EDX-9000A XRF 光谱仪

能量色散X荧光光谱仪---

铜合金分析仪

>从 1ppm 到 100wt% 的快速无损多元素分析

>可测量固体、液体、粉末和薄膜的厚度

无需处理,测试的格式和大小没有限制

样本

>用户友好的界面,易于使用的软件

>低成本,无限的客户支持

概述:

EDX9000A能量色散荧光光谱仪-合金牌号分析专家

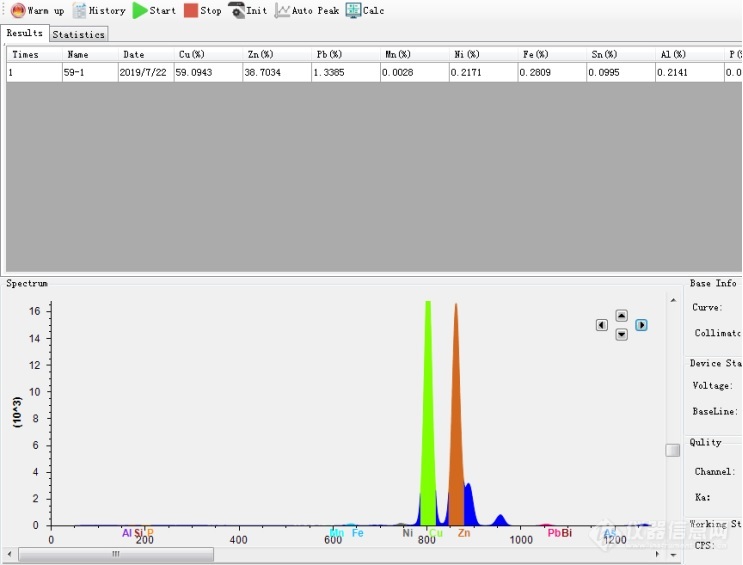

合金分析是识别样品化学成分的过程。使用X射线荧光(XRF)光谱仪不仅可以快速确定合金牌号PMI(Positive material Identification),而且可以准确获得整个合金材料的元素组成。 EDX9000A已广泛应用于需要合金成分分析的各个行业,从航空航天测试、原材料分析、质量控制、冶炼、金属加工、焊接,到废料回收和快速分类筛选。

使用实验室质量的分析仪器并使它们更接近工作现场是科学家和产品开发人员不断发展的目标。对于许多工业应用,尺寸和

速度的提高减少了对实验室测试的需求,并提高了现场人员最大限度地利用新开发技术的能力。XRF 光谱法正好属于这一类。新技术允许用户在几秒钟内得到答案,根据他们的发现做出决定,并避免昂贵且耗时的实验室之旅。无需等待数天来验证材料中的合金成分,工作现场的 QA/QC 操作员将当场知道产品是否合格。

特征

EDX-9000A作为一款专为合金元素分析而设计生产的光谱仪,兼顾耐用性、操作简便和高性价比。其显着优势主要包括

以最少的样品制备进行无损检测

快速分析 - 数据可在几秒钟内获得

操作便宜:无需专门的科学家即可由新手操作员操作

多功能技术可适应不同类型的基质样品

同时分析大多数金属元素

广泛接受的工业验证测试方法

高清内置摄像头,清晰显示仪器检测到的样品位置

>仪器规格

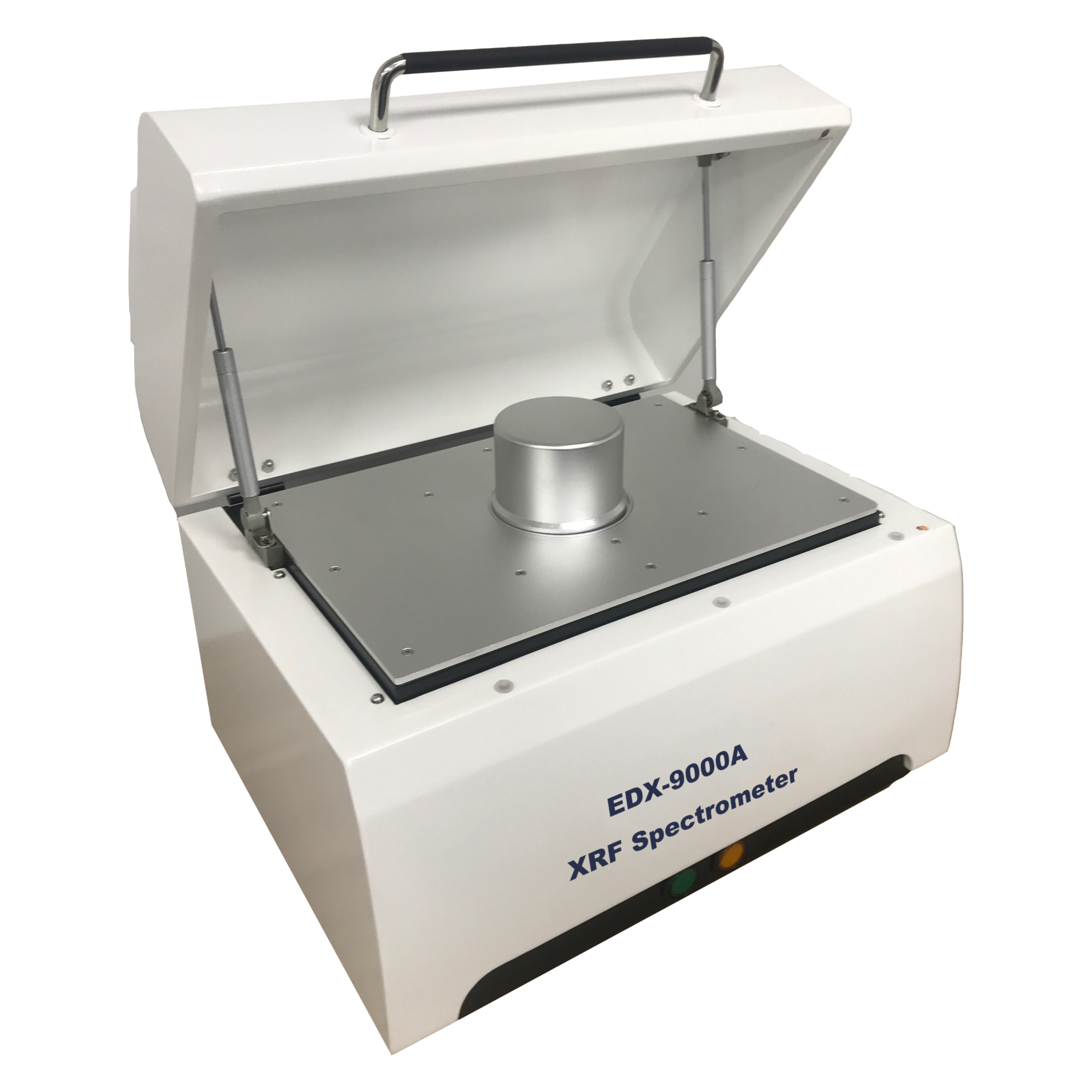

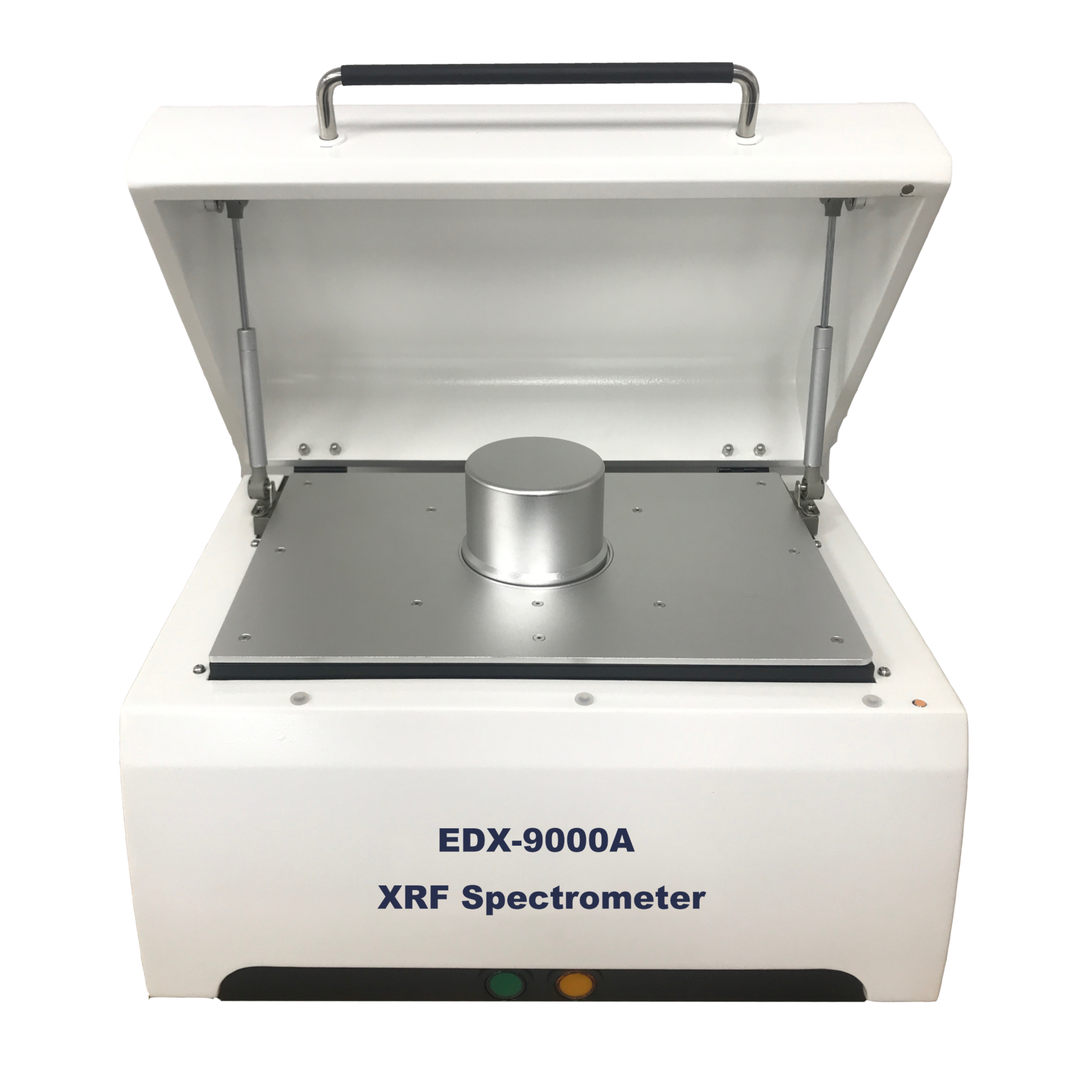

光谱仪尺寸:560mm*380mm*410mm

样品室尺寸:460mm*310mm*95mm

真空样品室尺寸:Φ150mm×高75mm

重量:45Kg

元素范围:Na11-U92

分析含量范围:1ppm- 99.99%

检测器:AmpTek高分辨率SDD

DPP分析仪:4096通道DPP分析仪

激发源:50W X射线管

高压机组:0-50kV

电源:220ACV 50/60HZ

环境:-10 °C 到35 °C

配饰

>标准 >可选

Ag-校准标准功率稳定器

真空泵合金标准样品

样品杯

USB电缆

电源线

测试麦拉

校准报告

保修卡

什么是 XRF 荧光光谱仪?

X 射线荧光涉及使用专业仪器通过将 X 射线束对准不同材料来分析不同材料。

名称中的荧光部分是指某些物质在接收 X 射线束时产生的辐射。

XRF 是一种分析技术,根据被分析材料中存在的元素,X 射线会给出不同的读数。

这种形式的分析是光谱分析:

光谱测量物质或材料与电磁波谱之间的相互作用

电磁波谱由不同波长的可见光、无线电波和 X 射线组成

电磁辐射是具有这些不同形式的能量,当原子吸收能量时就会发生,这会改变它们的电子行为。

一切都是由原子组成的,因此所有材料都应该发出电磁辐射。

因此,这提供了一种分析其中内容的方法。

XRF 可以提供元素的定量和定性分析,浓度范围从百万分之几 (ppm) 到更高的量。

这种分析适用于固体、液体和粉末。

EDX-9000A XRF Spectrometer

Energy Dispersive X Fluorescence Spectrometer---

Alloy Analyzer

Simply the Best

>Fast and Non-destructive multiple elements analysis from 1ppm to 100wt%

>Thickness measurement of solid matter, liquid, powder and thin film is possible

without processing and there is no restraint in terms of format and size of a test

sample

>User friendly interface, Easy of use Software

>Low cost with unlimited customer support

Overview:

EDX9000A Energy Dispersive Fluorescence Spectrometer-Expert of Alloy Grade Analysis

Alloy analysis is the process of identifying the chemical composition of a sample. Using X-ray fluorescence (XRF) spectrometer not only can quickly determine the alloy grade PMI (Positive material identification), but also accurately obtain the element composition of the entire alloy material. EDX9000A has been widely used in various industries that require alloy composition analysis, from aerospace testing, raw material analysis, quality control, smelting, metal processing, welding, to scrap recycling and rapid classification and screening.

Taking lab-quality analytical instruments and bringing them closer to the job site is an evolving objective for scientists and product developers. For many industrial applications, size and

speed improvements have reduced the need for laboratory testing and have increased the ability for personnel in the field to maximize the use of newly developed technology.XRF spectroscopy is squarely in this category. New technology allows users to get answers within seconds, make decisions on their findings, and avoid costly and time-consuming trips to the lab. Instead of waiting days to verify the alloy composition in a material, QA/QC operators at the work site will know on the spot whether the product is qualified.

The ESI XRF spectrometer can be widely used in the application fields:

-Alloy/scrap metal analysis. Extinguish different type of stainless steel of 304/316/321 by analyzing the metal content in the sample within 3 seconds.

-Sulfur/metals in oil/lubricant complying with ASTM-D4294(EDXRF), ASTM-D7039(WDXRF), ASTM-D2622(WDXRF), ASTM-D5453(UVF), ISO 8754(EDXRF)

- Jewelry/ precious metal. Identify the karat of the gold (9k, 14k, 18k, 22k etc.) sample in one second

- RoHs compliance (Cr, Cd, Pb, Hg, Br, As, Se, Sb, Bi). Fast screen the 8 heavy metals restricted by XRF spectrometer within 2 minutes per sample.

- Mineral and mining. Copper and gold mining exploration by bringing the handheld XRF to test the Cu and Au content in the field.

-Soil heavy metal pollution measurement.

-Coating/Plating thickness measurement- Non-destructive XRF analysis of both coating thickness and coating material concentration analysis

At the same time, ESI xrf element analyzer are also popular in the industries cement, clinker and cement materials, chemistry, cosmetics, education and scientific research, environment pollution,food and food ingredient,forensics and conservation ,plastic and rubber,process control, car and catalyst, semiconductors and etc.

EDX9000A is easy to operate, has excellent analytical performance, and can be extended to the following applications

>Coating thickness and film: analysis of multi-layer coatings, steel coatings, impurities, etc.

>Plating bath element analysis

>Analysis of catalyst precious metal elements

Features

As a spectrometer specially designed and produced for alloy element analysis, EDX-9000A takes into account durability, easy operation and high cost performance. Its significant advantages mainly include

Non-destructive testing with minimal sample preparation

Fast analysis – data is available in seconds

Inexpensive operation: can be run by novice operators without dedicated scientist

Versatile technique can accommodate different types of matrix samples

Simultaneous analysis of most metallic elements

Widely accepted industrial verification testing method

High-definition built-in camera, which clearly shows the sample location detected by the instrument

1年

是

有

1人次技术培训

1年一次

免费更换零件

4小时内响应,48小时上门

相关产品

仪器对比

仪器对比

关注

关注