surface so as to create the activesuperoxide radical (). Ultimately, these generated oxidantswill degrade the refractory organic compounds into smallmolecules like carbon dioxide (CO) and water (H,O).Nevertheless, the effective utilization of sunlight by the TiO,photocatalyst only accounts for 3-5% because of the wideband gap. In addition, the photogenerated electrons and holesare easy to recombine, thus limiting its practical application.To resolve such issues, TiO, is usually used in its modifiedform, such as doping metal and nonmetal elements, creating a ( Receiv e d : May 30, 2021 ) ( Revise d: J uly 23, 2021 ) ( Acce p ted : J uly 2S, 2021 ) special structure or morphology, coupling with other semi-conductors, sensitizing quantum cdots, and many othermethods.35-38 A porous structure can dramatically increase the surface areaand simultaneously enhance the diffuse reflection. This kind ofmaterial can absorb light sufficiently in terms of multiplescattering of light, which is thus widely applied for thephotocatalytic degradation of pollutants. A variety of synthetictechniques for the fabrication of porous TiO, has already beendeveloped. For example, by optimizing the humidity in theelectrospinning chamber, Aghasiloo et al. successfully synthe-sized novel porous TiO nanofibers (NFs). In this work, thesurface area of the as-prepared novel TiO catalyst was 128 mg-,2.13 times as that of TiO, nanofibers (60 m’g).Furthermore, it showed excellent degradation performancetoward methylene blue (MB) and the degradation efficiency ofthis material was over 70%, greatly exceeding that of TiO,nanofibers. Azimirad and his coauthors prepared hierarchicalporous TiO2 nanocomposites using two different methods forcomparison: spin coating technology and electrophoreticdeposition method. Zhao et al. came up with a new methodfor preparinggTiOz powder with dramatically enhancedcatalytic activity.In this work, the obtained TiOz photo-catalyst possessed a unique mesoporous structure, with thespecific surface aiirea up to130.940 m’ g, which wassynthesized using a conventional sol-gel method in combina-tion with a subsequent freeze-drying process. Consequently,porous TiO, is beneficial for enhancing the light scattering andsimultaneously improving the utilization rate of irradiatedsunlight, thus promoting its photocatalytic activity. Quantum dot sensitization is another effective method toimprove the photocatalytic performance of TiO. However,toxic heavy metal ions account for the majority of alreadyreported quantum dots, which are harmful to the environment.Recently, carbon dots (CDs) with the diameter less than 10nm have been reported as a new member of florescent carbonmaterials. It is composed of a quasidiscrete spherical core andsurface functional groups. CDs possess several prestigiousadvantages, including richness in source, low cost, nontoxicity,and ease of preparation. According to our previous work,incorporation of heteroatoms into CDs will not only promotethe fluorescence properties but can also dramatically improvethe electric properties, which makes them ideal candidates forphotocatalytic and electrocatalytic applications. In general,coupling TiO, with CDs or doped CDs could boost thephotocatalytic performance because of several potential effects:(1) The near-infrared properties of carbon dots are capable ofbroadening the visible light absorption range of TiO, andsimultaneously promote the light-harvesting ability. 2) The up-conversion or down-conversion fluorescence properties of CDsallow TiO, to produce more electrons and holes under lightirradiation. (3) CDs act as the electron transfer mediator,which promotes the separation efficiency of electron-holepairs. Zhang et al. reported a combination of CQDs and TiO,using an inorganic precipitation-peptization method.3 Underthe synergistic effect, the photocatalytic performance of TiO,was promoted significantly and the removal ratio of methylorange reached 91.04% under light irradiation. As a result, CDsensitization of TiO, can greatly promote its photocatalyticactivity. However, as far as we know, the investigation onsynthesis and photocatalytic activities of N-CDs/macroporousTiO, nanocomposites is still not available. In the present work, nitrogen-doped carbon dots (N-CDs)were prepared using a microwave-assisted hydrothermalmethod. A macroporous TiOz (m-TiO2) catalyst was preparedvia a simple sol-gel method using polystyrene (PS) micro-spheres as the sacrificial templates, followed by coupling withN-CDs to obtain N-CDs/m-TiO2 nanocomposites. Methyleneblue was employed as the simulated organic pollutant and thephotocatalytic performance of N-CDs/m-TiO, toward it wassubjected to in-depth investigation. The N-CDs/m-TiO2nanocomposites as the photocatalysts can be utilized for thetreatment of wastewater containing refractory organicpollutants, considering the advantages of cheapness, environ-mental compatibility, high photocatalytic performance, andsignificantly improved utilization rate of sunlight. N-CDs/m-TiO, nanocomposites have promising applications in sewagetreatment. EXPERIMENTAL SECTION Preparation of N-CDs. N-CDs were synthesized via amicrowave-assisted hydrothermal strategy. Typically, 1.0 g ofcitric acid (CA) and 0.9378 g of urea (U) were dissolved in 20mL of N,N-dimethylformamide (DMF) under stirring andsubsequent ultrasonication. The mixture was transferred into aPTFE autoclave in the microwave vessel (XH-8000Plus,Beijing Xianghu Science and Technology Development Co.,Ltd., China) at 180°C for 20 min, with the temperatureelevating rate of 15s ℃ min. Afterward, the obtainedproducts were cooled to room temperature and subjected todialysis for 48 h with the molecular weight cutoff of 3500.Eventually, the dialyzed product was freeze-dried and groundfor further use. Preparation of PS Spheres and TiO Sol. PS sphereswere synthesized by a conventional emulsion polymerizationmethod.4 First, to obtain the purified styrene monomer, thebought styrene solution was subjected to a pretreatment. Thedetailed procedures were described as follows: a certainamount of sodium hydroxide (5 wt%) was mixed with thestyrene solution. Subsequently, the mixed solution wassubjected to violent shaking so as to separate the polymer-mnoization inhibitor, which was :a phenolic compound. Thisprocedure was called extraction separation and it was repeatedthree times. Afterward, the obtained mixed solution wassubjected to decompressing distillation for further purificationand the purified styrene was finally obtained. After that,emulsion polymerization reaction was proceeded in a jacketreactor. A certain amount of deionized water was first addedinto the reactor with a temperature at 80 °C and a stirring rateof 350 rpm. Then, a mixture of the emulsifier (sodium styrenesulfonate) and the buffer (sodium hydrogen carbonate) waspoured into the reactor. After 10 min, a certain amount ofstyrene monomer was added into the system. One hour later,the initiator (potassium persulfate) was added into the reactor.Eventually, the reaction was continued for 18 h and themonodisperse PS spheres with an average size of 234 nm wereobtained. TiO, sol was first synthesized via a traditional sol-gelapproach with Ti(OCyH)4 as the precursor. The detailedprocedure was divided into three steps. At first, certainamounts of deionized water and absolute ethyl alcohol weremixed together to prepare solution A. Meanwhile, solution Bwas successfully prepared by slowly adding Ti(OCH,)4 andglacial acetic acid into ethanol solution under magnetic stirring.Finally, solution A was dripped slowly into solution B and Figure 1. Basic characterizations of the as-synthesized N-CDs. (a) TEM images (inset: the size distribution curve), (b) UV-vis absorption spectraof N-CDs,(c) Raman spectra and (d) FTIR spectra, and (e, f) XPS survey spectrum and C ls spectrum of N-CDs, respectively. continuously stirred for 30 min. The transparent andhomogeneous TiO, sol was obtained and it was set aside for12 h for further use. Preparation of m-TiO, Powders. A certain amount ofPSsuspension (6.95 wt %) was slowly introduced into TiO sol.Then, the mixture was subjected to continuous stirring andultrasonication. After that, the mixed solution was transferredonto an oven and heated at 70°C for 12 h, and the dried PSspheres and TiO, composite were prepared. To obtain thedesired macroporous TiO, the dried composite was furthersintered in a muffle furnace with the temperature set at 500 °Cfor 2 h and an elevating rate of 5 °C minto remove the PStemplate. Ultimately, the macroporous TiO2 was obtained anddenoted as m-TiO,. For convenient comparison, the pure TiOznanoparticles were prepared similarly to the synthesisprocedures of m-TiO without adding PS spheres. Preparation of N-CDs/m-TiO,Nanocomposites. TheN-CDs/m-TiO, nanocomposites were obtained by a thermaldeposition technique. The as-prepared m-TiO2 was transferredinto the N-CDs solution (8 mg L-) and transferred into aheating mantle with the setting temperature kept at 60 °C for12 h. Photoelectrochemical Characterization. Photoelectro-chemical measurements were carried out using a CHI-660Delectrochemical workstation (Shanghai Chenhua, China) thatwas equipped with a standard three-electrode system. The saturated calomel (SCE), platinum sheet, and as-preparedphotocatalysts were used as the reference, counter, andworking electrodes, respectively. In this work, the workingelectrodes were prepared using a facile dip-coating methodaccording to a previously reported work.sThe aqueoussolution of 0.1 mol L-NazSO was utilized as the electrolyte.As for photocurrent versus time measurements, a 450 W high-pressure mercury lamp worked as the light source with lightand dark cycles of 20 s at a fixed bias of 0 V versus SCE. Photocatalytic Degradation of MB. The photocatalyticperformances of the samples were measured according to thedegradation of methylene blue (MB) under UV lightirradiation. The experiment was conducted at a water-jacketreactor under ambient conditions. The distance between thelight source and the reactor was precisely controlled to be 20cm. The detailed procedures were as follows: 50 mg of as-prepared N-CDs/m-TiO2 nanocomposites was added into 150mL of MB solution (50 mg L-). Before turning on the lightsource, the mixture underwent mechanical stirring for 1 h inthe dark to reach the adsorption-desorption equilibrium. Afterthat, the solution was exposed to light irradiation. During thedegradation process, the samples were extracted from thesolution at intervals to record the absorption intensity at 664nm of MB. For comparison, the photocatalytic experiments ofTiO2 nanoparticles and m-TiO2 were consistent with theabove. Characterization. The surface morphology of allas-.prepared photocatalysts was recognized using scanningelectron microscopy (SEM, Hitachi SU-4800) with the voltageof 10 kV. The crystal phase of the as-prepared products wascharacterized through X-ray diffraction (XRD, Bruker D8Advance, Germany) with Cu Ka radiation at 10°min. Theultraviolet-visible diffuse reflectance spectra (UV-vis-DRS)of the catalysts were examinedi bya UV-3600 Plusspectrophotometer (Shimadzu, Japan)) with the scanningrange from 400 to 800 nm. The analysis of the elementalcomposition and valence state of all samples was conducted byX-ray photoelectron spectroscopy (XPS, ESCALAB 250XI,Thermo Fisher Electron Corporation, USA). The Ramanmeasurements were carried out by a Dilor LABRAM-1Bmultichannel confocal microspectrometer excited at 532 nm.The functional group analysis of the samples was conducted byFourier transform infrared spectroscopy (FT-IR, Nicolet 670,USA). A surface area analyzer (Autosorb iQ2, Quantachrome,USA) was employed to measure the surface area and pore sizedistribution. The photoelectrochemical tests were conductedutilizing a CHI 660E electrochemical workstation (Chenghua,China equipped with a typical three-electrode cell. RESULTS AND DISCUSSION Shown in Figure 1 are the basic characterizations of the as-prepared N-CDs. It was discovered that the as-prepared N-CDs were uniformly dispersed with an average diameter of 9.4nm (Figure 1a). Figure 1b shows the UV-vis absorptionspectrum of N-CDs, and two characteristic peaks at 239 and337 nm were discovered. The former represented then-n*transition of the carbon core, while the latter denoted then-n* transition of the C=0bond of the surface functionalgroups. The Raman spectrum of N-CDs is presented in Figurelc, which reveals two characteristic peaks of carbon located at1352 and1597 cm, which are assigned to the D-band and G-band, respectively. The D-band was attributed to theamorphous carbon, while the G-band was ascribed to thegraphite carbon. The peak intensity of G-band was strongerthan that of D-band, which demonstrated that the content ofgraphite carbon far outweighed that of amorphous carbonFunctional groups of N-CDs could be effectively revealed fromthe FT-IR spectra in Figure 1d. There existed an intense peakaround 3430 cm-, which was assigned to both C-OH andN-H stretching vibrations. The band located at 1128 cmwas attributed to the asymmetric stretching vibration of C-NH-C, while the band at 1572 cm-was ascribed to thebending vibration of N-H. The predominant peak at 1635cm- belonged to the C=0 group, and epoxy group bendingvibration was found at 1082 cm. Consequently, these datademonstrated the existence of the N element and a variety ofpolar functional groups including -OH, the epoxy group, C==O, C-N(C=N), and -NH, which was beneficial for thesensitization of N-CDs on the macroporous TiO, bycoordinating with Ti ions. In addition, the analysis of theXPS spectra was also conducted. As obviously observed fromthe survey spectrum in Figure le, the element composition ofas-synthesized N-CDs mainly included C,O, and N. The C 1sspectrum in Figure lf indicated the existence of the sphybridized orbital of carbon, which corresponded to C=C/C-C (284.75 eV), C=0 (286.15 eV), and C-N (287.1 eV).Thus, the XPS data further verified the successful doping of theN element into CDs and the existence of many functionalgroups. The formation of N-CDs/m-TiO, was examined by theanalysis of XRD patterns and FTIR spectra. Figure 2 exhibits Figure 2. XRD patterns of (a) N-CDs, (b) TiO, nanoparticles (NPs),(c) m-TiO2, and (d) N-CDs/m-TiOz the XRD patterns of N-CDs, TiOz nanoparticles (NPs), m-TiO2, and N-CDs/m-TiO2. A broad diffraction peak locatedbetween 21°and 28° was clearly observed, which corre-sSppoonded to the graphitic structure of N-CDs. Other samplesexhibited similar peaks at25.3°,37.8°,48.1°,53.8°,55.2°, and62.8°, which were assigned to the (101),(004),(200),(105),(211), and (204) planes of anatase TiO, and no peaks of therutile phase were discovered. The similar XRD patternsindicated that (1) the porous structure of m-TiO, failed tochange the original crystalline sizes and (2) N-CDs did notexert a great impact on the nucleation and crystal growth ofTiO, thus exerting little impact on the phase structure ofTiO. Consequently, these results confirmed the formation ofN-CDs/m-TiO. Shown in Figure 3 are the FTIR spectra of TiO, NPs, m-TiO, and N-CDs/m-TiO. For pure TiO, NPs, the peak Figure 3. FTIR spectra of TiO, NPs, m-TiO2, and N-CDs/m-TiO2· located between 3600 and 3300 cm-was attributed to thestretching vibration of -OH, while the peak located at 1600cm- was ascribed to the bending vibration of water molecules.Furthermore, the peak located at 465 cm-corresponded tothe stretching vibration of the Ti-O-Ti bond. Meanwhile, form-TiOz, the stretching vibration peak of C-N appeared at2350 cm.For N-CDs/m-TiO,, the observed peaks at 2840-2910 cm-, 1400 cm-, and 1633 cm-corresponded to thestretching vibration peak of the Csp-H bond, the symmetricstretching vibration peak of the C=C bond, and the vibrationabsorption band of C=O,respectively, which all belonged to the stretching vibration peaks of N-CDs.46,47 In addition, thepeak at 1050 cm- appeared, which was assigned to thebending vibration of C-NH-C, and the absorption peakswere red-shifted with the introduction of N-CDs. Theabsorption intensities of the peaks located between 3600 and3300 cm-were higher than those of TiO,NPs and m-Tio,,which may be explained by the fact that N-CDs were capableof promoting the generation of electrons and holes andenhancing the charge transfer rate. As a consequence, CQDswere beneficial for promoting the photocatalytic efficiency ofTiO. The present results further verified the successfulformation of the N-CDs/m-TiO, composite. The microstructures of TiO, NPs, m-TiO, and N-CDs/m-TiO, were further analyzed using SEM images displayed inFigure 4. Shown in Figure 4a is the SEM image of TiO,NPs, Figure 4. SEM images of (a) pure TiO,NPs, (b) m-TiO, and (c) N-CDs/m-TiO2. from which it could be seen that the as-prepared TiO showeda smooth surface with similar particle sizes and an irregularblocky shape. By contrast, the well-defined macroporousstructure of m-TiOz was observed, with a great deal ofuniform pores. The average diameter of these pores was about200 nm, smaller than that of the original PS template. Thissuggested that a significant shrinkage occurred after theremoval of the PS template by calcination. For N-CDs/m-TiO2 in Figure 4c, the introduction of N-CDs had little effecton the porous structure of m-TiO, and N-CDs were barelyobserved because of the nanometer-scale sizes. Shown in Figure 5 are N2 adsorption-desorption isothermsof pure TiO nanoparticles, m-TiO2, and N-CDs/m-TiO2, withthe inset figures of their pore size distributions. It could beobserved that the Nz adsorption-desorption isotherms of pureTiO, m-TiO2, and N-CDs/m-TiO, form hysteresis loops atrelative pressures of 0.7, 0.4, and 0.2, respectively. It belongedto the characteristic type ⅣV adsorption-desorption, with auniform pore size distribution. In addition, the pore structureof these samples was complicated. Compared with those ofTiO and m-TiO, the isotherm of N-CDs/m-TiO2 exhibited adelayed hysteresis loop. This phenomenon may be caused bythe insufficient degassing of N-CDs on the surface of m-TiO,resulting in the adsorption curve moving down and asimultaneous decrease in adsorption capacity. The inset in Figure Sa presented the pore size distribution ofpure TiO, nanoparticles, and a steep curve with the diameterranging from 2 to 10 nm was observed. It revealed that thepores were mainly composed of mesopores. As shown inFigure Sb, a high peak from 2 to 4 nm and a steep curve from80 to 147 nm were observed, which demonstrated thecoexistence of mesopores and macropores, and macroporesaccounted for the majority. By contrast, the peak intensity inthe mesopore region decreased significantly, while the curve in 1.0 Figure 5. Adsorption isotherms of (a) pure TiO, NPs, (b) m-TiO, and (c) N-CDs/m-TiO2(inset: their pore size distributions). Figure 6. (a) UV-DRS spectra of pure TiO, NPs, m-TiOz, and N-CDs/m-TiO, and (b) (ahv)1/2 versus hv curve of pure TiO, NPs, m-TiOz, andN-CDs/m-TiO,. the macropore region remained unchanged. This reflected thatthe incorporation of N-CDs inhibited the generation ofmesopores. The diameter of N-CDs was below 10 nm,which could accumulate or get inside the mesopores, thusblocking part of the mesopore structure. This phenomenonwas consistent with the conclusion obtained from the aboveXRD analysis that the as-prepared N-CDs were located on thesurface of m-TiOz, affecting the photocatalytic performance. The optical properties and energy band structures of allsamples were also subjected to in-depth investigation. Shownin Figure 6a are the UV-DRS spectra of all samples, fromwhich pure TiO NPs and m-TiO, showed similar absorptioncurves at a wavelength range from 200 to 700 nm. However,for N-CDs/m-TiO2, it showed a distinctive enhancedabsorption from 400 to 700 nm and the absorption intensityfar outweighed those of TiO, NPs and m-TiOz. This may beascribed to the fact that the photoluminescence property of N-CDs and the synergistic effect between N-CDs and m-TiOcould induce a redshift of the absorption wavelength. Zhang etal. prepared carbon quantum dots (CQDs) composited withlayered TiO, by a combination of the hydrothermal methodand precipitation-peptization method, and the compositeshowed both up- and down-conversion photoluminescence. Inthis work, the synergistic effect between CQDs and layeredTiO, enhanced the visible light absorption intensity,broadened the absorption range, and efficiently inhibited therecombination of photogenerated electrons and holes. Thepresent results obtained in this work also confirm the accuracyof the analysis mentioned above. In addition, the thresholdwavelengths (1) of pure TiO, NPs, m-TiO2, and N-CDs/m-TiO, were 398.75, 431.35, and 511.49 nm, respectively. Theband gap energy (E,) of target catalysts can be obtained fromthe following equation: The results indicated that the E, values of TiO, NPs, m-TiO, and N-CDs/m-TiO2 were 3.11, 2.87, and 2.42 eV,respectively, which corresponded to the (ahv)1/2 versus hvcurve in Figure 6b. The E, value of anatase TiO, was supposedto be 3.2 eV, which was higher than that of the as-preparedTiO, in this work. This suggested that the E, value of TiO2prepared by the sol-gel strategy effectively decreased. Also asexpected, the incorporation of N-CDs dramatically narrowedthe energy band gap of m-TiOz.This was ascribed to the factthat the carbon hybrid TiO, disordered the intermediate bandstructure and produced impurity energy levels, which narrowed the band gap of TiO, and broadened the light response range,thus enhancing visible light absorption.48,49 To further evaluate the separation efficiency of electron-hole pairs and transfer capability of the charge carriers, thetransient photocurrent versus time tests of all samples werecarried out using UV light as the light source, as can be seen inFigure 7. The N-CDs/m-TiO2 photoanode possessed the Figure 7. Transient photocurrent curves of pure TiONPs, m-TiO2,and N-CDs/m-TiO2 photoanodes at 0 V vs SCE, respectively, after 30s light on/off cycles. highest photocurrent intensity in comparison with other twophotoanodes. The higher photocurrent intensity meant thatunder the same light irradiation, more photogeneratedelectrons would efficiently transfer from the photoanode tothe counter electrode by an external circuit. Such superiorphotoelectrochemical activity of N-CDs/m-TiO2 was attrib-uted to its unique porous structure and sensitization of N-CDs.Considering the excellent photovoltaic conversion efficiencyand high stability, N-CDs/m-TiO, as the photocatalyst couldbe potentially applied in the practical wastewater purificationfield. The photocatalytic performance of all photocatalysts wasexamined using MB as the target pollutant under UV lightirradiation. Before the photocatalytic experiment, the mixturewas treated in the dark for 1 h to reach the adsorption balance.Shown in Figure 8a are the UV-vis spectra of MB solutiondegraded by the N-CDs/m-TiO2 photocatalyst at differentreaction times. The absorption intensity of the characteristicpeak of MB at 664 nm decreased rapidly as the exposure timeextended. After degradation for 180 min, the MB absorptionpeak intensity almost dropped to zero, which indicated that thedegradation of MB nearly achieved complete accomplishment. (a)2.0 (b) 100 —N-CDs@m-TiO, 0 -m-TiO. 1.5 15 min 80 -TiO.2 30 min 60 min 90 min 60 1.0 120 min 150 min +180 min 40 0.5 20 0.0 0 400 500 600 700 800 0 30 60 90 120 150 180 Wavelength (nm) Time (min) Figure 8. (a) UV-vis absorption spectrum of MB removal photocatalyzed by N-CDs/m-TiO, (b) decolorization rate of MB by differentphotocatalysts under UV light irradiation, and (c) cycling curve of MB removal photocatalyzed by N-CDs/m-TiO2 after five cycles. 328 Figure 9. (a) Photocatalytic degradation performance of N-CDs/m-TiO, in the absence and presence of h*, OH., and O,scavengers. (b,c) ESRspectra of DMPO-OH and DMPO-O,with N-CDs/m-TiO2 under light irradiation and in the dark, respectively. Figure 8b shows the photocatalytic degradation efficiency ofMB by three different catalysts with the initial concentration of50 mg L. It can be observed that both the decolorizationratio and the rate of N-CDs/m-TiO, were the highest(99.59%), far outweighing those of pure TiO, and m-TiOz.The remarkably enhanced degradation efficiency furtherconfirmed that N-CDs/m-TiOz as the photocatalyst could effectively and rapidly remove organic dyes like MB fromwastewater. In addition, the stability of these photocatalystswas investigated by monitoring the change in degradationefficiency during the five cycles. The decolorization ratio ofMB over N-CDs/m-TiO2 could still reach about 96% after fivecycles, indicating the excellent recycling ability of the N-CDs/m-TiO2 photocatalyst, as can be observed in Figure 8c. As a result, N-CDs/m-TiO, had promising applications in thetreatment of organic wastewater. To determine the major oxidants during the degradationprocess of MB, in situ capture experiments were performed inthe presence and absence of ht, OH, and O scavengers.Shown in Figure 9a are the corresponding testing results.Ethylene diamine tetra-acetic acid (EDTA), tert-butanol(TBA), and p-benzoquinone (BQ) were employed as ht,OH, and O scavengers, respectively. It could be seen thatthe addition of EDTA exerted little impact on the MB removalratio (down to 95.2%), which indicated that holes played aminor role in the photocatalytic degradation process.Conversely, the addition of TBA could considerably suppressMB removal and the removal ratio dropped down to only45.6% after degradation for 180 min, indicating that OH. actedas the major active species in the photocatalytic system. Bycontrast, MB removal was moderately suppressed to 70.8%with the addition of BO, which demonstrated that Owasalso the primary oxidant within the whole degradation process.Consequently, OH. and O were proved to be the majoractive oxidants during the photocatalytic degradation process.In addition, the ESR spin-trap measurement was conducted tofurther confirm the generation and existence of photoinducedoxidants. As obviously seen from Figure 9b, four characteristicpeaks (1:2:2:1) for DMPO-OH· were detected as irradiated bysimulated sunlight, while no ESR signals were detected in thedark. This suggested that OH. was generated on the surface ofN-CDs/m-TiO, by oxidization of H,O or OH. Similarly, theESR spectrum of DMPO-O2 in Figure 9c showed fourcharacteristic peaks (1:1:1:1), and no signals were observed inthe dark, which signified that O,was successfully formed overN-CDs/m-TiO, via the reduction of dissolvedO. The presentresults further confirmed that OH. and O,were the dominantactive oxidants during the decolorization period of MB by N-CDs/m-TiO,. On the basis of the above results and discussions, a possiblephotocatalytic pathway of N-CDs/m-TiO2 was proposed, aspresented in Figure 10. The incorporation of N-CDs could Figure 10. Proposed photocatalytic mechanism of N-CDs/m-TiOfor the degradation of MB under simulated sunlight irradiation. greatly enhance the light absorption ability due to the excellentconversion photoluminescence characteristics and simultane-ously reduce the energy band gap (E ) of m-TiOz. The as-prepared N-CDs evenly covered the surface of m-TiO2, whichwasaSconductive to the transmission of photogeneratedelectrons between m-TiOz and N-CDs, thus improving theseparation efficiency of electron-hole pairs. Furthermore,surface O2 eventually captured the electrons to form the activeoxidant O, which effectively inhibited the recombination of electrons and holes. On the other hand, the unique 3Dinterconnected porous structure offered more active sites forthe proceeding of photocatalytic reaction due to the increasedspecific surface area, and the nanometer-sized N-CDs couldenter the macropores. Meanwhile, such a porous structurecould achieve multilevel reflection of light, dramaticallyimproving the light absorption rate. Moreover, the aromaticring of MB was capable of forming a n-n conjugated structurewith the n orbital of N-CDs, thus resulting in the strengthenedabsorption of MB on the surface of the N-CDs/m-TiO,photocatalyst and thereby boosting the photocatalytic activity.As a result, the sensitization of N-CDs in combination with theunique porous structure could effectively enhance thephotocatalytic activity of TiOz. In summary, an efficient cocatalyst, N-CDs/m-TiO2, wasuccessfully prepared and employed for the degradation of MB,with significantly improved photocatalytic activity. Herein, N-CDs were synthesized via a facile one-step hydrothermalapproach and subsequently composited with m-TiO that wasprepared using the sol-gel method in combination with PSmicrospheres as the template to obtain the final N-CDs/m-TiO composite. For m-TiO, it possessed a unique macro-porous structure, which increased the surface areaandprovided abundant active sites for the photocatalyticdegradation of MB. Furthermore, the nanostructure of N-CDs made it well compounded with m-TiO, dramaticallyenhancing the photocatalytic performance under the syner-gistic effect between them. Due to the conversion lumines-cence property, the incorporation of N-CDs could also narrowthe energy band gap of m-TiOz. Impressively, after beingexposed to light irradiation for 180 min, the as-prepared N-CDs/m-TiO, showed superior photocatalytic performancetoward MB and the decolorization ratio reached 99.59%, whichfar outweighed that of pure TiO and m-TiO2. Altogether, thepresent cocatalytic system expanded the practical applicationof TiO, and simultaneously provided a novel methodology forthe rational design of a highly efficient photocatalyst for thetreatment of sewage containing refractory organic pollutants. AUTHOR INFORMATION Corresponding Authors Guiyun Yi - College of Chemistry and Chemical Engineering,Henan Polytechnic University, Jiaozuo 4S4003, China;Collaborative Innovation Center of Coal Work Safety andClean High Eficiency Utilization, Jiaozuo 4S4003, China;Henan Key Laboratory of Coal Green Conversion, Jiaozuo454003, China; Program for Innovative Research Team inthe University of Henan Province (21IRTSTHN006),Jiaozuo 454003, China; @ orcid.org/0000-0001-7278-7453; Email: ygyun@hpu.edu.cn Yulong Zhang - College of Chemistry and ChemicalEngineering, Henan Polytechnic University, Jiaozuo 4S4003,China; Collaborative Innovation Center of Coal Work Safetyand Clean High Efficiency Utilization, Jiaozuo 4S4003,China; Henan Key Laboratory of Coal Green Conversion,Jiaozuo 4S4003, China; Program for Innovative ResearchTeam in the University of Henan Province(21IRTSTHN006), Jiaozuo 454003, China;Do(rcid.org/0000-0003-1459-2054; Email: zhangyulong@hpu.edu.cn Zhengting Zhang - College of Chemistry and ChemicalEngineering, Henan Polytechnic University, Jiaozuo 4S4003,China; Collaborative Innovation Center of Coal Work Safetyand Clean High Efficiency Utilization, Jiaozuo 4S4003,China; Henan Key Laboratory of Coal Green Conversion,Jiaozuo 454003, China; Program for Innovative ResearchTeam in the University of Henan Province(21IRTSTHN006), Jiaozuo 454003, China Peng Li - College of Chemistry and Chemical Engineering,Henan Polytechnic University, Jiaozuo 454003, China;Collaborative Innovation Center of Coal Work Safety andClean High Efficiency Utilization, Jiaozuo 4S4003, China;Henan Key Laboratory of Coal Green Conversion, Jiaozuo454003, China; Program for Innovative Research Team inthe University of Henan Province (21IRTSTHN006),Jiaozuo 454003, China Xiuxiu Zhang - College of Chemistry and ChemicalEngineering, Henan Polytechnic University, Jiaozuo 4S4003,China; Collaborative Innovation Center of Coal Work Safetyand Clean High Efficiency Utilization, Jiaozuo 454003,China; Henan Key Laboratory of Coal Green Conversion,Jiaozuo 4S4003, China; Program for Innovative ResearchTeam in the University of Henan Province(21IRTSTHN006), Jiaozuo 454003, China Haiyang Fan - College of Chemistry and ChemicalEngineering, Henan Polytechnic University, Jiaozuo 4S4003,China; Collaborative Innovation Center of Coal Work Safetyand Clean High Efficiency Utilization, Jiaozuo 4S4003,China; Henan Key Laboratory of Coal Green Conversion,Jiaozuo 454003, China; Program for Innovative ResearchTeam in the University of Henan Province(21IRTSTHN006), Jiaozuo 454003, China Xiaodong Wang - Department of Materials Science andEngineering, Henan Polytechnic University, Jiaozuo 454003,China Chuanxiang Zhang - College of Chemistry and ChemicalEngineering, Henan Polytechnic University, Jiaozuo 4S4003,China; Collaborative Innovation Center of Coal Work Safetyand Clean High Efficiency Utilization, Jiaozuo 4S4003,China; Henan Key Laboratory of Coal Green Conversion,Jiaozuo 454003, China; Program for Innovative ResearchTeam in the University of Henan Province(21IRTSTHN006), Jiaozuo 454003, China Qi Sun - College of Chemistry and Chemical Engineering,Henan Polytechnic University, Jiaozuo 4S4003, China;Collaborative Innovation Center of Coal Work Safety andClean High Efficiency Utilization, Jiaozuo 454003, China;Henan Key Laboratory of Coal Green Conversion, Jiaozuo454003, China; Program for Innovative Research Team inthe University of Henan Province (21IRTSTHN006),Jiaozuo 454003, China Complete contact information is available at:https://pubs.acs.org/10.1021/acs.iecr.1c02081 Notes The authors declare no competing financial interest. This work was supported by the National Natural ScienceFoundation of China (51974110 and U1803114), theFundamental Research Funds for the Universities of Henan Province (NSFRF180313), the Education Department ScienceFoundation of Henan Province (19A440002 and 19A530002),the Key Scientific and Technological Project of HenanProvincee((202102210183), and the Young Key TeacherTraininngg Foundation of Henan Province’s Universitie(2017GGJS052). REFERENCES ( (1) D estek, M . A.; Aslan, A . D isaggregated renewable energyconsumption and environmental pollution n exus in G -7 countries. Renewable Energy 2020, 151, 1298-1306. ) ( (2) Han, X.;Sun, T.; Feng, Q.Study on environmental pollution loss measurement model of energy consumption emits and its ap p lication i n industrial parks. Sci. Total Enviro n .2019, 6 68,1 2 59-1266. ) ( ( 3) S arkodie, S. A.; Adams, S. Renewable energy, nuclear energy, andenvironmental pollution: Accounting for political institutional qua l ity in South Africa. Sci. Total Environ.2018, 6 43, 1590-1601. ) ( (4) Anser, M. K . ; H a nif, I.; Vo, X. V.; Alharthi, M. The long-run andshort-run influence of environmental pollution , energy consumption, and e conomic activities o n health quality in e merging c o untries.Environ. Sci. Pollut. Re s . 2020, 27,32518-3 2 532. ) ( (5) T rellu, C.; Vargas, H. O.; Mousset, E.; Oturan, N.; Oturan, M. A.Electrochemical t e chnologies f o r t h e treatment of pesticides. Cu r r.Opin. Electrochem. 2021, 26, 100677. ) ( (6) P an, Z .; Song, C .; L i,L.; Wang, H . ; P a n, Y . ; Wang, C.;Li, J; Wang, T .; F eng, X. M embrane technology c o upled w i th e l ectro-chemical advanced o x idation processes f or organic w astewatertreatment: R ecent advances a n d future p r ospects. Chem. En g . J. 2019, 3 76,120909. ) ( (7) Garcia-Segura, S. ; Ocon, J . D. ; Chong, M. N. Electrochemicaloxidation r emediation of real wastewater effluents 一 A r eview. Process Saf. Environ. Prot. 2018, 113, 48-67. ) ( (8) C hang, X.; v an d e r Zalm, J . ; Thind, S. S.; C h en, A . Electrochemical o xidation of l ignin a t e lectrochemically r educedTiO, nanotubes. J. E lectroanal. Chem. 2020, 863, 114049. ) ( (9) X iao, J ; W ang, C. ; Ly u , S. ; Liu, H.; Ji a ng, C. ; Le i , Y. Enhancement of Fenton degradation by catechol in a w i d e initial pH range. Sep. Purif. Technol . 2016, 169,202-209. ) ( (10) Gan, Q ; Ho u , H.; Liang, S.; Qiu, J.; Ta o , S.; Ya n g, L.; Yu , W.; Xiao, K .; Liu, B.; Hu, J ; W ang, Y.; Y a ng, J. S l udge-derived bi o char with multivalent iron as an efficient F e nton catalyst fo r degradation of4-Chlorophenol. S c i. T otal Environ. 2 020, 725,13 8 299. ) ( (11) Wang, C.; Y u, G .; Chen, H.; Wang, J. Degradation of norfloxacin by hydroxylamine enhanced f e nton s y stem: K i netics, mechanism and d e gradation pathway. Ch e mosphere 20 2 1, 270,129408. ) ( ( 12) Liu, G .; H uang, H.; Xie, R . ; F e ng, Q.; Fang, R.; S h u, Y. ; Zhan, Y .; Ye, X.; Zhong, C. Enhanced degradation of g aseous b enzene by a Fenton reaction. RSC Adv. 2017, 7,71-76. ) ( (13) S hekoohiyan, S . ; Moussavi, G.; Naddafi, K. Th e per o xidase-mediated b iodegradation of petroleum hydrocarbons in a H,0z-induced SBR using in - situ p r oduction of peroxidase: Biodegradation experiments a n d bacterial identification. J . Hazard. M ater. 2016, 313,170-178. ) ( (14) Nakayama, A.; Y amano, N.; Kawasaki, N. Biodegradation i n seawater of aliphatic polyesters. Polym. Degrad. S tab. 2019, 166, 290- 299. ) ( (15) Liao, X.; Z ou, R . ; L i , B .; T ong, T.; Xie, S.; Yu a n, B.Biodegradation of chlortetracycline by acclimated microbiota. Process Saf. Environ. Prot. 2017, 109, 11-17. ) ( (16) Deepracha, S .; A yral, A.; Ogawa, M. A c celeration o f the photocatalytic degradation o f organics b y in-situ r e moval of theproducts o f degradation. Appl. Catal, B 2021, 284,1 1 9705. ) ( (17) J u , H.; Fang, T.; Zhou, Y.; F e ng, X.; S o ng, T.; Lu, F. ; Liu, W. CsPbBrg-MoS,-GO na n ocomposites for boosting photocatalytic degradation performance. Appl. S u rf. Sci. 2021, 551, 149452. ) ( (18) B u jak, I. T.; K r alj, M. B.; Kosyakov, D. S.; U l’yanovskii, N. V . ;Lebedev, A. T.; Trebse, P . P h otolytic and ph o tocatalytic degradation ) of doxazosin in aqueous solution. Sci. Total Environ. 2020, 740,140131. (19) Liu, T.; Wang, L.; Sun, C.; Liu, X.; Miao, R.; Lv, Y. Acomparison of the photolytic and photocatalytic degradation offluvastatin. Chem. Eng.J. 2019,358, 1296-1304. ( (20) Liang, H .; T ai, X . ; D u , Z. Ph o tocatalytic degradation ofnonylphenol ethoxylate and i t s d egradation mechanism. J. M o l. L i q. 2020, 302,112567. ) ( (21) J eon, J.-P.; Kweon, D . H.; Jang, B. J; Ju, M. J.; Baek, J.-B. Enhancing the P h otocatalytic A c tivity of TiOz Catalysts. Adv. Sustainable Syst . 2020, 4, 2000197. ) (22) Yang, Y.; Meng, Q; Jiang, X.; Meng, S.; Zheng, X.; Zhang, S.;Fu, X.; Chen, S. Photocatalytic Performance of NiS/CdS Compositewith Multistage Structure. ACS Appl. Energy Mater. 2020, 3, 7736-7745. ( (23) Y ang, X.; Yang, Y.; Wang, B.; W ang, T . ; Wang, Y.; M e ng, D Synthesis and photocatalytic property of cubic phase C dS. Solid S tate Sci . 2019, 92,31-35. ) (24) Byzynski, G.; Melo, C.; Volanti, D. P.; Ferrer, M. M.; Gouveia,A. F.; Ribeiro, C.; Andres, J.; Longo, E. The interplay betweenmorphology and photocatalytic activity in ZnO and N-doped ZnOcrystals. Mater. Des. 2017,120,363-375. ( (25) Villa, K.; Murcia-Lopez, S. ; Morante, J. R. ; Andreu, T. Aninsight on the role of La in mesoporous W O , for the pho t ocatalytic conversion of m ethane into m e thanol. Appl. Catal, B 2016, 187, 30 - 36. ) ( (26) L ee, J .; Ham, S . ; Choi, D . ; Jang, D.J. Facile fabrication o f porous ZnS n a nostructures with a controlled a m ount of S va c anciesfor enhanced photocatalytic p erformances. N anoscale 2 018, 10, 14254-14263. ) (27) Mustafa, M. N.; Shafie, S.; Wahid, M. H.; Sulaiman, Y.Preparation of TiO, compact layer by heat treatment of electrospunTiO, composite for dye-sensitized solar cells. Thin Solid Films 2020,693,137699. ( (28) Naldoni, A.; A ltomare, M.; Zoppellaro, G . ; Liu, N.; Kment, S.;Zboril, R. ; Schmuki, P. Photocatalys i s with Reduce d TiOz: From Black TiO, t o Cocatalyst-Free Hydrogen Production. A CS C a tal 2019,9,345-364. ) ( (29) Zhang, X.; Zuo, G.; Lu, X.; Tang, C.; Cao,S. ; Yu, M. An a taseTiO, sheet-assisted synthesis of Ti+ self-doped mixed phase Ti O ,sheet with s uperior visible-light photocatalytic performance: Roles of anatase T iO, s h eet. J. Colloid Interface Sci. 2017, 490,7 7 4-782. ) ( (30) Meng, A.; Zhang, L.; C heng, B.; Yu, J. Dual Cocatalysts in TiOz Photocatalysis. Adv. Mater. 2019, 31,1807660. ) ( (31) Z hang, X .; Wu, Y.; Lv, Y.; Yu, Y.; Dong, Z. Formation mechanism, corrosion behaviour a n d bi o logical property ofhydroxyapatite/TiO2 coatings f abricated b y p l asma e l ectrolyticoxidation. Surf. Coat. Technol. 2020, 386, 125483. ) ( . (32) Zhang, X.; Peng, Z.; Lu, X.; Lv, Y. ; Cai , G.; Yang, L. ; Dong, Z Microstructural evolution and biologica l performance of Cu- incorporated TiO, c oating f abricated through one-step micro-arcoxidation. Appl. Surf. Sci.2020, S08, 144766. ) ( (33) Zhang, X.; Lu, X . ; L v , Y . ; Y a ng, L . ; Z h ang, E. ; Do n g, Z.Enhancement of Corrosion Resistance and Biological Pe r formances ofCu-Incorporated Hydroxyapatite/TiO, C oating by A d justing C u Chemical Configuration and Hydroxyapatite Contents. ACS Appl. Bio Mater. 2021, 4, 903-917. ) ( .(34) Sui, Y.; Wu, L.;Zhong, S.; Liu, Q. Carbon quantum dots/TiOznanosheets with d ominant (001) facets for e n hanced photocatalytic hydrogen e v olution. Appl. S u rf. S c i. 2 019, 480, 810-816. ) ( (35) Qi, K.; Liu, S.-Y.; Qiu , M. Photocatalytic performance of TiO,nanocrystals with/without o xygen d e fects. C hin. J . Catal. 2018, 39, 867-875. ) ( (36) Rawool, S. A.; Yadav, K. K.; Polshettiwar, V. Defective TiO, forphotocatalytic CO, c onversion to fuels a nd chemicals. C hem. S c i. 2021, 1 2,4267-4299. ) ( ( 37) Hu, X.; H u , X. ; Pe n g,Q.; Zhou , L.; Tan, X.; Jiang, L.; T a ng, C.;.Wang, H.; Liu, S. ; Wang, Y.; Ning, Z. Mechanisms u nderlying the ) ( photocatalytic d egradation p a thway of ciprofloxacin wi t h het e roge-neous T iO. C h em. Eng. J.2 0 20, 3 8 0, 122366. ) ( (38) L i , H.; Wu, X.; Yin, S.; K a tsumata, K.; Wang, Y. Effec t of ru t il e TiO, on t h e p h otocatalytic p erformance of g-CN4/brookite-TiOz- xNy photocatalyst for NO decomposition. Appl. Surf. Sci. 2017, 392, 531-539. ) ( (39) A ghasiloo, P.; Yousefzadeh, M .; Latifi, M.; Jose, R. Highlyporous TiO, n a nofibers b y hu m id-electrospinning with enhancedphotocatalytic properties. J. Alloys Compd. 2019, 790,257-265. ) ( ( 40) Azimirad, R. ; Safa, S . ; E b rahimi, M . ; Y o usefzadeh, S.;Moshfegh, A. Z. Photoelectrochemical a c tivity of graphene q uantumdots/hierarchical porous TiO photoanode. J. Al l oys Compd. 201 7 , 721,36-44. ) ( (41) Zhao, J.; He, Y .; Zhang, L.; Lu, K. Preparation of porous T iOz powder w i th m e soporous str u cture by freeze-drying method. J. AlloysCompd. 2016, 678, 36-41. ) ( (42) Z hang,Z.; Yi, G .; Li, P.; Zhang, X.; Fan, H.; Zhang, Y.;Wang,X.; Zhang, C . A m inireview on doped carbon dots for photocatalyticand electrocatalytic applications. Nanosca l e 2020, 1 2 , 13899 - 13906. ) ( (43) Z hang, L.-Y.; Han, Y.-L.; Yang, J.J.; Deng, S.-L. ; Wang, B.-Y.Construction a nd p h otocatalysis of c arbon quantum dots/layeredmesoporous t itanium dioxide (CQDs/LM-TiO2) c o mposites. Appl. Surf. Sci . 2021, 546, 149089. ) ( (44) K urozuka, A.; O nishi, S.; Nagano, T.; Yamaguchi, K.; Suzuki,T.; Minami, H . Em u lsion po l ymerization wi t h a b i o su rfactant. Langmuir 2017, 33, S814-5818. ) ( (4S) S un, Y .; Wang, C . ; G u , G.; M a , Y. ; Xiong, Z.; Liu, Y.Fa c ile synthesis of free-metal t e rnary composites for ultra-fast photocatalytic degradation of organic pollutant. C atal. Today 2020, 3 4 0, 294-301. ) ( (46) L i, F .; Tian, F .; Liu, C.; Wang, Z.; Du, Z . ; L i , R.; Z hang, L. One-step s ynthesis of nanohybrid carbon dots and TiO, c omposites with enhanced ul t raviolet light active photocatalysis. RSC Adv. 2015, S, 8389-8396. ) ( (47) Wei, X . ; Wang, C. ; Ding, S.; Y a ng, K.; Tian, F.; L i , F . O ne-step synthesis of Ag n anoparticles/carbon dots/TiO, n anotube arrays composite p h otocatalyst w i th en h anced pho t ocatalytic act i vity.J. Environ. Chem. Eng. 2021,9,104729. ) ( (48) D uo, F.; W ang, Y . ; Fan, C.; Zhang, X . ; Wang, Y. Enhanced visible light photocatalytic activity and stability o f CQDs/BiOBrcomposites: The upconversion effect of CQDs. J. Alloys Compd. 2016, 685,34-41. ) ( (49) Wei, G.; Zhao, X.; D u , K.; Huang, Y.; An, C.; Qiu, S.; Liu, M.; Y ao, S .; Wu, Y. F lexible a symmetric s u percapacitors m ade of 3Dporous hierarchi c al CuCo2O4@CQDs an d FezO3@CQDs withenhanced performance. Electrochim. Acta 2018, 283, 248-259. ) ACS Publications@ XXXX American Chemical Societyhttps://doi.org/acs.iecr.cnd. Eng. Chem. Res.XXXX, XXX, XXX-XXXA Bhttps://doi.org/acs.iecr.cnd. Eng. Chem. Res. XXXX, XXX, XXX-XXX 大幅提高光催化活性的N-掺杂碳点/大孔二氧化钛复合材料(N-CDs/TiO2)的构建 01 前言 在此,我们首次将m-TiO2与N-CDs复合,得到了一种新型的协同催化剂(N-CDs/m-TiO2)。用亚甲基蓝(MB)作为模拟污染物,研究了光催化性能。(MB)作为模拟污染物来研究光催化性能。并发现独特的三维互连多孔结构不仅大大增加了表面积,而且提供了高密度的可利用活性位点,促进了质量和电荷转移过程。此外,由于N-CDs出色的转化发光特性,所获得的N-CDs/m-TiO2拥有显著增强的光吸收能力,同时伴随着能量带隙的大大降低。N-CDs/m-TiO2在照射180分钟后对MB的脱色率为99.59%,远远超过TiO2的脱色率。显著增强的光催化性能归功于N-CDs的增效作用和M-TiO2的增效作用和独特的多孔结构,使其在实际的废水净化中具有良好的应用前景。 02简介 如今,环境污染和能源短缺是许多国家面临的两大挑战。越来越多的人担心,工业化的快速发展不仅会加速能源消耗,而且会导致有毒和难降解有机污染物的大量产生,对人类的健康构成威胁。因此,在过去的几十年里,人们在以下方面做出了很大努力开发先进的技术来处理含有难降解有机污染物的废水处理技术。这些这些方法主要包括电化学氧化法,5-8芬顿降解,9-12生物降解,13-15和光催化技术。16-20尤其是光催化技术被认为是降解这些特别是光催化技术被认为是降解这些有害有机污染物的有前途的方法,因为太阳能作为一种取之不尽、用之不竭的环境友好型能源资源。一般来说,光催化的效率取决于你所使用的光催化剂的类型,因为不同的光催化剂的光催化活性不同。表现出明显的差异。近年来,作为光催化剂的半导体,包TiO2,CdS、ZnO、WO3、ZnS等,由于其优越的光催化性能,已成为研究的重点。21-26 其中,TiO2因其较高的光催化性能吸引了大量的研究关注。其中,TiO2因其高的光催化活性、无毒、低成本和和良好的稳定性而引起了人们的极大关注。TiO2已被应用于各种技术领域,如光催化氢气进化、光电转换、废水处理和能源储存。27-34TiO2的带隙很宽,为3.2eV,对应于387的紫外线。对应于387纳米的紫外线,也就是说,只有一小部分的阳光可以被有效吸收。因此,高活性的电子和空穴产生了高度活跃的电子和空穴。一般来说,空穴可以从OH-和H2O中捕获电子,从而形成一个羟基自由基(-OH),而电子能够吸收催化剂表面的O2,从而产生活性的超氧自由基(-O2-)。最终,这些生成的氧化剂会将难降解的有机化合物降解为小分子,如二氧化碳(CO2)和水(H2O)。然而,TiO2光催化剂对太阳光的有效利用只占3%。光催化剂对阳光的有效利用只占3-5%,因为它的带隙很宽。此外,光产生的电子和空穴容易重新结合,因此限制了其实际应用。为了解决这些问题,TiO2通常以其改性的形式被使用。如掺入金属和非金属元素,创造一个特殊结构或形态,与其他半导体耦合,使量子点敏化,以及许多其他方法。35-38多孔结构可以大大增加表面积,并同时增强漫反射,这种材料可以在多重散射方面充分吸收光,因此被广泛应用于污染物的光催化降解。多种合成已经开发了多种合成技术来制造多孔TiO2。。例如,通过优化电纺室的湿度,Aghasiloo等人通过优化电纺室的湿度,成功合成了新型多孔TiO2纳米纤维(NFs)39。在这项工作中,所制备的新型TiO2催化剂的表面积为128平方米g-1,是TiO2纳米纤维(60 m2 g-1)的2.13倍。此外,它对亚甲基蓝(MB)和对亚甲基蓝(MB)表现出优异的降解性能。该材料的降解效率超过70%,大大超过了TiO2纳米纤维。Azimirad和他的合作者们制备了分层的多孔的TiO2纳米复合材料,使用两种不同的方法进行比较:旋涂技术和电泳技术。40 Zhao等人提出了一种新的方法来制备TiO2粉末,其催化活性显著提高。41 在这项工作中,所获得的TiO2光催化剂具有独特的介孔结构,其比比表面积高达130.940 m2 g-1。这是用传统的溶胶-凝胶法,结合随后的冷冻干燥过程合成的。因此,多孔TiO2有利于增强光散射并同时提高辐照利用率,从而促进其光催化作用。量子点敏化是另一种有效的方法来提高提高TiO2的光催化性能。然而。有毒的重金属离子占了已经报道的量子点的大部分,对环境是有害的。最近,直径小于10纳米的碳点(CD)作为新的成员被报道。它是由一个准离散的球状核心和表面功能团组成。CD拥有几个著名的的优势,包括来源丰富、成本低、无毒性。和易于制备。根据我们以前的工作,42在CD中加入杂原子不仅可以提高荧光特性,而且还可以极大地改善电性能,这使它们成为理想的候选材料,用于光催化和电催化应用的理想选择。一般来说,将TiO2与CD或掺杂的CD耦合可以提高光催化性能,因为有几个潜在的影响。1)碳点的近红外特性能够拓宽TiO2的可见光吸收范围,同时促进其光收集能力。2)CDs的上转换或下转换荧光特性允许TiO2在光照下产生更多的电子和空穴。(3)CD作为电子转移的媒介。它促进了电子-空穴对的分离效率。Zhang等人报道了采用无机沉淀法将CQD和TiO2使用无机沉淀-沉淀法43。在协同作用下,TiO2的光催化性能得到了显著的提升,在光照下对甲基橙的去除率达到91.04%。因此,CD敏化TiO2可以大大促进其光催化活性。然而,据我们所知,有关CD敏化的研究N-CDs/微孔TiO2纳米复合材料的合成和光催化活性的调查。纳米TiO2的合成和光催化活性的研究仍未见踪影。 祥鹄仪器在此文献中使用过程 N-CDs的制备。N-CDs是通过以下方法合成的微波辅助的水热策略。通常情况下,将1.0克柠檬酸(CA)和0.9378克尿素(U)溶解在20摄氏度的水中。20mL的N,N-二甲基甲酰胺(DMF)中,在搅拌和随后进行超声处理。该混合物被转移到一个微波容器中的PTFE高压釜(XH-8000Plus, Beijing Xianghu Science and Technology Development Co,Ltd., 中国),在180℃下进行20分钟,温度提升速度为15℃/分钟。温度上升速度为15℃/min-1。之后,得到的产品冷却到室温并进行在分子量为3500的条件下透析48小时。最后,透析后的产品被冷冻干燥和研磨以供进一步使用。 03结论 综上所述,我们成功地制备了一种高效的助催化剂,即N-CDs/m-TiO2,并将其用于降解甲基溴。显著提高了光催化活性。在这里,NCDs是通过一个简单的一步水热法合成的,随后与m-TiO2复合组成,采用溶胶-凝胶法,结合PS微球作为模板,以获得最终的N-CDs/TiO2复合材料。对于m-TiO2来说,它具有独特的大孔结构,这增加了表面积,并为光电池提供了丰富的活性位点。此外,NCD的纳米结构使其与m-TiO2很好地复合在一起,极大地提高了光催化性能。由于N-CDs的转换发光特性,它的加入也可以缩小的能带间隙。令人印象深刻的是,经过在光照180分钟后,所制备的NCDs/m-TiO2显示出对甲基溴的卓越的光催化性能。脱色率达到99.59%,这远远超过了纯TiO2和m-TiO2的性能。总的来说,本发明目前的协同催化系统扩大了TiO2的实际应用范围,并同时提供了一种新的催化剂。发展了TiO2的实际应用,同时为合理设计高效的光催化系统提供了一种新的方法。处理含有难降解有机污染物的污水。

关闭-

1/10

-

2/10

还剩8页未读,是否继续阅读?

继续免费阅读全文产品配置单

北京祥鹄科技发展有限公司为您提供《一种高效助催化剂N-掺杂碳点/大孔二氧化钛复合材料(N-CDs/TiO2)中构建合成方法检测方案(微波合成仪)》,该方案主要用于金属材料基复合材料中其他检测,参考标准《暂无》,《一种高效助催化剂N-掺杂碳点/大孔二氧化钛复合材料(N-CDs/TiO2)中构建合成方法检测方案(微波合成仪)》用到的仪器有多用途微波化学合成仪、Nanocube 多功能微波水热平行合成仪。

我要纠错