葵花籽压榨饼蛋白质和脂肪含量,干酪乳清蛋白质含量的检测

检测样品 其他食品

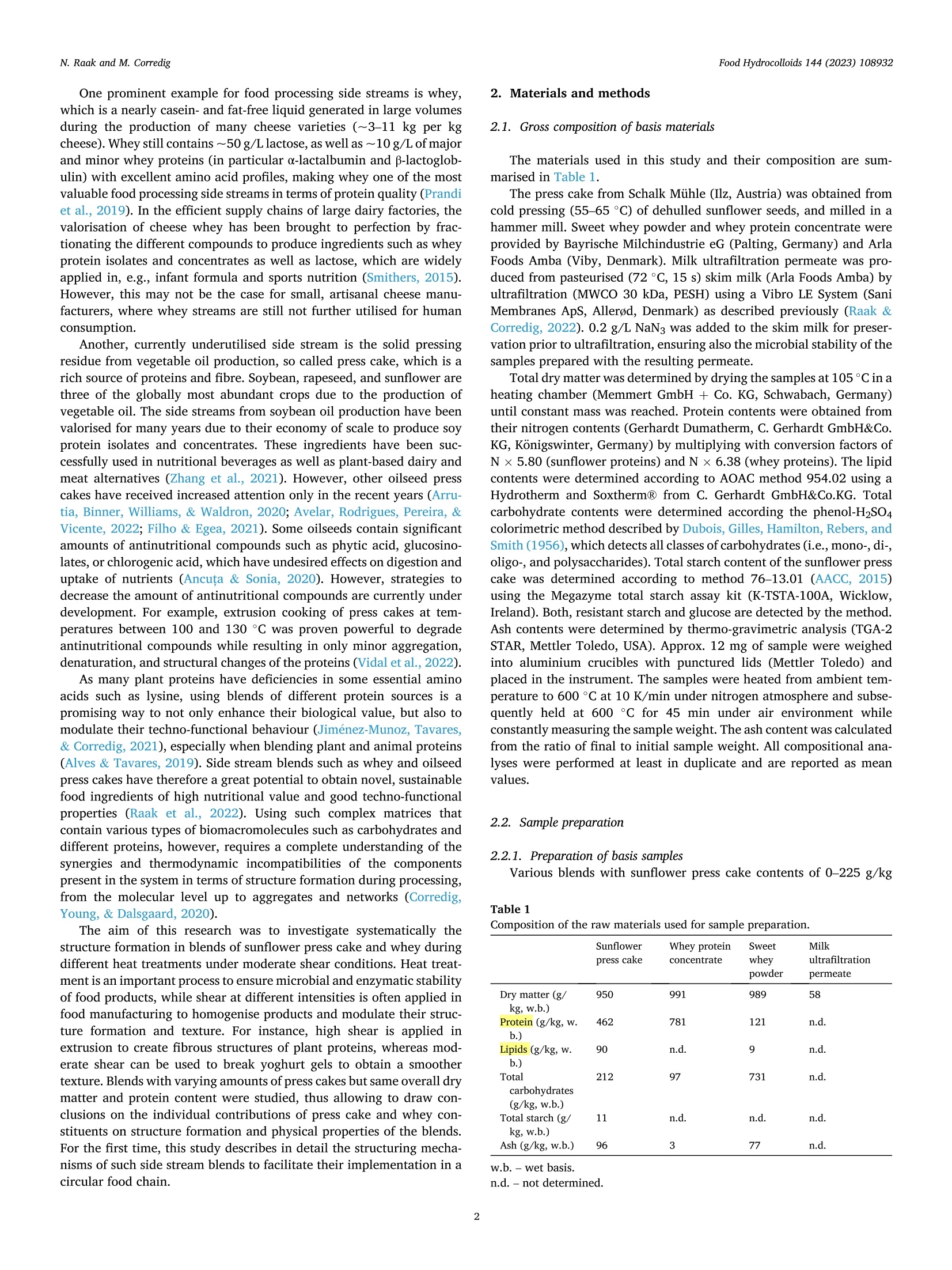

检测项目 营养成分

参考标准 GB 5009.5 食品安全国家标准 食品中蛋白质的测定

方案详情文

智能文字提取功能测试中