锤子

简介:

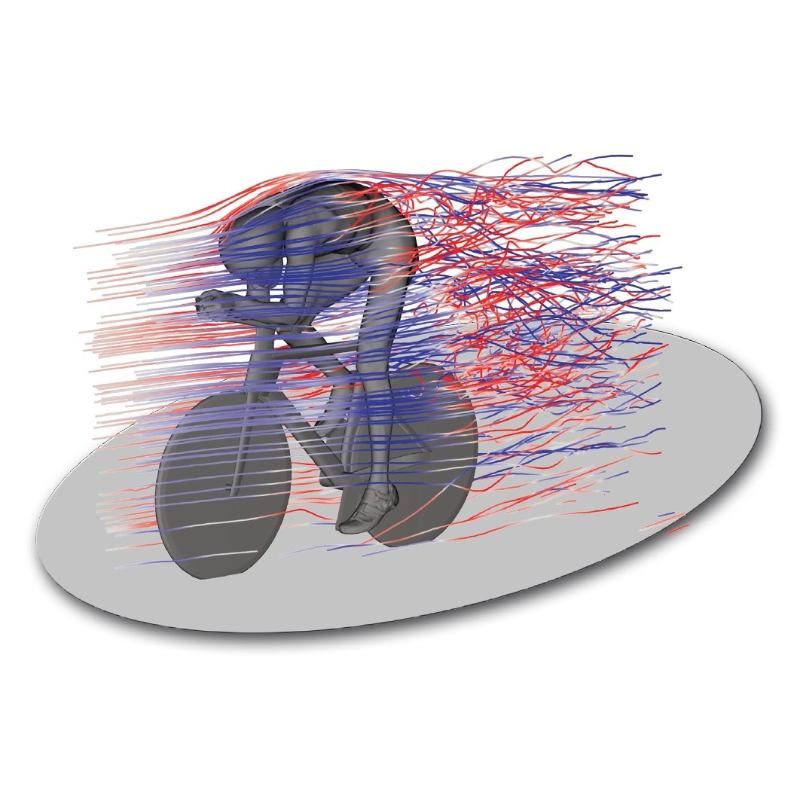

Electrostatic, rotating bell (ESRB) application is one of the most important coating application techniques for industries with demanding specifications for optical attractiveness of coatings, such as automotive. The ESRB process involves production of droplets using a high-speed rotating bell, which are subsequently transported to the substrate being coated via shaping air [1-3]. An electrical potential is applied between the bell and the substrate which further helps droplet atomization and transport. This research investigates the effects of inertia, centrifugal force, drag force, and electrostatic force on the atomization mechanism and particle size distribution using an automotive OEM base coat formulation. Coating flow rate (CFR), shaping air flow rate (SAFR), bell speed (BS), and electrostatic potential (EP) were used as primary parameters to create various atomization conditions and particle size distributions. The atomization mechanism, ligament formation, and particle size distribution were measured using high-speed laser shadowography and image processing. The effects of governing forces and particle size generated on efficiency of droplet transfer to the substrate and optical appearance of the coatings were studied to generate operating windows for optimum process efficiency and appearance.

打开失败或需在电脑查看,请在电脑上的资料中心栏目,点击"我的下载"。建议使用手机自带浏览器。

相关产品更多>>

下载该资料的还下载了

推荐学习更多>>

- 注意:

- 1、下载文件需消耗流量,最好在wifi的环境中下载,如果使用3G、4G下载,请注意文件大小。

- 2、下载的文件一般是pdf、word文件,下载后如不能直接浏览,可到应用商店中下载相应的阅读器APP。

- 3、下载的文件如需解压缩,如果手机没有安装解压缩软件,可到应用商店中下载相应的解压缩APP。