方案详情文

智能文字提取功能测试中

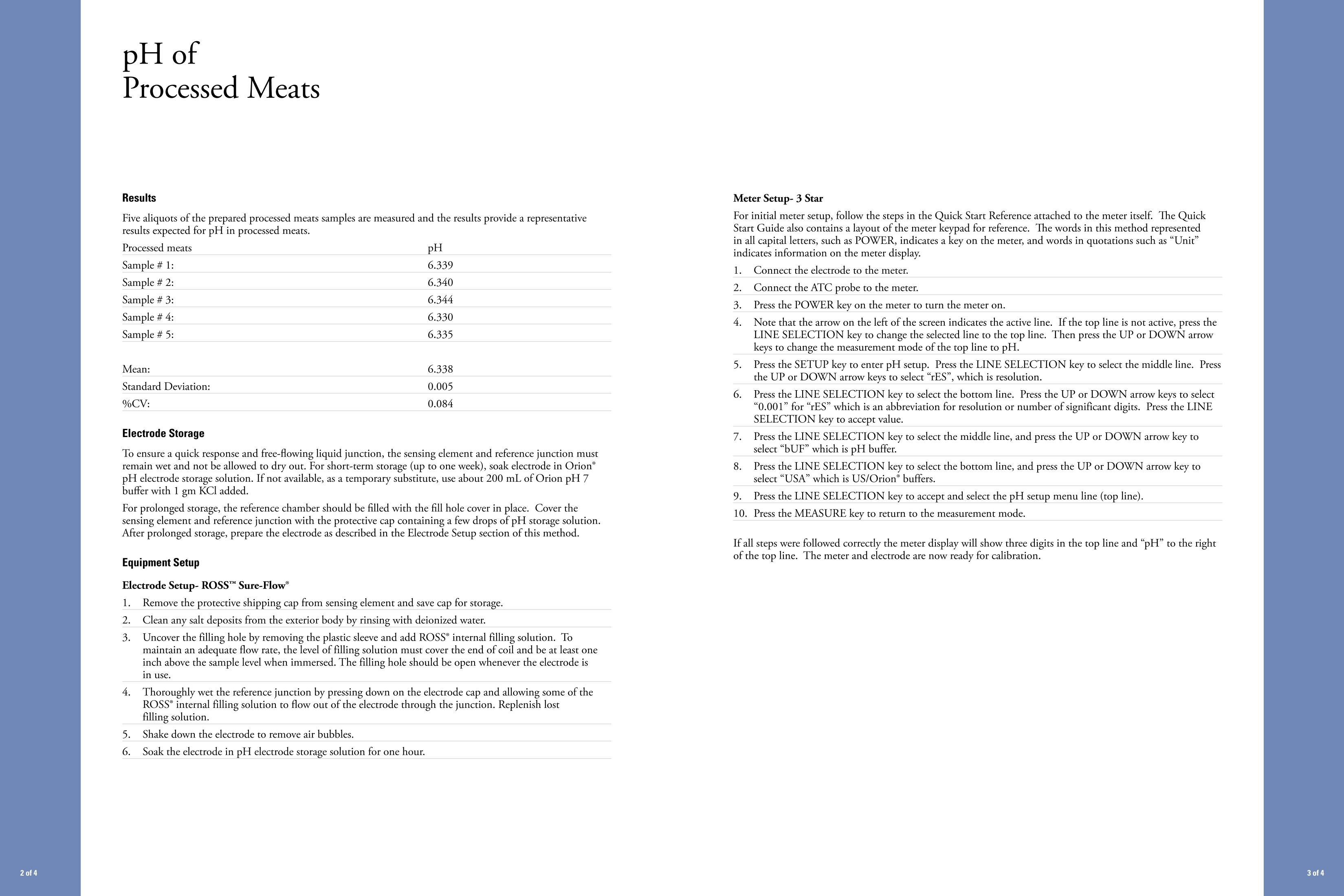

pH ofProcessed Meats Star SeriesMethod Note M-1402-E 03/05 RevB pH ofProcessed Meats Calibration and Analysis 1. Allow all the standards and the samples to attain room temperature for precise measurements since themeasurement is temperature sensitive. 2C.alibrate the meter using the pH 7.00 buffer followed by the pH 4.01 buffer, stirring the standards ata uniform rate. 3P.lace electrode and ATC probe into beaker with pH 7.00 buffer standard such that the electrode tip isfully immersed in the solution. Press the CALIBRATE key. pH·ProcessedMeats· Orion ROSS@Sure-Flow@8172BNWPpH Electrode Introduction pH measurements are made in solutions, which contain substantial amounts of dissolved salts. Under theseconditions, conventional pH electrodes make measurements quickly and precisely. 4.Wait for stable reading (1-2minutes). Enter standard value of 7.00 using the UP and DOWN arrowkeys and the DECIMAL /DIGIT key. 5.Press CALIBRATE key to accept 7.00 standard and press the STIRRER key to turn the stirrer off. 6.Rinse electrode and ATC probe with deionized water. Gently remove excess solution from the outersleeve of the electrode by dabbing with a clean paper tissue. Do not wipe or rub the sensing element ofthe electrode. 17.1Place the electrode and ATC probe into beaker with the pH 4.01 buffer standard such that theelectrode tip is fully immersed in the solution. 1. 3 Star benchtop pH meter 1112000 2. ROSSSure-Flow°pH electrode 8172BNWP 3. ATC temperature probe 927007MD 4. Magnetic stir plate and bar 096019 5. Benchtop electrode stand 1110001 6. Beakers (50 mLand 500 mL) 8.Wait for a stable reading (1-2 minutes). Enter standard of 4.01 using the UP and DOWN arrow keysand the DECIMAL /DIGITkey. 7. Graduated cylinder (30 mL and 200 mL) 8.Balance 9. Press MEASURE key to accept 4.01 standard and to move to the measure mode of the meter. 10. Rinse the electrode and ATC probe thoroughly with deionized water. Gently remove excess solutionfrom the outer sleeve of the electrode by dabbing with a clean paper tissue. Do not wipe or rub thesensing element. Required Solutions Cat.No. 1. pH 4.01 buffer,5x60 mL 910460 2. pH 7.00 buffer, 5x60 mL 910760 11. Place the electrode and ATC probe into prepared sample such that the electrode tip is fully immersedin the solution. Press the MEASURE key on the meter. The pH icon will flash as the measurement isbeing made. The pH icon will become solid and the display value will freeze when a stable reading isachieved. This value is logged and printed automatically. 3. pH 10.01 buffer, 5 x 60 mL 911060 4. Reference filling solution, ROSS° reference filling solution 810007 5. Electrode storage solution 910001 Remember, rinse electrodes with deionized water between measurements. Penetrate each sample to thesame depth to reproduce sample measurement. Upon completion of samples, rinse the electrode withdeionized water and store the electrode according to instructions in the Electrode Storage section of thismethod note. 6. Deionized water Calibration Standard Preparation 1. Using a graduated cylinder, transfer 30 mL of the pH 7.00 buffer into a 50 mL beaker. 2. Using a graduated cylinder, transfer 30 mL of the pH 4.01 buffer into a 50 mL beaker. Sample Preparation 1. Weigh 40.0 grams of the processed meat (97 % fat free ham) sample. Tear the sample to small pieces. 2. Soak the sample in 200 mL of the deionnized water for an hour. 3. Using a graduated cylinder, measure 30 mL of the prepared sample into a 50 mL beaker. Mix samplewith Orion° stirrer. 4.Repeat this procedure for additional measurements. ( Environmental Instruments Water Analysis Instruments ) www.thermo.com 166 Cummings CenterBeverly, MA 01915 USAM-1402-E 03/05 RevB248094-001 Toll Free: 1-800-225-1480Tel:1-978-232-6000Dom. Fax:1-978-232-6015IntlFax:978-232-6031www.thermo.com/waterO 2005 Thermo Electron Corporation RegisteredIs O9001:2000 All rights reserved Results Five aliquots of the prepared processed meats samples are measured and the results provide a representativeresults expected for pH in processed meats. Processed meats pH Sample # 1: 6.339 Sample # 2: 6.340 Sample #3: 6.344 Sample #4: 6.330 Sample #5: 6.335 Mean: 6.338 Standard Deviation: 0.005 %CV: 0.084 Electrode Storage To ensure a quick response and free-flowing liquid junction, the sensing element and reference junction mustremain wet and not be allowed to dry out. For short-term storage (up to one week), soak electrode in Orion°pHelectrode storage solution. If not available, as a temporary substitute, use about 200 mL of Orion pH 7buffer with 1 gm KCl added. For prolonged storage, the reference chamber should be filled with the fill hole cover in place. Cover thesensing element and reference junction with the protective cap containing a few drops of pH storage solution.After prolonged storage, prepare the electrode as described in the Electrode Setup section of this method. Equipment Setup Electrode Setup- ROSS" Sure-Flow° 1.Remove the protective shipping cap from sensing element and save cap for storage. 2..Clean any salt deposits from the exterior body by rinsing with deionized water. 3. Uncover the filling hole by removing the plastic sleeve and add ROSS°internal filling solution. Tomaintain an adequate flow rate, the level of filling solution must cover the end of coil and be at least oneinch above the sample level when immersed. The filling hole should be open whenever the electrode isin use. 4 Thoroughly wet the reference junction by pressing down on the electrode cap and allowing some of theROSS internal filling solution to flow out of the electrode through the junction. Replenish lostfilling solution. 5.Shake down the electrode to remove air bubbles. For initial meter setup, follow the steps in the Quick Start Reference attached to the meter itself. The QuickStart Guide also contains a layout of the meter keypad for reference. The words in this method representedin all capital letters, such as POWER, indicates a key on the meter, and words in quotations such as “Unit"indicates information on the meter display. 2. Connect the ATC probe to the meter. 1 Connect the electrode to the meter 3.Press the POWER key on the meter to turn the meter on. 4.Note that the arrow on the left of the screen indicates the active line. If the top line is not active, press theLINE SELECTION key to change the selected line to the top line. Then press the UP or DOWN arrowkeys to change the measurement mode of the top line to pH. 5. 1Press the SETUP key to enter pH setup. Press the LINE SELECTION key to select the middle line. Pressthe UP or DOWN arrow keys to select “rES”, which is resolution. 6.Press the LINE SELECTION key to select the bottom line. Press the UP or DOWN arrow keys to select“0.001”for "rES” which is an abbreviation for resolution or number of significant digits. Press the LINESELECTION key to accept value. 7.P1ress the LINE SELECTION key to select the middle line, and press the UP or DOWN arrow key toselect “bUF”which is pH buffer. 8.Press the LINE SELECTION key to select the bottom line, and press the UP or DOWN arrow key toselect“USA”which is US/Orion° buffers. 9. Press the LINE SELECTION key to accept and select the pH setup menu line (top line). 10. Press the MEASURE key to return to the measurement mode. If all steps were followed correctly the meter display will show three digits in the top line and“pH" to the rightovof the top line. The meter and electrode are now ready for calibration. of of ofof

关闭-

1/2

-

2/2

产品配置单

赛默飞中国实验室产品事业部为您提供《肉制品中pH值检测方案 》,该方案主要用于腌腊肉制品中理化分析检测,参考标准《暂无》,《肉制品中pH值检测方案 》用到的仪器有台式pH/ORP/ISE/溶解氧/电导率测量仪、Orion 3-Star台式(便携式)pH/ORP测量仪。

我要纠错