方案详情文

智能文字提取功能测试中

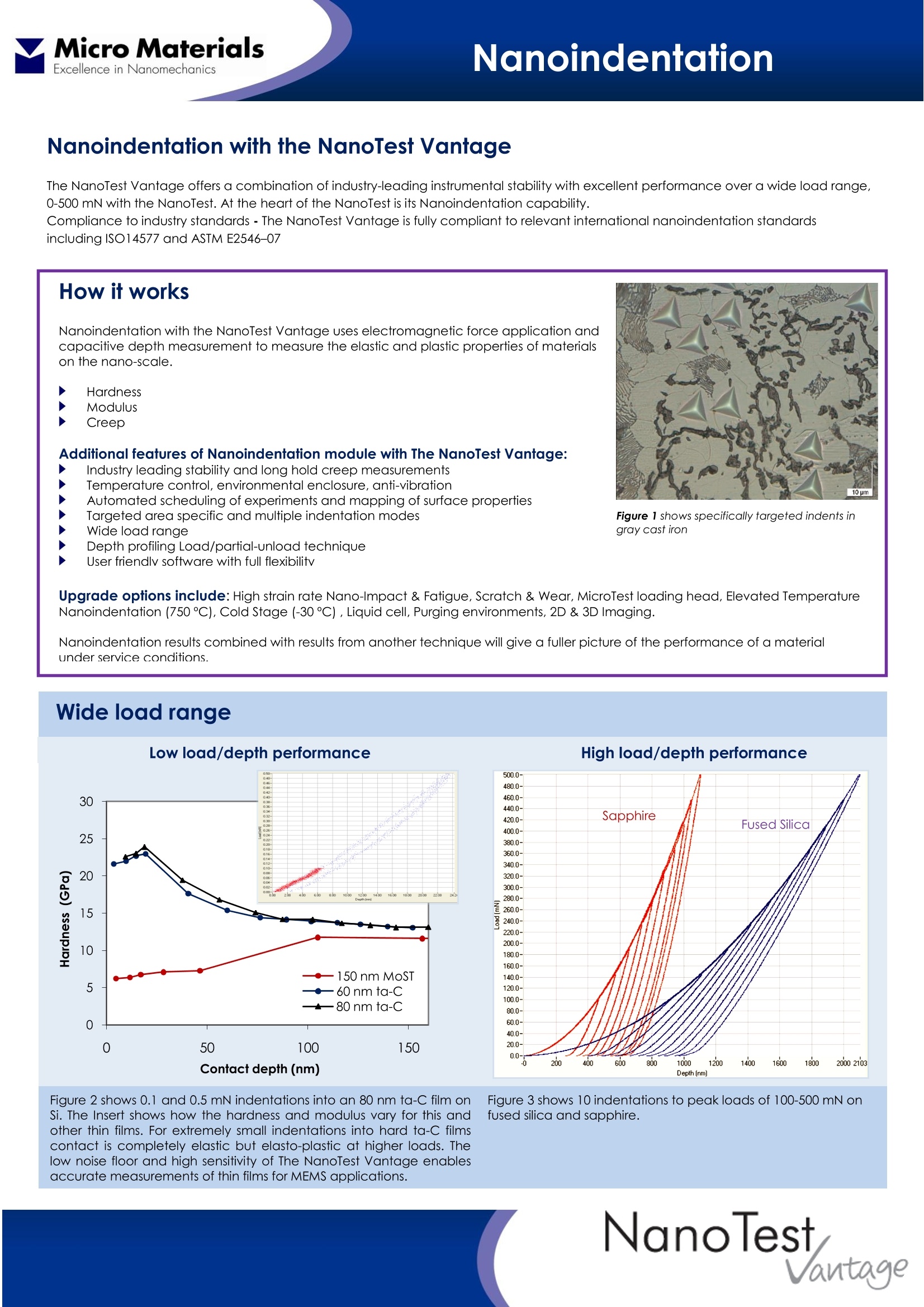

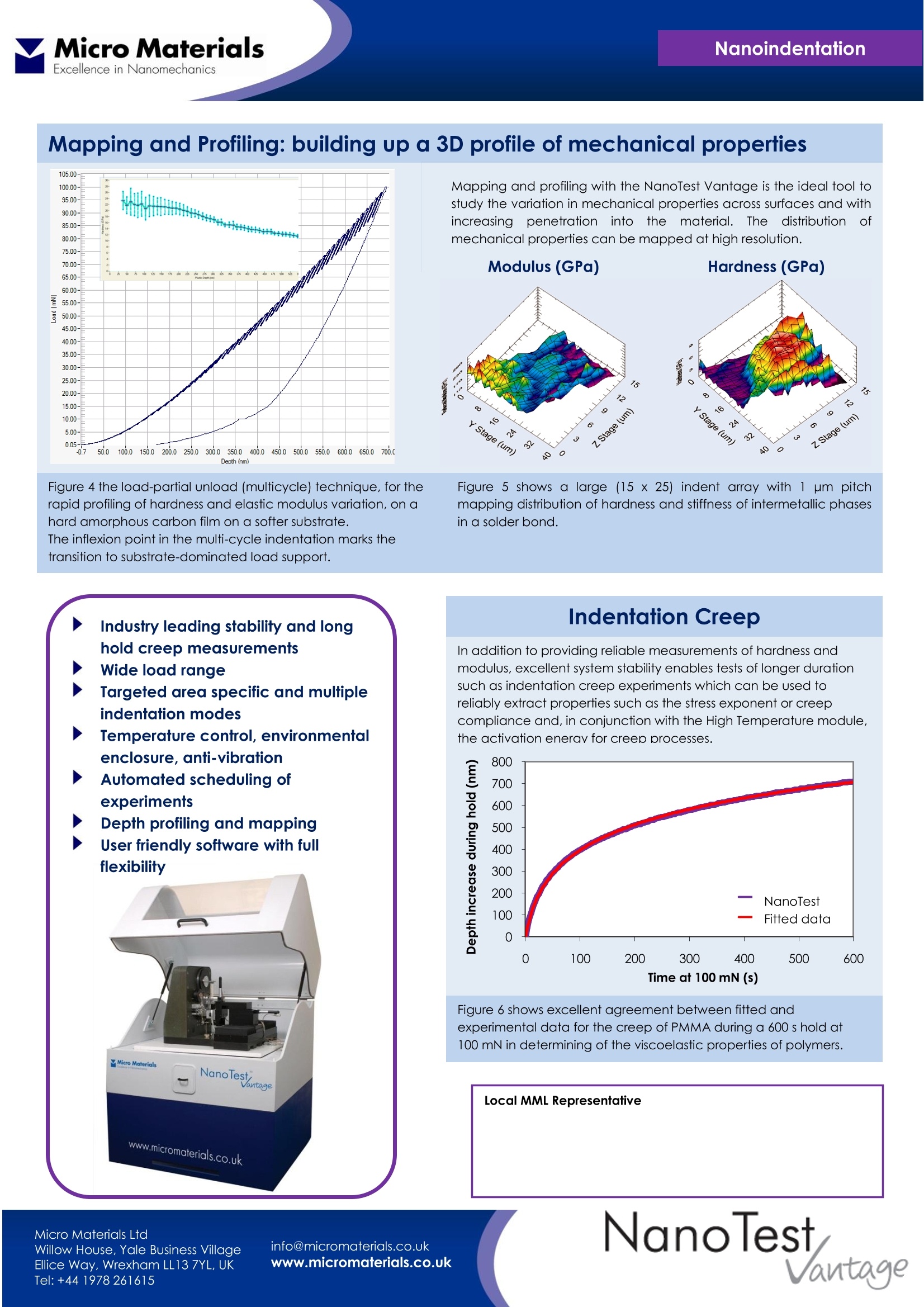

要评估在严重机械载荷下的材料力学性能,需要硬度和韧性的知识。即使硬质合金中粘结剂和碳化物晶粒尺寸的细微变化也会对刀具寿命产生巨大影响。在高性能冲压等应用中,控制疲劳性能的是表面下的力学性能。采用微压痕法可以测定不同硬质合金的力学性能。 NanoTest Vantage和Xtreme系统配备了30 N高负载头极大地扩展了系统的能力,可以覆盖纳米和微米范围。它可以单独配备高负载头,也可以与低负载头一起配备。对于双负载头系统,低负载和高负载头永久并排安装,允许轻松转移两者之间的样品。通常使用微压痕测试的材料包括硬质合金、金属、形状记忆合金。微压头可以在高温(最高850°C)或惰性环境中进行对以上材料进行微观硬度、微冲击和疲劳、微划痕和磨损等测试。 图1为WC-Co三种商品等级的塑性指标随荷载的变化情况。 图2微压痕数据与刀具寿命之间存在明显的直接关联。Micro MaterialsExcellence in NanomechanicsNanoindentation Nanoinde n tat i on wit h the NanoTest Vantage The NanoTest Vantage offers a combination of industry-leading instrumental stability with excellent performance over a wide load range,0-500 mN with the NanoTest. At the hear t of the NanoTest is its Nanoindentation capability. Compliance to industry standards - The NanoTest Vantage i s fully compliant to relevant i nternational nanoindentation standards including I SO14577 and ASTM E2546-07 How it wor k s Nanoindentation with t he NanoTest Vantage uses electromagnetic force application and capaci t ive depth measurement to measure the elastic and plastic proper ti es of materials on the nano-scale. Hardness Modulus Creep Addit i ona l feat u re s o f Nan o in d entatio n modu l e w it h Th e Nan o Te s t Vantage : Industry leading stability and long hold creep measurements Temperature control, environmental enclosure, anti-vibration 10 Automated scheduling of exper i ment s and mapping of surface properties Targeted area speci f ic and mult i ple indentation modes Wide load range Figure 1 shows specifically targeted indents i n gray cast iron Depth profiling Load/partial-unload technique User friendlv software with ful l flexibilitv U p grade o pt ion s in cl ude: High strain rate Nano-Impact & Fatigue, Scratch & Wear, MicroTes t loading head, Elevated Temperature Nanoindentation (750℃), Cold Stage (-30℃), Liquid cell, Purging environments , 2D & 3D Imaging . Nanoindentation results combined with resul t s from another technique will give a fuller picture of the performance of a material under service conditions. Wide load range Figure 2 shows 0.1 and 0.5 mN indentations i nto an 80 nm ta-C f ilm on Si. The Inser t shows how the hardness and modulus vary for this and other thin films. For extremely small indentations into hard ta-C films contact is completely elastic but elasto-plastic at higher loads. The low noise floor and high sensitivity of The NanoTest Vantage enables accurate measurements of thin films for MEMS applications. Figure 3 shows 10 indentations to peak loads of 100-500 mNon fused s ilica and sapphire. Mapping and Prof i ling : bui l ding up a 3D p r o fil e of mechanical p r ope r t i es Deot h (nm) Figure 4 the load-partial unload (multicycle) technique , for the rapid prof i ling of hardness and elastic modulus variation, on a hard amorphous carbon film on a softer substrate.The inflexion point in the mul t i-cycle indentation marks the transition to substrate-dominated load support . In du s tr y leadi n g stabil i ty a n d lo n g hol d c r eep me a su r eme n ts Wid e load rang e Ta rg ete d ar e a speci f ic and m u l t ip l e i nd ent at i on m odes T emper a ture c ontrol, env i ronme n ta l enclos u re , a n ti -v i b rat i on A ut omated sched u l i n g of e x pe ri me n t s De pt h profili n g a n d m ap p in g Us e r f rien dly softwa re with ful l Micro Materials Ltd Willow House, Yale Business Villag e Ellice Way, Wrexham LL13 7YL, UK Tel : +44 1978261615 info@micromaterials.co.uk www.micromaterials.co.uk Mapping and profiling with the NanoTest Vantage is the ideal tool to s t udy the variation in mechanical proper t ies across surfaces and with increasing penetration into the material. The distribution of mechanical properties can be mapped at high resolution. Figure 5 shows a large (15 x 25) i ndent array with 1 pm pitch mapping distribution of hardness and stiffness of intermetallic phases in a solder bond. Indentation Creep In addition to providing reliable measurements of hardness and modulus, excellent system stability enables tests of longer duration such as indentation creep experiments which can be used to reliably extrac t properties such as the stress exponent or creep compliance and, i n conjunction with the High Temperature module,the activation enerav for creep processes. Figure 6 shows excellent agreement between fitted and exper i mental data for the creep of PMMA during a 600 s hold at 100 mN in determining of t he viscoelastic proper t ies of polymers.

关闭-

1/2

-

2/2

产品配置单

北京正通远恒科技有限公司为您提供《纳米力学测试系统在硬质合金方面的应用》,该方案主要用于合金中机械性能检测,参考标准《暂无》,《纳米力学测试系统在硬质合金方面的应用》用到的仪器有纳米力学测试系统/纳米压痕仪 NanoTest Vantage。

我要纠错