全自动裂变径迹成像及分析系统-版本4

Training Module (New) 软件部分培训模块(新) A major new feature is a training module that overlays results from a “teacher” on those obtained by a novice at fission track analysis.(一个主要的特点是培训模块,在裂变径迹分析方面,它能用新手的分析结果覆盖原来的版本。) Discrepancies are automatically highlighted for correction, comment of discussion. (能够自动高亮以显示更正的地方及点评。) The system greatly facilitates training of new analysts. (此系统大大地提高操作者的分析技能。) Automated Length Measurements (New) 长度自动测量(新) A major advance in Version 4 is the inclusion of new tools for measurement of track lengths. (版本V. 4中新增了轨迹长度测量的新工具的内容。) For the first time measurement of 3D semi-track lengths is now possible. (现在,它使首次的3D 跟踪,样品表面下的长度测量成为可能。) An automated confined track measurement tool is also available.(还配备了约束全径迹自动测量工具方便使用。) These tools are aided by a new 3D cross-section Window that enables a vertical slice through the image stack to be examined. (这些工具借助于一个3D的横截面视窗,使一个垂直薄片在通过图像层积时能够被检测到。) Automated Scratch detection (New) 自动划痕检测 (新) Etched polishing scratches remain problematic in some etched apatite grains, and can interfere with automatic counting. (在一些风化的磷灰石硬粒上,被风化且抛光的划痕会对自动计数产生影响。) Now polishing scratch features can be detected automatically and deleted automatically after inspection. (现在, 有抛光的划痕特征的痕迹可被自动探测并在检测后被自动删除掉。) |

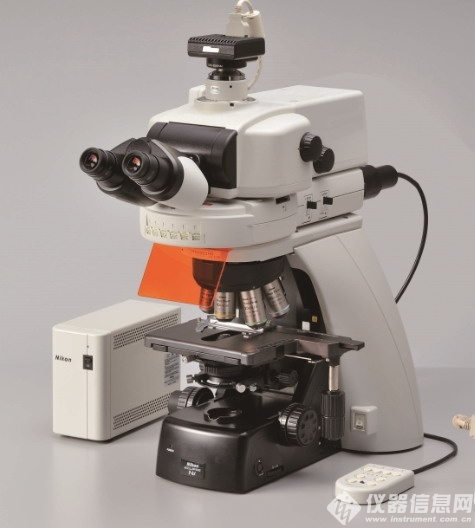

Track Studio Suite Version 4 径迹工作室套装 V4版本 The Melbourne Thermochronology Group, with Autoscan System Pty Ltd are pleased to announce a major upgrade to Version 4 of their digital image-based Fission Track Studio Suite, comprising the microscope control and image acquisition system TrackWorks 4, and the automated and computer-assisted fission track and analysis system FastTracks 4 . (墨尔本热年代学集团 与Autoscan System Pty Ltd一同愉快地宣布,他们的基于数码成像的裂变径迹工作室套装升级到V4版,包括显微镜控制及图像采集系统TrackWorks 4 和自动的计算机辅助的裂变径迹及分析系统FastTracks 4.) Version 4 is a major upgrade that includes many new improvements and additional features in the core software system, as well as several new advanced Extension Modules, in addition to those Extensions available with Version 3 of the Suite. (V4版主要是对核心软件系统进行升级, 包括很多新的改进及额外的特征 , 以及几个新的先进的扩展模块, 除了那些扩展模块套装的V3版也可使用。) Version 4 also takes advantage of new developments in hardware capabilities, in particular the integration of a new generation of very fast, high-resolution digital microscope cameras, and advanced stages that dramatically improve system performance. (V.4 在硬件能力上也有所提升,尤其是 新一代快速高清晰度的数码显微镜照相机的整合,及先进的载物台引人注目地提升改进系统的表现。)

|

Features from Vers 4Vers 4 特点 Fully automatic advanced optical metallographic microscope 全自动高级光学金相显微镜 1. 2.5X, 5X, 10X, 20X, 50X, 100X high-precision new standard EC objective lenses. (1. 2.5X、5X、10X、20X、50X、100X 高精度新标准 EC 物镜.) 2. Wide field binocular observation, 10x/23 high eye points, with visual compensation eyepiece. (2.宽视场双目观察,10x/23 高眼点,带视度补偿目镜.) 3.7 The hole alignment objective lens converter contains position coding, and the objective lens can be aligned and adjusted to increase the space of standard magnification. (3.孔对中物镜转换器含位置编码,物镜可对中调节,增加标准放大倍数空间.) 4. Automatic driving and focusing in the Z-axis direction, with the same step pitch, can be precise up to 10nm. (4. Z 轴方向上自动驱动和调焦,相同步距,可精确到 10nm.) 5. A transparent and reflective light system with independent light sources. The universal achromatic lighting device for transmitting and reflecting light has a 6-digit automatic function converter, which has the functions of observing the reflected light field, observing the transmitted light field, and reserving functional positions. (5.带独立光源的透、反射光系统。透反射光万能全消色差照明器具有6位自动功能转换器, 具有反射光明场观察功能、透射光明场观察功能和预留功能位置. High precision two axis automated loading platform 高精度两轴自动化载物台 1. Electrification of microscope XY stage, with a stroke of 75 mm × 50 mm. (1.显微镜 XY 载物台电动化,行程 75 mm×50 mm.) 2. Resolution of 0.1 μ m, repeatability+/-1 μ m. (2.分辨率 0.1μm,重复性+/-1μm.) 3. Equipped with an electric mobile handle. (3.具备电动移动手柄) High precision digital color camera\ 高精度数字化彩色相机 1. CMOS image sensor with a resolution of not less than 4.19 million pixels (2048 × 2048) and a transmission speed of not less than 40fps. (1.CMOS 图像传感器,分辨率不低于 419 万像素(2048×2048), 传输速度不低于 40fps.) 2. Synchronized display, continuous and lag free images, real-time full field preview without delay. (2.同步显示,图像连续、无滞后,全视野实时无延迟预览.) 3. Equipped with image acquisition software that supports real-time and synchronized image capture. (3. 配备图像采集软件,支持实时采集、同步捕捉图像.) Anti vibration table 防振台 Load capacity: 55-90 pounds, horizontal resonance frequency: 6.3 Hz, vertical resonance frequency: 6.8 Hz, damping mode: active 负载能力:55 - 90 磅,水平共振频率:6.3 Hz,垂直共振频率:6.8 Hz,减震方式:主动; | Core Features of Version 4V.4版本的核心特征 Version 4 includes many improvements to the user interface and performance that make the new system a pleasure to use. (包括对用户界面及表现进行的很多改进-使得新系统乐于被人们使用。) Fully automated control of microscopes, scanning tables, and image acquisition systems, enabling manual and/or automatic completion of mineral fracturing Variable diameter trace recognition and quantity statistics; Measure the length of fission tracks and calculate their distribution characteristics; Identify C-axis and measure Dpar and Dper Parameters (可对显微镜、扫描台和图像采集系统的完全自动化控制,实现人工和/或自动完成矿物的裂 变径迹识别、数量统计;测量裂变径迹长度、统计其分布特征;识别 C 轴和测量 Dpar、Dper 参数。) Specific features include: (突出的新特征包括:) 1. Export coordinate systems in multiple formats for use in other positioning systems such as laser ablation, electron probes, etc. (ASI RESOLUTION), NewWave laser ablation system, Cameca electron probe, Horiba XploRA plus Raman spectrometer, etc。 [导出多种格式的坐标系统,用于其它定位系统如激光剥蚀、电子探针等(ASI RESOlution 和 NewWave 激光剥蚀系统、Cameca 电子探针、Horiba XploRA plus 拉曼仪等)] 2. Automatically identify and remove scratches during the sample preparation process. (自动识别和清除制样过程中的擦痕) 3. Automatic detection and sorting of apatite particles suitable for fission track counting. (自动检测与分选适用于裂变径迹计数的磷灰石颗粒.) 4. Obtain holographic 3D images of the sample, suitable for EDM and LA-ICP-MS. (获取样品全息三维图片,适用于 EDM 和 LA-ICP-MS) 5. Based on the processing and matching fusion technology of reflected and transmitted light images, a complete set of track recognition and measurement tools, to achieve radial detection Offline measurement of traces. (基于反射光和透射光图像的处理和匹配融合技术、齐全的径迹识别和测量工具,实现径 迹的离线测量.) 6. Image magnification inspection function, used for identifying tracks or manually checking automatically identified tracks and measurements. (图像放大检视功能,用于识别径迹或手工检查自动识别的径迹、测量) 7. has a training module. (具有培训模块) 8. Manual and automatic measurement of 3D radius trace length and direction, as well as profile inspection function. (手工和自动测定 3D 半径迹长度和方向、剖面检视功能) 9. Automatically calculate the true three-dimensional direction closed fission track length relative to the C-axis. (自动计算相对于 C 轴的真实三维方向封闭裂变径迹长度) 10. Automatic recognition of C-axis and measurement of Dpar and Dper parameters, automatic calculation and analysis of results. (自动识别 C 轴和测量 Dpar 和 Dper 参数,自动计算和分析结果) 11. Automatic puzzle function. (自动拼图功能)

|

15天

1月

暂无此项服务;额外提供免费培训

36小时内

否

1天内

否

7天

1月

否

否

是

是

是

是

先维修后付款

维修手册

不支持

定制化生产销售型

相关产品

仪器对比

仪器对比

关注

关注

样本下载

样本下载