方案详情文

智能文字提取功能测试中

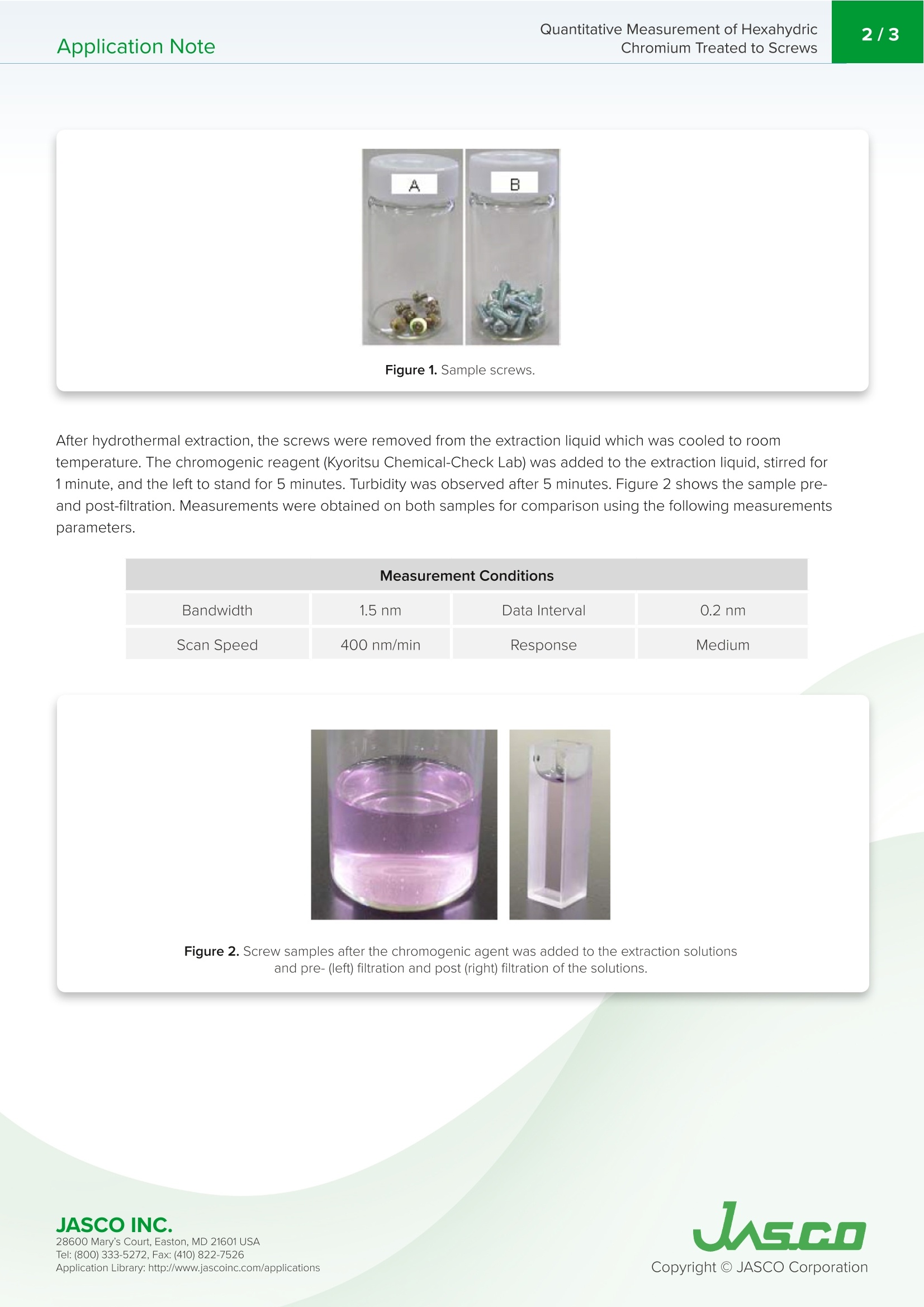

通过水热萃取法从两个钢螺钉中提取铬。将螺钉置于25mL纯化水中,并在80摄氏度下加热30分钟。这些条件可能会根据样品类型和法规遵从性而发生变化。Application Note Quantitative Measurement of HexahydricChromium Treated to Screws2/3 UV-0015 Quantitative Measurement of Hexavalent Chromium Treatment to Metal Screw s In t ro d uc t ion Hexavelent chromium (Cr(VI)) is a sign i ficantly hazardous material regu l ated by OSHA wi t h r efe r ence to 29CFR p arts 1910 a nd 1915, by RoHS direct i ve, and by I EC -62321wh i c h st r ictly con t rols and reg u lates the use of specif i c h azardous materials in a wide range o f industr i al processes as well as electr i cal and electronic products. This application n ote descr i bes the extraction and q u anti f ication of residual chromium from the treatment o f two samples of screws us i ng a chromogenic reaction and UV-Visible spectroscopy. V-630 UV-Visible Spectrophotomete r The chromium f r om two steel screws (F i gure 1) was extrac t ed via Hydrot h ermal Extract i on. T h e screws were p laced in 25 mL of pu rif ied wate r and heated at 80 degrees Cels i us f or 30 minutes. These cond iti ons are sub j ect to cha n ge dependi n g on t h e samp l e type a n d regulatory compliance Keywords V-630,U V -V i si bl e/NIR , M a t e ri a l s, IE C-62321, 29C F R p ar t 1910, 29C F R p a r t 1915 Exper i mental T h e chrom iu m f r om t wo steel sc r e ws (Fig u re 1) was e xtra c t ed via Hydrot h ermal Ext r ac ti on. The screws were placed i n 25 mL of puri f ied water and heated at 80 degrees Celsius for 30 minu t es. These co n ditions are subject to change depe n ding on the chromium coati n gs for a par t icular sc r ew. Appl i c a t i on Note Figure 1. Sam p l e s cr ew s. Afte r hydrot h ermal extra c t i on, the screws were removed f rom the extract i o n liq u id which was cooled to room temperatu r e. The chromogen i c r eagent (Kyoritsu Chem i cal -C h eck Lab) was added to the ext r action liquid, st i rred for 1 minute, and the l eft to stand for 5 mi n utes. Turbidity was observed after 5 m i nutes. Fig u re 2 shows t h e sample pre-and post-filtration. Measurements were obtained on both samples for compar i son using the f ollowing measurements parameters. Measurement Conditions Bandwidth 1.5nm Data Interval 0.2nm Scan Speed 400 nm/min Response Medium Figure 2. Sc rew samp le s af ter t h e chro m og eni c ag en t w as a dde d t o t he e xtr a ction solution s and p r e- (le ft ) f ilt ra ti on an d post (r igh t) filt r atio n o f t he sol u t ions . 28600 Mary's Cour t , E a s to n , M D 21601US A UASGO A ppli c a tio n Lib r ary: htt p://www.jas co in c .c o m/a pp l icatio n s Res ul ts The spec t ra of t he samples before a n d after f iltrat i o n are i l lustra t ed in F i gure 3. T he s p ec t r u m of t h e sample before filtra t ion shows a highe r b asel in e, which i s due to the dispe r sion o f interferin g substa n ces in t h e solu t ion. A t h ree wavelength quant i tative analysis was performed to conf i rm the effects of the interfe r i ng substa n ces. Table 1 shows t he results of the peak height calcu l at i ons. Rega r dless of the pretreatment, almost identical results we r e obtained. Figure 3. A b s or pt ion spect ra of s a m pl es A a nd B bef or e (p ur p l e) a n d a f ter (b lue) f i l t ra tio n . Table 1. P e ak h eight calc ul at i o n r e s ul ts of scr e w s am pl e s A and B . Sample A Sample B Before After Before After 1 Wavelength Abs at 542 nm 0.10393 0.09288 0.06365 0.04482 3 Wavelength Peak height: 542 nmBase: 402, 635nm 0.08782 0.08765 0.03932 0.03915 Three wave l e n gth qua n titative a n alysis was examined on the p eak h eight calc u lated with p e a k wave l ength at 402nm and a base wavelength at 635 a nd 542 nm. The calibration c u rve obtained by the diphenylcarbazide method i n Application Note UV-0004 was appl i ed to t h is quan ti tative analysis. Table 2 shows the concentration of Cr (VI) for samples A and B using a two-sided 95% confidence interval and both samples A and B fall wi th in ±0.005 mg/L of the conf i dence i nte r val . Table 2. Qu an tit a t i v e r e s ults o f C r (Vl ) i n s c r e w sa m p l e s. Sample A Sample B Before After Before After 0.135±0.006 mg/L 0.135±0.006 mg/L 0.059±0.005 mg/L 0.059±0.005 mg/L JASCO INC. 28600 Mary's Cour t , E a s to n , M D 21601US A

关闭-

1/3

-

2/3

还剩1页未读,是否继续阅读?

继续免费阅读全文产品配置单

佳士科商贸有限公司为您提供《金属螺钉六价铬处理的定量测定》,该方案主要用于金属材料基复合材料中定量测量、金属材料检测,参考标准《暂无》,《金属螺钉六价铬处理的定量测定》用到的仪器有jasco紫外可见分光光度计 V-700。

我要纠错

推荐专场

紫外、紫外分光光度计、紫外可见分光光度计、UV

更多相关方案

咨询

咨询