方案详情文

智能文字提取功能测试中

Cell Culture System for: Hybridoma Mammalian cell culture –bioreactor All the Infors range can be supplied in an alternative configuration to provide an excellent bioreactor. The following adaptations are made: The added security from contamination using magnetic drive (except Minifors) and slow speed motor The option of gentle and reliable "dry" temperature control by block or pad or a water jacketed system Special accessories such as Marine and "cell lift" type impellors Spin filter Sterile sampling system Gas mix,including spearate addition of CO2 into the sinter sparger or head space. Round bottom vessels: All vessels are with top axial magnetic drive (easier cleaning, with no crevices) except Minifors and water circulation for temperature control. The top plate is equipped with 10mm, PG13.5 and rounded -thread 19mm ports on larger sizes of vessel (depending on type). These can be fitted with a septum and retaining collar to allow flaming of the port during inoculation etc. The vessel is sterilized along with the reagent bottles in an autoclave or sterilized in-situ. For better handling, a stainless steel holder is available for hanging the reagent bottles on the side of the culture vessel for autoclavable systems.. The vessel has two handles on the top plate and protection on the sides for the side arms of double-jacketed glass units for added security when emptying or cleaning. Stirring For stirring of insect cell cultures, a one or more marine-type impellors are used as standard (options available), with a brushless motor with integral speed controller for speeds up to 20 - 300 rpm. x-DDC Control System: All fermenter models except Minifors incorporate the x-DDC (eXtended DDC microprocessor control) which uses a high-performance digital system. With the use of almost identical instrumentation, the step from Bench-scale to larger equipment is made considerably easier. The control panel is compact and is usually mounted above the base unit for clear visibility. The panel can be removed if required. Programming of parameters is via a splashproof keypad with a rotary knob for navigation and an LCD display. Communication is via a robust data-cable. For each fermenter, process information such as parameter set points, PID values etc are stored automatically on an interchangeable "memory card" . This allows changes in fermentation processes by fitting an alternative card or downloading a recipe without re-programming and the chance of errors plus an unlimited number of recipes to be stored. An "open frame" gas supply system with four magnetic valves allow addition of components for automatic mixing of gasses for oxygen supplementation. An optional mass flow control valve ensures a controlled, steady flow of gas into the vessel. Agitation & temperature control. Four high-accuracy digital peristaltic pumps supplied as standard with the option to add an integral analogue feed pump. Addition and removal of liquids is therefore possible with a standard system (using the antifoam pump for medium take-off). Accepts a conductive probe for automatic control of antifoam addition or media addition/removal in a vessel. Works together with the integral peristaltic pumps. Minifors has a simpler, integrated control system based on the same operating panel as the Mulittron incubator shakers. This allows easy changing of set points, calibration and controller options in a way familiar to anyone moving from shake flask to fermentation. It can operate with IRIS software in exactly the same way as other units and comes with IRIS Light and a data cable included in the basic package. An "open frame" gas supply system with four magnetic valves (2 integral valves for Minifors) allow automatic mixing of gasses for low energy regulation of pH and DO in cell culture, and for oxygen supplementation in classical fermentations. An optional mass flow control valve ensures a controlled, steady flow of gas into the vessel. CO2 addition can be made into the head space. Agitation & temperature control. Set points and controller setup Set points are entered into the controller prior to inoculation and stored on a memory card. The vessel was allowed to equilibrate prior to inoculation. The pO2 actual value stays above the set point up to (and some time after) inoculation. Temperature 37°C pH 7.2 DO 30-50% Agitation 40 - 130 rpm O2 (Gases) 2 or 3 gas for dissolved oxygen plus CO2 control of pH in place of liquid acid PH Control The pH probe is calibrated prior to the autoclave cycle (refer to Instruction Manual). CO2 gas and liquid base is used to maintain the pH set point. pH control parameters are: Base Sodium bicarbonate, 7.5% solution Acid Supplied as CO2 gas, if needed. Transfer tubing Narrow bore silicone tubing with Marprene inserts, as supplied (4mmOD) Vessel inlet 4mm fixed pipes in the vessel top plate PID values: factory default setting should be used unless it is clear adjustment is needed (hunt or drift). Dissolved Oxygen (pO2) Control The dissolved oxygen electrode is normally calibrated after the autoclave cycle (refer to .Instruction Manual) but can be calibrated in air beforehand for cell culture applications. Control of pO2 can be cascaded and should be set to GasMIx for optimum results The controller automatically maintains the pO2 setpoint using 2 (Minifors) or 3 gases (Air, O2, N2). The gas flow rate should be constant and set at a fairly low rate eg typically 0.05-0.3 vessel volumes per minute (VVM). Continuous Feed Feed pumps can be calibrated using the standard tubing to keep track of the liquid quantities entering and exiting the vessel. Either a digital pump with shot and delay dosing or an analogue, continuously-variable pump can be used for medium addition. Samples should be taken several times a day to measure glucose and cell density (stain and count cells and/or nucleii). If, as is typical, cells are to be retained and just the medium exchanged, a spin filter is added to the vessel and cell-free medium removed at a rate adjusted to match the medium input. Iris v5 software can be used to control nutrient addition. Example methodology Medium Eg. modified DMEM medium which needs supplements and 5-10% foetal calf serum (FCS). As serum is both expensive and can lead to excessive foaming, other serum-free media are also available commercially. Use of antifoam in the medium can help suppress foaming and/or addition of reagents such as Pleuronic can help protect cells. Before sterilization, glass vessels are often coated with a barrier such as SigmaCote ® to prevent attachment of cells to the walls. Inoculum An inoculum can be prepared in an Infors Shaker (Multitron or Minitron, with CO2 control) or in a spinner flask (1000ml, filled to 600ml, stirred at 80-90rpm at 37oC. Approximately 500ml at a density of ~ 5x105 cells/ml are needed from this culture. If the cells are to be immobilised on beads, preliminary work in spinners or shake flasks should establish the correct conditions before attempting to undertake full-scale culture in a fermenter. Method Electrodes should have been calibrated before autoclaving (100% in air for pO2). • Sterilize the vessel with a little (10-20ml) phosphate buffer solution (PBS) or water for 60 minutes • If necessary, remove any remaining liquid from the vessel. • Add eg. 1.45 -1.95L of cell culture media to a. 3.6LTV vessel. • Inoculate eg. 50 ml of concentrated cell suspension to provide a starting cell count of ~106 cells/ml, either by pouring under a laminar flow hood or from a flask equipped with an inoculation needle or from a syringe. After 3-4 days of batch process, medium perfusion can be set at the rate of approximately 0.5-1 working volumes per day. Batch, fed-batch and perfusion cultures can last typically for a further 7-10 days and up to 60+ days plus in some cases. Hybridoma culture in bioreactors is extremely cell line and conditioning dependent. These guidelines are, at best, an approximation to provide a starting point. For example, if growth is poor the concentration of cells in the inoculum may have to be increased or serum concentration altered. Additional Ideas for further Optimisation: 1) Use of Pluronic at 0.1-0.4% (BASF/GIBCO) to protect cells plus use an antifoam such as Sigma O-30 at 0.1% with addition via pump if necessary when foaming is a significant problem. The pluronic would allow a slightly faster gas flow rate by preventing cells and bubbles from being in direct contact. 2) Use of low flow rate of 0.01-0.05 VVM with micro-sparger (eg as low as 0.5 micron) for very small, slow bubbles. Pulsed sparging may also help (On/Off rate determined empirically and may change with increasing cell density i.e. longer On, shorter Off). A ring sparger with a low gas flow rate can work in some circumstances and would be an inexpensive, rapid first step. 3) Use of perfusion culture will certainly enhance cell growth. Accurate control of glucose and glutamate addition will produce higher yields by matching growth to available nutrient and keeping build-up of lactate/ammonia to a minimum. Glucose additions as low as 0.1g/l have been used but this tends to aid product formation - higher concentrations (up to 4g/l) enhance cell growth. Fed-batch would be a good first step to see if improvement is possible with just neutralisation of lactate by pH control. 4) Cell numbers can be estimated from rate of glucose consumption (sample) or inferred from the respiratory quotient RQ. A mass spectrometer or exit O2/CO2 analyser will be necessary for this technique and rates of CO2 evolution/O2 uptake are only likely to be measurable in actively growing, relatively dense cultures. Glucose feed could be optimised by holding RQ to a particular value eg. 1.7. IRIS SEQUENCE FOR RQ CACLUALTION: #0 Definitions for simple RQ calculation DEF WV=2.0 DEF O2=(20.95-ExitO2.v) DEF CO2=(ExitCO2.v-0.03) DEF CER=CO2*Flow.v/WV DEF OUR=O2*Flow.v/WV RQ.v=CER/OUR //where WV=working volume of culture //O2=amount of oxygen consumed // CO2=amount of carbon dioxide produced. // Exit O2 and Exit CO2 values from mass spec (channels 17 & 18) //MS inlet in fermenter settings matched to MS outlet allocation. For control fo a feed pump add these lines: Feed Pump.sp=IF(RQ.v>1.15){Feed Pump.sp-1}ELSE{Feed Pump.sp} Feed Pump.sp=IF(RQ.v<0.95){Feed Pump.sp+1}ELSE{Feed Pump.sp} Feed Pump.sp=IF(Feed Pump.sp<0){Feed Pump.sp=0}ELSE{Feed Pump.sp} Feed Pump.sp=IF(Feed Pump.sp>100){Feed Pump.sp=100}ELSE{Feed Pump.sp} //Feed Pump.sp is for inbuilt pump 0-100% On //Flow rate could be calculated as pump secs x calibration factor // This could then be used to update working volume to allow for increase over time Cell Culture System for: HybridomaMammalian cell culture –bioreactor

关闭-

1/5

-

2/5

还剩3页未读,是否继续阅读?

继续免费阅读全文产品配置单

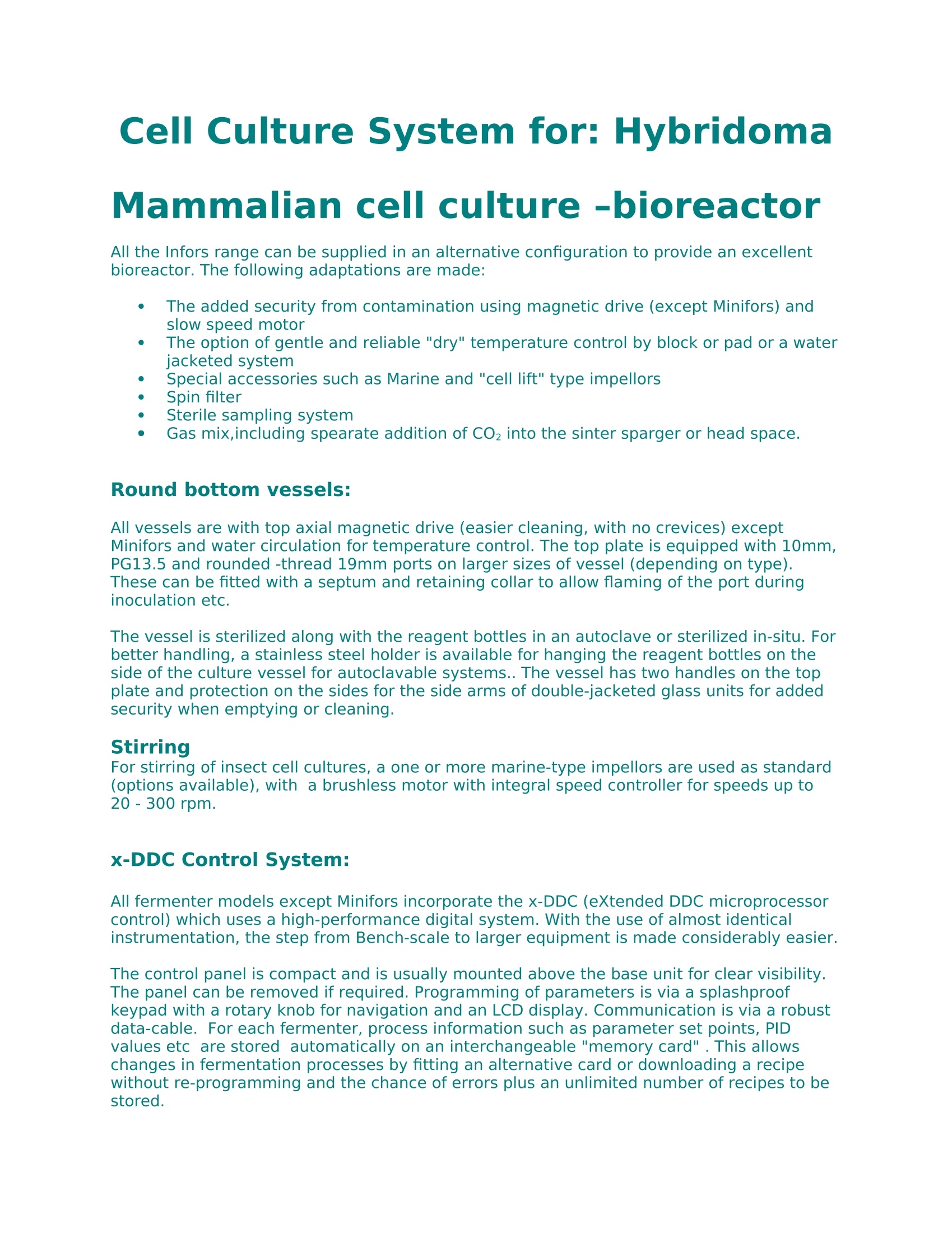

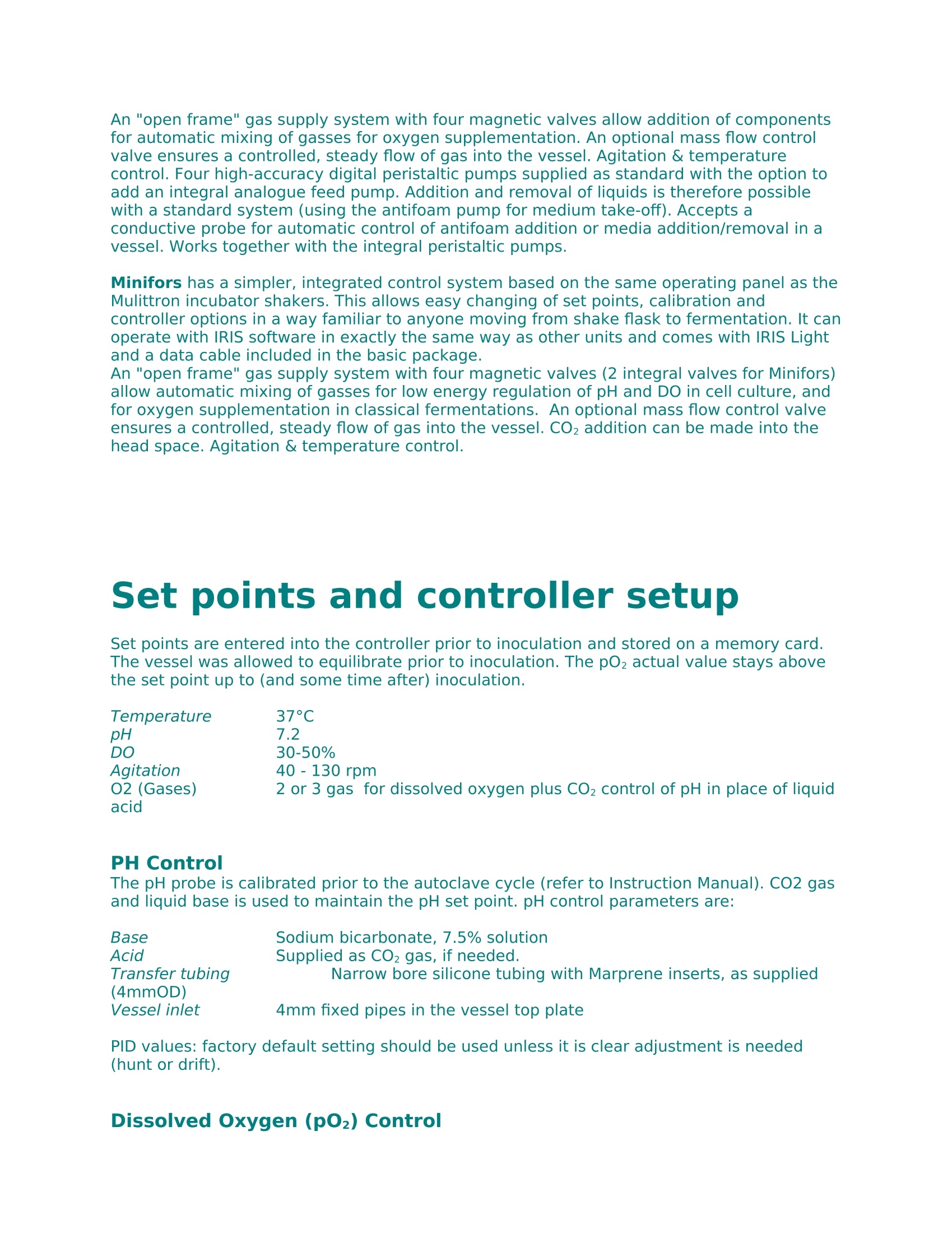

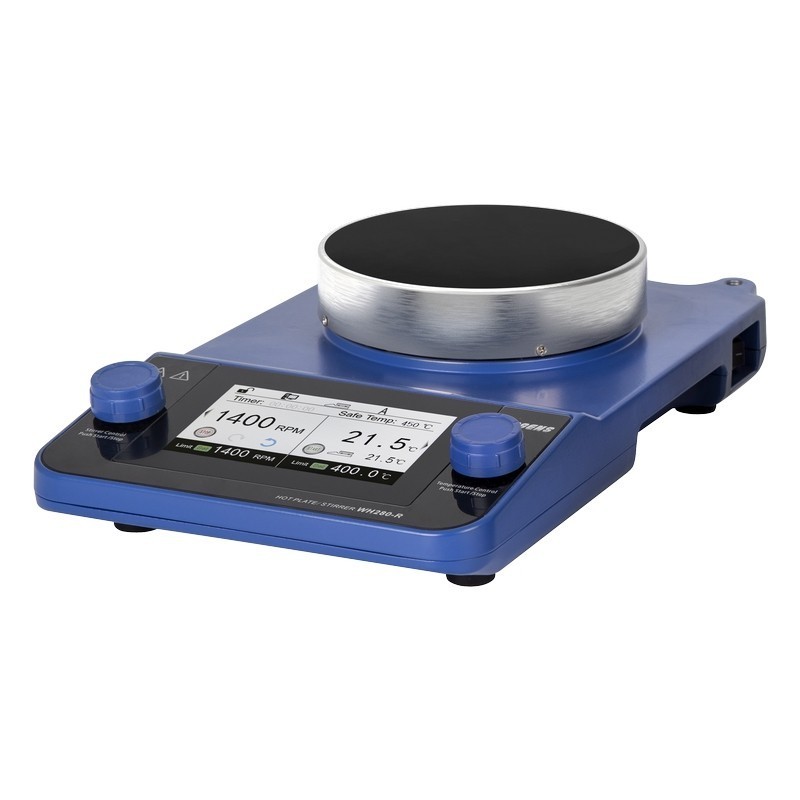

维根技术(北京)有限公司(WIGGENS)为您提供《杂交瘤细胞中细胞培养检测方案(搅拌器)》,该方案主要用于癌细胞/肿瘤细胞中细胞培养检测,参考标准《暂无》,《杂交瘤细胞中细胞培养检测方案(搅拌器)》用到的仪器有WIGGENS WH280-R加热磁力搅拌器、WIGGENS D-500Pro 数显均质乳化器、WIGGENS APOLLO不锈钢液氮储存运输罐、WIGGENS WCI-40T三气培养箱。

我要纠错

推荐专场

搅拌器、磁力搅拌器、电动搅拌器

更多相关方案

咨询

咨询