方案详情文

智能文字提取功能测试中

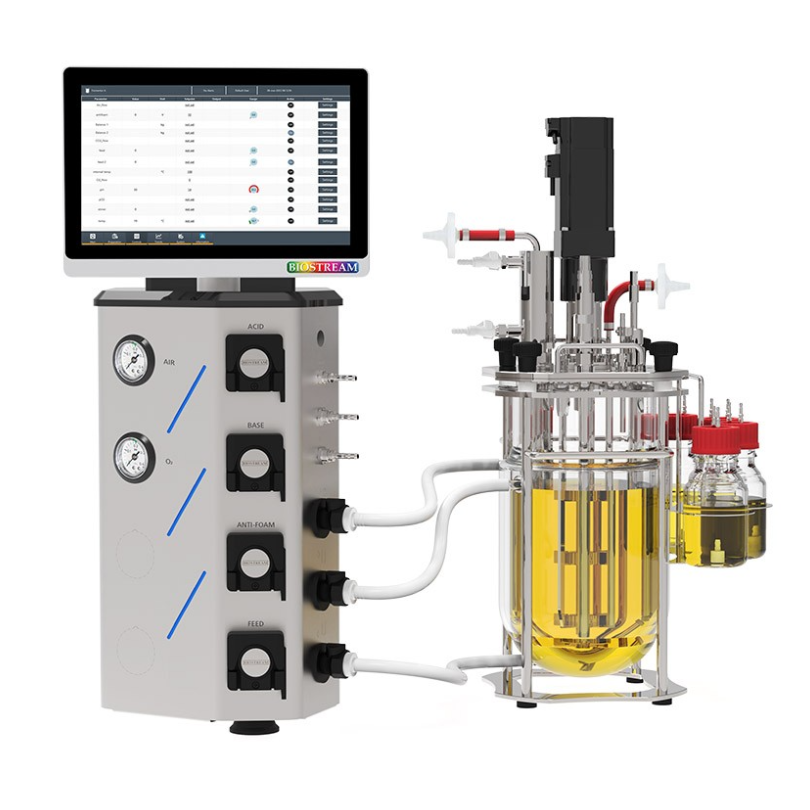

发酵罐在酵母菌的分批培养中的应用分批反应操作是指基质灭菌、接种以后,除了好氧反应需要在反应过程中通入无菌空气、消除泡沫所用的消泡剂以及维持一定pH值所用酸碱之外,反应过程中不再加入反应基质。基质浓度、产物浓度以及细胞浓度均随反应进行的时间而变化,尤其是菌体本身将经历不同的生长阶段(在培养的过程中,微生物的生长可分为迟缓期、对数生长期、减速期、静止期),显示出不同的催化活力。基本特征是:反应物料一次加入一次卸出;反应器物系的组成仅随时间而变化,即随着培养的进行,基质的浓度下降,菌体量增加,产物增加。因此属于一非稳态过程。Yeast culture –batch and with feeding.The fermenter is supplied in a configuration to provide an excellent bioreactor for this purpose. * Powerful, top drive system with lubricated mechanical seal (magnetic options for Techfors) * Jacketed system for efficient heat transfer. * High-accuracy pumps for addition of pH control reagents, antifoam and feed (option on some units) * Control of dissolved oxygen by stirrer speed as standard (air flow, pressure & oxygen, supplement options) * Optional analogue feed pump for variable speed additon * Analogue input/output for addition of external pumpsand sensros for eg. OD and MethanolVessels: All vessels are stainless steel (1.4435) with a dished base and top plate in several standard sizes. Temperature control can be by water circulation with either a heating element or steam injection into a pocket/exchanger.All vessels are with a mechanical seal drive (magnetic coupling for cells). The drive shaft has a simple and secure connection for the motor. The top plate is equipped with 10mm, PG13.5 and standard, rounded -thread 19mm ports which can be fitted with a septum and retaining collar to allow flaming of the port during inoculation etc. (number and type varies according to specific fermenter). Bottom ports are 25mm Ingold standard and numbers vary by size.The vessels are sterilized in situ (Techfors and Techfors S) with automatic sequencing. Reagent bottles and inlet pipes etc are usually autoclaved separately (options & alternatives, depending on size and configuration).. StirringThe fermenter has a powerful brushless motor with integral speed controller for speeds from 100 - 1500 rpm, depending on the vessel size and number of impellors. Powerful fluid cooled motors are standard for Techfors.x-DDC Control System:All fermenter models except Minifors incorporate the x-DDC (eXtended DDC microprocessor control) which uses a high-performance digital system. With the use of almost identical instrumentation, the step from Bench-scale to larger equipment is made considerably easier.The control panel is compact and is usually mounted above the base unit for clear visibility. The panel can be removed if required. Programming of parameters is via a splashproof keypad with a rotary knob for navigation and an LCD display. Communication is via a robust data-cable. For each fermenter, process information such as parameter set points, PID values etc are stored automatically on an interchangeable "memory card" . This allows changes in fermentation processes by fitting an alternative card or downloading a recipe without re-programming and the chance of errors plus an unlimited number of recipes to be stored.An "open frame" gas supply system with four magnetic valves allow addition of components for automatic mixing of gasses for oxygen supplementation. An optional mass flow control valve ensures a controlled, steady flow of gas into the vessel. Agitation & temperature control. Four high-accuracy digital peristaltic pumps supplied as standard with the option to add an integral analogue feed pump. Addition and removal of liquids is therefore possible with a standard system (using the antifoam pump for medium take-off). Accepts a conductive probe for automatic control of antifoam addition or media addition/removal in a vessel. Works together with the integral peristaltic pumps.发酵罐在酵母菌的分批培养中的应用 分批反应操作是指基质灭菌、接种以后,除了好氧反应需要在反应过程中通入无菌空气、消除泡沫所用的消泡剂以及维持一定 pH 值所用酸碱之外,反应过程中不再加入反应基质。 基质浓度、产物浓度以及细胞浓度均随反应进行的时间而变化,尤其是菌体本身将经历不同的生长阶段(在培养的过程中,微生物的生长可分为迟缓期、对数生长期、减速期、静止期),显示出不同的催化活力。 基本特征是:反应物料一次加入一次卸出;反应器物系的组成仅随时间而变化,即随着培养的进行,基质的浓度下降,菌体量增加,产物增加。因此属于一非稳态过程。 Yeast culture -batch and with feeding. The fermenter is supplied in a configuration to provide an excellent bioreactor forthis purpose. * Powerful, top drive system with lubricated mechanical seal (magnetic options forTechfors) * Jacketed system for efficient heat transfer. * High-accuracy pumps for addition of pH control reagents, antifoam and feed(option on some units) * Control of dissolved oxygen by stirrer speed as standard (air flow, pressure &oxygen, supplement options) * Optional analogue feed pump for variable speed additon * Analogue input/output for addition of external pumpsand sensros for eg. OD and Methanol Vessels: All vessels are stainless steel (1.4435) with a dished base and top plate in severalstandard sizes. Temperature control can be by water circulation with either aheating element or steam injection into a pocket/exchanger. All vessels are with a mechanical seal drive (magnetic coupling for cells). The driveshaft has a simple and secure connection for the motor. The top plate is equippedwith 10mm,PG13.5 and standard, rounded -thread 19mm ports which can be fittedwith a septum and retaining collar to allow flaming of the port during inoculationetc. (number and type varies according to specific fermenter). Bottom ports are25mm Ingold standard and numbers vary by size. The vessels are sterilized in situ (Techfors and Techfors S) with automaticsequencing. Reagent bottles and inlet pipes etc are usually autoclaved separately(options & alternatives, depending on size and configuration).. Stirring The fermenter has a powerful brushless motor with integral speed controller forspeeds from 100-1500 rpm, depending on the vessel size and number of impellors.Powerful fluid cooled motors are standard for Techfors. x-DDC Control System: All fermenter models except Minifors incorporate the x-DDC (eXtended DDCmicroprocessor control) which uses a high-performance digital system. With theuse of almost identical instrumentation, the step from Bench-scale to largerequipment is made considerably easier. The control panel is compact and is usually mounted above the base unit for clear visibility. The panel can be removed if required. Programming of parameters is via asplashproof keypad with a rotary knob for navigation and an LCD display. Communication is via a robust data-cable. For each fermenter, process informationsuch as parameter set points, PID values etc are stored automatically on aninterchangeable "memory card". This allows changes in fermentation processes byfitting an alternative card or downloading a recipe without re-programming andthe chance of errors plus an unlimited number of recipes to be stored. An "open frame" gas supply system with four magnetic valves allow addition ofcomponents for automatic mixing of gasses for oxygen supplementation. Anoptional mass flow control valve ensures a controlled, steady flow of gas into thevessel. Agitation & temperature control. Four high-accuracy digital peristalticpumps supplied as standard with the option to add an integral analogue feedpump. Addition and removal of liquids is therefore possible with a standard system(using the antifoam pump for medium take-off). Accepts a conductive probe forautomatic control of antifoam addition or media addition/removal in a vessel.Works together with the integral peristaltic pumps.

关闭-

1/3

-

2/3

还剩1页未读,是否继续阅读?

继续免费阅读全文产品配置单

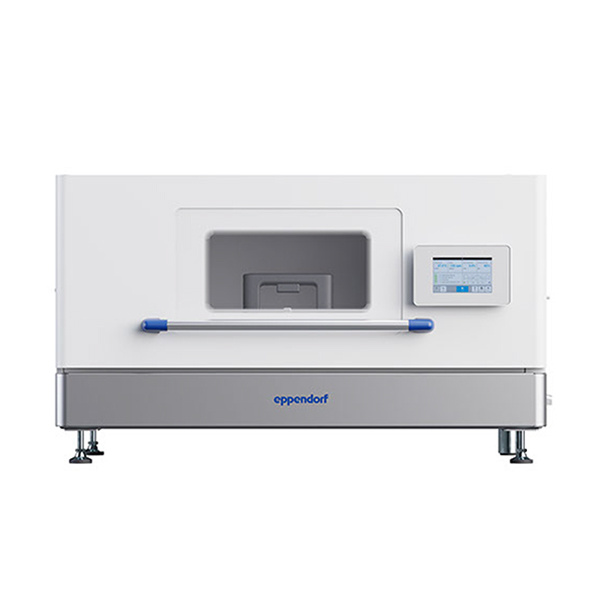

上海博奥思生物技术有限公司为您提供《发酵罐在酵母菌的分批培养中的应用》,该方案主要用于生物发酵中应用介绍检测,参考标准《暂无》,《发酵罐在酵母菌的分批培养中的应用》用到的仪器有博奥思 双侧臂细胞培养瓶、博奥思 BIOMIX drive 1/ drive 4分体式细胞培养磁驱搅拌器、博奥思 BH200-C1低速生物培养磁力搅拌器、博奥思 Microtron 高速振荡培养箱、博奥思 B3 / B5 / B7 通用振荡培养箱、博奥思 BCI-850C 细胞工厂 / CO2 培养箱、博奥思 Celrol Pro 滚瓶培养装置。

我要纠错

推荐专场

搅拌器、磁力搅拌器、电动搅拌器

更多相关方案

咨询

咨询