方案详情文

智能文字提取功能测试中

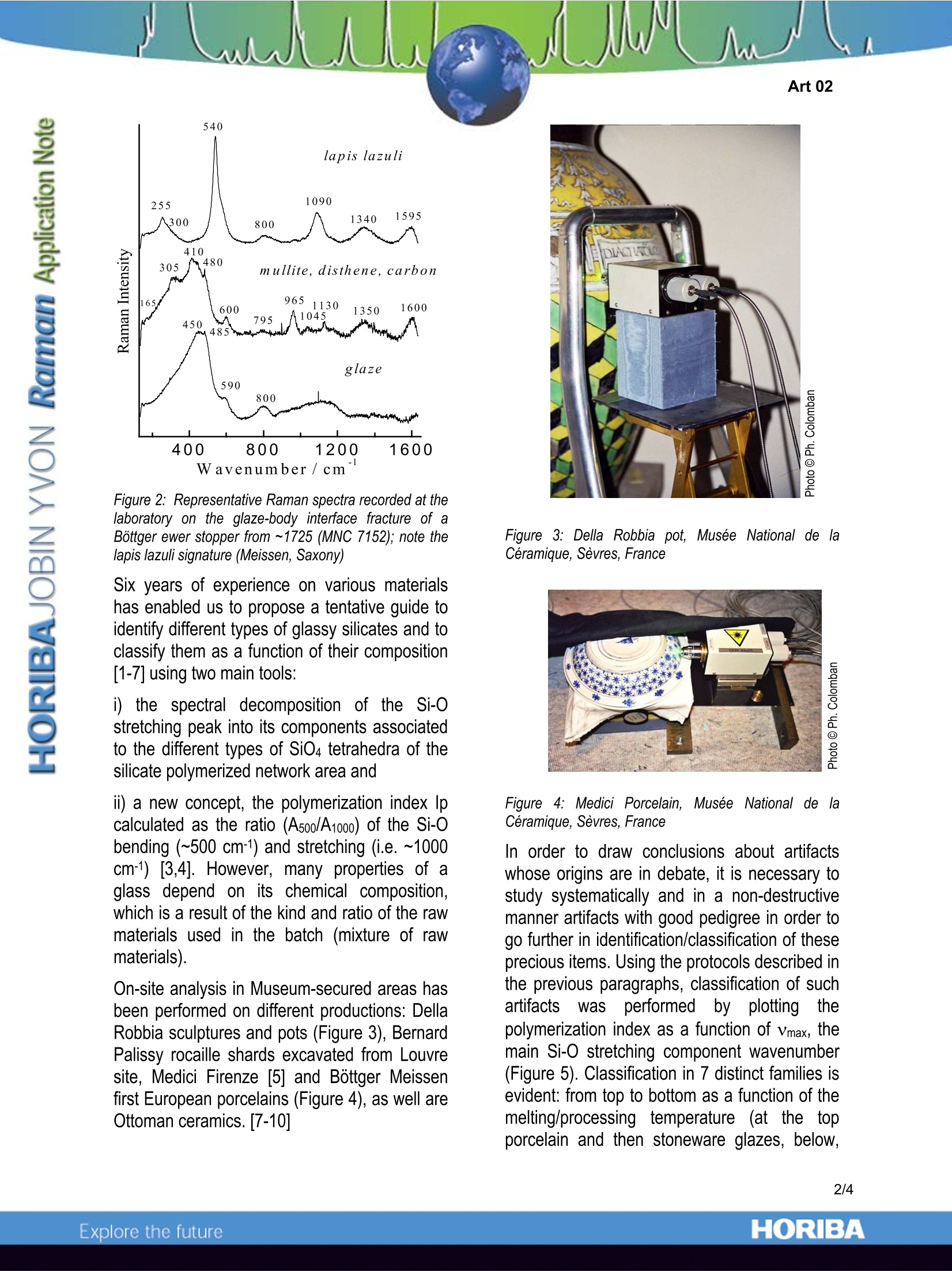

Art 02 Archaeometric analysis of ancient pottery Philippe Colomban,LADIR UMR7075 CNRS & UPMC, Thiais, France Leadingexpertsgenerallybase theircertification of ancient artifacts on sstylisticanalysis and on personal sensory perceptions.However, greater objectivity is mandatory foridentification and dating purposes. Differentmanufacturing technologies often resultlt inproducts of very similar external appearance(from the visual and sensory points of view), butwhichdiffer completely in their micro/nanostructure. A lot of information about theproduction1process remains written in thesample and non-destructive Raman analysis ofthe micro-structure (for ceramics) and nano-structure (for glasses and enamels) offers away to retrieve the information, which assists inthe identification and sometimes dating ofancient artifacts (Figure 1). Figure 1: Iznik dishes during analysis with a HE532 &Superhead instrument, Musee National de la Ceramique,Sevres, France As an1 opticamlrethod.Raman(micro)-spectroscopy offers a great advantage overmost other techniquesintthatt it canbeperformed without any contact with the studiedartifact, both in the laboratory using high-resolution, large spectral window instruments,as well as on-site using medium resolution,portable instruments. All applicationsin tthee sScience,artt aandtechnology of glass, glazes a:nd (enamelsconsist in a controlled modification of the 3D Si-O network by replacement of Si4+ covalentbonded atoms by non-covalent bonded atoms,hence decreasing the number of Si-0 bridgesandtheconnectivityotthenetwork.Consequently, the melting temperature, theviscosity at a given temperature, i.e. anyphysical/chemical properties related to thedensity and network connectivityy (thermalexpansion, ion diffusion, reactivity, etc.) aremodified accordingly. Direct relationships between the silica content,or more precisely the ratio between the glass-former (chiefly Si and Al -oxides) and the fluxcontent (Na, K, Ca, Pb oxides) and theproperties of glassy ssiilliiccaatteses have beenestablished for a long time (Seeger’s rules).Because strong covalent bonded structureshave Raman signatures orders of magnitudelarger than those of ionic ones, the Ramanspectrum of a silicate consists, as a firstapproximation, solely of the signature of the Si-O network(Si-0 stretching, bending andlibrational/collective modes). Because a SiO4 tetrahedron is a solid chemicaland vibrational entity (molten silicates retain astrong polymericc character), it is wellestablishedthatthedifferenttetrahedralarrangementshavee characteristicRamansignatures (Figure 2). These arrangementsinclude an isolated tetrahedron referred to asQo, tetrahedra linked by a common oxygenatom (Si207 or Q1), tetrahedra linked by sharing2 oxygen atoms(three(Si3Og)andntetrahedral-cycles: Q2), tetrahedra linked bysharing 3 oxygen atoms (Q3, e.g. in somechains, ribbons and layers) and Q4 (as in puresiO2). Figure 2: Representative Raman spectra recorded at thelaboratory on the glaze-body interface fracture of aBottger ewer stopper from ~1725 (MNC 7152); note thelapis lazuli signature (Meissen, Saxony) Six years of experience on various materialshas enabled us to propose a tentative guide toidentify different types of glassy silicates and toclassify them as a function of their composition[1-7]using two main tools: i) the spectral decomposition of the Si-Ostretching peak into its components associatedto the different types of SiO4 tetrahedra of thesilicate polymerized network area and ii) a new concept, the polymerization index Ipcalculated as the ratio (A500/A1000) of the Si-Obending (~500 cm-1) and stretching (i.e. ~1000cm-1) [3,4]. However, many properties of aglass depend on its chemical composition,which is a result of the kind and ratio of the rawmaterials used in the batch (mixture of rawmaterials). On-site analysis in Museum-secured areas hasbeen performed on different productions: DellaRobbia sculptures and pots (Figure 3), BernardPalissy rocaille shards excavated from Louvresite, Medici Firenze [5] and Bottger Meissenfirst European porcelains (Figure 4), as well areOttoman ceramics. [7-10] Figure 3: Della Robbia pot, Musee National de laCeramique, Sevres, France Figure 4: Medici Porcelain, Musee National de laCeramique, Sevres, France In order to draw conclusions about artifactswhose origins are in debate, it is necessary tostudy systematically and in a non-destructivemanner artifacts with good pedigree in order togo further in identification/classification of theseprecious items. Using the protocols described inthe previous paragraphs, classification of suchartifactswasperformed by plottingtthepolymerization index as a function of Vmax, themain Si-O stretching component wavenumber(Figure 5). Classification in 7 distinct families isevident: from top to bottom as a function of themelting/processing temperature (at the topporcelain and then stoneware glazes, below, faience and terra-cotta glazes and glasses, alltypes of low temperature processed silicates),and from left to right as function of the main flux. Figure 5: Plots of the polymerization index as a functionof the main Si-0 stretching component wavenumber However, Iznik and Kutahya wares and thehistory of their production remain a source ofdebate among scholars. The exact origin of“lznik” products (lznik, Damascus, Istanbul,Kutahya or elsewhere) is still an open question.As for Medici porcelains, wares (and shards)being very rare, they are not well documentedand some fakes have been made for centuries.Some of the earlier fritwares are generallyassigned to Iznik productions (blue and whitewares sometimes classified as Touran, Roumior Abraham of Kutahya style), but theirproduction by Kutahya kilns was questioned.The real development of the production ofKutahya wares dates back to the end of the 17thcentury,following theemancipationofByzantine and Armenian Christian communities.Furthermore, copies or fakes were made sincethe 19th century in different places. The same analysis and classification was thusperformed on Iznik and Kutahya wares (Figure6). Some of the Kutahya glazes can1beassociated to family 7 (PbO-rich glass) butsome of them are also located in the Iznikgroup (e.g. sample 7460). On the other hand,Iznik glazes are all located in between family 5(Na2O+ PbO) and family 4 (Na2O-rich silicates) except for two types of glazes located in family7 (PbO-rich) and in family 2 (CaO-rich). The Raman signature of the Iznik productionthus appears to be fairly homogeneous. This isdue to the fact that Iznik manufacturers werecontrolled by the nakkashane, the Ottomanoffice for decor and drawing. By contrast, thesignificant variation in the Raman signature ofthe Kutahya glazes reflects the autonomy ofdifferent production centers working accordingtoo thee Kutahya style. Furthermore, theprocedure was also efficient to discriminatebetween early and late lznik production, basedon a small compositional shift of the silicateglaze at the decline of the production (17thcentury) [8]. Figure 6: Bi-plot of the polymerization index (lp) as afunction of the Si-0 stretching wavenumber maximum forthe series of lznik and Kutahya fritware glazes. Samplelabel: Curator' assignment (lz, lznik; Ku, Kutahya), color(b: blue, r:red, ...), artifact record number. The two parameters Ip and Vmax, thus appear tobe goodtoolsforr(classification.anddifferentiationn betweenKutahya andznikOttoman pottery is relatively straightforwardfrom the Raman fingerprint [7,8]. Analysis of the colorless/white regions of thesamples always reveals the more or less strongRaman signature of a-quartz (Figure 7). Bymodifying the focal point of the laser with theXYZ plate it is possible to confirm that the whitecolor is obtained by an o-quartz-rich slip deposited below the glaze. This quartz layer isat the origin of the high gloss and very powerfulcolored decor. Note that the technique of awhite a-quartz slip to mask the red color of thebody was already used forrVietnameseporcelain and stoneware. MNC 8408 Wavenumber/cm Figure 7: As-recorded spectra for lznik glazes. Note thevery strong quartz fingerprint for white glaze due to thecharacteristic quartz slip deposited on the body, belowthe glaze layer. Strongly colored regions give a strong Ramansignature, nearly free of any background(Figure 7). The ways to obtain a blue glaze arerather limited: copper in alkaline silicate(turquoise), cobalt (blue) and lapislazuli(ultramarine blue), whatever the fluxing agent[7]. The last rpigment has avery typicalresonance Raman signature when excited withthe 532nm laser. If small amounts of cobalt(copper) dissolve in the glaze, no specificRaman signature is expected. Saturation leadsto cobalt mixed silicates or to cobalt aluminate.Cobalt-containing Mn-rich ores (spinels) canalso be used as blue pigments, if the firing isconducted in a reducing atmosphere. Theobserved color excludes the use of lapis lazuliand Cu. In most blue regions analyzed, we only observed the Raman signature of the glaze, which indicates that cobalt is dissolved withinthe glaze network. In conclusion, this work has shown that Ramanmicroanalysis is invaluable in assisting in thecharacterization of all types of ceramic artifacts.The information obtained on the composition ofthe glaze and pigments can yield importantinformation on the fabrication and processing ofthese ancient artifacts and may even helpputting to rest many controversies about theprovenance of certain pieces. References: 1. Ph. Colomban, Glasses, Glazes and Ceramics- Recognitionof the Ancient Technology from the Raman Spectra, chapter inRaman Spectroscopy in Archaeology and Art History, EdwardsHGM and Chalmers JM (Eds), Royal Society of Chemistry,London, 2005, ch13. 2. Ph. Colomban, F. Treppoz, Identification and Differentiationof Ancient and Modern European Porcelains by Raman Macro-and Microspectroscopy, J. Raman Spectr. 32 (2001) 93-102 3. Ph. Colomban, Polymerisation Degreeand RamanIdentification of Ancient Glasses used for Jewellery, CeramicsEnamels and Mosaics, J. Non-Crystalline Solids 323 [1-3](2003) 180-187. 4. Ph. Colomban, O. Paulsen Raman Determination of theStructure and Composition of Glazes, J. Amer. Ceram. Soc. 88i[2](2005)390-395. 5. Ph. Colomban Recent Case studies in the Raman Analysisof Ancient Ceramics: Glaze Opacification in Abbasid Pottery,Medici and 18th century French Porcelains, Iznik and KutahyaOttoman Fritwares and Unexpected Lapis Lazuli Pigment inLajvardina Wares, Mater. Res. Soc. Symp. Proc. 2005 vol 852,P. Vandiver, J. Mass & A. Murray Eds.008.4. 6. Ph. Colomban, C. Truong, A Non-destructive Raman Studyof the Glazing Technique in Lustre Potteries and Faiences (9h-14th centuries) : Silver ions, Nanoclusters, Microstructure andProcessing, J. Raman Spectrosc. 35[3] (2004) 195-207. 7. Ph. Colomban, V. Milande, L. Le Bihan, On-site RamanAnalysis of Iznik pottery glazes and pigments, J. RamanSpectrosc. 35 (2004)527-535. ( 8. Ph. Colomban, R . d e Laveaucoupet, V . M i lande, O n SiteRaman Analysis of Kutahya fritwares, J . Raman Spectroscopy36 [9](2005)857-863. ) ( 9. P h. Colomban, V. Milande, On S ite Analysis of the earliestknown Meissen Porcelain and Stoneware, J . Raman Spectrosc.37 (2006). ) 10. Ph. Colomban, A. Tournie, L. Bellot-Gurlet, Ramanldentification of glassy silicates used in ceramic, glass andjewellry: a tentative differentiation guide, J. Raman Spectrosc.37 (2006) 841-852. ( France : HORIBA Jobin Yv o n S.A.S., 23 1 rue de Lille, 59650 Villeneuve d'Ascq. T e l:+3 3 (0)3 20 59 18 0 0,Fax: + 33 (0)3 2059 18 08. Email : raman@jobinyvon.fr w ww.jobinyvon.fr USA: HORIBA Jobin Yvon Inc., 3880 Park Avenue, Edison, NJ 08820-3012. Te l :+1-732-494-8660, Fax:+1-732-549-2571. Email : raman@jobinyvon.com www.jobinyvon.com Japan: HORIBA Ltd., JY Optical Sales Dept., 1-7-8 Higashi-kanda, Ch i yoda-ku, Tok y o 101-0031.Tel: +81 (0)3 3861 8231 , Fax: +81 (0)3 3861 8259. Email: raman@horiba.com Germany: +49 (0)62518475-0 I taly:+39 02 57603050 U K : +44 (0)20 8204 8142 4/4 China: +86(0)10 68492216 ) ORIBAExplore the future In conclusion, this work has shown that Raman microanalysis is invaluable in assisting in the characterization of all types of ceramic artifacts. The information obtained on the composition of the glaze and pigments can yield important information on the fabrication and processing of these ancient artifacts and may even help putting to rest many controversies about the provenance of certain pieces.

关闭-

1/4

-

2/4

还剩2页未读,是否继续阅读?

继续免费阅读全文产品配置单

HORIBA(中国)为您提供《古陶瓷中年代鉴定检测方案(激光拉曼光谱)》,该方案主要用于陶瓷中年代鉴定检测,参考标准《暂无》,《古陶瓷中年代鉴定检测方案(激光拉曼光谱)》用到的仪器有null。

我要纠错

相关方案

咨询

咨询