方案详情文

智能文字提取功能测试中

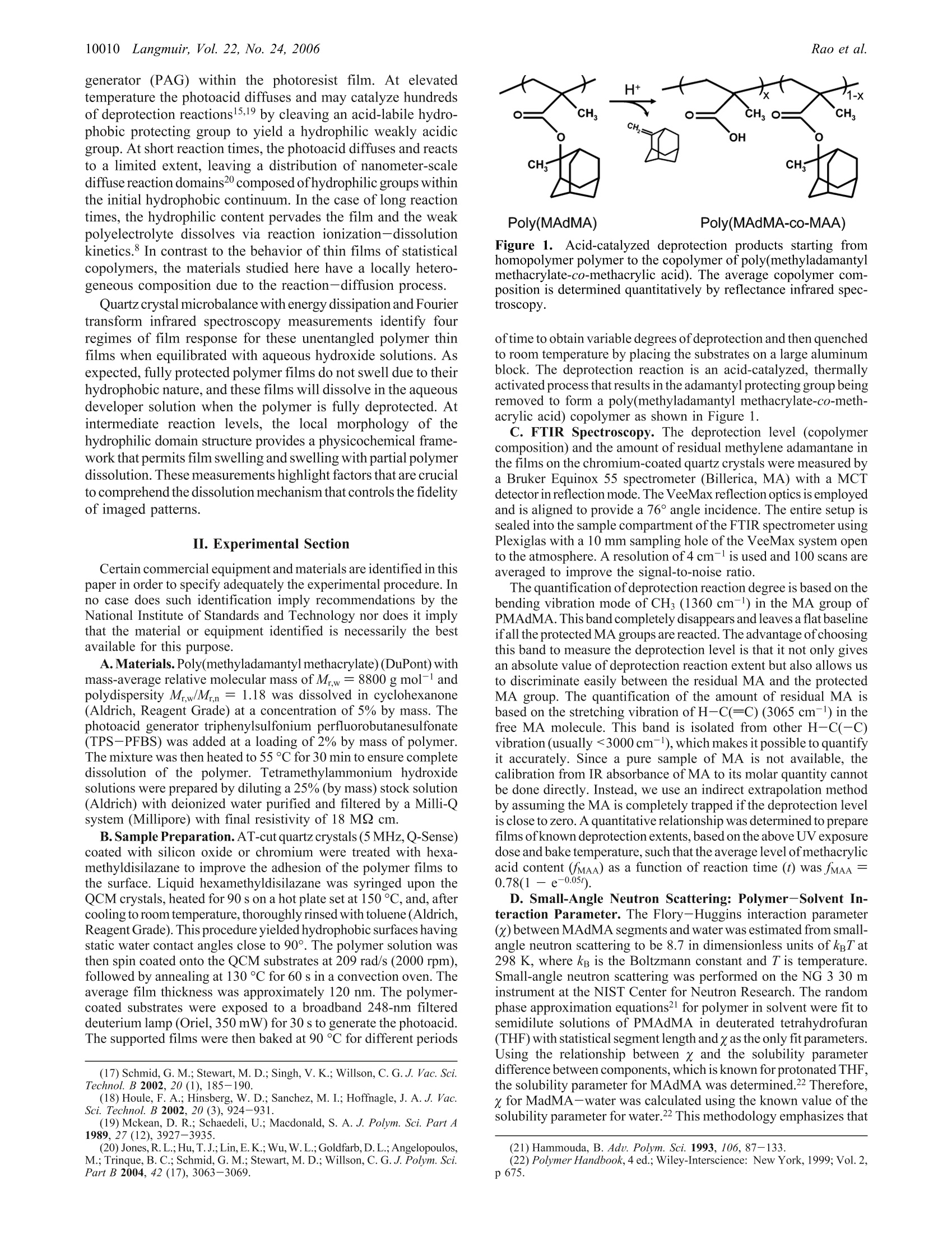

Langmuir 2006, 22, 10009-1001510009 10010 Langmuir, Vol. 22, No. 24, 2006Rao et al. Effect of Deprotection Extent on Swelling and Dissolution Regimes ofThin Polymer Films .Ashwin Rao, Shuhui Kang, Bryan D. Vogt, Vivek M. Prabhu,* Eric K. Lin,Wen-Li Wu, and M. Muthukumar Polymers Division, National Institute of Standards and Technology, Gaithersburg, Maryland 20899, andDepartment ofPolymer Science and Engineering, University of Massachusetts,Amherst, Massachusetts 01003 Received June 20, 2006. In Final Form: September 11, 2006 The response of unentangled polymer thin films to aqueous hydroxide solutions is measured as a function ofincreasing weakly acidic methacrylic acid comonomer content produced by an in situ reaction-diffusion process.Quartz crystal microbalance with energy dissipation and Fourier transform infrared spectroscopy measurements areused to identify four regimes: (I) nonswelling, (II) quasiequilibrium swelling, (III) swelling coupled with partial filmdissolution, and (IV) film dissolution. These regimes result from chemical heterogeneity in local composition of thepolymer film. The acid-catalyzed deprotection of a hydrophobic group to the methacrylic acid tends to increase thehydrophilic domain size within the film. This nanoscale structure swells in aqueous base by ionization of the methacrylicacid groups. The swollen film stability, however, is determined by the hydrophobic matrix that can act as physicalcross-links to prevent dissolution of the polyelectrolyte chains. These observations challenge current models of photoresistfilm dissolution that do not include the effects of swelling and partial film dissolution on image quality. I. Introduction The microlithography industry has successfully developed newmaterials to image sub-45-nm features through systematic changesin the chemistry and composition of the polymeric photoresistmaterials. Resolving these structures depends on the change inpolymer solubility over a narrow range of chemical compositionthat is controlled through a chemical reaction during the imagingprocess. This change in film composition is produced by anacid-catalyzed deprotection reaction that converts hydrophobicgroups to weakly acidic groups. As the concentration of acidicgroups increases, the polymer becomes soluble in an aqueoushydroxide solution (developer). One key element in the designof new photoresist polymer materials is controlling theionizationof the polymer during the dissolution process. Numerous approaches have been taken to understand pho-toresist polymer dissolution through the application of percolationmodels,2-4 the investigation of interfacial reaction kinetics, thedevelopment of a surface-etching critical ionization model,.and the combination of reaction kinetics with a critical ionizationmodel.8,9 These studies focused on the kinetics ofthe dissolutionprocess and have highlighted the influence of the polymermolecular weight and developer pH, especially with regard to ( *Corresponding author. F ax: (301)975-3928.E-mail: v prabhu@nist.gov. TPresent address: Department o f Chemical Engineering, Arizona S tateUniversity, Tempe, AZ 85287. ) ( University of Massachusetts. ) ( (1) Ito, H. Adu . Polym. Sci. 2005, 172, 37- 2 45. ) ( (2) Oertel, H. K.; Weiss, M.; Dammel, R.; Theis, J. Mic r oelectron. Eng. 1990, 11(1 -4 ),267-270. ) ( ( 3 ) Yeh, T. F. ; Shih, H. Y . ;Reiser, A . Macromol . 1992 , 25 (20) , 534 5 -5352.(4) Yeh, T. F .; Reiser, A.; Dammel, R . R . ; Pawlowski, G.; Roeschert, H. M acromol. 1 993, 26 ( 15),3862-3869. ) ( (5) Hunek, B .; C u ssler, E. AIChE J. 2003, 4 8, 661-672. ) ( (6) Tsiartas, P. C .; Flanagin, L . W.; Hinsberg, W.D.; Henderson,C. L .; Sanchez, ) ( I . C.; Bonnecaze, R. T.; Willson, C . G . Macromol. 1997, 30, 4656-4664. ) ( ( 7) Burns, S. D .; S chmid, G. M.; Tsiartas, P. C . ; Willson, C. G .; Flanagin, L. J. Vac. Sci. Techno l . B 2002, 2 0(2),537-543. ) ( (8) Hinsberg, W.; Houle, F . A.; L ee, S. W.; Ito , H.; Kanazawa, K. Macromol. 2005,38(5), 1 882-1898. ) ( ( 9) Houle, F . A.; Hinsberg, W. D .; Sanchez, M . I. Macromol. 2 0 02, 35(2 2 ), 8591 - 8600. ) correlations to surface roughening. These models and experimentswere developed primarily for a previous generation of photoresistmaterials that did not swell during development but dissolvedin a manner similar to an etching process. However, manyionizable polymers can swell when exposed to an aqueoussolution. For these classes of photoresist polymers, the effectof swelling on the rate of dissolution and the influence of thepolymer chemistry on swelling remain poorly characterized;swelling may occur for polymers below the entanglementmolecular weight and in the absence ofchemical cross-links.10-13These swollen film can be stable over long times, suggesting thepresence of a restoring force that limits the swelling and inhibitsdissolution. In this case, the solvent permeates the entire filmand swelling is coupled to the chain ionization.8,12 To suppressswelling, additives and inert comonomers13 are often incorporatedinto these photoresist formulations. However, this can also leadto problems in other aspects of resist design, such as transparencyand sensitivity. In this work, we investigate the response of a thin film to anaqueous base solution as a function of the average compositionofthe polymer as it changes during an acid-catalyzed deprotectionreaction. The photoacid reaction-diffusion process used inmodern photolithography produces a chemically heterogeneousthin film.9,14-18 In this process, a photoacid is generated by lightexposure from an initial random distribution of photoacid (10) Ito, H.; Wallraff, G. M.; Fender, N.; Brock, P. J.; Hinsberg, W. D.;Mahorowala, A.; Larson, C. E.; Truong, H. D.; Breyta,G.; Allen, R. D. J. Vac.Sci. Technol.B 2001, 19 (6),2678-2684. (11) Ito, H.; Hinsberg, W.D.; Rhodes, L.; Chang, C. Proceedings of the SPIE,Advances in Resist Technology and Processing XX 2003, 5039, 70-79. (12) Prabhu, V.M.; Vogt, B. D.; Wu, W. L.;Douglas, J. F.; Lin, E. K.; Satija,S. K.; Goldfarb, D. L.; Ito, H. Langmuir 2005,21(15),6647-6651. (13) Ito, H.; Allen, R. D.; Opitz,J.;Wallow, T. I.; Troung, H. D.; Hofer, D. C.; Varansai, P. R.; Jordhamo, G. M.; Jayaraman, S.; Vicari, R. Proceedings ofthe SPIE, Aduances in Resist Technology and Processing XVII 2000, 3999,2-12. (14) Houle, F. A.; Hinsberg, W. D.; Sanchez, M. I. J. Vac. Sci. Technol. B2004,22(2),747-757. (15) Houle, F. A.; Hinsberg, W. D.; Morrison, M.; Sanchez, M. I; Wallraff,G.; Larson, C.; Hoffnagle, J. J. Vac. Sci. Technol. B 2000, 18 (4),1874-1885. (16) Hinsberg, W. D.; Houle, F. A.; Sanchez, M. I.; Wallraff, G. M. IBM J.Res.Dev. 2001,45(5),667-682. generator (PAG) within the photoresist film. At elevatedtemperature the photoacid diffuses and may catalyze hundredsof deprotection reactions15,19 by cleaving an acid-labile hydro-phobic protecting group to yield a hydrophilic weakly acidicgroup. At short reaction times, the photoacid diffuses and reactsto a limited extent, leaving a distribution of nanometer-scalediffuse reaction domains20 composed of hydrophilic groups withinthe initial hydrophobic continuum. In the case of long reactiontimes, the hydrophilic content pervades the film and the weakpolyelectrolyte dissolves via reaction ionization-dissolutionkinetics.8 In contrast to the behavior of thin films of statisticalcopolymers, the materials studied here have a locally hetero-geneous composition due to the reaction-diffusion process. Quartz crystal microbalance with energy dissipation and FourierttSransform infrared spectroscopy measurements identify fourregimes of film response for these unentangled polymer thinfilms when equilibrated with aqueous hydroxide solutions. Asexpected, fully protected polymer films do not swell due to theirhydrophobic nature, and these films will dissolve in the aqueousdeveloper solution when the polymer is fully deprotected. Atintermediate reaction levels, the local morphology of thehydrophilic domain structure provides a physicochemical frame-work that permits film swelling and swelling with partial polymerdissolution. These measurements highlight factors that are crucialto comprehend the dissolution mechanism that controls the fidelityof imaged patterns. II. Experimental Section Certain commercial equipment and materials are identified in thispaper in order to specify adequately the experimental procedure. Inno case does such identification imply recommendations by theNational Institute of Standards and Technology nor does it implythat the material or equipment identified is necessarily the bestavailable for this purpose. A. Materials. Poly(methyladamantyl methacrylate)(DuPont) withmass-average relative molecular mass of Mr,w=8800 g mol- andpolydispersity Mr,w/Mr,n= 1.18 was dissolved in cyclohexanone(Aldrich, Reagent Grade) at a concentration of 5% by mass. Thephotoacid generator triphenylsulfonium perfluorobutanesulfonate(TPS-PFBS) was added at a loading of 2% by mass of polymer.The mixture was then heated to 55 °℃ for 30 min to ensure completedissolution of the polymer. Tetramethylammonium hydroxidesolutions were prepared by diluting a 25% (by mass) stock solution(Aldrich) with deionized water purified and filtered by a Milli-Qsystem (Millipore) with final resistivity of 18 MQ cm. B. Sample Preparation. AT-cut quartz crystals (5MHz, Q-Sense)coated with silicon oxide or chromium were treated with hexa-methyldisilazane to improve the adhesion of the polymer films tothe surface. Liquid hexamethyldisilazane was syringed upon theQCM crystals, heated for 90 s on a hot plate set at 150°C, and, aftercooling to room temperature, thoroughly rinsed with toluene (Aldrich,Reagent Grade). This procedure yielded hydrophobic surfaces havingstatic water contact angles close to 90°.The polymer solution wasthen spin coated onto the QCM substrates at 209 rad/s (2000 rpm),followed by annealing at 130°C for 60 s in a convection oven. Theaverage film thickness was approximately 120 nm. The polymer-coated substrates were exposed to a broadband 248-nm filtereddeuterium lamp (Oriel, 350 mW) for 30 s to generate the photoacid.The supported films were then baked at 90 °C for different periods ( (17) Schmid, G. M . ; S t ewart, M . D.; S i ngh, V . K.; W i llson, C. G . J. V ac. Sci.Technol. B2002,20(1),185-190. ) ( (18) H oule, F. A .; H insberg, W. D . ; S a nchez, M. I.; H o ffnagle, J. A. J . Vac. Sci. Technol. B 2002, 20 (3), 924-931. ) ( (19) M ckean, D. R.; S chaedeli, U.; Macdonald, S . A. J. P olym. Sci. Part A 1989, 27(12),3927-3935. ) ( (20) Jones, R .L.; Hu, T.J. ; Lin,E. K.; Wu, W.L.;Goldfarb,D.L.; Angelopoulos, M.; T rinque, B . C.; Schmid, G. M.; Stewart, M. D.;Will s on, C. G . J. Polym. S c i.Part B 2004, 4 2 (17),3063-3069. ) Poly(MAdMA) Poly(MAdMA-co-MAA) Figure 1. Acid-catalyzed deprotection products starting fromhomopolymer polymer to the copolymer of poly(methyladamantylmethacrylate-co-methacrylic acid). The average copolymer com-position is determined quantitatively by reflectance infrared spec-troscopy. oftime to obtain variable degrees of deprotection and then quenchedto room temperature by placing the substrates on a large aluminumblock. The deprotection reaction is an acid-catalyzed, thermallyactivated process that results in the adamantyl protecting group beingremoved to form a poly(methyladamantyl methacrylate-co-meth-acrylic acid) copolymer as shown in Figure 1. C. FTIR Spectroscopy. The deprotection level (copolymercomposition) and the amount of residual methylene adamantane inthe films on the chromium-coated quartz crystals were measured bya Bruker Equinox 55 spectrometer (Billerica, MA) with a MCTdetector in reflection mode. The VeeMax reflection optics is employedand is aligned to provide a 76° angle incidence. The entire setup issealed into the sample compartment of the FTIR spectrometer usingPlexiglas with a 10 mm sampling hole of the VeeMax system opento the atmosphere. A resolution of 4 cm-l is used and 100 scans areaveraged to improve the signal-to-noise ratio. The quantification of deprotection reaction degree is based on thebending vibration mode of CH (1360 cm-l) in the MA group ofPMAdMA. This band completely disappears and leaves a flat baselineifall the protected MA groups are reacted. The advantage ofchoosingthis band to measure the deprotection level is that it not only givesan absolute value of deprotection reaction extent but also allows usto discriminate easily between the residual MA and the protectedMA group. The quantification of the amount of residual MA isbased on the stretching vibration of H-C(=C) (3065 cm-) in thefree MA molecule. This band is isolated from other H-C(-C)vibration (usually <3000 cm-l), which makes it possible to quantifyit accurately. Since a pure sample of MA is not available, thecalibration from IR absorbance of MA to its molar quantity cannotbe done directly. Instead, we use an indirect extrapolation methodby assuming the MA is completely trapped if the deprotection levelis close to zero. A quantitative relationship was determined to preparefilms ofknown deprotection extents, based on the above UV exposuredose and bake temperature, such that the average level of methacrylicacid content (fMAA) as a function of reaction time (t) was fMAA=0.78(1- e-0.05r). D. Small-Angle Neutron Scattering: Polymer-Solvent In-teraction Parameter. The Flory-Huggins interaction parameter(x) betweenMAdMA segments and water was estimated from small-angle neutron scattering to be 8.7 in dimensionless units of kgT at298 K, where kg is the Boltzmann constant and T is temperature.Small-angle neutron scattering was performed on the NG 3 30 minstrument at the NIST Center for Neutron Research.The randomphase approximation equations21 for polymer in solvent were fit tosemidilute solutions of PMAdMA in deuterated tetrahydrofuran(THF) with statistical segment length and y as the only fit parameters.Using the relationship between x and the solubility parameterdifference between components, which is known for protonated THF,the solubility parameter for MAdMA was determined.22 Therefore,x for MadMA-water was calculated using the known value of thesolubility parameter for water.22 This methodology emphasizes that ( (21) Hammouda, B. Adu. P o lym. Sci. 1993, 1 0 6, 87-133. ) ( 0I(22) Polymer Handbook, 4 ed.; Wiley-Interscience: Ne w York , 1999 ; Vol. 2, p 675. ) a large chemical mismatch exists between the PMAdMA segmentsand aqueous solutions. E. Quartz Crystal Microbalance Technique. The response ofthe thin films to varied concentrations of TMAH solutions wasmeasured by a quartz crystal microbalance(Q-Sense) with dissipationmode (QCM-D). The QCM-D setup follows the changes in theresonance frequency (~5 MHz) as well as the overtones (15,25, and35 MHz) of the polymer-coated quartz crystal. After mounting thequartz crystals onto the temperature-controlled QCM flow cell(maintained at 298 K), the polymer films were equilibrated for 5min in deionized water. The liquid flow rate was adjusted to 1.025mL/min. During this equilibration stage, changes in the crystalresponse can be attributed to viscosity and density effects from thewater23 with negligible water absorption into the film. Afterequilibrating the polymer film in water, liquid flow was switchedto introduce aqueous TMAH solutions into the cell. Changes in theresonance frequency as well as energy dissipation of the polymer-coated quartz crystals upon exposure to TMAH solutions were thenmeasured as a function oftime. The shifts in the resonance frequencyas well as energy dissipation were calculated relative to the resonancefrequency and energy dissipation of the coated crystal when immersedin water. For the polymer films used in this study, we were unableto accurately measure the shifts in the overtone frequencies due tothe rapid kinetics and large dissipative losses in highly swollenfilms. Therefore, only changes in the fundamental frequency of thequartz and the energy dissipation at this frequency will bepresented;uncertainties are calculated as the estimated standard deviation fromthe mean. In the case where the limits are smaller than the plottedsymbols, the limits are left out for clarity. The QCM technique²4 monitors the change in the mass of anoscillating quartz crystal. In a vacuum, the change in mass (Am) ofa rigid film coated onto the surface of the quartz crystal causes ashift in resonance frequency (AF=Fo -F) that can be calculatedusing the Sauerbrey relationship where Fo is the fundamental resonance frequency ofthe quartz crystaland pq and hg are the density and thickness of the quartz crystal.However, if the coated film is viscoelastic in nature and is immersedin a liquid, the change in the resonance frequency is given by24 where ω=2nF,=yn/pw, h is the thickness of the viscoelasticfilm; uj is the elastic shear modulus of the viscoelastic film, and niand ?i are the shear viscosities of the liquid and viscoelastic film,respectively. The viscoelastic nature of the coated over layer alsoresults in a viscous loss (dissipation) within the film, which is givenby24 For such a film, determination of the film thickness requires thesimultaneous measurement of the shift in the resonance frequencyas well as the energy dissipation.25,26 One can then use eqs 2 and3 to determine the thickness as well as the viscoelastic propertiesof the film. However, since there are four independent variables (p,u,n, and h) involved in the above equations, an accurate estimationof the material parameters requires the measurement ofAF and AD ( (23)Kanazawa, K. K.; Gordon, J . G. Anal. Chim. Acta 1985 , 175,99-105.(24) Voinova, M . V.; R odahl, M.; Jonson, M.; Kasemo, B. Phys. S c r. 1 9 99, 59 (5), 391 - 396. ) ( (25) Kanazawa,K . K . Faraday Discus s . 1 9 97, (107),77-90. ) ( (26) White, C. C.; Schrag, J . L.J. Chem. Ph y s. 1999,111(24) ,1 1192 - 11206. ) Figure 2. Change in QCM frequency (AF) after exposure to 0.065N tetramethylammonium hydroxide solution for different averagemethacrylic acid copolymer content (fMAA). for the fundamental resonance frequency, as well as the harmonicovertones of the fundamental frequency. II.Results Polymer thin films with different average methacrylic acid(fMAA) concentrations were prepared by the in situ acid-catalyzeddeprotection reaction,27 where the hydrophobic PMAdMA isconverted into a methacrylic acid containing copolymer, as shownin Figure 1. The photoacid reaction-diffusion kinetics dependson UV exposure dose and photoacid generator (PAG) loading,which define the acid concentration, as well as photoacidchemistry and size, which determine the acidity anddiffusivity.15,16,18,28-31 To avoid complications from these factors,a constant photoacid concentration is maintained by completephotolysis of a dilute PAG concentration by UV exposure. Asystematic variation of deprotection is produced by changing thereaction time. This approach results in thin films with amorphology in chemical composition induced by photoaciddeprotection in contrast with films prepared from statisticalcopolymers. The response of these films to water and aqueous hydroxidesolutions was characterized by the time dependence ofthe QCM-Dsignal. In Figure 2, the change in resonance frequency (AF)upon exposure to a 0.065 N TMAH solution is shown versusequilibration time for an average fMAA ranging from 0 to 0.78mole fraction. The corresponding change in energy dissipation(AD) by the polymer film is shown in Figure 3. Qualitatively,a drop in the resonance frequency may be interpreted as filmswelling, while an increase in the resonance frequency indicatesfilm dissolution. Similarly, an increase in the dissipation can beinterpreted as being representative of viscous losses due to theswollen film. ( (27) Kang,S . H.; Prabhu, V.M.; Vogt, B.D . ;Lin , E. K.; W u , W.1.; Turnquest, K. Polymer 2006, 47(18),6293-6302. ) (28) Stewart,M. D.; Tran, H. V.; Schmid, G. M.; Stachowiak, T. B.; Becker,D. J.; Willson, C. G. J. Vac. Sci. Technol. B 2002,20(6),2946-2952. (29) Ablaza, S. L.; Cameron, J.F.; Xu, G. Y.; Yueh, W. J. Vac. Sci. Technol.B 2000, 18 (5), 2543-2550. (30) Stewart, M. D.; Somervell, M. H.; Tran, H. V.;Postnikov,S. V.; Willson,C. G. Proc. SPIE 2000, 3999,665-674. (31) Wallraff,G.; Hutchinson,J.;Hinsberg, W.; Houle, F.; Seidel, P.;Johnson,R.; Oldham, W. J. Vac. Sci. Technol. B 1994, 12(6),3857-3862. Figure 3. Change in QCM energy dissipation (AD) after exposureto 0.065 N tetramethylammonium hydroxide solution for differentaverage methacrylic acid copolymer content (fMAA). The lowest fMAA investigated were0 and 0.31, in which nomeasurable mass uptake was observed upon exposure to purewater or TMAH. From Figure 2, once the fMAA is increased to0.41, swelling occurs as evidenced by the decrease in the quartzoscillation frequency and the kinetics ofswelling plateaus withinminutes. There is no further change in frequency for times aslong as 45 min. Hence, we refer to these stable films as beingin a quasiequilibrium state. The short-time behavior is shown tohighlight the time scale of the film response. As the average fMAAis increased to 0.60, the response to the hydroxide solution hasfaster kinetics as well as a larger frequency change that isindicative of increased film swelling. The same trend is observedfor fMAA = 0.70. However, we notice that, with enhanced filmswelling, there is a slight recovery in AF leading to a shallowminimum followed by a plateau. This effect is amplified as theaverage MAA content increases, as seen from the right-handside of Figure 2 forMAA=0.74,0.76, and0.77. The film responseis to first swell and then exhibit a form of relaxation leading toa positive change in AF, consistent with partial dissolution ofthe film. This preswelling followed by dissolution providesevidence for a clear transition in film behavior as a function ofthe average film composition and processing conditions. However,in these cases, the plateau response indicates that the polymerremains in a swollen quasiequilibrium condition. Note that forfMAA=0.74, 0.76, and 0.77, the dissipation of these films atquasiequilibrium is still significant, corresponding to a highlyswollen structure. An overall positive change in AF due tosignificant mass loss is observed only at the highest/MAA=0.78. The energy dissipation measured in the QCM measurementqualitatively tracks the mechanical response of the film. At thelowest fMAA = 0.31, where no swelling is observed, the energydissipation is near zero, indicating an elastic film where theSauerbrey expression can be used to quantify film thickness.8,32,33However, as the film swells, the energy dissipated increases,reaching a level of 265×10-6 for fMAA = 0.70. Therefore, thefilms with the largest change in frequency (most swollen) displaya measurable viscous response. As the fMAA increases, the AD ( (32) Lee, S. W.; Hinsberg, W. D.; Kanazawa, K. Anal. Chem.2 0 02,74 (1 ) ,125-131. ) ( ( 33) V ogt, B. D.; L in, E . K.; Wu, W . L.; White, C . C . J. Phys. Chem. B 2004, 108 (34),12685-12690. ) Figure 4. Polyelectrolyte quasiequilibrium phase behavior deter-mined from the long-time QCM response in frequency (AF) anddissipation (AD). Four regimes are observed: (I) nonswelling films(0

-

1/7

-

2/7

还剩5页未读,是否继续阅读?

继续免费阅读全文产品配置单

瑞典百欧林科技有限公司为您提供《光刻胶薄膜中溶涨性能检测方案(石英晶体天平)》,该方案主要用于其他中溶涨性能检测,参考标准《暂无》,《光刻胶薄膜中溶涨性能检测方案(石英晶体天平)》用到的仪器有QSense卓越版四通道石英晶体微天平、QSense Explorer扩展版石英晶体微天平、QSense全自动八通道石英晶体微天平。

我要纠错

相关方案

咨询

咨询