方案详情文

智能文字提取功能测试中

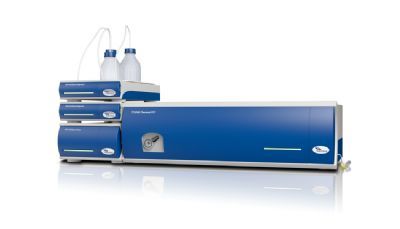

Fractionation of Industrial Starch Polysaccharides by Field-Flow Fractionation Justin R. Engle and S. Kim R. Williams Department of Chemistry and Geochemistry, Colorado School of Mines, Golden, CO 80401, krwillia@mines.edu Objectives >Determine best sample preparation techniques for the dissolutionof starch in organic media >Perform fractionation of amylose and amylopectin components ofindustrially important starch samples using thermal field-flowfractionation (ThFFF) >Determine molecular weight (MW) for amylopectin Background Starches are important macromolecules with many industrialapplications, particularly in the food and pharmaceutical industries.Their uses range from gelling agents to drug transport and evenenergy storage. Properties of starches vary based on the plant orbacterial source and are connected to the amylose and amylopectincontent. Amyloseis a linear polysaccharide with a-1,4 glycosidebonds and has a molecular weight around 106 Daltons. Amylopectin isa highly branched polysaccharide with a-1,6 glycoside bonds along aa-1,4 glycoside bond chain backbone and has a molecular weightaround 107 Daltons [1]. SHOH Amylopectin Characterization of starch has previously been performed using size-exclusion chromatography (SEC). The use of SEC for polysaccharides is limited due to low exclusion limits of the packedcolumn and shear degradation of the ultrahigh molecular weightcomponents. An alternative to SEC is field-flow fractionation (FFF). In1994, Lou et al. reported the use of thermal FFF (ThFFF) to performthe separation of pullulan with varying molecular weight and of cornstarch with varying amylose and amylopectin content [2]. ThFFF usesa temperature field applied perpendicular to the carrier liquid flow topromote the retention and fractionation of analytesbased on the ratio of thermal diffusion coefficient D- to normal diffusion coefficient D. The retention time t, of the analyte is therefore controlledby the temperature difference across the channel At, the size andmolecular weight of the analyte, and parameters that affect Dr. D = DrAT In the past decade, flow FFF has been in the spotlight with respect topolysaccharides analyses [3-5] using an aqueous carrier liquid.Separation of polysaccharides of starches by flow FFF is based solelyon the hydrodynamic size of the macromolecule whereas ThFFF hasan additional composition sensitivity. Instrumentation Thermal channel: Model T-101 (Postnova Analytics, Salt Lake City, UT)Length: 32 cm Breadth:2 cm Thickness:0.0127 cm Model T-101 thermal channel (cover removed). On-line Detection Dawn EOS multi-angle light scattering (MALS), Optilab DSPdifferential refractometer (dRI), and quasi-elastic light scattering (QELS) fromWyatt Technologies, Santa Barbara, CA. Data Analysis Berry fitting method used for molecular weight and root mean squared(rms) radius calculations Experimental Starch samples with varying amylose content (0, 25,50, 70%) wereprovided by National Starch and Chemical Company (Bridgewater,NJ).Carrier liquid was distilled dimethyl sulfoxide (DMSO), flow rate of0.1mL/min. Temperature programming was used: initial AT=80C for 10minutes then decayed to AT=10C. Sample Preparation Method 1: starch cooked in distilled dimethyl sulfoxide (DMSO) in an oilbath at~80℃ for 3 days with constant stirring. Sample concentrationswere 1.0 mg/mL. Method 2: starch cooked in 90% aq. DMSO in a boiling water bath (94-96℃) for 1 hour with constant stirring. Sample was extracted whentemperature was near room temperature. Sample concentration 2.0mg/mL. Results and Discussion for Cooking Method 1 Figure 1-Fractogram of 100% amylopectin with molecular weight overlay.Sample prepared by Method 1. Molar mass signal 2.0x10° Observations for Cooking Method 1 >Figure 1 light scattering trace shows sample retention Sample retained between 20 to 50 minutes is likely amylopectinMW increases with increasing elution time Measured MW range from 5.0x10° to 3.5x10 Da Literature values for amylopectin from plant sources is ~107 Da >Figure 2 has similar light scattering trace as Figure 1 Sample retained from 20 minutes to 60 minutes -likely that ofamylopectin MW initially increases with elution time MW range of 5.0x105to 1.7x10 Da Range is significantly lower than literature (10 Da) AcknowledgmentsNSF-CHE-0515521 Dr. Tom Hahn (National Starch)Dr. Claudia Lohmann (Colorado School of Mines)Dr. Sohyel Tadjiki (Postnova Analytics)J. Ray Runyon (Colorado School of Mines) Results and Discussion for Cooking Method 2 Figure 3-Fractogram of 50% amylose and 50% amylopectin with molecular weightoverlay. Sample prepared by Method 2 Observations for Cooking Method 2 >Figure 3 fractogram significantly different than that of fractogramsobtained by cooking Method 1 (Figures 1 and 2)Shorter retention of sample (from ~4 minutes to 45 minutes) than seenin cooking Method 1 Range 1x10° to 8x106 Da assuming amyloopectin elution at 20 minValues lower than literature (107 Da) Molar mass signal follows lgo trace Table1 -Calculated molecular weight averages for amylopectin in Figures 1-3from elution time of 20 minutes and onwards. Sample (prepmethod) MW(g/mol) 0% amylose (1) 100% amylopectin .一 (1.6±0.2)x10 50% amylose (1)50% amylopectin (1.2±0.1)x106 50% amylose (2)50% amylopectin (3.6±0.4)x10 Conclusions >Both cooking methods allowed complete dissolution of starch>Cooking Methods 1 and 2 yielded different elution profiles >Both cooking methods generally led to lower MWs for amylopectin(assuming elution after 20 minutes) than literature value (10 Da) >Weak dRI signals may be contributing to underestimation of Ms Future work >Collection of amylose and amylopectin via organic flow field-flowfractionation to use as size standards >ThFFF-MALS-dRI for quantification of amylose and amylopectincontent Comparison of amylose and amylopectin content using standardiodine potentiometric titration method to determine accuracy ofquantification of amylose and amylopectin content. >Calculation of thermal diffusion and molecular (normal) diffusionbased on retention times References [1] Richardson, S.; Gorton, L. Anal. Chim. Acta. 497, 27-65 (2003). ( [ 2] Lou, J.; Myers, M.N.; Giddings, J.C. J. Li q . Chromatogr . 17 , 3239-3260 (1994). ) [3] Wittgren, B.; Wahlund, K.-G.; Andersson, M.; Arfvidsson, C. Int. J. Polym.Anal. Charact. 7, 19-40 (2002). [4] Roger, P.; Baud, B.; Colonna, P. J. Chromatogr A. 917, 179-185 (2001). [5] Stevenson, S.G.; You, S.; Izydorczyk, M.S.; Preston, K.R. J. Liquid Chromatogr. 26,2771-2781(2003).

关闭-

1/1

上海积利科学仪器有限公司为您提供《热场场流分离仪分析超大分子量工业淀粉》,该方案主要用于其他粮食加工品中理化分析检测,参考标准《暂无》,《热场场流分离仪分析超大分子量工业淀粉》用到的仪器有热场场流分离仪。

我要纠错

推荐专场

相关方案

咨询

咨询