方案详情文

智能文字提取功能测试中

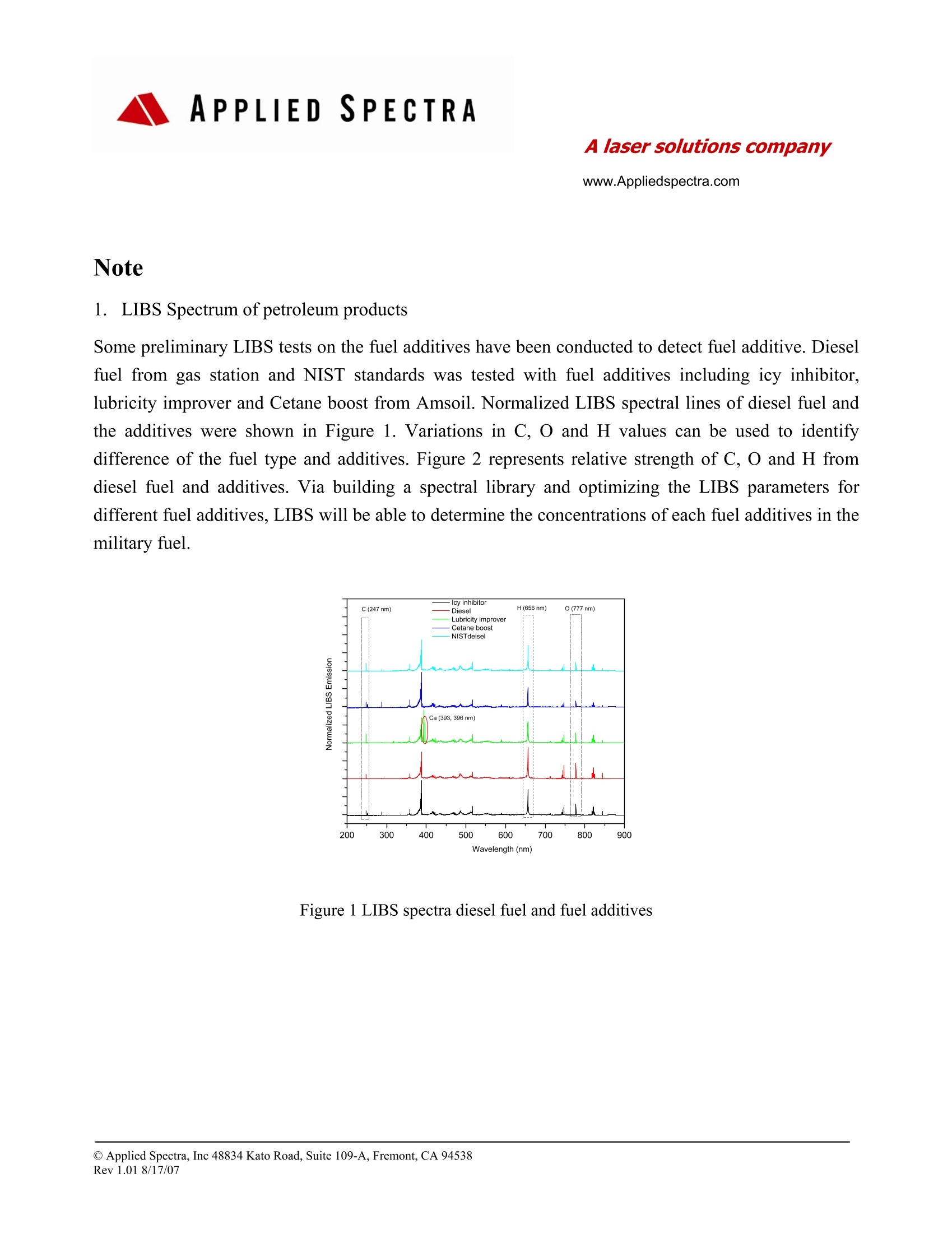

APPLIED SPECTRA A laser solutions company www.Appliedspectra.com Application Note # 1001Petroleum detection using LIBS technology Summary Ensuring proper fuel additive levels during fuel storage, distribution and usage as well as in the initialadditive injection processes is critical to good performance of the vehicles. Laboratory analysis of fuelproperties includes at least 100 ASTM POL specific test methods. Implementation of these analyticalsystems at the petroleum sites and transport lines can help identify fuel quality before use of theproduct. However none of the current employed methods are designed to detect dissolved particulatecontaminates. Furthermore, none of the current tests will assess additive concentrations, or monitoradjustment of these concentrations on an As Needed Basis. Applied Spectra performed LIBS test on various petroleum products and successfully demonstratedthe capability using LIBS to identify different petroleum products. LIBS tests was able to providethese testing capabilities, in real-time and without consumables. When bulk petroleum products aresampled by LIBS methodology and compared to a resident data base, a unique “Bar Code typesignature"helps to identify the materials of interest and their concentrations. Process A dedicated LIBS system was built to demonstrate several proof of concepts for LIBS for real-timepetroleum analysis without sample preparation. The work used an Echelle spectrometer withbroadband detection and enabled identification of carbon, hydrogen and oxygen as well as otherelements simultaneously. A Nd: YAG laser at the fundamental wavelength (1064 nm) delivered thelaser beam to the sample using an optical mirror. The laser-induced plasma was imaged onto theentrance slit of the spectrometer/ICCD system through an optical fiber. C, H and O are the major elements in the petroleum products; their LIBS spectral ratios providedistinct signatures for analysis. The LIBS signatures appear similar and difficult to discriminate byeye because of common spectral lines and bands. However, these LIBS spectra can be computeranalyzed to show differences. ( OA p plied Spectra, Inc 48834 K a to R o ad, Suite 1 0 9-A, F r emont, CA 94 5 38 ) ( Rev 1 .01 8/17/07 ) Alaser solutions company www.Appliedspectra.com Note 1. LIBS Spectrum of petroleum products Some preliminary LIBS tests on the fuel additives have been conducted to detect fuel additive. Dieselfuel from gas station and NIST standards was tested with fuel additives including icy inhibitor,lubricity improver and Cetane boost from Amsoil. Normalized LIBS spectral lines of diesel fuel andthe additives were shown in Figure 1. Variations in C, O and H values can be used to identifydifference of the fuel type and additives. Figure 2 represents relative strength of C, O and H fromdiesel fuel and additives. Via building a spectral library and optimizing the LIBS parameters fordifferent fuel additives, LIBS will be able to determine the concentrations of each fuel additives in themilitary fuel. Figure 1 LIBS spectra diesel fuel and fuel additives A laser solutions company www.Appliedspectra.com Figure 2 LIBS signal strength for C, O and H from diesel fuel and fuel additives 2.. Detection of impurities in petroleum products using LIBS LIBS easily verified the existence of vanadium in a crude oil sample from NIST (RM 8505). Theconcentration of vanadium in this sample was 390±10 ug/g (390 ppm). Figure 3 shows the measuredLIBS spectra for V in crude oil; all the V ion lines can be clearly identified. The detection limit (DL)can be determined as 40 ppm. Even for these preliminary experiments, we can measure ppm level ofmetal impurities in petroleum. Further optimization of the system will result in better performance. Figure 3 LIBS spectra of NIST RM 8505 crude oil at center wavelength ( C A pplied Spectra, Inc 48834 K ato R oad, Suite 1 09-A, F remont, CA 9 4 538Rev 1.01 8/17/07 ) A laser solutions company www.Appliedspectra.com 3.. Sample identification APartial Least Square Discrimination (PLSD) algorithm is used to discriminate the differentpetroleum and additive components. The table shows our preliminary validation of LIBS foridentifying typical additives: Training Sets Test Sample alcohol Diesel Lubricant additive Methanol Motor Oil Cetane Booster alcohol 0.597647 0.005531 -0.09782 0.29348 -0.03297 0.234125 Diesel -0.07689 1.155526 0.042903 -0.07933 -0.01942 -0.0228 L lubricant additive -0.31801 0.072139 0.72058 0.291005 0.077979 0.156307 methanol 0.30008 0.062214 0.085423 0.713371 0.00651 -0.1676 Motor oil 0.162648 0.066277 0.009905 -0.2451 0.966647 0.039618 Cetane Booster 0.228905 -0.15144 0.162901 -0.40867 0.093119 1.075182 The numbers in the table represent the similarity of the test sample to the training set; values close toone represent a match. Alcohol and methanol have very similar signatures (Figure 2) yet thealgorithm was able to discern the differences.The identification algorithm is still in thedevelopment stage for further accuracy improvement. 4. Comparison of LIBS signatures in lubricants LIBS spectra were measured from new and used motor oil, and show difference in the primaryspecies making up the molecular structure. The used oil was from a 2003 vehicle with ~5000 milesbefore the oil change. Figure 4 shows broadband LIBS spectra. Metal residues are commonly found inused motor oil. Mg was present in the new motor oil, but a significant difference in the ratio ofelements and strong Mg line emission in the used motor oil is obvious. These data demonstrate thepotential of LIBS as the tool to perform oil sample property test and determination of metalwear in the power system. LIBS measurements also were made from four different commercial motor oil samples (Chevron,Shell, Valvoline and Mobil) with grade of 10W-30. The normalized (by the strongest CN intensity)spectra are shown in Figure 5. As plotted in the figure, although the strength of CN and C2 spectral ( C A pplied Spectra, Inc 48834 K ato R oad, Suite 1 09-A, F remont, CA 9 4 538Rev 1 .01 8/17/07 ) A laser solutions company www.Appliedspectra.com peaks was similar, the difference in the element peaks was significant. For example, only Mobil motoroil contained Na, not the other three. Chevron motor oil produced the strongest peaks for O, N and H,but did not contain Mg. All four motor oils contained calcium; the Ca peaks in the Valvoline motoroil were the strongest (almost double the line intensity compared to the other three brands). Using thesame algorithm, the four different motor oil can be easily identified (Table 2). (a) Figure 4 LIBS of clean and used motor oil. (a) Broadband and (b) high resolution. Figure 5 LIBS of different motor oil. ( C A pplied Spectra, Inc 48834 K ato R oad, Suite 1 09-A, F remont, CA 9 4 538Rev 1 .01 8/17/07 ) A laser solutions company www.Appliedspectra.com Training Sets Test Sample Chevron Mobil Shell Valvoline Chevron 0.910115 0.030373 0.060773 -0.001260 Mobil 0.045872 1.098783 0.136103 -0.280757 Shell 0.277781 -0.035519 1.162941 -0.405203 Valvoline -0.088101- 0.124879 0.007161 0.970383 Table 2. Matching coefficients for each motor oil sample type against different training sets. Conclusion In the preliminary tests, Applied Spectra demonstrated LIBS can successfully detect ppm levels ofcontaminants and fuel additives in the petroleum products. Fuel qualities can be monitored by LIBStechnology for improving vehicle performance. LIBS applications in petroleum products can be usedboth in storage facilities and field vehicles. C Applied Spectra, Inc Kato Road, Suite A, Fremont, CA ev . 图1 柴油燃料和燃料添加剂的LIBS光谱图2 柴油燃料和燃料添加剂中C、O、H的LIBS信号强度在初步测试中,应用光谱证明了LIBS可以成功检测石油产品中含量为ppm级的污染物和燃料添加剂。燃料质量可以通过LIBS技术监测用以提高车辆性能。LIBS可用于存储设备和现场车辆。

关闭-

1/6

-

2/6

还剩4页未读,是否继续阅读?

继续免费阅读全文产品配置单

北京富尔邦科技发展有限责任公司为您提供《石油产品中元素检测方案(激光诱导击穿)》,该方案主要用于原油中含量分析检测,参考标准《暂无》,《石油产品中元素检测方案(激光诱导击穿)》用到的仪器有美国ASI 激光诱导击穿光谱仪(LIBS)。

我要纠错

推荐专场

相关方案

咨询

咨询