方案详情文

智能文字提取功能测试中

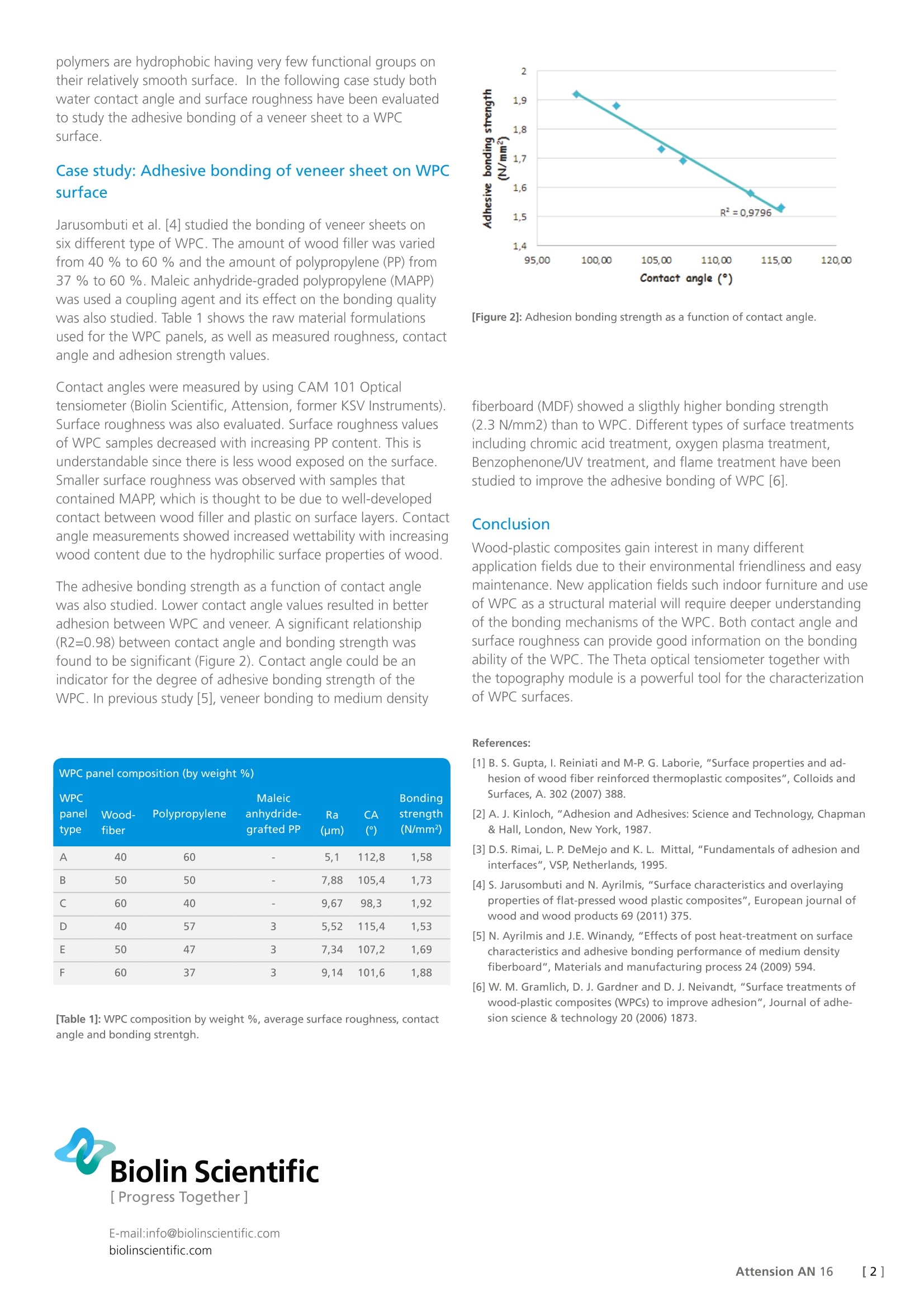

Biolin Scientific[ Progress Together] [Application Note] 16 Adhesion to wood-plastic composites This application note illustrates how the Attension Theta Optical Tensiometercombined with the 3D topography module can be utilized to study adhesion towood-plastic composites. Introduction Wood-plastic composites (WPCs) [1] are composed of threemain ingredients: recycled thermoplastics, such as polyethylene,polypropylene and polyvinyl chloride, wood filler and additives.The plastic part constitutes 30- 70 % of the mass of WPC andthe wood filler the additional 30 -70 %.About5% of WPCare additives to improve their processing, stability and physicalappearance. Wood-plastic composites are relatively new materialsas they started to emerge at the beginning of 90's. The mostwidespread use of WPCs is in outdoor decking but it is alsoused in railings and siding as well as park benches and indoorfurniture. Wood-plastic composites are thought to be moreenvironmentally friendly and require less maintenance than thealternatives of solid wood treated with preservatives. [Figure 1]: Wood-plastic composites In some applications, the ability to coat or bond the WPC isneeded. For example, overlaying the WPC panels with veneersheets improves their appearance and properties for furnituremanufacturing. Bonding of WPCs is required to fabricatelaminated beams for structural applications. Adhesion is extremelyimportant in both of these processes. The adhesion mechanismcan be divided into three categories: l) mechanical interlocking,II) physical bonding and III) chemical bonding [2]. Together thesemechanisms are responsible for adhesion and usually one ofthem plays a dominant role. Mechanical interlocking strengthdepends on the size and the geometry of the locking sites; thussurface topography. Topography will increase the surface area andthus increase the binding sites for other adhesion mechanisms. Attension Theta combined with 3D topography module Physical bonds include hydrogen and van der Waals bonds whichare generally relatively weak. Chemical bonding is strongerand bonds include metallic, atomic and ionic bonds.Availablephysical and chemical bonds depend on the surface chemistryof the substrate and are sometimes collectively described asthermodynamic adhesion [3]. Wettability of the surface is closely related to the adhesion sincebetter wettability usually indicates better adhesion. As most of thesurface modification methods will influence both the roughnessof the surface and the chemical composition, the separation ofthese two is important for comprehensive understanding of theadhesion process. The Theta optical tensiometer combined with3D topography module enable quick and easy measurement ofboth surface roughness and contact angle. As with any composite materials, the properties of a WPC depencon the properties of its components. Wood is a hydrophilic porouscomposite of cellulose, lignin and hemicellulose that are rich infunctional groups like hydroxyls. On the other hand, thermoplastic polymers are hydrophobic having very few functional groups ontheir relatively smooth surface. In the following case study bothwater contact angle and surface roughness have been evaluatedto study the adhesive bonding of a veneer sheet to a WPCsurface. Case study: Adhesive bonding of veneer sheet on WPCsurface Jarusombuti et al. [4] studied the bonding of veneer sheets onsix different type of WPC. The amount of wood filler was variedfrom 40 % to 60 % and the amount of polypropylene (PP) from37 % to 60 %. Maleic anhydride-graded polypropylene (MAPP)was used a coupling agent and its effect on the bonding qualitywas also studied. Table 1 shows the raw material formulationsused for the WPC panels, as well as measured roughness, contactangle and adhesion strength values. Contact angles were measured by using CAM 101 Opticaltensiometer (Biolin Scientific, Attension, former KSV Instruments).Surface roughness was also evaluated. Surface roughness valuesof WPC samples decreased with increasing PP content. This isunderstandable since there is less wood exposed on the surface.Smaller surface roughness was observed with samples thatcontained MAPP, which is thought to be due to well-developedcontact between wood filler and plastic on surface layers. Contactangle measurements showed increased wettability with increasingwood content due to the hydrophilic surface properties of wood. The adhesive bonding strength as a function of contact anglewas also studied. Lower contact angle values resulted in betteradhesion between WPC and veneer. A significant relationship(R2=0.98) between contact angle and bonding strength wasfound to be significant (Figure 2). Contact angle could be anindicator for the degree of adhesive bonding strength of theWPC. In previous study [5], veneer bonding to medium density WPC panel composition (by weight %) WPC Maleic Bonding panel Wood- Polypropylene anhydride- Ra strength type fiber grafted PP (um) (N/mm²) A 40 60 5,1 112,8 1,58 B 50 50 7,88 105,4 1,73 C 60 40 9,67 98,3 1,92 D 40 57 3 5,52 115,4 1,53 E 50 47 3 7,34 107,2 1,69 F 60 37 3 9,14 101,6 1,88 [Table 1]: WPC composition by weight %, average surface roughness, contactangle and bonding strentgh. [Figure 2]: Adhesion bonding strength as a function of contact angle. fiberboard (MDF) showed a sligthly higher bonding strength(2.3 N/mm2) than to WPC. Different types of surface treatmentsincluding chromic acid treatment, oxygen plasma treatment,Benzophenone/UV treatment, and flame treatment have beenstudied to improve the adhesive bonding of WPC [6]. Conclusion Wood-plastic composites gain interest in many differentapplication fields due to their environmental friendliness and easymaintenance. New application fields such indoor furniture and useof WPC as a structural material will require deeper understandingof the bonding mechanisms of the WPC. Both contact angle andsurface roughness can provide good information on the bondingability of the WPC. The Theta optical tensiometer together withthe topography module is a powerful tool for the characterizationof WPC surfaces. ( References: ) [1] B. S. Gupta, I. Reiniati and M-P.G. Laborie, "Surface properties and ad-hesion of wood fiber reinforced thermoplastic composites", Colloids andSurfaces, A. 302 (2007) 388. [2] A. J. Kinloch, "Adhesion and Adhesives: Science and Technology, Chapman& Hall,London, New York, 1987. [3] D.S. Rimai, L. P. DeMejo and K. L. Mittal, "Fundamentals of adhesion andinterfaces", VSP, Netherlands, 1995. [4] S. Jarusombuti and N. Ayrilmis, "Surface characteristics and overlayingproperties of flat-pressed wood plastic composites", European journal ofwood and wood products 69 (2011)375. [5] N. Ayrilmis and J.E. Winandy,"Effects of post heat-treatment on surfacecharacteristics and adhesive bonding performance of medium densityfiberboard", Materials and manufacturing process 24 (2009) 594. ( [6] W. M. Gramlich, D. J. Gardner and D. J. Neivandt, "Surface treatments of wood-plastic com po sites (WPCs) to im pr ove adhesion", J ournal of adhe- sion science & technolog y 20 (2006)1873. ) []Attension AN

关闭-

1/2

-

2/2

产品配置单

瑞典百欧林科技有限公司为您提供《光学接触角仪在木材/塑料复合物粘附的应用》,该方案主要用于木材/板材中null检测,参考标准《暂无》,《光学接触角仪在木材/塑料复合物粘附的应用》用到的仪器有Attension Theta Flex 光学接触角仪、Theta Lite 光学接触角仪、Theta QC 光学接触角仪。

我要纠错

相关方案

咨询

咨询