方案详情文

智能文字提取功能测试中

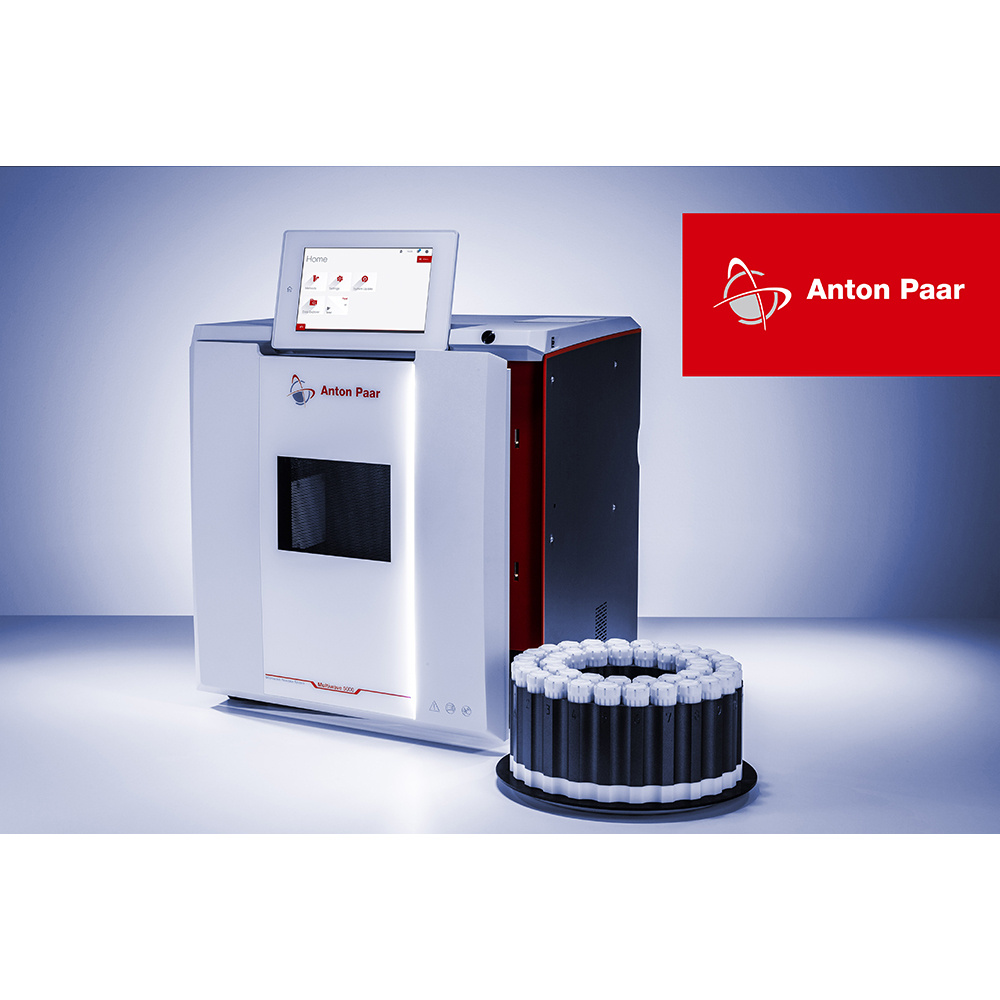

Microchemical Journal 96 (2010) 4-11Contents lists available at ScienceDirectMicrochemical Journal J.S.F. Pereira et al. / Microchemical Journal 96 (2010) 4-115 0026-265X/$ - see front matter 2010 Elsevier B.V. All rights reserved.doi:10.1016/j.microc.2009.12.016 journal homepage: www.elsevier.com/locate/microc Determination of metals and metalloids in light and heavy crude oil by ICP-MS afterdigestion by microwave-induced combustion Juliana S.F. Pereira, Diogo P. Moraes, Fabiane G. Antes, Liange O. Diehl, Maria F.P. Santos D,Regina C.L. Guimaraes, Teresa C.O. Fonseca, Valderi L. Dressler , Erico M.M. Floresa,* Departamento de Quimica, Universidade Federal de Santa Maria, 97105-900, Santa Maria, RS, Brazil and Instituto Nacional de Ciencia e Tecnologia Bioanalitica, Campinas, SP, Brazil"Departamento de Ciencias Matematicas e Naturais, Universidade Federal do Espirito Santo, 29932-540, Sao Mateus, ES, Brazil Centro de Pesquisas e Desenvolvimento Leopoldo Americo Miguez de Mello-CENPES/PETROBRAS S. A.,21941-945, Rio de Janeiro, RJ, Brazil Article history: Received 21 November 2009Received in revised form 23 December 2009Accepted 24 December 2009 Available online 11 January 2010 Keywords:Microwave-induced combustionLight and heavy crude oilMetals and metalloids ICP-MS A BSTRACT A method for light and heavy crude oil digestion using microwave-induced combustion (MIC) in closedvessels is described for further determination of Ag, As, Ba, Bi, Ca, Cd, Cr, Fe, K, Mg, Li, Mn, Mo,Ni, Pb,Rb, Se,Sr, Tl, V, and Zn by inductively coupled plasma mass spectrometry (ICP-MS). Conventional microwave-assisted acid digestion (MW-AD) in pressurized vessels and analyte determination by inductively coupledplasma optical emission spectrometry (ICP OES) were also used for results comparison. For MIC procedure,samples were wrapped in polyethylene films and combusted using 20 bar of oxygen and 50 ul of 6 mol1-ammonium nitrate as aid for ignition. The concentration of nitric acid used as absorbing solution wasevaluated (1, 2, 4, 7, 10 and 14 mol1) using an additional reflux step after combustion. Accuracy wasevaluated for As, Ba, Ni, Se V, and Zn using certified reference material (CRM) with similar matrixcomposition and for Cr, Fe, K, Mg, Mn, and Mo by neutron activation analysis (NAA). Recovery tests werealso performed for all the analytes by MIC and they were better than 97% using 2 mol1-1 nitric acid asabsorbing solution (with reflux step). Agreement with certified values and NAA results was better than 95%.Using MIC it was possible to obtain lower limits of detection (LODs) by ICP-MS and also by ICP OES incomparison with those obtained by MW-AD. In spite of both sample preparation techniques wereapparently suitable for crude oil digestion, MIC was preferable in view of the possibility of using dilutednitric acid as absorbing solution that is an important aspect to minimize interferences by ICP-MS and ICPOES. In order to avoid polyatomic interferences on 52cr and 56Fe determinations by ICP-MS, a dynamicreaction cell with ammonia gas was used. Residual carbon content in digests obtained by MW-AD and MICwas 15% and<1%, respectively. Using MIC the simultaneous digestion of 8 samples was possible in less than30 min. 1. Introduction Crude oil is composed essentially of hydrocarbons, however alsocontaining oxygen, sulfur, nitrogen and metals [1,2]. Metal andmetalloid constituents could be naturally found in crude oil or theycould be added during production, transportation and storage. Ingeneral, these elements are present in crude oil as inorganic salts(mainly as chloride and sulfates ofK, Mg, Na and Ca), associated withthe water phase of crude oil emulsions, or as organometalliccompounds of Ca, Cu, Cr, Mg, Fe, Ni, Ti, V and Zn adsorbed in water-oil interface, acting as emulsion stabilizers [2,3]. Even in traceamounts, the presence of some elements could be deleterious to ( * C or responding author.T e l./fax: +55 55 3220 9445. E-mail address: f lore s @quimica.uf s m.br (E. M.M. Flo r es). ) refining processes, especially due to corrosion, catalyst poisoning andby affecting the quality of refined products [4]. In addition, somemetals could be responsible for environmental pollution and emissionof mutagenic and carcinogenic compounds [5,6]. On the other hand the presence of Ni, V, Fe and Cu could affectthe activity of catalysts resulting in an increase of gas and cokeformation and reducing yields of gasoline [2]. At high temperaturepower generators, the presence of metallic constituents, as V, K, Mgand Ca, may lead to ash deposits on the turbine rotors, reducing theefficiency of heat transfer and causing corrosion [2]. Therefore, theoccurrence of inorganic constituents in crude oil is of considerableinterest for petroleum industry and is necessary to developmethods to determine them in light and specially in heavy crudeoil emulsions for which the conventional methods present somelimitations. Nowadays, the production of heavy crude oil (°API lower than 19)has increased significantly and, as a consequence, refineries are processing higher amounts of this type of oil [7]. However, heavycrude oil could present several problems related to matrix complexity,making the application of conventional techniques of elementaldetermination and classic sample preparation methods more difficult8-101. Literature data concerning to metal and metalloid determinationsin crude oils had a great improvement and different techniques havebeen used for crude oil digestion or using direct sample introductionfor further determination by inductively coupled plasma massspectrometry (ICP-MS) or inductively coupled plasma optical emis-sion spectrometry (ICPOES). Particularly, the use of ICP-MS is suitablefor trace element determination due to multielement capacity and lowlimits of detection (LODs) achieved.Analysis of crude oil is describedin literature by sample dilution in organic solvents [11,12] or usingmicroemulsions [5,13,14]. However, the use of these procedures isfrequently associated with atomic absorption spectrometry techni-ques or ICP OES. The use of organic solvents or microemulsions withsurfactants in ICP-MS could cause plasma instability, matrix inter-ferences and carbon deposits on sampler and skimmer cones [12,15].In view of this, some alternatives have been proposed in order tominimize these interferences, as the use of dynamic reaction cell(DRC) coupled to ICP-MS[16]. Metal determination in crude oil and residual fuels is recom-mended by the American Society of Testing Materials (ASTM) byusing dry ashing or dilution in organic solvents according to ASTM D5863 [17] and ASTM D 5708 [18] methods for Ni, V, Fe and Nadeterminations by flame atomic absorption spectrometry (F AAS) andNi, V and Fe determinations by ICP OES, respectively. In one of thesemethods, the digestion of sample (1 to 20 g) is carried out usingconcentrated sulfuric acid in an open glass vessel. The mixture isheated using an infrared lamp until dryness and the residual carbon isburned in a muffle furnace at 525 C. After, the inorganic residue isdigested with concentrated nitric acid, evaporated to dryness anddiluted with 5% (v/v) nitric acid [18]. In spite of relatively goodperformance of this method for crude oil digestion, the samplepreparation procedures are particularly prone to some drawbacks astime consuming, risks of analyte losses, contamination and lowsample throughput. In addition, these procedures could be notcompatible with modern requirements for trace analysis, usingmultielement techniques, as ICP-MS. In this sense, the use of microwave radiation as a potential samplepreparation technique has been applied in the last years due to highefficiency of heat transfer and sample digestion efficiency [19,20].Microwave-assisted acid digestion (MW-AD) using concentratedacids for crude oil decomposition has been used for further metaland non-metal determinations, allowing high efficiency of sampledecomposition and minimizing risks of analyte losses and contami-nation [21-23]. Despite the good efficiency of sample digestion, theuse of concentrated acids could increase the blank values and cannotbe supported by some analytical techniques, as ICP-MS and ICP OES,and a subsequent step could be necessary to remove (or dilute) theacid excess [24-26]. In this respect, combustion techniques areparticularly more effective for the conversion of matrix compounds tothe correspondent oxidation products due to high temperatureachieved [27,28]. Microwave-induced combustion (MIC) technique was proposed inrecent years in order to combine the advantages of microwave-assisted digestion and combustion techniques, allowing the digestionof samples that are difficult to bring into solution with a high samplethroughput and the application of reflux step after combustion,improving analyte recoveries [29]. The feasibility of this samplepreparation technique has been demonstrated for digestion ofbiological samples [30,31], elastomers [32], coal [33] and petrochem-ical samples,as petroleum coke [34,35], heavy crude oil [36] and crudeoil distillation residues [37,38] using diluted solutions for most ofapplications. In this work, MIC is proposed by the first time for light andheavy crude oil emulsion digestion for further determination of Ag,As, Ba, Bi, Ca, Cd, Cr, Fe, K, Mg, Li, Mn, Mo, Ni, Pb, Rb, Se, Sr, Tl, V,and Zn by ICP-MS. Different concentrations of nitric acid (1 to14 moll-l) were evaluated as absorbing solution using a refluxstep. In order to avoid polyatomic interferences over 52Cr and 56Fedeterminations by ICP-MS, a dynamic reaction cell with ammoniaas reaction gas was evaluated. Results obtained with the proposedprocedure by MIC were compared with those using MW-AD anddetermination was also performed by ICP OES for some elements.The efficiency of digestion was checked by the residual carboncontent in digests. Accuracy was evaluated using certified refer-ence material (CRM) with similar matrix composition and byneutron activation analysis (NAA). For Ag, Bi, Ca, Cd, Li, Pb,Rb, Sr,Tl and Zn a comparison of results with previous digestion by MW-AD was performed. Recovery tests were also performed for allanalytes. 2. Materials and methods 2.1. Instrumentation Crude oil samples were decomposed by MIC and MW-AD using amultiwave 3000 microwave sample preparation system (Anton Paar,Graz, Austria) with software version of v1.27-Synt (to run with amaximum pressure rate of 3 bar s for MIC procedure) [39]. Thesystem was equipped with eight high-pressure quartz vessels withan internal volume of 80 ml (maximum pressure and temperature of80 bar and 280°C, respectively). For MIC digestion, a commercialquartz holder was used to insert the samples inside the quartzvessels. An inductively coupled plasma mass spectrometer (PerkinElmer-SCIEX, Model Elan DRC II, Thornhill, Canada) equipped with aconcentric nebulizer (Meinhard Associates, Golden, USA), a baffledcyclonic spray chamber (Glass Expansion, Inc., West Merbourne,Australia) and a quartz torch with a quartz injector tube (2 mm i.d.)was used for analysis of digests after MIC and MW-AD. Instrumentalperformance optimization, including nebulizer gas flow rate, RFpower and ion lens voltage, was performed and operational condi-tions are described in Table 1. Chromium and Fe measurements byICP-MS were performed with DRC using ammonia (purity higher than99.999%) as reaction gas. The DRC parameters were adjusted in orderto minimize the interferences on 52cr+, 53cr+, 54Fe+ and 56Fe+isotopes. Adjustment of the reaction gas flow rate and the rejectionparameter q (RPq), that defines the low mass boundary of the ionstability region in the reaction cell, were optimized in order to obtainthe lowest LOD. The range of NH and RPq values were studied from0.1 to 1.2 ml min-1 and 0.1 to 0.75, respectively. Metal determination in digests was also carried out using aninductively coupled plasma optical emission spectrometer with axialview configuration (Model Spectro Ciros CCD, Spectro AnalyticalInstruments, Kleve, Germany) equipped with a cross flow nebulizercoupled to a double pass-Scott type spray chamber.Plasma operatingconditions and selected wavelength are also described in Table 1.This equipment was also used for the determination of residualcarbon content and conditions were selected according to literature[33]. For ICP-MS and ICP OES determinations, argon 99.996% (WhiteMartins - Praxair, Sao Paulo, Brazil) was used for plasma generation,nebulization and auxiliary gas. 2.2. Reagents, standards and samples All the reagents used were of analytical grade (Merck,Darmstadt,Germany). Water was purified using a Milli-Q system, (18.2MQ cm,Millipore, Billerica, USA) and it was used to prepare all reagents and Table1Operational parameters for trace element determination by ICP-MS and ICP OES. Use of DRC-ICP-MS. RCC measurements were performed according to reference [44]. standard solutions. Multielement stock standard solution containing10 mg-of all the elements studied (SCP33MS, SCP Science, Quebec,Canada) was used to prepare analytical standards by sequentialdilution in 5% (v/v) HNO3 (Merck) in the range of 0.025 to 10 ug1for ICP-MS and 5 to 100 ug1 for ICP OES. Ammonium nitrate solution (6moll-1) was used as igniter forMIC procedure and it was prepared by dissolving the salt (Merck) inwater. Small discs of paper (15 mm of diameter, about 12 mg), withlow ash content (Black Ribbon Ashless, Schleicher and Schuell, Dassel,Germany) were also used to aid the combustion process. The paperwas previously cleaned with 10% (v/v) HNO for 40 min in anultrasonic bath and further washed with water. After, the paper wasdried in class 100 laminar bench (CSLH-12, Veco, Brazil). Concentrated nitric acid (Merck) was purified using a sub-boilingsystem (Milestone, Model Duopur, Bergamo, Italy) and it was used toprepare the absorbing solutions evaluated for MIC procedure and formicrowave-assisted acid digestion in closed vessels. The accuracy was checked using analyte addition and by analysisof CRM (NIST SRM 1634c, Trace metals in fuel oil). Spiked sampleswere performed by addition of 2.5 pl of 10mg1-1 multielementreference solution (SCP33MS) and 10 pl of 1000 mg 1-of Ca, Ni andK reference solutions (due to higher concentration of these elementsin samples). Spikes were performed on the sample inside thepolyethylene wrap before its sealing. Natural emulsified light crude oil (identified as C and D) and heavycrude oil samples (identified as A and B) with °API in the range of 10to 35 were used. Samples were homogenized by heating in an oven at60℃ for 20 min previously to digestion by MIC and MW-AD. For MICprocedure, samples were wrapped in polyethylene films as previouslydescribed in literature [36]. Microwave-assisted acid digestion was performed for all samplesinvestigated for further results comparison with those obtained byMIC. In this sense, about 250 mg of crude oil samples were weighedinside quartz vessels and 6 ml of concentrated nitric acid and 2 ml of30% (v/v) H202 were added. The operational conditions and theheating program used were carried out according to the conditionsrecommended by the manufacturer [39] as follows: 400 W for 10 min(ramp of 10 min), 1000 W for 10 min (ramp of 10 min) and 0 W for20 min (cooling). After cooling, digests were diluted with water to30 ml in a polypropylene vessel for further analysis. For the proposed procedure by MIC, polyethylene films containingsample masses in the range of 100 to 500 mg were placed togetherwith the filter paper on the quartz holder. Ammonium nitrate (50 ul of6 mol1- solution) was immediately added to the paper. The holdercontaining the sample was placed inside the quartz vessel, previouslycharged with 6 ml of absorbing solution (1,2, 4, 7, 10 or 14 mol1-1HNO3). After closing and capping the rotor, the vessels werepressurized with oxygen at 20 bar for 1 min. Rotor with the vesselswas placed inside the microwave cavity and the selected program wasstarted. The microwave irradiation program used for MIC was: i)1400 W for 60 s (sample ignition), ii) or 1400 W for 5 min (optionalreflux step) and iii) 0 W for 20 min (cooling step). After digestion thepressure of each vessel was released and the resultant solutions weretransferred into polypropylene vessels and diluted with water to30 ml for further analysis by ICP-MS or ICP OES. After each run,holders were soaked in concentrated HNO3 for 10 min followed byrinsing with water. 3. Results and discussion 3.1. Optimization of DRC-ICP-MS Despite of multielement capability of ICP-MS, some elements areseriously affected by isobaric and polyatomic interferences that aregenerated from several precursors, such as sample matrix, reagentsand plasma gases. Concerning the elements studied in this work, moresignificant interferences were observed for the more abundantisotopes of Cr and Fe (52cr+, 53cr+, 54Fet and 56Fet) due to thecombinations of argon isotopes with oxygen and carbon isotopes [40].To overcome these drawbacks using low resolution ICP-MS instru-ments, some technologies, as DRC, have been developed using an inertor a reaction gas to destroy polyatomic ions. More specifically, when areaction gas is used, this gas could be added to the reaction cellpositioned after the interface of the instrument [41]. The use of NHghas been described to minimize polyatomic ion interferences over Crand Fe isotopes [16]. Therefore, this approach was evaluated in thiswork for the determination of Cr and Fe in crude oil after digestion byMIC and MW-AD. Operational conditions of DRC were optimizedusing blank solution and 1ug 1-1 Cr and Fe standard solutions. Thesesolutions were prepared in the presence of 1000 mg1l of carbon and5%(v/v) HNO3 in order to match the digests obtained by MW-AD(taking into account the relatively high RCC values obtained in digestsusing this method). Initially, the NH flow rate was evaluated in the range of 0.1 to1.2 ml min, while the RPq value was maintained at 0.25 and thebest condition for each isotope was chosen in view of better LODsachieved (Fig. 1). It is important to point out that the LOD was significantlydecreased using higher flow rates of NH for all isotopes evaluated.In order to achieve better LODs and to reduce the measurement time,the NH flow rate around 0.5 ml min- was selected for furtherstudies. After, the RPq influence was evaluated from 0.1 to 0.75,maintaining the NH flow rate at 0.5 ml min一1,according to Fig. 2. Fig. 1. Influence of NH, flow rate (from 0.1 to 1.2 ml min-1,RPq value of 0.25) on (A) m/z 52Cr+; (B) m/z 53cr+;(C) m/z 54Fe+;(D) m/z 56Fe+. It was possible to observe that the best RPq values for 52cr+,53cr+,54Fe+and 56Fe+ were 0.45,0.45, 0.45 and 0.50, respectively. Since theLODs for 52cr*and 56Fe were lower in comparison with thoseobtained for 53cr+and 5Fe+, these isotopes (52Cr+and 56Fet) wereused for further Cr and Fe determination in light and heavy crude oilby DRC-ICP-MS. 3.2. Microwave-assisted acid digestion Sample preparation procedure based on MW-AD was investigatedfor light and heavy crude oil digestion and a comparison with theproposed MIC procedure was performed. After digestion, determina- Results for trace element determination in heavy (samples A and B) and light (samplesC and D) crude oil by ICP-MS after microwave-assisted acid digestion. Results in ug g1(mean and standard deviation for n=3). Results for Ca, K and Mg were obtained by ICPOES. A B C D Ag <0.03 <0.03 <0.03 <0.03 As <0.12 <0.12 1.92±0.15 <0.12 Ba 0.730±0.060 8.15±0.52 0.468±0.033 1.13±0.11 Bi <0.03 <0.03 <0.03 <0.03 Ca 5.72±0.51 415±38 8.29±0.73 752±26 Cd <0.02 <0.02 <0.02 <0.02 Cr <0.05 0.055±0.005 <0.05 0.248±0.030 Fe 1.64±0.21 2.51±0.24 1.97±0.17 4.18±0.38 K 7.57±0.65 105±11 2.72±0.18 181±11 Li 0.099±0.008 1.63±0.17 <0.04 <0.04 Mg <0.40 152±16 2.23±0.18 134±11 Mn 0.042±0.003 <0.03 <0.03 0.059±0.006 Mo 0.067±0.006 0.241±0.021 0.111±0.01 <0.025 Ni 23.6±0.2 11.2±1.1 21.3±0.1 4.12±0.34 Pb <0.03 0.194±0.020 0.571±0.051 0.951±0.085 Rb <0.03 0.252±0.023 <0.03 <0.03 Se <0.20 1.47±0.16 <0.20 0.194±0.020 Sr <0.07 43.1±4.2 0.095±0.008 60.6±4.1 Tl <0.02 <0.02 <0.02 <0.02 2.99±0.20 13.8±1.4 11.1±0.6 2.80±0.19 Zn <0.25 1.31±0.14 1.83±0.14 2.41±0.22 (heavy crude oil) and D (light crude oil). On the other hand, higherconcentration of Ni was observed in sample A (heavy crude oil) and C(light crude oil), and for V in samples B (heavy crude oil) and C (lightcrude oil). Nickel and V, due to higher concentrations, weredetermined by ICP-MS and also by ICP OES and agreement betterthan 95% was obtained between then results for both techniques. The concentration of other elements, as As, Ba, Cr, Li, Mn, Mo, Rband Se varied in a wide range among the samples of light and heavycrude oil emulsions. In view of the high acid concentration in digeststhe samples were diluted to minimize the interferences in thedetermination step, especially by ICP-MS. As a consequence, forsome samples, As, Ba, Cr,Mg, Mo, Pb, Se, Sr and Zn were below theLODs obtained by ICP-MS (Mg was determined by ICP OES). For Ag, Bi,Cd and Tl they were not detected in all the investigated samples. Incase of these elements, as the concentration in samples was extremelylow, and even using MIC with sample masses up to 500 mg, they werenot detected in crude oil. 3.3. Evaluation of the operational conditions, absorbing solution andreflux step of MIC procedure In previous work, MIC was applied for heavy crude oil digestionand sample introduction in the system was performed usingpolycarbonate capsules or polyethylene films to wrap the samples[36]. However, for less viscous samples, such as light crude oilemulsions, the operational conditions of digestion by MIC and thematerial to wrap the samples were not investigated. On the otherhand, for heavy crude oil samples, the use of these materials wasevaluated only for further chlorine and sulfur determination [36]. Inview of this, an initial study was performed in order to evaluate theuse of polycarbonate capsules or polyethylene films to wrap light andheavy crude oil emulsions for further metals and metalloidsdetermination. It was observed that polycarbonate capsules containedlow concentrations of all analytes studied and its use was suitable towrap the samples. However, the maximum sample mass that could beadded inside the capsule was about 250 mg. Additionally, ParafilmMQ (American National Can, Chicago, USA) was also investigated towrap the samples and as analyte concentration was in the range of 40to 1800 pggthis material was not used for further studies. The use of polyethylene film to wrap light and heavy crude oilemulsions was evaluated and low level of analytes were foundallowing its use in MIC method. Using this film the combustion wascomplete even using light crude oil emulsions with no apparentresidues and it was possible to use up to 500 mg of crude oil. It isimportant to point out that for light crude oil digestion, it wasnecessary to use high amounts of polyethylene to wrap the samples,since this type of crude oil presents less viscosity (after sampleintroduction inside the wrap, sample becomes to flow to the bottomof the wrap). Even using more polyethylene,blank values were alwayslow and the combustion was always complete. In the present study, the operational conditions (maximumsample mass, ignition time and maximum pressure achieved duringcombustion of samples) used for MIC procedure were selected basedon previous work [36]. Initial studies were performed in order toevaluate the behavior of light crude oil digestion by MIC and it wasobserved that a complete combustion always occurred when 20 bar ofO2 and 500 mg of sample were used without exceeding the maximumpressure recommended by manufacturer. These conditions were inagreement to literature data for heavy crude oil digestion by MIC [36].Therefore, MIC digestion for light and heavy crude oil samples wasperformed using 20 bar of oxygen for 500 mg of sample. Under theseconditions, sample combustion started about 6 s after the microwaveirradiation, the combustion time was about 25 s and the temperatureachieved was always higher than 1400°C. This high temperatureassures a complete decomposition of organic matrix minimizing theRCC in digests. The choice of the absorbing solution to retain analytes aftercombustion is important to achieve suitable recoveries. It isdependent of the analytes and should be compatible with the chosendetermination techniques [28]. Moreover, if microwave radiation iscontinuously applied after the combustion, the absorbing solutionrefluxes inside the quartz vessel assuring quantitative analyterecovery. In this sense, nitric acid solutions in concentration of 1, 2,4, 7, 10 or 14 mol1-1 were evaluated as absorbing solution, using areflux step (5 min) after combustion.These studies were performedfor sample “A” and the best condition was applied for the othersamples studied. Results obtained in digests by MIC are shown inTable 3. In general, it was observed that all the results obtained for analyteswere in agreement in comparison with values obtained by micro-wave-assisted acid digestion. For As, Ba, Cr, Li, Mn and Sr theagreement was lower than 75% between the results obtained by MICusing 1 mol 1- HNOs and this solution was not suitable for allanalytes investigated. On the other hand, using 2 mol1-1 HNOs, theresults for all elements investigated were in agreement better than95% in comparison with results obtained by MW-AD and the RSDvalues were lower than 5%. In addition, it was observed that resultsobtained by MIC using 2 mol1-1HNOs were similar than those obtainedusing higher nitric acid concentrations (7, 10 and 14 mol1).Therefore, this solution was selected for further tests. It is important to point out that despite the results obtained bymicrowave-assisted acid digestion had been in agreement with thoseobtained by MIC, even using diluted nitric acid as absorbing solution, theuse of concentrated acids is not desirable for analyte determination byICP-MS and ICP OES. During measurements of digests in highconcentrations of nitric acid it was necessary to dilute the samples tominimize interferences [12,15] and consequently, the concentration ofsome analytes was lower than LODs making possible the determinationof As, Cr, Rb, Se and Sr only in digests obtained by MIC (Table 3). Spike recoveries were evaluated using 2 mol1-1 HNO3 asabsorbing solution and reflux step for further analytes determination.In this case, standard reference solutions were added inside samplewrap previous to its sealing. This study was performed for sample“A". Recoveries obtained for all the analytes were in the range of 97 to103% and relative standard deviation values were lower than 5%. In Element MW-AD MIC, absorbing solution (HNO3, mol1-1) 1 2 4 7 10 14 Ag <0.03 <0.003 <0.003 <0.003 <0.003 <0.003 <0.003 As <0.12 0.076±0.003 0.100±0.005 0.098±0.004 0.099±0.003 0.101±0.005 0.099±0.003 Ba 0.730±0.060 0.028±0.001 0.710±0.030 0.662±0.021 0.680±0.030 0.702±0.021 0.695±0.032 Bi <0.03 <0.003 <0.003 <0.003 <0.003 <0.003 <0.003 Ca 5.72±0.51 5.50±0.21 5.67±0.14 5.71±0.20 5.68±0.17 5.70±0.19 5.69±0.22 Cd <0.02 <0.002 <0.002 <0.002 <0.002 <0.002 <0.002 Cr <0.05 0.027±0.001 0.041±0.002 0.043±0.003 0.042±0.002 0.043±0.003 0.040±0.002 Fe 1.64±0.21 1.55±0.05 1.61±0.07 1.57±0.06 1.59±0.07 1.68±0.05 1.71±0.06 K 7.57±0.65 7.52±0.32 7.61±0.35 7.62±0.28 7.55±0.32 7.54±0.31 7.56±0.36 Li 0.099±0.008 0.070±0.002 0.102±0.003 0.098±0.003 0.103±0.005 0.101±0.004 0.098±0.003 Mg <0.40 <0.30 <0.30 <0.30 <0.30 <0.30 <0.30 Mn 0.042±0.003 0.029±0.001 0.046±0.002 0.048±0.003 0.047±0.002 0.048±0.002 0.051±0.001 Mo 0.067±0.006 0.065±0.003 0.066±0.002 0.066±0.003 0.067±0.002 0.065±0.002 0.069±0.003 Ni 23.6±2.0 23.8±0.8 22.6±1.1 24.9±1.6 24.9±1.8 24.9±1.4 22.7±1.0 Pb <0.03 <0.004 <0.004 <0.004 <0.004 <0.004 <0.004 Rb <0.03 0.015±0.001 0.014±0.001 0.015±0.001 0.013±0.001 0.016±0.001 0.014±0.001 Se <0.20 0.068±0.003 0.073±0.003 0.069±0.002 0.075±0.003 0.067±0.002 0.066±0.002 Sr <0.07 0.049±0.002 0.062±0.002 0.073±0.003 0.069±0.003 0.068±0.002 0.070±0.003 Tl <0.02 <0.003 <0.003 <0.003 <0.003 <0.003 <0.003 V 2.99±0.20 2.84±0.14 2.88±0.12 2.89±0.15 2.85±0.11 3.03±0.14 3.00±0.12 Zn <0.25 <0.06 <0.06 <0.06 <0.06 <0.06 <0.06 order to evaluate the necessity of the use of an additional reflux step,sample A was digested by MIC using 2 mol1-HNO3 as absorbingsolution without reflux step. It was observed that without the refluxstep the RSD was in the range of 8 to 15% and recoveries for someanalytes were not quantitative (between 82 and 94%). 3.4. Metal and metalloid determination by ICP-MS and ICP OES in lightand heavy crude oil emulsions after MIC digestion Samples of light and heavy crude oil were analyzed after MIC usingICP-MS and ICP OES. Calcium, K, and Mg were determined only by ICPOES. The other elements were determined preferentially by ICP-MSand only Ni and V were also determined by ICP OES for further resultscomparison. Results are shown in Table 4. Table 4 Analysis of light (samples C and D) and1 heavy (samples A and B) crude oils by ICP-MSafter digestion by MIC using 2 mol1-1HNOs as absorbing solution and reflux step.Results in pg g(mean and standard deviation for n=3). Results for Ca, K and Mgwere obtained by ICP OES. Element Samples A C D Ag <0.003 <0.003 <0.003 <0.003 As 0.100±0.005 0.130±0.008 1.82±0.09 0.080±0.004 Ba 0.710±0.030 8.23±0.28 0.490±0.024 1.10±0.04 Bi <0.003 <0.003 <0.003 <0.003 Ca 5.67±0.14 403±23 8.25±0.41 747±30 Cd <0.002 <0.002 <0.002 <0.002 Cr 0.041±0.002 0.057±0.002 0.050±0.002 0.240±0.010 Fe 1.61±0.07 2.56±0.11 2.05±0.10 4.20±0.20 K 7.61±0.35 101±5 2.66±0.11 186±9 Li 0.102±0.003 1.65±0.07 <0.005 <0.005 Mg <0.30 157±5 2.19+0.11 141±7 Mn 0.046±0.002 0.023±0.001 0.024±0.001 0.061±0.003 Mo 0.066±0.002 0.260±0.010 0.106±0.010 <0.003 Ni 22.6±1.1 10.7±0.5 21.7±0.7 4.01±0.11 Pb <0.004 0.190±0.006 0.550±0.010 0.921±0.008 Rb 0.014±0.001 0.240±0.010 <0.005 <0.005 Se 0.073±0.003 1.50±0.06 <0.02 0.190±0.001 Sr 0.062±0.002 42.2±1.9 0.091±0.001 57.9±2.7 Tl <0.003 <0.003 <0.003 <0.003 V 2.88±0.12 14.5±0.7 10.6±0.6 2.69±0.11 Zn <0.06 1.35±0.05 1.81±0.11 2.39±0.10 The concentration of analytes in samples A, B, C and D was in awide range. The same behavior was observed between resultsobtained by MW-AD and MIC, since no relation could be establishedfor results for light and heavy crude oil emulsions. As describedbefore, high concentrations of Ca, Fe, K, Mg and Sr were observed insamples B and D that represents a light and heavy crude oil,respectively.Nickel was presented in high concentrations in samplesA (heavy crude oil) and C (light crude oil) and higher values for Vwere observed in samples B (heavy crude oil) and C (light crude oil). In general, using MW-AD, the concentration of Ag, As, Bi, Cd, Cr, Pb,Tl and Zn in digests were lower than LODs determined by ICP-MS.Onthe other hand, for digests obtained by MIC using diluted nitric acid,As, Ba, Cr, Fe, Mn, Pb and V could be determined in all the studiedsamples (Table 4). Only for samples A and C, the concentration of Mgwas lower than the LOD obtained by ICP OES. Results obtained by MICwere compared with those obtained by MW-AD and agreement betterthan 95% was observed. Additionally, results obtained by ICP-MS andICP OES for Ni and V were also in agreement better than 97% and bothtechniques could be used for these analyte determination. In order to check the accuracy,MIC (using 2 mol1-HNO3) wasapplied for CRM NIST 1634c. After digestion, analytes were deter-mined by ICP-MS and ICP OES and results are shown in Table5. Results obtained after digestion of CRM NIST 1634c by MIC were inagreement higher than 95% for all the analytes studied. No statisticaldifference (confidence level of 95%) was observed for Ni and Vconcentrations obtained by ICP-MS and ICP OES. Accuracy was also evaluated by analysis of sample “B” by NAA(Neutron Activation Analysis Laboratory, Comissao Nacional deEnergia Nuclear, Instituto de Pesquisas Energeticas e Nucleares,IPEN, Sao Paulo, Brazil) under neutron flow of 102 n cm-2s-1 inthe range of 10 to 30s (for K, the irradiation time was 6 h). Before thehalf-life of each element, gamma activity measurements wereperformed in a hyperpure Ge detector (GX 2020, Canberra) linkedto a spectrometer. The radioisotopes measured, energy applied andhalf-life were: 76As (559.09 keV, 1.10 days), 51Cr (320.10 keV,27.8 days), 59Fe (1099.32 keV, 44.60 days), 27Mg (1014.40 keV,9.45 min), 56Mn (846.60 keV, 2.58 h), 99Mo (140.51 keV, 2.76 days)and 42K (1524.70 keV, 12.52 h). It is important to notice that resultsobtained by MIC using diluted nitric acid were in agreement betterthan 95% with those obtained by NAA for As, Cr, Mn and Mo (for Fe, Kand Mg the LOD by NAA was higher than the values found using MIC). Table 5 Determination of trace elements in crude oil (CRM and Sample“B") using MIC procedure and sample analysis by NAA and comparison of LODs obtained by MW-AD and MIC. Resultsand LODs for Ca, K and Mg were obtained by ICP OES determinations. Element Concentration, ug g,mean± standard deviation (n=3) Limit of detection, ugg-1 (3o) Certified value (NIST 1634c) MIC (2 mol1-1) NIST 1634c NAA, Sample B MIC (2 mol1-), Sample B MW-AD MIC Ag nd nd <0.003 <0.03 <0.003 As 0.143±0.006 0.139±0.024 0.127±0.004 0.130±0.008 <0.12 <0.010 Ba 1.8 1.77±0.11 nd 8.23±0.28 <0.18 <0.012 Bi nd nd <0.003 <0.03 <0.003 Ca nd nd 403±23 <0.80 <0.45 Cd nd nd <0.002 <0.02 <0.002 Cr nd 0.06±0.01 0.057±0.002 <0.05 <0.003 Fe 一 nd <13 2.56±0.11 <0.10 <0.015 K nd <300 101±5 <0.60 <0.40 Li nd nd 1.65±0.07 <0.04 <0.005 Mg nd <645 157±5 <0.40 <0.30 Mn nd 0.024±0.005 0.023±0.001 <0.03 <0.004 Mo nd 0.25±0.02 0.260±0.010 <0.025 <0.003 Ni 17.5±0.2 17.4±0.8 nd 10.7±0.5 <0.02 <0.006 Pb - nd nd 0.190±0.006 <0.03 <0.004 Rb nd nd 0.240±0.010 <0.03 <0.005 Se 0.102±0.004 0.104±0.010 nd 1.50±0.06 <0.20 <0.020 Sr nd nd 42.2±1.9 <0.07 <0.007 Tl nd nd <0.003 <0.02 <0.003 28.2±0.4 28.1±1.3 nd 14.5±0.7 <0.06 <0.015 Zn 一 nd nd 1.35±0.05 <0.25 <0.060 nd: not determined. Concerning the LODs listed in Table 5, it was observed that valuesobtained by MIC were always lower in comparison with thoseobtained by MW-AD. This is an important aspect for elementsdetermination in light and heavy crude oil emulsions. AlthoughMW-AD could be applied for some analyte determination,particularlyfor those that are presented in high concentrations, the time for thisdigestion was relatively long (60 min). Using MIC with a reflux step,the digestion time was 25 min (including the cooling step) and up toeight samples could be processed simultaneously which are impor-tant aspects for routine analysis allowing a convenient samplethroughput. One of the important aspects is related to the suitabilityof the resultant solutions for determinations by ICP-MS and ICP OESminimizing interferences due to high acid concentration. In addition,digests obtained by MIC were also compatible for metals andmetalloids determination by ICP OES. 3.5. Residual carbon content The efficiency of MIC and microwave-assisted acid digestionprocedures was evaluated by residual carbon content measurementsin digests according to previous work [33]. Using microwave-assistedacid digestion the RCC was about 15% whereas the RCC in MIC digestswere always below 1%. This result can be explained in view of the hightemperature achieved during the combustion by MIC (higher than1400°C). As for the proposed method only diluted solutions arerequired, digests are suitable to be analyzed by techniques moresusceptible to interferences by residual carbon content or excessiveacid concentration. 4. Conclusions The proposed method by MIC was suitable for light and heavycrude oil emulsions digestion for further simultaneous determinationof Ag, As, Ba, Bi, Ca, Cd, Cr, Fe, K, Li, Mg, Mn, Mo, Ni, Pb, Rb, Se, Sr, Tl,Vand Zn by ICP-MS and ICP OES. It is possible to use a solution as dilutedas 2 mol1-1 HNOs to obtain quantitative recoveries for all analytes,using a reflux step after the combustion. Therefore, MIC avoids the useof concentrated acids, significantly reducing the laboratory wastesand analysis time, which is an important aspect for routine analysis. It was possible to obtain a single and also suitable solution for analytesdetermination using ICP OES and ICP-MS. In addition, LODs obtainedby MIC were always lower in comparison with those obtained bymicrowave-assisted acid digestion. The use of MIC showed goodperformance for light and heavy crude oil digestion and residualcarbon content was lower than 1%. On the other hand, RCC in digestsobtained by MW-AD were about 15%. The results obtained for CRMs by MIC under optimized conditionswere in agreement with certified values. The proposed MIC methodallows the combustion of relatively high sample masses (500 mg)without exceeding 50% of the maximum operating pressure (80 bar),combining good performance for crude oil digestion, safety andrelatively high sample throughput. Therefore, based on its particularcharacteristics, MIC combined to ICP-MS determination can beproposed for elements determination in light and heavy crude oilemulsions complying with the recent requirements of crude oilindustry. Acknowledgements The authors are grateful to CENPES-PETROBRAS, INCT-Bio/CNPqand Fapergs for supporting this study. ( References ) [1] J.H. Gary, G.E. Handwerk, Petroleum Refining Technology and Economics, Fourthed Marcel Dekker Inc, New York, 2001, 441 pp. [2] J.G. Speight, Handbook of Petroleum Analysis, John Wiley and Sons Inc, NeweJersey, 2001,519 pp. ( [3] S .Matar, Chemistry of Petrochemical P rocess, Second edGulf Published Company, Houston, 2000, 392 pp. ) [4] J.G. Speight, Handbook of Petroleum Product Analysis, John Wiley and Sons Inc,New Jersey, 2002, 454 pp. [5]R1.M.S.Souza, A.L.S. Meliande, C.L.P. da Silveira, R.Q. Aucelio, Determination of Mo,Zn, Cd, Ti, Ni, V, Fe, Mn, Cr and Co in crude oil using inductively coupled plasmaoptical emission spectrometry and sample introduction as detergentless micro-emysions Misrochem182(2006)137-141mulsior Miicrochem. J.82 ([6]B. Skrbic, J. Novakovic, N. Miljevic, Mobility of heavy metals originating frombombing of industrial sites, J. Environ. Sci. Health A 37 (2002) 7-16. [7] M.S. Rana, V. Samano,J. Ancheyta, J.A.I. Diaz, A review of recent advances onprocess technologies for upgrading of heavy oils and residua, Fuel 86 (2007)1216-1231. [8] J. Heilmann, S.F. Boulyga, K.G. Heumann, Accurate determination of sulfur ingasoline and related fuel samples using isotope dilution ICP-MS with directsample injection and microwave-assisted digestion, Anal. Bioanal. Chem. 380(2004)190-197. [9] M.Murillo,N. Carrion, J. Chirinos, Determination of sulfur in crude oils and relatedmaterials with a Parr bomb digestion method and inductively coupled plasmaatomic emission spectrometry, J.Anal. At. Spectrom. 8 (1993) 493-495. [10] W.R. Kelly, P.J. Paulsen, K.E. Murphy, R.D. Vocke Jr., L.-T. Chen, Determination ofsulfur in fossil fuels by isotope dilution thermal ionization mass spectrometry,Anal. Chem. 66 (1994)2505-2513. [11]J. Mora, J.L. Todoli, F.J.Sempere, A. Canals,V. Hernandis,Determination of metalsin lubricating oils by flame atomic absorption spectrometry using a single-borehigh-pressure pneumatic nebulyzer, Analyst125 (2000)2344-2349. [12] G. Caumette, C.-P. Lienemann, I. Merdrignac, H. Paucot, B. Bouyssiere, R. Lobinski,Sensitivity improvement in ICP MS analysis of fuel and light petroleum matricesusing a microflow nebulizer and heated spray chamber sample introduction,Talanta 80 (2009) 1039-1043. [13] R.E.Santelli,E.P. Oliveira, M.F.B. de Carvalho, M.A. Bezerra, A.S. Freire,Total sulfurdetermination in gasoline, kerosene and diesel fuel using inductively coupledplasma optical emission spectrometry after direct sample introduction asdetergent emulsions, Spectrochim. Acta Part B 63 (2008) 800-804. [14] R.E.Santelli, M.A. Bezerra, A.S. Freire, E.P.Oliveira, M.F.B. de Carvalho, Non-volatilevanadium determination in petroleum condensate, diesel and gasoline preparedas detergent emulsion using GF AAS, Fuel 87 (2008)1617-1622. [15] Z. Hu, S. Hu, S. Gao, Y. Liu, S. Lin, Volatile organic solvent-induced signalenhancements in inductively coupled plasma-mass spectrometry: a case of studyof methanol and acetone, Spectrochim. Acta Part B 59 (2004) 1463-1470. [16] M. Ben-Younes, D.C. Gregoire, C.L. Chakrabarti, Effectiveness of ammonia inreducing carbon-based polyatomic ion interferences in electrothermal vaporiza-tion collision cell inductively coupled plasma mass spectrometry, Spectrochim.Acta Part B 58 (2003)361-372. [17] Annual Book of ATSM Standard, ASTM D 5863, Standard test method fordetermination of nickel, vanadium, iron, and sodium in crude oils and residualfuels by flame atomic absorption spectrometry, 2000. ( [18 ] Annual Book of ATSM Standard, A STM D 5708, Standard t e st method for determination of nickel, vanadium, and iron i n crude oils and r e sidual fuels byinductively coupled plasma (ICP) atomic emission spectrometry, 2002. ) [19] Z. Mester, R. Sturgeon, Sample Preparation for Trace Element Analysis, Elsevier,Amsterdam, 2003,1286 pp. ( [20] J .T. Castro, E.C. Santos, W.P.C. Santos, L.M. Costa, M . K o rn, J.A. N o brega, M.G.A. K orn,A critical evaluation of digestion procedures for coffee samples using diluted nitric acid in closed v essels f or i nductively coupled plasma opt i cal emi s sion spectrometry, Talanta 78 (2009 ) 1378-1382. ) [21] P. Kulkarni, S. Chellam, D.W. Mittlefehlft, Microwave-assisted extraction of rareearth elements from petroleum refining catalysts and ambient fine aerosols priorto inductively coupled plasma-mass spectrometry, Anal. Chim. Acta 581 (2007)247-259. [22] J. Heilmann, S.F. Boulyga, K.G. Heumann, Development of an isotope dilution laserablation ICP-MS method for multi-element determination in crude and fuel oilsamples,J. Anal. At. Spectrom. 24 (2009) 385-390. [23] R.A.A. Munoz, P.R.M. Correia, A.N. Nascimento, C.S. Silva, P.V. Oliveira, L. Angnes,Electroanalysis of crude oil and petroleum-based fuel for trace metals: evaluationof different microwave-assisted sample decompositions and stripping techniques,Energy Fuels 21 (2007) 295-302. [24] I.I.Stewart,J.W.Olesik, Steady state acid effects in ICP-MS,J. Anal. At. Spectrom. 13(1998)1313-1320. [25]] I.I. Stewart, J.W. Olesik, The effect of nitric acid concentration and nebulizer gasflow rates on aerosol properties and transport rates in inductively coupled plasmasample introduction, J. Anal. At. Spectrom. 13 (1998) 1249-1256. [26]A./ Fernandez, M. Murillo, N.Carrion, Influence of operational conditions on theeffects of acids in inductively coupled plasma atomic emission spectrometry,J. Anal. At. Spectrom. 9 (1994) 217-221. [27]|J J.S. Barin, E.M.M. Flores, G. Knapp, Trends in sample preparation using combustiontechniques, in: M.A.Z. Arruda (Ed.), Trends in Sample Preparation, Hauppage,Nova Science Publishers, New York, 2006,pp. 73-114, chapter 3. [28]E.M.M. Flores, J.S. Barin, M.F. Mesko, G. Knapp, Sample preparation techniquesbased on combustion reactions in closed vessels- a brief overview and recentapplications, Spectrochim. Acta Part B 62 (2007)1051-1064. [29] E.M.M. Flores, J.S. Barin, J.A. Medeiros, G. Knapp, Microwave-assisted samplecombustion: a technique for sample preparation in trace element determination,Anal. Chem. 76 (2004) 3525-3529. [30] M.F. Mesko, D.P. Moraes,J.S. Barin, V.L. Dressler, G. Knapp,E.M.M. Flores, Digestionof biological materials using the microwave-assisted sample combustiontechnique, Microchem.J.82 (2006) 183-188. [31]F1.A. Duarte, J.S.F. Pereira, J.S. Barin, M.F. Mesko, V.L. Dressler, E.M.M. Flores, G.Knapp, Seafood digestion by microwave-induced combustion for total arsenicdetermination by atomic spectrometry techniques with hydride generation,J. Anal. At. Spectrom. 24 (2009) 224-227. [32]D.P. Moraes, M.F. Mesko, P.A. Mello, J.N.G. Paniz, V.L. Dressler, G. Knapp, E.M.M.Flores, Application of microwave-induced combustion in closed vessels for carbonblack-containing elastomers decomposition, Spectrochim. Acta Part B 62 (2007)1065-1071. [33]E.M.M. Flores, M.F. Mesko, D.P. Moraes, J.S.F. Pereira, P.A. Mello, J.S. Barin, G.Knapp, Determination of halogens in coal after digestion using the microwave-induced combustion technique, Anal. Chem. 80 (2008)1865-1870. [34] J.S.F. Pereira, L.O. Diehl, F.A. Duarte, M.F.P.Santos, R.C.L.Guimaraes, V.L. Dressler,E.M.M. Flores,Chloride determination by ion chromatography in petroleum cokeafter digestion by microwave-induced combustion,J. Chromatogr. A 1213 (2008)249-252. ( [35] | 1 P .A. Mello, C.K. Giesbrecht,M.S. Alencar, E.M. Moreira, J.N.G. Paniz, V.L. Dressle r ,E.M.M. F lores, Determination o f sulfur in petroleum coke combining closed v essels microwave-induced combustion and inductively coupled plasma-opticalemission spectrometry, Anal.Let t . 41 (2008)1623-1632. ) ( [36] J .S.F. Pereira, P.A . Mello, D.P . Moraes, F.A. Duarte, V.L. Dressler, G. Knapp, E.M.M. Flores, Chlorine and sulfur determination in extra-heavy crude oil by ind u ctively coupled plasma optical emission spectrometry after microwave-induced com- b ustion, Spectrochim. Acta Part B 64 (2009) 554-558. ) ( [37] P . 1 A. Mello,J.S.F. P e reira, D.P. Moraes, V.L.Dressler, E. M .M. Flores, G. Knapp, Nick e l, vanadium and s u lfur d e termination b y inductively coupled p l asma op t icalemission spectrometry in crude oil distillation residues after microwave-induced combustion,J.Anal. At. Spectrom. 24 (2009)911 - 916. ) [38]J.S.F.Pereira, P.A. Mello, F.A. Duarte, M.F.P. Santos, R.C.L. Guimaraes, G. Knapp, V.L.Dressler, E.M.M. Flores, Feasibility of microwave-induced combustion for10digestion of crude oil vacuum distillation residue for chlorine determination,Energy Fuels 23 (2009)6015-6019. ( [39] | Anton Paar GmbH, Microwave S a mple Pr e paration System, Software versionv1.27-Synt,Graz, Austria, 2003. ) ( [ 40] T .W. M ay, R . H. Wiedmeyer, A t a b le of polyatomic in t erferences in ICP-MS, At. S pectr. 19 (1998)150-155. ) [41]S:.D. Tanner, V.I. Baranov, D.R. Bandura, Reaction cells and collision cells for ICP-MS: a tutorial review, Spectrochim. Acta Part B 57 (2002) 1361-1452. A method for light and heavy crude oil digestion using microwave-induced combustion (MIC) in closed vessels is described for further determination of Ag, As, Ba, Bi, Ca, Cd, Cr, Fe, K,Mg, Li,Mn, Mo,Ni, Pb, Rb, Se, Sr, Tl, V, and Zn by inductively coupled plasma mass spectrometry (ICP-MS). Conventional microwaveassisted acid digestion (MW-AD) in pressurized vessels and analyte determination by inductively coupled plasma optical emission spectrometry (ICP OES) were also used for results comparison. For MIC procedure,samples were wrapped in polyethylene films and combusted using 20 bar of oxygen and 50 μl of 6 mol l−1 ammonium nitrate as aid for ignition. The concentration of nitric acid used as absorbing solution was evaluated (1, 2, 4, 7, 10 and 14 mol l−1) using an additional reflux step after combustion. Accuracy was evaluated for As, Ba, Ni, Se V, and Zn using certified reference material (CRM) with similar matrix composition and for Cr, Fe, K, Mg, Mn, and Mo by neutron activation analysis (NAA). Recovery tests were also performed for all the analytes by MIC and they were better than 97% using 2 mol l−1 nitric acid as absorbing solution (with reflux step). Agreementwith certified values and NAA results was better than 95%. Using MIC it was possible to obtain lower limits of detection (LODs) by ICP-MS and also by ICP OES in comparison with those obtained by MW-AD. In spite of both sample preparation techniques were apparently suitable for crude oil digestion, MIC was preferable in view of the possibility of using diluted nitric acid as absorbing solution that is an important aspect to minimize interferences by ICP-MS and ICP OES. In order to avoid polyatomic interferences on 52Cr and 56Fe determinations by ICP-MS, a dynamic reaction cell with ammonia gas was used. Residual carbon content in digests obtained by MW-AD and MIC was 15% and b1%, respectively. Using MIC the simultaneous digestion of 8 samples was possible in less than30 min.

关闭-

1/8

-

2/8

还剩6页未读,是否继续阅读?

继续免费阅读全文产品配置单

安东帕(上海)商贸有限公司为您提供《轻油重油中Ag, As, Ba, Bi, Ca, Cd等元素检测方案(微波消解仪)》,该方案主要用于原油中含量分析检测,参考标准《暂无》,《轻油重油中Ag, As, Ba, Bi, Ca, Cd等元素检测方案(微波消解仪)》用到的仪器有安东帕高性能微波消解系统Multiwave 5000。

我要纠错

相关方案

咨询

咨询