雾化形成在静电旋转钟镀膜中的应用

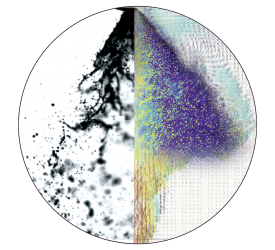

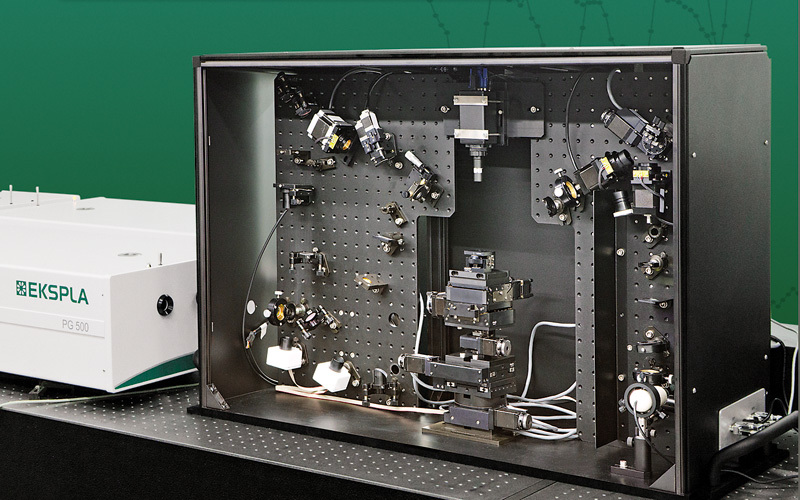

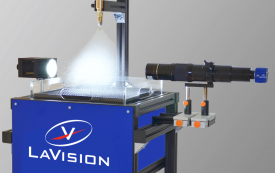

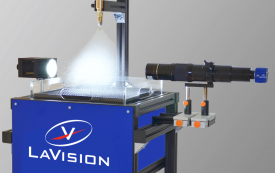

Electrostatic, rotating bell (ESRB) application is one of the most important coating application techniquesfor industries with demanding specifications for optical attractiveness of coatings, such as automotive. TheESRB process involves production of droplets using a high-speed rotating bell, which are subsequentlytransported to the substrate being coated via shaping air [1-3]. An electrical potential is applied between thebell and the substrate which further helps droplet atomization and transport. This research investigates theeffects of inertia, centrifugal force, drag force, and electrostatic force on the atomization mechanism andparticle size distribution using an automotive OEM base coat formulation. Coating flow rate (CFR), shapingair flow rate (SAFR), bell speed (BS), and electrostatic potential (EP) were used as primary parameters tocreate various atomization conditions and particle size distributions. The atomization mechanism, ligamentformation, and particle size distribution were measured using high-speed laser shadowography and imageprocessing. The effects of governing forces and particle size generated on efficiency of droplet transfer to thesubstrate and optical appearance of the coatings were studied to generate operating windows for optimumprocess efficiency and appearance.