生物制药发酵液中pH检测方案(pH计)

检测样品 生物药品药物研发

检测项目 理化性质

参考标准 HJ 1147-2020 水质 pH值的测定 电极法

方案详情文

智能文字提取功能测试中

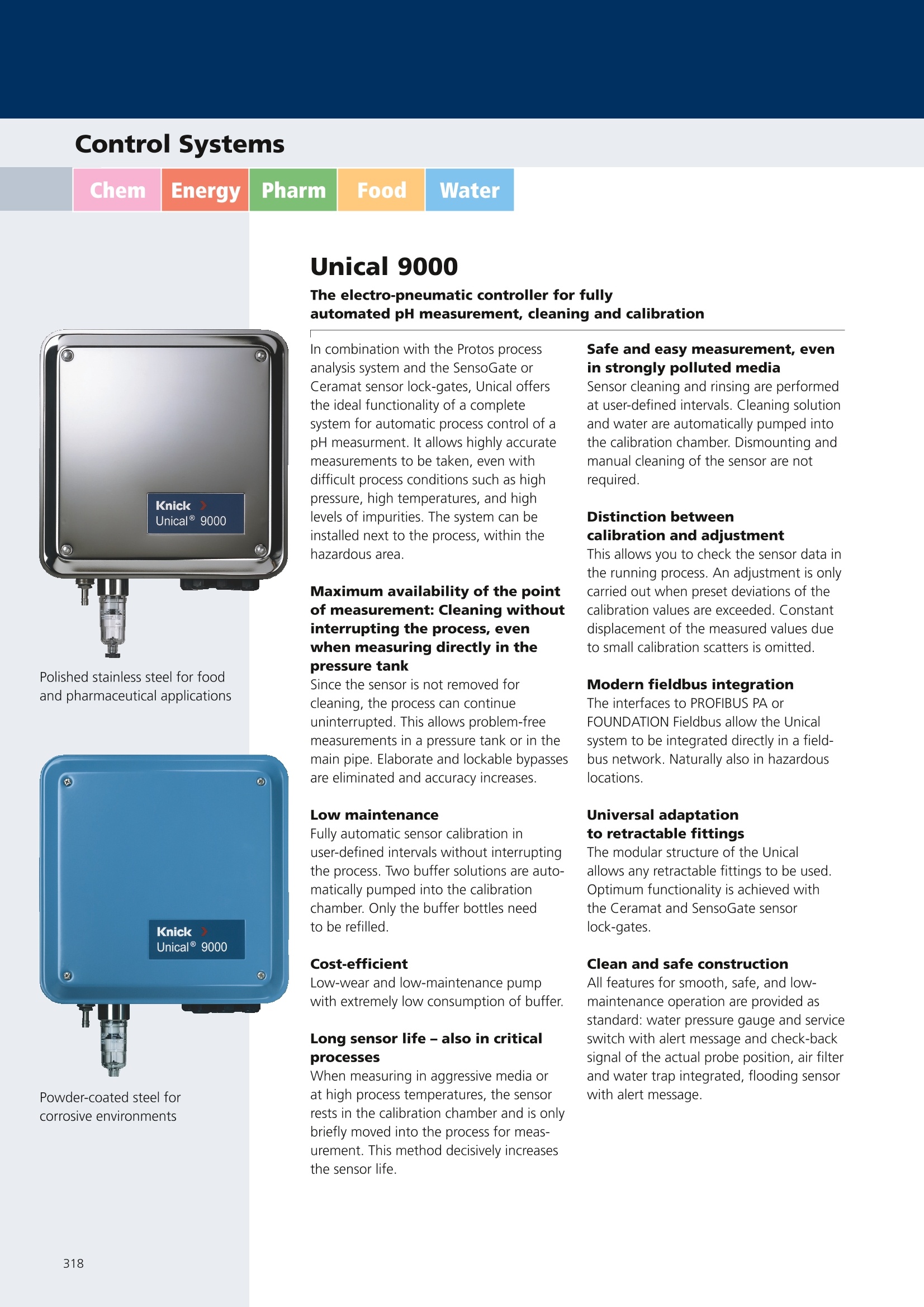

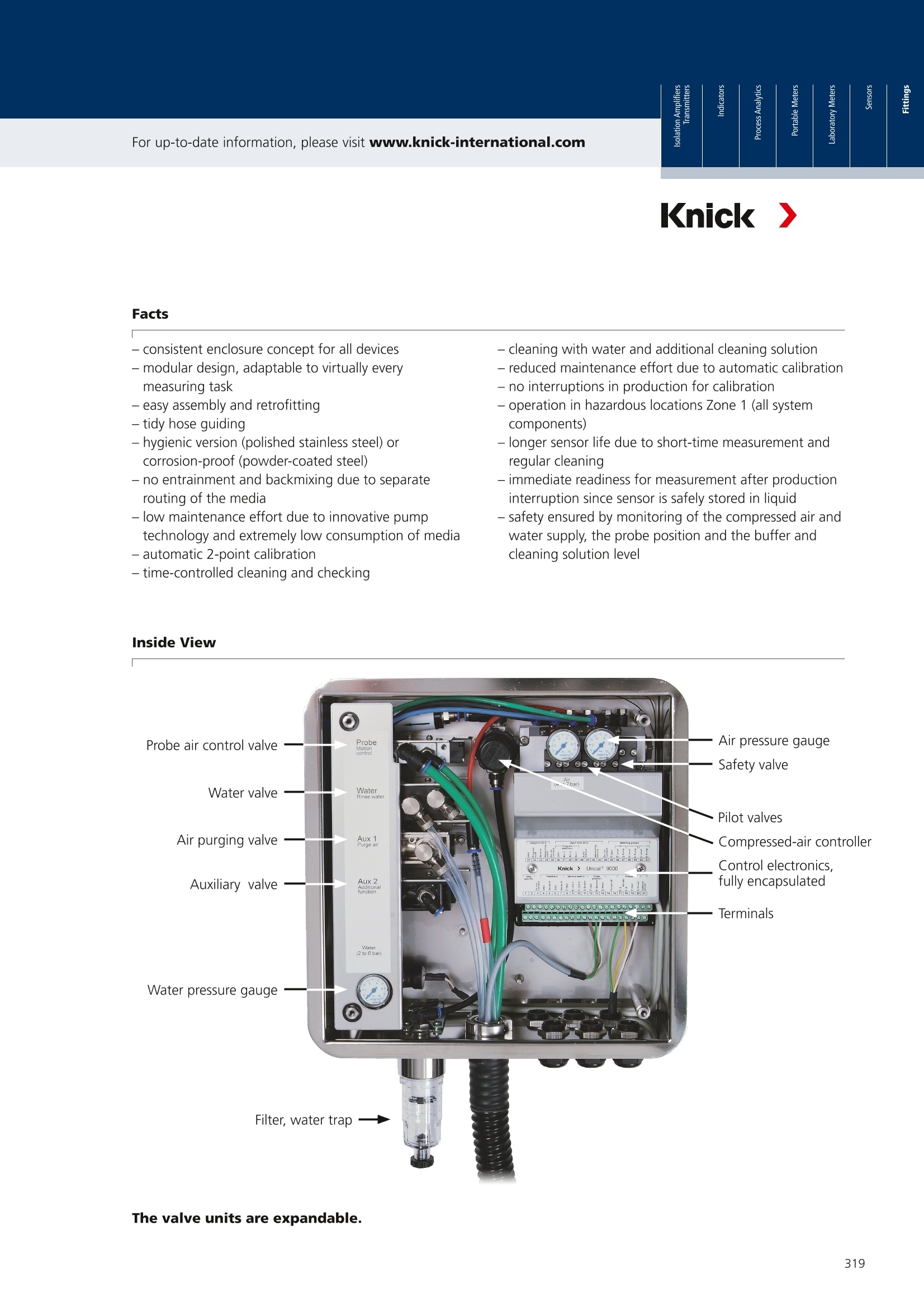

For up-to-date information, please visit www.knick-international.comKnick> Unical 9000 The electro-pneumatic controller for fullyautomated pH measurement, cleaning and calibration Polished stainless steel for foodand pharmaceutical applications Powder-coated steel forcorrosive environments In combination with the Protos processanalysis system and the SensoGate orCeramat sensor lock-gates, Unical offersthe ideal functionality of a completesystem for automatic process control of apH measurment. It allows highly accuratemeasurements to be taken, even withdifficult process conditions such as highpressure, high temperatures, and highlevels of impurities.The system can beinstalled next to the process, within thehazardous area. Maximum availability of the pointof measurement: Cleaning withoutinterrupting the process, evenwhen measuring directly in thepressure tank Since the sensor is not removed forcleaning, the process can continueuninterrupted. This allows problem-freemeasurements in a pressure tank or in themain pipe. Elaborate and lockable bypassesare eliminated and accuracy increases. Low maintenance Fully automatic sensor calibration inuser-defined intervals without interruptingthe process. Two buffer solutions are auto-matically pumped into the calibrationchamber. Only the buffer bottles needto be refilled. Cost-efficient Low-wear and low-maintenance pumpwith extremely low consumption of buffer. Long sensor life - also in criticalprocesses When measuring in aggressive media orat high process temperatures, the sensorrests in the calibration chamber and is onlybriefly moved into the process for meas-urement. This method decisively increasesthe sensor life. Safe and easy measurement, evenin strongly polluted media Sensor cleaning and rinsing are performedat user-defined intervals. Cleaning solutionand water are automatically pumped intothe calibration chamber. Dismounting andmanual cleaning of the sensor are notrequired. Distinction betweencalibration and adiustment This allows you to check the sensor data inthe running process. An adjustment is onlycarried out when preset deviations of thecalibration values are exceeded. Constantdisplacement of the measured values dueto small calibration scatters is omitted. Modern fieldbus integration The interfaces to PROFIBUS PA or FOUNDATION Fieldbus allow the Unicalsystem to be integrated directly in a field-bus network. Naturally also in hazardouslocations. Universal adaptationto retractable fittings The modular structure of the Unicalallows any retractable fittings to be used.Optimum functionality is achieved withthe Ceramat and SensoGate sensorlock-gates. Clean and safe construction All features for smooth, safe, and low-maintenance operation are provided asstandard: water pressure gauge and serviceswitch with alert message and check-backsignal of the actual probe position, air filterand water trap integrated, flooding sensorwith alert message. - time-controlled cleaning and checking Inside View Control Systems Unical 9000 New, Innovative Pump Design for Low Maintenance Costs -no usual pistons/cylinders - no wear Modular Flexibility for Very Simple Adaptation - The buffer or cleaning solution bottles (3.5l) are replaceable active, self-sustaining units with integrated pumpeasy refilling of buffer or cleaning solution, without removing the pump - The pump units are automatically recognized by the system. - The closure consists of a conveyor cap with funnel and buttoned lid. :- This innovative construction provides previously unknown flexibility and service friendliness. For up-to-date information, please visit www.knick-international.com Knick> Overview-The Complete System Safe Pump System with Minimum Buffer Consumption and Minimum Entrainment Control Systems Unical 9000 Control Systems Unical 9000 Product Line Order No. Basic unit For up-to-date information, please visit www.knick-international.com Accessories for Unical 9000 Order No. Pipe-mount kit for Unical 9000 ZU 0601 Pipe-mount kit for media adapter ZU 0606 Connection kit for Unical 9000 (water and air) ZU 0656 Spare Parts and Retrofit Parts for Unical 9000 Order No. Media connection, rinse, 5 m (FKM gaskets) ZU 0572/1 Media connection, rinse, 5 m (EPDM gaskets) ZU 0572/2 Media connection, rinse, 10 m (FKM gaskets) ZU 0573/1 Media connection, rinse, 10 m (EPDM gaskets) ZU 0573/2 Media connection, rinse, 15 m (FKM gaskets) ZU 0652/1 Media connection, rinse, 15 m (EPDM gaskets) ZU 0652/2 Media connection, rinse + cal, 5 m (FKM gaskets) ZU 0574/1 Media connection, rinse + cal, 5 m (FKM gaskets), steel balls instead of glass balls*) ZU 0574/1S Media connection, rinse + cal, 5 m (EPDM gaskets) ZU 0574/2 Media connection, rinse + cal, 10 m(FKM gaskets) ZU 0575/1 Media connection, rinse + cal, 10 m (EPDM gaskets) ZU 0575/2 Media connection, rinse + cal, 17 m (FKM gaskets) ZU 0653/1 Media connection, rinse+ cal,17 m (EPDM gaskets) ZU 0653/2 Media interface for standard probes ZU 0576 Metering pump (PP, FKM) with empty 3.5-L bottle ZU 0580/1 Metering pump (PP, EPDM) with empty 3.5-L bottle ZU 0580/2 Metering pump (PP,EPDM) with empty 3.5-L bottle, steel balls instead of glass balls*) ZU 0580/2S Metering pump (PP, FKM) with empty 3.5-L bottle, Ex ZU 0580 X/1 Metering pump(PP,EPDM) with empty 3.5-L bottle, Ex ZU 0580 X/2 *) included with special version -001 Control Systems Unical 9000 Spare Parts and Retrofit Parts for Unical 9000 -continued Order No. Supplementary air purging kit ZU 0587 Supplementary Aux 2 kit ZU 0588 Media adapter (FKM gaskets) ZU 0577/1 Media adapter (EPDM gaskets) ZU 0577/2 Media adapter, Ex (FKM gaskets) ZU 0577 X/1 Media adapter, Ex (EPDM gaskets) ZU 0577 X/2 Service switch, coated steel ZU 0729 NC Service switch, coated steel, Ex ZU 0729 XC Service switch, polished stainless steel ZU 0729 NS Service switch, polished stainless steel, Ex ZU 0729 XS Service Parts for Unical 9000 Order No. Air pressure switch ZU 0632 Water pressure switch ZU 0633 Probe valve, complete ZU 0634 Water valve ZU 0714 Sensor dismount guard, complete ZU0644 Air purge valve, complete ZU 0636 Aux 2 valve, complete ZU 0637 Piezo valve for valve block ZU 0638 Gasket for port at media adapter (EPDM) ZU 0639 Filter insert (5 ... 10 pm) ZU 0640 Replacement filter housing ZU 0641 Electronics module, tested,encapsulated ZU 0642 Electronics module, tested, encapsulated, Ex ZU 0642 X Small-parts set (various screws, springs etc.) ZU 0643 Multiplug service set, FKM gaskets ZU0812/1 Multiplug service set,EPDM gaskets ZU0812/2 Reed switch, short (service part for multiplug) ZU 0813/1 Knick Dimension Drawings Wall mounting Pipe mounting Media connection All dimensions in mm. Connection to probe (e.g. Ceramat WA 150) and media adapter Control Systems Unical9000 Dimension Drawings-continued Pipe mounting Pipe diameter: 30 ... 65 mm 应用背景 在生物制药的生产控制中,pH是过程控制中的关键参数。由于制药行业的特殊性,测量偏差可有较大会对最终生产结果的影响。因此,制药行业已经不断的优化过程控制工具,以不断提高测量的可靠性、稳定性和数据获取。在术语下总结,就是Process Analytical Technology (PAT). 制药传感器必须是可灭菌的(SIP)和可就地清洗的(CIP),为了获得有关其日常性能的有价值的信息,理想情况下,传感器应配备存储相关质量参数的芯片。Knick Memosens传感器以易于阅读的传感器雷达图(图表)提供了这些信息。 传感器雷达图可配置在许多Knick分析仪上,是一个理想的工具以实时监测和控制传感器的性能。雷达图支持操作人员做出维护决策,并有助于提高传感器的寿命和降低运营成本。附加的“加载图”显示传感器的曝光取决于pH和温度。最后但同样重要的是,Knick公司的传感器提供制药认证,这些认证包括FDA、USP88、ATEX等。主要挑战 数百名操作人员执行2点校准,在批处理开始之前需要进行3点校准做调整,批处理结束后,他们进行3点校准/验证。 这样导致的结果就是:花了很多工时; 即使工作按照SOP完成,也有很多不确定性:需要时刻记住正确的缓冲液,缓冲液一旦溢出会影响生产;需要非常有耐心以避免错误的校准,如电极掉在地板上… ATEX环境:需要特殊的服装,允许进入生产设施的房间 总之:浪费了大量的生产时间,甚至是价值不菲的产品,如何解决工艺监测中pH的测量问题呢:自动化!pH自动化解决方案 为了实现生物发酵过程中的pH监测,Knick提供了一种自动化测量、清洗及校准pH的解决方案,本方案采用Knick全新的Unical 9000(X)全自动清洗校准系统,摒弃了传统的在线pH监测,需要定期的人工维护的缺陷,很好的满足了在发酵过程中pH的无人值守在线监测,并满足上述监测条件。 Unical 9000(X)是一套通过气动控制的集pH 测量、清洗和校准一体的全自动化装置,这套系统是基于模块和功能所架构的,附件包含电子控制器,过滤器和阀门。另有配液器是用来调节校准液和清洗液供给的。 德国原厂提供以下最佳适配部件作为此套全自动在线分析系统的核心:Protos 3400(X) 模块化过程分析Unical 9000(X) 可伸缩式护套控制器SensoGate WA130H X 卫生型伸缩护套小结 Knick的Unical 9000(X)是真正意义上的免维护在线pH监测系统,通过气动控制的集pH 测量、清洗和校准一体的全自动化,主机Protos可以根据变色程度精确设定清洗程序,在线pH电极SE555可以准确和可重现的测量,甚至在CIP/SIP周期后,同时该WA130SensoGate卫生、气动操作的伸缩式连接件,周全的设计使得传感器闸门的维护特别简单,几乎所有维护工作都可在现场执行,无需求助于车间。松开耦合螺母即可轻松分离驱动器与浸入管,无需全部拆除。浸入管通过卡口联接器分开,可以仅替换受应力影响特别严重的工艺浸湿部分,包括校准腔,有助于节省成本。 同时,工艺浸湿部件和校准腔具备良好的可清洁性和可消毒性,已通过EHEDG认证。这使SensoGate具有优异的能力来满足食品和制药行业的要求以及FDA管辖的生产工艺的验证。科伲可(上海)电子测量仪器贸易有限公司上海市黄浦区复兴中路369号大同商务大厦5楼501室

关闭-

1/12

-

2/12

还剩10页未读,是否继续阅读?

继续免费阅读全文产品配置单

科伲可(上海)电子测量仪器贸易有限公司为您提供《生物制药发酵液中pH检测方案(pH计)》,该方案主要用于生物药品药物研发中理化性质检测,参考标准《HJ 1147-2020 水质 pH值的测定 电极法》,《生物制药发酵液中pH检测方案(pH计)》用到的仪器有Knick Memosens数字pH传感器SE555、Knick SensoGate伸缩式连接件、cCare pH自动清洗校准系统 。

我要纠错