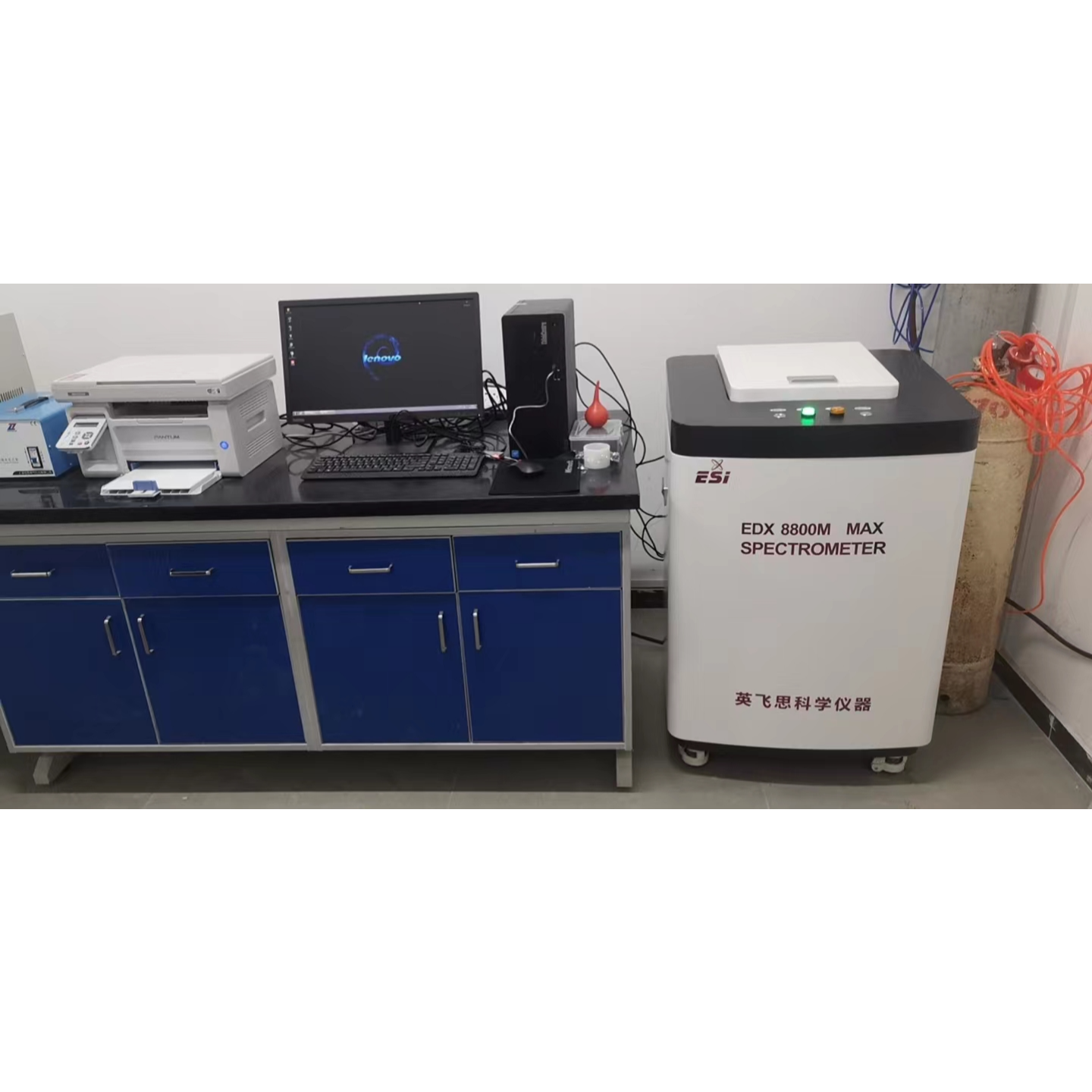

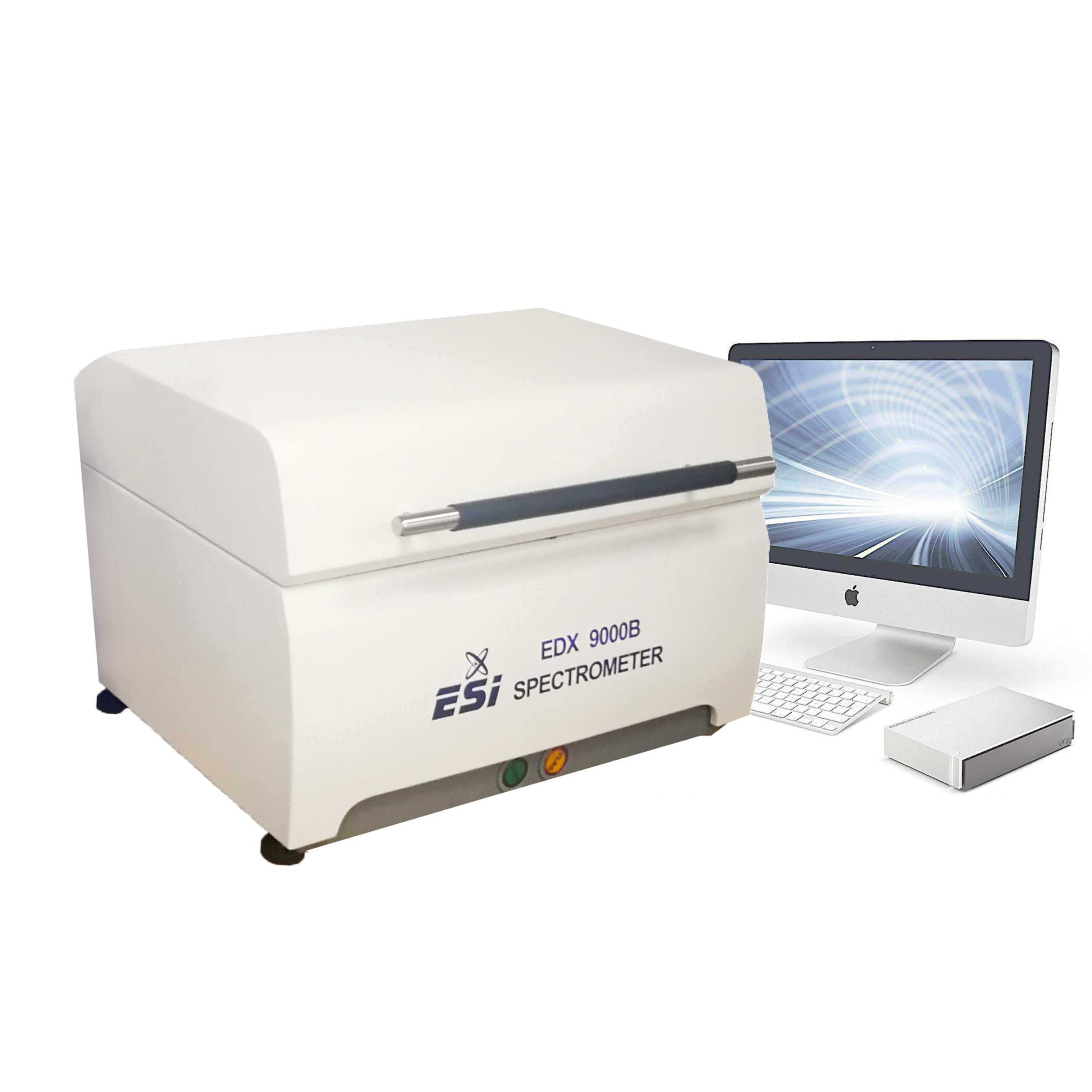

英飞思便携式快速矿石矿产成分分析仪Compass300光谱仪背景介绍ESI 先进的 ED-XRF 光谱仪提供采矿产品的现场定量分析,与耗时的实验室分析相比,从而将接收结果的时间从几天缩短到几秒钟。通过采矿、矿物或其他源自地球的地质材料回收的材料包括各种贱金属——贵金属、铁、铀、煤、钻石、石灰石、油页岩、岩盐和钾——所有这些都可以有效地由 ESI 出色的 ED-XRF 分析仪进行分析。 许多法规限制了允许释放到大气中的有毒化合物和金属的数量。 ESI 提供创新的解决方案,帮助客户在生产过程中监测气体排放和土壤和沉积物的安全处理。从样品制备到综合分析,我们帮助客户生成准确的数据,以做出明智的环境决策。ESI ED-XRF 光谱仪构成了采矿和矿物材料常规定性和定量分析测定的终极技术和系统,操作成本极低,无需耗时的样品制备。ESI 分析仪具有出色的性价比和出色的低检测水平,使其成为采矿和勘探行业的最佳选择。当今先进的检测器可以在生产线和现场对轻元素和氧化物进行简单且经济的分析。基于 ED-XRF 的解决方案的一些应用示例包括:1.水泥是多种矿物质的混合物。控制元素组成和属性(如强度、凝固、时间和颜色)至关重要。 ED-XRF 用于分析原料成分、生料、熟料和最终的水泥产品(水泥、熟料和生料中的 Na、Mg、Al、Si、S、K、Ca 和 Fe)。2.石灰石是水泥的主要成分,转化为石灰。它是最常见的矿物之一,ED-XRF 是一种常用的分析方法(石灰、石灰石和白云石中的 Na、Mg、Al、Si、K、Ca 和 Fe)。3.沙子也是水泥的一种成分,但主要用于生产玻璃。对玻璃制造特别有价值的是低铁,它形成了一个重要的子应用(砂和玻璃中的钠、镁、铝、硅、钾、钙和铁)。4.粘土用于制作各种陶瓷制品、工艺品、砖块等成品。监测 Ti 和 Fe 含量对于颜色控制很重要。低成本 ED-XRF 设备可以执行这种分析,而高端 ED-XRF 仪器可以测量所有其他主要元素(镁、铝、硅、钙、钛、高岭土和其他粘土中的铁)。5.铝土矿是一种含铝量高的矿物,是金属生产中铝的最重要来源(铝土矿中的铝、硅、钛和铁)。6.磷酸盐岩是化肥和磷酸生产中磷的主要来源。 ED-XRF 通常用于测量岩石、磷酸溶液和肥料(磷酸盐岩石和肥料中的 P、S、Ca、Fe)。7.地质土壤调查:只需扣动扳机,微量金属元素就会受到控制。8.野外找矿分析它可以快速准确地跟踪矿化异常并划定矿石边界。对于工业品位要求相对较低的矿石,很容易得出边界品位的结论。并可扫描核心样品进行扫描。9.矿山项目分析便携式Compass300可以在短时间内圈出关键矿脉进行关键挖掘。快速分离矿石品位、次品位和废石。矿山生产效率整体提升,大大降低检测和运输成本特征:样品没有形状或尺寸限制; 可以是固体、液体或粉末形式测量时间:10 到 300 秒,取决于变量固体 X 射线源:4 瓦迷你 Rh/Ag 靶 X 射线管多准直器,多滤光片自动调节检测元素范围广:镁(Mg)到铀(U)GPS地图功能; 可以自动保存测量位置数据传输技术结果下载到台式计算机以进行长期存储和报告生成轻便的手持仪器; 可用的最轻的系统之一电池寿命超过五 (5) 小时; 包括充电器系统随附两块电池,无需额外充电高分辨率样品相机,可快速轻松地进行样品对准; 确保准确的阅读位置特点和优势• Compass 300配备的SDD检测器优势高分辨率:通常优于130ev,降低相邻元素干扰,并提高轻元素检测效果高计数率:150,000 cps (high count per second)得到相同的强度,只要普通Si Pin检测器的0.2~0.05倍的时间,即Si Pin在设定分析时间为100秒的話,对SDD而言,得到相同的强度,只需5~20秒高灵敏度:灵敏度提高6-10倍。低背景值,提高元素检测下限• 便携,坚固,紧凑的设计,轻松实现现场高精度样品无损检测• 可分析各种样品形态:包括矿体、矿块、矿渣、矿粉、粗矿、精矿、尾矿、土壤、泥土、泥浆、灰尘、粉尘、过滤物、薄膜、废水、废油、液体样品等• 只需制备少量样品便可进行无损检测• 一键测试,一键打印报告• 可选配大容量电池,无需外部供电情况下可实现长时间工作应用领域分析矿种涵盖从Mg至U之间的金属、非金属、贵重金属和稀有金属矿等勘查多元素现场快速分析,可广泛应用于普查、详查的各个过程,追踪矿化异常,扩展勘查范围。可大大减少送回实验室样品的数量,从而节约运输和分析费用岩芯检测快速分析岩芯和和其他钻探样品,建立矿山三维图,分析储量,可大大提高钻探现场及时决策效率开采过程控制矿体边界圈定,矿脉走向判定,对开采过程进行精确管理和控制,对矿石品位进行随时检测品位控制对精矿、矿渣、矿尾等矿物品位进行精确快速分析,为矿物贸易、加工以及再利用提供价值判断依据环境分析快速对矿石周围环境、尾矿、粉尘、土壤污染等进行分析与检测,评估矿石环境修复效果石油化工:燃料,润滑油,添加剂中的硫元素分析,磨损金属分析刑侦及公安:证据分析,材料匹配,爆炸物等食品,化妆品和药品:添加剂控制,原材料,有害金属,包装材料等什么是 XRF?XRF 表示 X 射线荧光。在分析过程中,材料被短波长辐射 X 射线的高能入射光束激发并被电离。内部电子从较低能量的轨道(通常是 K 和 L 轨道)射出,使样品中的原子不稳定,直到电子空穴被来自较高能量的外部轨道的电子填充。当电子从高能轨道移动到低能轨道时,能量以 X 射线的形式释放,这是存在的原子类型的特征。样品的连续电离和入射光束能量的吸收允许分析受激材料发射的复杂 X 射线光谱。能量色散 X 射线 (EDX) 光谱仪用于测量检测到的发射 X 射线光谱的不同波长的能量强度。在不同波长下测得的峰值强度是每种元素的特征,并且与样品中存在的元素的丰度成正比。每种元素的准确定量丰度是通过将这些数据与已知成分的矿物和岩石标准进行比较来确定的。Compass300-Portable XRF Mineral/Soil AnalyzerBackgroundand Introduction ESI advanced ED-XRF spectrometers provide on-site quantitative analysis of mining products, thereby reducing the time for receiving results from days to seconds, compared to time consuming laboratory analysis. Materials recovered by mining, minerals or other geological materials that originate from the earth consist of all kinds of base metals - precious metals, iron, uranium, coal, diamonds, limestone, oil shale, rock salt and potash - all of which can be efficiently analyzed by ESI outstanding ED-XRF analyzers.Numerous regulations limit the amount of toxic compounds and metals that are permitted to be released into the atmosphere. ESI provides innovative solutions to help customers to monitor emissions of gases and safe handling of soils and sediments in their production. From sample preparation to comprehensive analysis, we help customers to generate accurate data for making smart environmental decisions.ESI ED-XRF spectrometers form the ultimate technique and systems for routine qualitative and quantitative analytical determinations of mining and minerals materials, with very low operational costs and no need for time consuming sample preparations.ESI analyzers deliver excellent price-performance combined with outstanding low levels of detection, making them the superior choice for the mining and exploration industry. Today' s advanced detectors enable easy and affordable analysis of light elements and oxides in the production lines and in the field.Some application examples of ED-XRF based solutions include:1.Cement is a blend of several minerals. It is critical to control the elemental composition and properties such as strength, setting, time and color. ED-XRF is being used to analyze the raw components, raw meal, clinker, and the final cement product (Na, Mg, Al, Si, S, K, Ca, and Fe in Cement, Clinker, and Raw Meal).2.Limestone is the major component of cement, and is converted into lime. It is one of the most common minerals and ED-XRF is a popular method being used for its analysis (Na, Mg, Al, Si, K, Ca, and Fe in Lime, Limestone, and Dolomite).3.Sand is also a component of cement, but is mainly used for producing glass. Particularly valuable for glassmaking is low iron, which forms an important sub-application (Na, Mg, Al, Si, K, Ca, and Fe in Sand and Glass).4.Clays are used in a variety of ceramic goods, artifacts, bricks and other finished products. Monitoring Ti and Fe content is important for color control. Low cost ED-XRF devices can perform this analysis, while high-end ED-XRF instruments can measure all other major elements (Mg, Al, Si, Ca, Ti, Fe in Kaolin and other Clays).5.Bauxite is a mineral that is high in aluminum and forms the most important source of aluminum for metal production (Al, Si, Ti, and Fe in Bauxite).6.Phosphate rock is the major source of phosphorus used in fertilizer and phosphoric acid production. ED-XRF is commonly used to measure the rock, phosphoric acid solutions, and fertilizer (P, S, Ca, Fe in Phosphate Rock and Fertilizer).7.Geological soil survey:Simply pull the trigger and the trace metal elements are under control.8.Field prospecting analysisIt can quickly and accurately track mineralization anomalies and delineate ore boundaries. For ore with relatively low industrial grade requirements, it is easy to get a conclusion of the cut-off grade. And can scan the core samples for scanning.9.Mine project analysisPortable Compass300 can circle key veins in a short period of time for key mining. Quickly separate ore grades, sub-grades and waste rock. The overall improvement of mine production efficiency, greatly reducing the cost of testing and transportationFeatures:No shape or size limit for samples which can be in solid, liquid or powder formMeasurement Times: 10 to 300 seconds depending on variablesSolid X-Ray Source: 4watts mini Rh/Ag-Target X-Ray TubeMultiple Collimator, Multiple Filters with automatic adjustWide Element Range of Detection: Magnesium(Mg) through Uranium (U)GPS Mapping Feature can automatically save the location of a measurementData transfer technology results download to desktop computer for long-term storage and report generation Light hand-held instrument one of the lightest systems availableBattery life of over five (5) hours includes chargertwo batteries included with system at no additional chargeHigh resolution sample camerafor quick and easy sample alignment insure accurate reading location

留言咨询

留言咨询

400-860-5168转5890

400-860-5168转5890

留言咨询

留言咨询

400-860-5168转5890

400-860-5168转5890

留言咨询

留言咨询

400-860-5168转2414

400-860-5168转2414

留言咨询

留言咨询

400-860-5168转5890

400-860-5168转5890

留言咨询

留言咨询

400-860-5168转5890

400-860-5168转5890

留言咨询

留言咨询

400-860-5168转5890

400-860-5168转5890

留言咨询

留言咨询

400-860-5168转5890

400-860-5168转5890

留言咨询

留言咨询

留言咨询

留言咨询

400-860-5168转4410

400-860-5168转4410

留言咨询

留言咨询

留言咨询

留言咨询

400-617-6366

400-617-6366

留言咨询

留言咨询

400-860-5168转5890

400-860-5168转5890

留言咨询

留言咨询

留言咨询

留言咨询

400-860-5168转2414

400-860-5168转2414

留言咨询

留言咨询

400-860-5168转2128

400-860-5168转2128

留言咨询

留言咨询

400-860-5168转5890

400-860-5168转5890

留言咨询

留言咨询

400-860-5168转1750

400-860-5168转1750

留言咨询

留言咨询

400-675-0653

400-675-0653

留言咨询

留言咨询

留言咨询

留言咨询

400-801-8356

400-801-8356

留言咨询

留言咨询

400-617-6366

400-617-6366

留言咨询

留言咨询

400-617-6366

400-617-6366

留言咨询

留言咨询

留言咨询

留言咨询

留言咨询

留言咨询

留言咨询

留言咨询

留言咨询

留言咨询

400-806-0325

400-806-0325

留言咨询

留言咨询

400-617-6366

400-617-6366

留言咨询

留言咨询

400-860-5168转5890

400-860-5168转5890

留言咨询

留言咨询

400-860-5168转4446

400-860-5168转4446

留言咨询

留言咨询