方案详情文

智能文字提取功能测试中

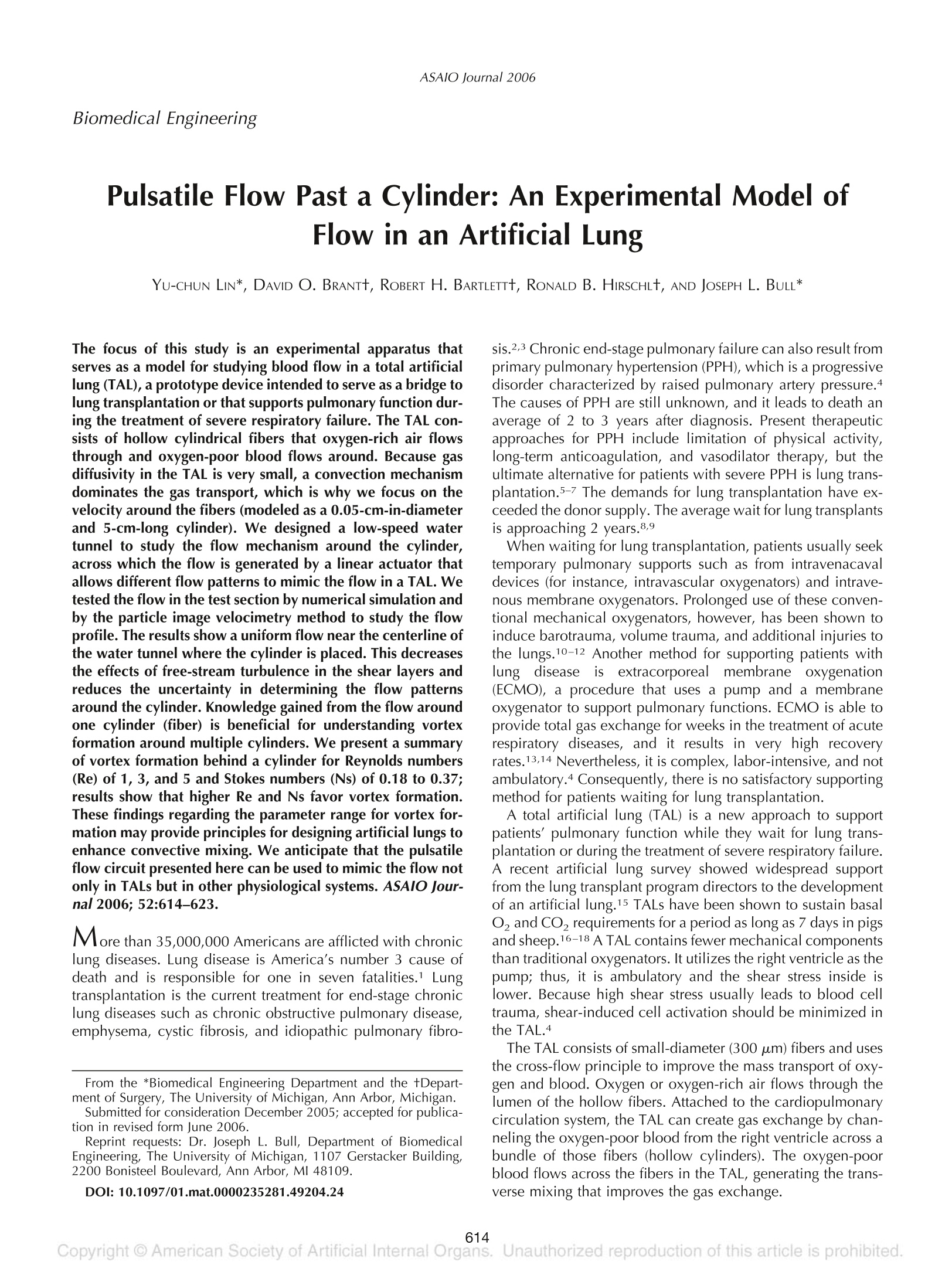

ASAIO Journal 2006Biomedical Engineering 615PULSATILE FLOW PAST A CYLINDER: EXPERIMENTAL MODEL AN ARTIFICIAL LUNG Pulsatile Flow Past a Cylinder: An Experimental Model ofFlow in an Artificial Lung Yu-CHUN LIN*, DAVID O. BRANT+, ROBERT H. BARTLETT+, RONALD B. HIRSCHL+, AND JOSEPH L. BULL* The focus of this study is an experimental apparatus thatserves as a model for studying blood flow in a total artificiallung (TAL), a prototype device intended to serve as a bridge tolung transplantation or that supports pulmonary function dur-ing the treatment of severe respiratory failure. The TAL con-sists of hollow cylindrical fibers that oxygen-rich air flowsthrough and oxygen-poor blood flows around. Because gasdiffusivity in the TAL is very small, a convection mechanismdominates the gas transport, which is why we focus on thevelocity around the fibers (modeled as a 0.05-cm-in-diameterand 5-cm-long cylinder). We designed a low-speed watertunnel to study the flow mechanism around the cylinder,across which the flow is generated by a linear actuator thatallows different flow patterns to mimic the flow in a TAL. Wetested the flow in the test section by numerical simulation andby the particle image velocimetry method to study the flowprofile. The results show a uniform flow near the centerline ofthe water tunnel where the cylinder is placed. This decreasesthe effects of free-stream turbulence in the shear layers andreduces the uncertainty in determining the flow patternsaround the cylinder. Knowledge gained from the flow aroundone cylinder (fiber) is beneficial for understanding vortexformation around multiple cylinders. We present a summaryof vortex formation behind a cylinder for Reynolds numbers(Re) of 1, 3, and 5 and Stokes numbers (Ns) of 0.18 to 0.37;results show that higher Re and Ns favor vortex formation.These findings regarding the parameter range for vortex for-mation may provide principles for designing artificial lungs toenhance convective mixing. We anticipate that the pulsatileflow circuit presented here can be used to mimic the flow notonly in TALs but in other physiological systems. ASAIO Jour-nal 2006; 52:614-623. M ore than 35,000,000 Americans are afflicted with chroniclung diseases. Lung disease is America’s number 3 cause ofdeath and is responsible for one in seven fatalities.1 Lungtransplantation is the current treatment for end-stage chroniclung diseases such as chronic obstructive pulmonary disease,emphysema, cystic fibrosis, and idiopathic pulmonary fibro- ( From the * Biomedical E ngineering Department a nd t he + Depart-men t of S urgery, The University of M ichigan, Ann Arbor, Michigan.Submitted for consideration December 2005; accepted forpublica- tion in revised form June 2006. ) ( R eprint requests: Dr. Joseph L. Bull , Department of Biomedical Engineering, The University of Michigan, 1107 Gerstacker Bui l ding, 2200 Bonisteel Boulevard, Ann Arbor, MI 48109. ) ( DOI: 1 0.1097/01.mat.0000235281.49204.24 ) sis.2,3 Chronic end-stage pulmonary failure can also result fromprimary pulmonary hypertension (PPH), which is a progressivedisorder characterized by raised pulmonary artery pressure.4The causes of PPH are still unknown, and it leads to death anaverage of 2 to 3 years after diagnosis. Present therapeuticlapproaches for PPH include limitation of physical activity,long-term anticoagulation, and vasodilator therapy, but theultimate alternative for patients with severe PPH is lung trans-plantation.5-7 The demands for lung transplantation have ex-ceeded the donor supply. The average wait for lung transplantsis approaching 2 years.8,9 When waiting for lung transplantation, patients usually seektemporary pulmonary supports such as from intravenacavaldevices (for instance, intravascular oxygenators) and intrave-nous membrane oxygenators. Prolonged use of these conven-tional mechanical oxygenators, however, has been shown toinduce barotrauma, volume trauma, and additional injuries tothe lungs.10-12 Another method for supporting patients withlungdiseaseilssextracorporealmembraneoxygenation(ECMO), a procedure that uses a pump and a membraneoxygenator to support pulmonary functions. ECMO is able toprovide total gas exchange for weeks in the treatment of acuterespiratory diseases, and it results in very high recoveryrates.13,14 Nevertheless, it is complex, labor-intensive, and notambulatory.4Consequently, there is no satisfactory supportingmethod for patients waiting for lung transplantation. A total artificial lung (TAL) is a new approach to supportpatients’ pulmonary function while they wait for lung trans-plantation or during the treatment of severe respiratory failure.A recent artificial lung survey showed widespread supportfrom the lung transplant program directors to the developmentof an artificial lung.15 TALs have been shown to sustain basaO2and CO, requirements for a period as long as 7 days in pigsand sheep.16-18 A TAL contains fewer mechanical componentsthan traditional oxygenators. It utilizes the right ventricle as thepump; thus, it is ambulatory and the shear stress inside islower. Because high shear stress usually leads to blood celltrauma, shear-induced cell activation should be minimized inthe TAL.4 The TAL consists of small-diameter (300 um) fibers and usesthe cross-flow principle to improve the mass transport of oxy-gen and blood. Oxygen or oxygen-rich air flows through thelumen of the hollow fibers. Attached to the cardiopulmonarycirculation system, the TAL can create gas exchange by chan-neling the oxygen-poor blood from the right ventricle across abundle of those fibers (hollow cylinders). The oxygen-poorblood flows across the fibers in the TAL, generating the trans-verse mixing that improves the gas exchange. The blood film thickness in the TAL is more than 10 redblood cell (RBC) layers; thus, the diffusion of the gas throughthe thick film layer takes a long time. However, in the naturalsystem, the RBCs are exposed to a one-cell-thin layer of bloodfilm and achieve gas exchange in a short period of time.Therefore, to simulate the natural system, TALs use fibers toinduce blood mixing to oxygenate blood faster. When theblood is mixed or moved in the TALs (or other types of oxy-genators), the RBCs can be brought closely to the surface area,a process that introduces gases into the blood more rapidly.19The cross-stream mixing caused by the secondary flow (suchas vortices) helps the mass transfer of oxygen and blood. Thus,the study of cross-flow pattern around a fiber is crucial for a fullunderstanding of mass transfer and blood flow in a TAL. The mass transfer inside the TAL can be described by theconvection-diffusion equation, which, in the dimensionlessform, is shown in Equation (1). where ((ūV)C)) and diffusionV’C). The Stokes number is inthe range of 0.2 to 0.4, and the Reynolds number usuallyvaries from 0.1 to 10 in the TAL (depending on the geomet-ric design). Because the gas diffusivity of oxygen in blood isvery small, the Peclet number is very large, which indicatesthe convection term is dominant. Therefore, understandingthe mass transfer and approaches to enhance it requires anunderstanding of the velocity field. Consequently, the focusof this paper is the flow field around a cylindrical fiber. To understand the flow field, two assumptions are made thatallow us to do an experiment that fits some of the properties ina TAL. In our model, we considered first the fiber of the highflow rate area, where the shear rate is high enough that we canassume the viscosity is relatively constant. Moreover, the widthbetween the fibers (300 um) is much larger than the diameterof the RBCs; thus, we treated the blood as a homogeneous fluidrather than as a two-phase mixture. Consequently, the velocityaround the cylinder can be described by the Navier-Stokesequation. To model the flow in a TAL, we designed a low-speed watertunnel to study the pulsatile flow across a cylinder (represent-ing the fiber in TAL) at low Reynolds numbers (Re <10). Theprevious designs of the water tunnels are for high Re flows, inwhich the viscous effects are small and the mechanical bound- ary layer along the wall is relatively much thinner than in thelow Re flows. However, the flow in a TAL is at low Renumbers, and this requires us to develop an appropriate ex-perimental apparatus in which to study the time-dependentflow. The objective of this study, therefore, is to design and use anexperimental method to study the flow features around a fiberl at low Reynolds numbers. Because the blood flow in a TAL isdriven by the right ventricle, the flow across the fibers ispulsatile (oscillatory flow but with minimum flow rate largerthan zero). Unfortunately, pulsatile flow about a cylindricabody has not been studied at low Reynolds numbers (Re=0.1to 10).Steady and unsteady (including oscillatory and pulsa-tile) flows across an immersed body have been investigatedextensively in many applications of engineering, such as heatexchanger tube bundles, marine structures, and building andchimney design. However, most of those investigations fo-cused on high Reynolds numbers,20 and little is known aboutthe effect of pulsatility on low Reynolds number flow around acylinder. Although the actual TAL is composed of many fibers,we consider pulsatile flow past a single cylinder to be a startingpoint for our investigations because of the fundamental natureof this configuration; for example, fiber arrays can be assem-bled from single fibers, and the knowledge base of correspond-ing steady flow work allows the effects of pulsatility to bereadily discerned from the present work. We expect knowl-edge of the effects of pulsatility on secondary flows to facilitateintelligent TAL design. The experimental flow model developed in this study couldalso be used in model systems to study blood flow in or aroundother devices such as endovascular devices, catheters for drugdelivery, intravascular oxygenators, and other membrane de-vices. The previous investigations for studying in vitro testingof cardiovascular devices only studied pressure and mean flowrate and were mostly focused on matching the physiologicalbehavior.21-23 Our study focuses on measuring the velocity byusing particle image velocimetry (PIV), in which the free-stream turbulence will interfere with the results. Therefore, weaimed to design a low-speed water tunnel to perform uniformand low-turbulence flow to developed results that could beapplied to other kinds of devices. Methods An experimental apparatus was built up to examine thepulsatile flow effects to the flow around an immersed body ina low Reynolds numbers’ range. This setup was designed tostudy the vortex formation around the fiber (cylinder) inside aTAL or in in vitro experiments, using the PIV method. The sameexperimental setup is also applicable to study the flow aroundendovascular devices or other devices that may be used inhuman body. This investigation was designed to study vortex formationaround the cylinder in in vitro experiments, using the PIVmethod. This model was scaled up for easier observation andflow visualization because the fibers inside the TAL are verysmall (300 um). The relevant dimensionless parameters (Stokesnumber and Reynolds number) were kept the same as in theMC3's BioLung (Michigan Critical Care Consultant, Ann Ar-bor, MI). The top and side views of the experimental circuit are shown in Figure 1. Top (a) and side views (b) of the experimental apparatus. The laser and the camera were placed perpendicular to each other. Thissetup was equipped with a linear actuator to generate the flow and four one-way valves to direct the flow. Figure 1. We tested the flow in the low-speed water tunnel byusing PIV and the numerical method; a circular cylinder thatrepresented the fiber inside the TAL was then placed in the testsection. The flow was generated by an electromechanical linearactuator and was monitored by a flow sensor that was locatedbefore the water tunnel. The direction of the flow was regulatedby four one-way valves, and a water tank was used as the watersource. The water was seeded with neutral-buoyancy reflectiveparticles, and an Nd-YAG laser was shaped into a planar flatsheet of light to provide illumination from the top of the watertunnel. The illuminated particle region was captured by a high-gain charge-coupled device (CCD) camera. Water Tunnel Design Design of a Low-Speed Water Tunnel. Morel24 stated that itis more art than science to design a water tunnel; most designsrelied on the experiences and ingenuity of the designers. Most ofthe previous water tunnel designs were based on trial and error.Numerical approaches to optimize water tunnel designs havebeen presented (e.g., 24-27 most of them are for high Reynoldsnumber wind tunnels), but the majority of them have idealizedthe problems of water tunnel designs by using incompressible,inviscid equations. Based on previous investigations26,28-36 ofhigh-speed wind tunnel design and calculations, we designed alow-speed water tunnel for our flow visualization study. Computational Approximation The flow in different designs was computed by using Fluent(Fluent Inc., Laconia, NH) computational fluid dynamics software(the results of the simulation are shown in the Results section). Toobtain a numerical solution, a discretization method is used toapproximate the governing differential equations by a system of algebraic equations. These algebraic equations of variables atdiscrete locations in space and time can then be solved numeri-cally. Fluent utilizes a finite-volume scheme, in which the governequations are described on the basis of control volume aroundthe node point. This technique involves integrating the governingequations for each control volume, which yields discrete equa-tions that conserve each variable on a control-volume basis. Contraction Section There are several components to the water tunnel. A contrac-tion was located before the test section, which can reduce themean and fluctuating velocities’ variance to a smaller portion ofthe average velocity. It also increases the mean velocity, whichallows a honeycomb-shaped flow straightener to be placed in alow-speed region before the contraction; therefore, the pressurelosses decrease.31 To design a contraction section, several thingsneed to be taken into account: contraction ratio, contractionlength, cross-sectional shape, and wall shape. Contraction Section: Contraction Ratio and Length The design of the contraction section is shown in Figure 2.A contraction ratio between 6 and 9 (based on cross-sectionalarea) is normally used in low-speed wind tunnels.23,31,35 Thecontraction ratio cross -sectional area of the water tunnel before the contraction\cross sectional area of the water tunnel after the contraction in our design is 4 because the flow rate in the water tunnel isrelatively small compared with the wind tunnel’'s flow rate.The contraction length is related to the radius before thecontraction and the contraction ratio. Although excessive con- Figure 2. Schematic illustrating the settling section, contraction,and test section. traction lengths generate relatively thick boundary layer thick-ness, insufficient contraction length might cause boundarylayer separation. From Morel's previous study,29 the length ofthe contraction duct should decrease as the contraction ratioincreases to above 4. The contraction length can be dividedinto two parts: the inlet section before the inflection point andthe outlet section after the inflection point. We chose the inletsection length (l;) to be 0.264 times the width before contrac-tion (W) and outlet section length (l) to be 0.281 times W 32 Contraction Section: Cross-Sectional Shape and Wall Shape The cross-sectional shape and wall shape of the contractionsection are other problems to consider. For a noncircular crosssection, the flow near the corners of a polygonal section tendsto migrate laterally and to separate. However, in a well-de-signed square contraction, the separation might be preventedby adding small corner fillets.31 We used a square cross sectionand made the corners obtuse angles. Some simple geometriesof the wall shape can be built by using the Laplace equation.Many analytical and numerical schemes have been derived,but there is no wholly satisfactory method of theoretical wallshape design. In our original design, the second derivative of the half thechannel width of the contraction section is a function of theaxial direction coordinate, x.32 Because of machining limita-tions, the final design does not ideally follow the originaldesign. However, the actual shape of the contraction contouris not of great significance, but the smoothness of the contourform is much more important than exact dimensions. Each endof the wall must join the parallel section very smoothly, espe-cially at the narrow end.31 Settling Section The settling section is located before the contraction section.The settling chamber is required to place the "honeycomb"and/or the screen before the contraction nozzle. A "honey-comb" is a honeycomb-shaped structure that can force theflow to go in practically the same direction to reduce theturbulence of flow. The honeycomb is usually placed beforethe contraction in a water tunnel to ensure the uniformity ofthe flow. A screen may be used with the same function, but a Figure 3. Design and layout of the observation assembly, topview and side view. An acrylic disc is attached to the end of a tube.This disc can be replaced or redesigned for alternative arrange-ments. "singing"effect (caused by of the same resonance of the vortexshedding) might be a problem in the water tunnel.37 A settling section length of 0.5 times the inlet diameter isoften used.35 The settling section length is the same size as theinlet diameter in our design because the length of the honey-comb is longer. The typical ratio of length-to-cell diameter ofthe honeycomb is about 6 to 8, and about 150 honeycombcells per settling chamber diameter (or about 25,000 totalcells) are adequate for the wind tunnel.31,35,37 Nevertheless, itis laborious and costly to manufacture one.38 Besides, a hon-eycomb with this small cell diameter in a water tunnel mightproduce very high resistance to the flow. We used plasticdrinking straws to construct two different length-to-cell diam-eter (17 and 33) honeycombs. The cross-sectional cell numberis about 225 in the one with length-to-cell diameter of 17. Test Section The test section is located after the contraction nozzle andmounted with a removable assembly that allows easier re-placement of the cylinders. The design and fixture of theassembly is shown in Figure 3. In the design, a transparentacrylic circular plate (a disc) with a diameter of 5 cm isattached to an acrylic tube that creates an observation windowin the center of the assembly. The assembly then is placed inthe wall of the test section, one for each side of the watertunnel. Through a small hole in each disc, a stainless steel wire(diameter = 0.15 mm) is inserted into the test section. Ahollow needle (the cylinder) with a diameter of 0.5 mm isplaced over the wire to cover the edge of the small hole (tocover the tiny distortion around the small hole), and the needleis secured to prevent it from rotating in the flow. The disc isreplaceable, which allows future designs of different geometricarrangements of the cylinders. Linear Actuator Assembly and Construction Figure 4 shows the assembly of the linear actuator. The flowacross the cylinder is driven by an electromechanical linear Figure 4. Linear actuator assembly. A linear actuator was attached to a piston inside a cylinder. The motor of the linear actuator rotatesthe drive screw, which in turns pushes a shaft out to generate linear motion. actuator (Smart Bug linear actuator, Ultra Motion, Mattituck,NY) attached to a piston inside a cylinder-pump assembly. Thepiston was made of polyethylene, with diameter of 3 inches. Arubber o-ring is seated in a groove on the piston to preventleaking. A threaded stainless steel rod (0.5-inch diameter)connects the piston to the shaft of the linear actuator. There are several considerations in the linear actuator selec-tion. Some of the important factors are the speed, load rating ormaximal force, and stroke length. When delicate control isneeded, the accuracy and the programmability should be eval-uated. These requirements are addressed by capabilities of thechosen components. The linear actuator in our laboratory isequipped with a programmable, brushless DC servomotor(SmartMotor, SM1720, Animatics Co., Santa Clara, CA) withmaximum speed of 4.6 inches per second, maximum force of500 pounds, and linear resolution of 64,000 counts per inch.This motor rotates the drive screw by using a synchronoustiming belt drive with belt ratio of 4:1. The turning of the screwpushed a ball bearing drive nut along the screw and thenpushes a shaft out to generate linear motion. The stroke lengthof the linear actuator in our laboratory is 7.2 inches, whichmakes generating larger flow rates possible. To in产crease theaccuracy of the linear actuator, two normally open externallyadjustable position switches were placed on the housing of theshaft to regulate the position and prohibit overshooting. An8-inch potentiometer and an anti-backlash nut were alsoadded in the linear actuator to improve control and preventbacklash. Particle Image Velocimetry Method The velocities in the field around the cylinder were mea-suredl byPIV method((recently reviewedibby Adrian[2005]39). PIV is a nonintrusive velocity measurement thatprovides instantaneous velocity over global domains. Earlyquantitative velocity measurements, such as Pitot-statictubes and hot-wire anemometers, require the insertion of aprobe, which might interfere with the flow. Other nonintru-sive velocity measurements, such as the laser-Doppler an-emometer, mostly give the information of the velocity at thepoint where the probe is attached. Additionally, PIV offers apromising method of investigation for complex flow fields(such as vortices and secondary flow) where the direction ofthe flow is difficult to predict and hard to resolve with othermethods. The PIV setup consists of several components: a transparenttest section seeded with reflective particles, a light source toilluminate the section of interest, a recording medium to sense the light from the particles (such as a CCD camera, a film, orholographic plates), and a processing system for analyzing theinformation from the recording device. The illumination wasprovided by a pulsed Nd-YAG laser (model: Solo III 15Hz, No:16155, wave length 266~1064 nm, New Wave Inc., Fremont,CA) whose bean passed through a cylindrical lens (Modular-Focus,f = -6 mm, Rodenstock Co.,Munich, Germany) andwas shaped into a laser light sheet (<1 mm in thickness and100 mm in width). The laser light sheet illuminates polyamideparticles (diameter, 20 pm; density, 1.03 g/cm3, Dantec Dy-namics Co., Skovlunde, Denmark) that are seeded into deion-ized water in the test section. The test section has a removableassembly made of clear acrylic that allows optical transpar-ency. In the test section, the velocity of the fluid of the inter-ested area is measured and made visible by reflecting light offthe seeding particles. The measurement of the velocity in the area of interest at aparticular time is achieved by capturing a two-image sequencesynchronized two light pulses from the laser, using a CCDcamera (Flowmaster 3S; resolution: 1280 ×1024 pixels; LaVi-sion Inc., Goettingen, Germany) with proper temporal andspatial separation. Each image of the area of interest wascalibrated and scaled by a calibration grid. The images thenwere divided into small subsections called interrogation areasand processed by PIV software (Davis 6.2, LaVision Inc., Goet-tingen, Germany). The interrogation areas of each image framewere cross-correlated with each other, and the correlationprocess produced a peak of the tendency of the particlesmoving direction. By repeating the cross-correlation for eacharea, a map of the velocity vectors was obtained. The cross-correlation mode was chosen because, compared with auto-correlation, the cross-correlation mode has higher space reso-lution by increasing the correlation peak.40 This process isrepeated at different times to obtain a time sequence of thevYelocity field. Time-Dependent Flow Across a Cylinder The flow patterns of the pulsatile flow across a cylinder thatrepresented the fiber in a TAL were examined by the PIVmethod. The cylinder was scaled up to 500 um in diameter foreasier observation and was positioned in the center of the testsection. Pulsatile flows were generated by programming theservo motor of the linear actuator to control the movement ofthe piston. The movement of the piston determined the flowrates and flow directions by pushing water out or pulling waterinto the hollow column at different speeds. The mean veloci-ties of the flow passing through the cylinder varied from 0.2 TTL signal Figure 5. Diagram of linear actuator synchronization. The linearactuator was synchronized with the PlV system and the flowmeter.Atransistor-transistor logic signal is sent from the linear actuator totrigger the operation of laser, camera, and flowmeter. cm/s to 1 cm/s, yielding Reynolds numbers of 1 to 5. Becausethe flow is time-dependent, synchronization between the flowand the measuring system was needed. This synchronization is illustrated in a schematic diagramthat shows the linear actuator, PIV system, and flowmeter (Fig.5). First, the linear actuator sends out a pulse of a transistor-transistor logic signal at different phases of the flow to the PIVsystem and a flow sensor (Flo-Sensors, Model 104, McMillanCo., Norton, MA). This signal triggers the emission of the laser,the operation of the camera, and the recording of the flowsensor. After the triggering, two laser pulses are emitted withproper temporal separation (to maintain the shift between twoparticles within 2 pixels), and the images around the cylinderthat were made visible by those two pulses are captured by theCCD camera. The flow sensor monitors the flow that is gen-erated by the linear actuator and outputs analog signals thatare transformed into digital signals by an analog-digital board(Personal Measurement Device, PMD-1208LS, MeasurementComputing Corporation, Norton, MA). By repeating this trig-gering procedure, the mean flow and the flow fields of eachphase of the pulsatile flow can be recorded and analyzed. Asa result, we can use the data from the flow sensor to track thecorrelated time of the PIV images and develop the time line ofthe vortex formation. Results and Discussion The flow in the water tunnel was examined first without acylinder, using the numerical and the PIV methods; we theninvestigated the pulsatile flow effect on vortex formation byplacing a cylinder in the test section of the water tunnel. Oneof the most essential considerations in a water tunnel design islow levels of turbulence or the uniformity of the flow becausethe effect of free-stream turbulence in shear layers is strong.The uniform mean velocity also allows us to compare with theprevious results of other investigations in steady flow and toapproximate the flow across a single fiber in the TAL. Wemeasured the velocity field in the test section of the watertunnel to ensure low turbulence, uniformity, and parallel of thevelocity. Pulsatile flows across a cylinder that mimicked theflows in a TAL were also investigated. Figure 6. Velocity vectors in the test section of the water tunnel.Fluent 5.5 was used to estimate the flow in different designs of thewater tunnel. Computational Fluid Dynamics Estimation of Water TunnelDesigns An example of velocity estimates computationally in a two-dimensional model of the water tunnel is shown in Figure 6.The flow is from left to right, and the average input velocity is0.1 centimeters per second. This corresponds to an inputReynolds number of 0.5 (based on the cylinder diameter,which is 0.5 mm), which is within the range of Reynoldsnumbers in TAL (0.1 to 10). The velocity vectors of the testsection were plotted, and the vector lengths indicate the mag-nitude of the velocity. The velocity profile is relatively bluntand uniform near the centerline of the water tunnel after thecontraction. Because the cylinder will be placed near thecenterline of the water tunnel, the flow across the cylinder isrelatively uniform. The length of contraction is about 0.634times the size of the outlet diameter in this figure, and thecontraction ratio is 4 in this example. Particle Image Velocimetry Results of the Test Section An example of the two-dimensional velocity field, measuredby the PIV method, near the centerline of the test section isshown in Figure 7. The flow in Figure 7 is from left to right, andthe length of the vectors represents the magnitude of thevelocity. The average velocity of the flow is 0.7 cm/s, whichcorresponds to a Reynolds number of approximately 3.5(based on the diameter of the cylinder).The erroneous vectorsin the picture are due to the discontinuity of the materialsaround the openable observation window. Since the cylinderwill be placed in the centerline of the test section, thoseerroneous vectors can be filtered or masked out. From Figure 7, we can confirm that the velocity profile isrelatively uniform near the center of the test section, where thecylinder will be placed. The Reynolds number of this figure iswithin the range of the Reynolds numbers in the TAL; bytesting the PIV method on the test section, we confirmed thatthis can be a method to study the flow across the cylinders inbench-top experiments. Figure 7. Velocity vectors in the test section. Flow is from left toright; length of the vectors represents the magnitude of the velocity.Erroneous vectors around the edge of the picture are due to thediscontinuity of the material of the test section. Flow Profile Validation ln writing the program for the motor, we generated a sinu-soidal, pulsatile wave form by the linear actuator to approxi-mate the flow inside the artificial lung. Figure 8 represents thesinusoidal flow generated by the linear actuator; the pulmo-nary artery flow in the native pulmonary system is shown inFigure 9 (the dimensionless numbers used to generate theresults were about the same allowed scaling). Although theflow profiles do not look the same, the profile in Figure 9 willresult in similar flow profile in Figure 8 when adding somecompliance to the TAL. The compliance is added to mimic the low resistance andhigh compliance in the natural pulmonary circulation system.With a compliance chamber in series with the TALs, the designcan match the pulmonary impedance more closely and pre-vent right ventricle failure, which researchers have shown to Figure 8. Flow wave form generated by linear actuator (the flowapproximates the flow inside the artificial lung in parallel with thenative lungs with 100% of flow through the device.) Figure 9. Blood flow inside the pulmonary artery (flow rate froman animal experiment of the ECMO laboratory at The University ofMichigan). be one of the complications of TAL used in animal experi-ments.41 Their results show that with the compliance elementconnected in series with the TAL, the flow is more like asinusoidal wave form before entering the TAL. A TAL with acompliant housing has also been designed42; the blood flowrate profile is very similar to the flow profile in Figure 8. In fact,by writing different programs for the motor, the linear actuatorcan generate different forms of flow. This provides us theoption to test the effects of different wave forms and frequencyto the flow around the cylinder. In the future, we hope this canalso apply to testing different flow patterns in the PA fordifferent patients in the TAL for optimization design. Pulsatile Flow Past a Circular Cylinder The pulsatile flow around a single cylinder was investigatedto understand the flow across a fiber inside a TAL. Pulsatileflows with average velocities of 0.2 cm/s to 1 cm/s were passedacross a cylinder (diameter = 500 um). For each phase of thepulsatile flow, more than 40 images were captured and ana-lyzed. Images of each phase of the flow were then processed incross-correlation mode by PlV software with an interrogationarea of 32 x32 pixels. This mode consists of two frames of rawimages of the area of interest; the algorithm computed all theinterrogation area of the two images, yielding a map of velocityvectors and streamlines. An example of streamlines and velocity vectors around acylinder in pulsatile flow is shown in Figure 10 and Figure 11.The cylinder is in the center of the image, as indicated by thearrow, but is not visible in the figure. The flow is from left toright, with a Reynolds number of 1 (a mean Reynolds number,based on the cylinder’s diameter) and a Stokes number of 0.37.This figure is the average of 30 images at the phase of 1.9m(where 2 m corresponds to a full cycle), which is at the phase ofapproaching zero velocity. The lines depict the streamlinesaround the cylinder, and the arrows are the velocity vectorswhose lengths are proportional to the magnitudes of the ve-locities. As shown in Figure 11, two vortices were formed behind thecylinder, indicating reversed flow after the cylinder. This flowreversal can supply fluid to the back surface of the cylinder,which has been shown to enhance heat and mass transfer. It Figure 10. Example of streamlines around the cylinder at phase1.9m (refer to inserted picture). Flow is from left to right, with a meanReynolds number of 1 and Stokes number of 0.37. Two vorticeswere formed behind the cylinder (cylinder is in the center but is notvisible in the PlV vector field) was shown in other studies that the supply of the fluid mayenhance the heat transfer on the back surface of the cylinder inpulsatile flows.43,44 Imposing pulsation to the flow also in-creases the mass transfer downstream of the cylinder.45 Inanother study, the oxygen transfer in the commercial oxygen-ators did not deteriorate in pulsatile flow in in vitro experi-ments; however, a decay of oxygen transfer was observed inthe steady flow cases.46 The authors propose that this differ-ence of oxygen transfer might be due to the "washing mech-anism" of the pulsatile flow. The flow might "wash out" theclots on the fibers, and the additional mixing might be aug-mented by the high and low flow rates. Unlike standard oxygenators that use an external pump, aTAL using the right ventricle as the pump should be designedfor a low flow resistance and pressure drop. Most traditional Figure 11. Example of velocity vectors around the cylinder. Thecylinder is not visible in the original image; the circle was drawn forillustrating only. The flow is from left to right, with mean Re =1 andNs =0.37. The reversed flow behind the cylinder supplies fluid tothe back surface of the cylinder. oxygenators are constructed with many layers of hollow fibersto approximate the large surface area in natural lungs, whosesurface area is about 50 to 200 m². These oxygenators haveexternal pumps that can provide the power to pump bloodthrough these dense fiber layers; therefore, the large pressuredrop across the fibers’ bed is of minor importance. Miniaturefibers packed closely in the TAL might increase the surfacearea and retain the small size for portable and intracorporealapplication, but tightly packed fibers also raise the resistanceto the blood flow, requiring more blood from the heart. Hence,the size of the fibers in a TAL becomes an optimization prob-lem to consider. To determine the optimal fiber size and velocity, we attemptedto find a proper relation of Reynolds number versus Stokes num-ber of vortex formation. We examined vortex formation in pul-12satile flows with mean Reynolds numbers of 1, 3, and 5 andStokes numbers of 0.18 to 0.37. These numbers are within therange of typical values of current TALs. A summary of the relationof the Stokes number and average Reynolds number to the vortexformation is shown in Figure 12. In Figure 12, circles are thevalues in which vortices were observed behind the cylinder atsome time during the model cardiac cycle, and the trianglesindicate the parameter values for which no vortex formed behindthe cylinder. There was no vortex formed behind the cylinderwhen Stokes numbers are below 0.22. Vortices were formed atStokes numbers above a critical value. The "critical region"inFigure 12 highlights the transitional values of vortex formation. Atthe Stokes number of 0.22, no vortices were discovered forReynolds numbers of 1 and 3. While increasing the Reynoldsnumber to 5, vortices were developed. Over the critical region,vortices were observed even at small Reynolds numbers of 1 and3. No vortex was observed at this range of Reynolds numbers inthe steady flow. As shown in Figure 12, higher Reynolds numbers and Stokesnumbers favor vortex formation. This suggests that higherReynolds numbers and Stokes numbers might enhance themixing and therefore augment the gas exchange. Reynoldsnumber is a function of the fiber diameter, the mean flowvelocity, and the kinematic viscosity; designing the TAL toincrease fiber diameter and Reynolds number would decreasethe total surface area of the fibers and diminish the gas ex-change. Stokes number is a function of the fiber diameter,pulsatile flow frequency, and the kinematic viscosity; a higherStokes number results from a larger fiber diameter and/or ahigher frequency of the flow in the same device and environ-ment. However, the frequency of the blood flow cannot becontrolled; it reflects the physiological condition of each pa-tient, and it may restrict the design capabilities and the TALfunctionality if it is below a certain value. Smaller Reynolds numbers from smaller-diameter fibers thusincrease the number of fibers in the TAL, the total surface area,and gas exchange. Moreover, a lower flow rate (which resultsin smaller Reynolds number) might allow adequate time forgas exchange. However, it might raise the resistance to theflow and not generate sufficient mixing. ln principle, an eligible TAL design could be chosen withdimensionless numbers within the critical region of Figure 12,where the Reynolds numbers and Stokes numbers are largeenough to generate the vortices and mixing but still maintainlarge surface area and low resistance. However, the optimaldesign of the TAL might be more complicated because there is no Figure 12. Parameters of formation of vortices. Reynolds numbers = 1 through 5, Stokes number = 0.18 through 0.37. Circles are thevalues in which vortices formed at some phases of the cycle; triangles are values in which no vortices formed. simple relation between the size of the fibers, the frequencies ofthe flow, and the dimensionless numbers. Furthermore, the di-mensionless numbers of a TAL might not be easily changed andchosen by simply varying several geometric design features. Theinteraction of flow structures resulting from multiple fibers mightalso be important. Nonetheless, these results presented here are afirst step toward understanding pulsatile flow in an artificial lung,which is a phenomenon that is difficult to measure inside anactual artificial lung, and these results provide new informationregarding this fundamental problem. Conclusions An experimental model was designed to study flow inside aTAL by using the PIV method. This study aimed to investigatethe flow patterns around the fibers inside a TAL in in vivoexperiments to optimize TAL design. Flow patterns were in-vestigated with a low-speed water tunnel with removable as-sembly, which allows us to examine the effects of pulsatileflow across a cylinder that simulates TAL fibers. This watertunnel is also applicable for studying flow in a variety ofmembrane devices, endovascular devices, and catheters fordrug delivery. We tested the flow in the test section of thewater tunnel without a cylinder by using numerical simulation,a flowmeter, and the PIV method. The results showed that thevelocities are relatively uniform near the centerline of thewater tunnel where the cylinder is placed. Pulsatile flow patterns around a single cylinder in the watertunnel with an average Reynolds number of 1, 3, and 5 wereexamined by using the PIV method. The images of the area ofinterest were cross-corrected with each other and yieldedvelocity vectors. Vortices are formed behind the cylinder athigh Stokes number, whereas no vortices form in steady flow atthis range of Reynolds numbers. The findings of this studyprovide new information of vortex formation at low Reynoldsnumbers in pulsatile flow; and supplying principles for TALdesign, including the following: 1. Higher Stokes number and Reynolds number favor vortexformation after the cylinder, which may potentially increasethe mixing of oxygen and blood in the TAL. 2. Smaller Reynolds numbers from smaller-diameter fibersincrease the number of fibers that can be packed in TAL andthus increase the total surface area and gas exchange. How-ever, this might reduce mixing. 3. In principle, a TAL could be designed such that theresulting dimensionless parameters correspond to the desiredformation of secondary flows, which will likely depend on gasexchange and device resistance criteria. Acknowledgments This work was supported by NIH grant R01-HL69420. We thankSteven Emanuel for help with machining. References 1. American Lung Association annual report. Available at: http://www.lungusa.org/data. Accessed June, 2005. 2. Borst HG, Schafers HJ: Lung transplantation. Clin Invest 71: 98-101,1993. 3. Nathan SD: Lung transplantation: disease-specific considerationsfor referral. Chest 127:1006-1016,2005. 4. Zwischenberger JB, Anderson CM, Cook KE, et al: Development ofan implantable artificial lung: challenges and progress. ASAIOJ47:316-320,2001. 5. Runo JR, Loyd JE: Primary pulmonary hypertension. Lancet 361:1533-1544,2003. 6. Nicod LP: Pulmonary hypertension. Swiss Med Wkly 133: 103-110, 2003. 7. Sitbon O, Humbert M, Simonneau G: Primary pulmonary hyper-tension: current therapy. Prog Cardiovasc Dis 45: 115-128,2002. 8. Keller CA: The donor lung: conservation of a precious resource.Thorax 53:506-513,1998. 9. United Network for Organ Sharing (UNOS/OPTN) annual report.Available at: http://www.unos.org. Accessed June 2005. 10. Dreyfuss D, Saumon G: Ventilator-induced lung injury: lessonsfrom experimental studies. Am J Respir Crit Care Med 157:294-323,1998. 11. Lee WL, Slutsky AS: Ventilator-induced lung injury and recom-mendations for mechanical ventilation of patients with ARDS.Semin Respir Crit Care Med22:269-280,2001. 12. Kolobow T: Volutrauma, barotrauma, and ventilator-induced lunginjury: lessons learned from the animal research laboratory. CritCare Med 32: 1961-1962,2004. 13. Jurmann MJ, Haverich A, Demertzis S, et al: Extracorporeal mem-brane-oxygenation as a bridge to lung transplantation. EurJ Cardio-Thorac Surg 5: 94-98, 1991. 14. Demertzis S, Haverich A, Ziemer G, et al: Successful lung trans-plantation for posttraumatic adult respiratory-distress syndromeafter extracorporeal membrane-oxygenation support. J HeartLung Transplant 11:1005-1007, 1992. 15. Haft JW, Griffith BP, Hirschl RB, et al: Results of an artificial-lungsurvey to lung transplant program directors. J Heart Lung Trans-plant 21:467-473,2002. 16. Cook KE, Makarewicz AJ, Backer CL, et al: Testing of an intratho-racic artificial lung in a pig model. ASAIO J 42: M604-M609,1996. 17. Witt SA, Alpard SK, Lick SD, et al: Total artificial lung preoperativemanagement: a 7-day survival study in sheep. Crit Care Med27:A22-A22,1999. 18. Lynch WR, Montoya JP, Brant DO, et al: Hemodynamic effect ofa low-resistance artificial lung in series with the native lungs ofsheep. Ann Thorac Surg 69: 351-356,2000. 19. Nose Y (edn): The oxygenator. Saint Louis, Mosby; 1973. 20. Williamson CHK: Vortex dynamics in the cylinder wake. Ann RevFluid Mech 28: 477-539,1996. 21. Pantalos GM, Koenig SC, Gillars KJ, et al: Characterization of anadult mock circulation for testing cardiac support devices.ASAIO J 50:37-46,2004. 22. Sharp MK, Dharmalingam RK: Development of a hydraulic modelof the human systemic circulation. ASAIOJ45:535-540,1999. 23. Vermette P, Thibault J, Laroche G: A continuous and pulsatile flowcirculation system for evaluation of cardiovascular devices.Artif Organs 22: 746-752, 1998. 24. Morel T: Comprehensive design of axisymmetric wind-tunnelcontractions.J Fluids Eng Trans ASME 97: 225-233,1975. 25. Bell JH, Mehta RD: Boundary-layer predictions for small low-speed contractions. AIAA J 27: 372-374,1989. 26. Bossel HH: Computation of axisymmetric contractions. AIAA J 7:2017, 1969. 27. Chmielewski GE: Boundary-layer considerations in the design ofaerodynamic contractions.J Aircraft 11: 435-438, 1974. 28. Whitehead LG, Wu LY, Waters MHL: Contracting ducts of finitelength. Aeronautic Q 2: 254-271,1951. 29. Morel T: Design of 2-dimensional wind-tunnel contractions. JFluids Eng Trans ASME99: 371-378,1977. 30. Laidler P, Walkden F: Design of axisymmetric ducts for incom-pressible flow. Aeronautic Q 28: 21-27,1977. 31. Mehta RD, Bradshaw P: Design rules for small low-speed windtunnels. Aeronautic J 83: 443-449, 1979. 32. Mikhail MN: Optimum design of wind-tunnel contractions. AIAAJ17:471-477,1979. 33. Downie JH, Jordinson R, Barnes FH: On the design of 3-dimen-sional wind-tunnel contractions. Aeronautic J 88: 287-295,1984. 34. Su YX: Flow-analysis and design of 3-dimensional wind-tunnelcontractions.AIAAJ29:1912-1920,1991. 35. Jewel B, Barlow WHR, Alan Pope (edn): Low-Speed Wind TunnelTesting. New York: John Wiley & Sons Inc., 1999. 36. Gordon R, Imbabi MS: CFD simulation and experimental valida-tion of a new closed circuit wind/water tunnel design. J FluidsEng Trans ASME 120: 311-318,1998. 37. Lumley JL, McMahon JF: Reducing water tunnel turbulence bymeans of a honeycomb.J Basic Eng 89:764,1967. 38. Loehrke Rl, Nagib HM: Control of free-stream turbulence bymeans of honeycombs: balance between suppression and gen-eration.J Fluids Eng Trans ASME 98: 342-353,1976. 39. Adrian RJ: Twenty years of particle image velocimetry. Exp Fluids39:159-169,2005. 40. Keane RD, Adrian RJ: Theory of cross-correlation analysis of PIVimages. Appl Sci Res 49: 191-215, 1992. 41. HaftJW, Alnajjar O, Bull JL, et al: The effect of artificial lung complianceon right ventricular load. ASAIO J 51:769-772,2005. 42. Cook KE, Perlman CE, Seipelt R, et al: Hemodynamic and gastransfer properties of a compliant thoracic artificial lung. ASAIOJ51:404-411,2005. 43. Kikuchi Y, Suzuki H, Kitagawa M, et al: Effect of pulsating Strouhalnumber on heat transfer around a heated cylinder in pulsatingcross-flow. JSME Int J Series B Fluids Thermal Eng 43:250-257,2000. 44. Papadakis G, Bergeles G: Numerical simulation of the flow andheat transfer around a cylinder with a pulsating approachingflow at a low Reynolds number. Proc Inst Mech Eng Part C JMech Eng Sci 215: 105-119, 2001. 45. Sung HJ, Hwang KS, Hyun JM: Experimental study on mass-transfer from a circular-cylinder in pulsating flow. Int J HeatMass Transfer 37: 2203-2210,1994. 46. Pennati G, Fiore GB, Inzoli F, et al: Mass transfer efficiency of acommercial hollow fibre oxygenator during six-hour in vitroperfusion with steady and with pulsatile blood flow. Int J ArtifOrgans 21: 97-106,1998. opyright O American Society of Artificial Internal Organs.Unauthorized reproduction of this article is prohibited.

关闭-

1/10

-

2/10

还剩8页未读,是否继续阅读?

继续免费阅读全文产品配置单

北京欧兰科技发展有限公司为您提供《人工肺模型,脉动流 中流场,速度矢量场检测方案(粒子图像测速)》,该方案主要用于内脏器官中流场,速度矢量场检测,参考标准《暂无》,《人工肺模型,脉动流 中流场,速度矢量场检测方案(粒子图像测速)》用到的仪器有德国LaVision PIV/PLIF粒子成像测速场仪、Imager LX PIV相机。

我要纠错

推荐专场

CCD相机/影像CCD

更多相关方案

咨询

咨询