方案详情文

智能文字提取功能测试中

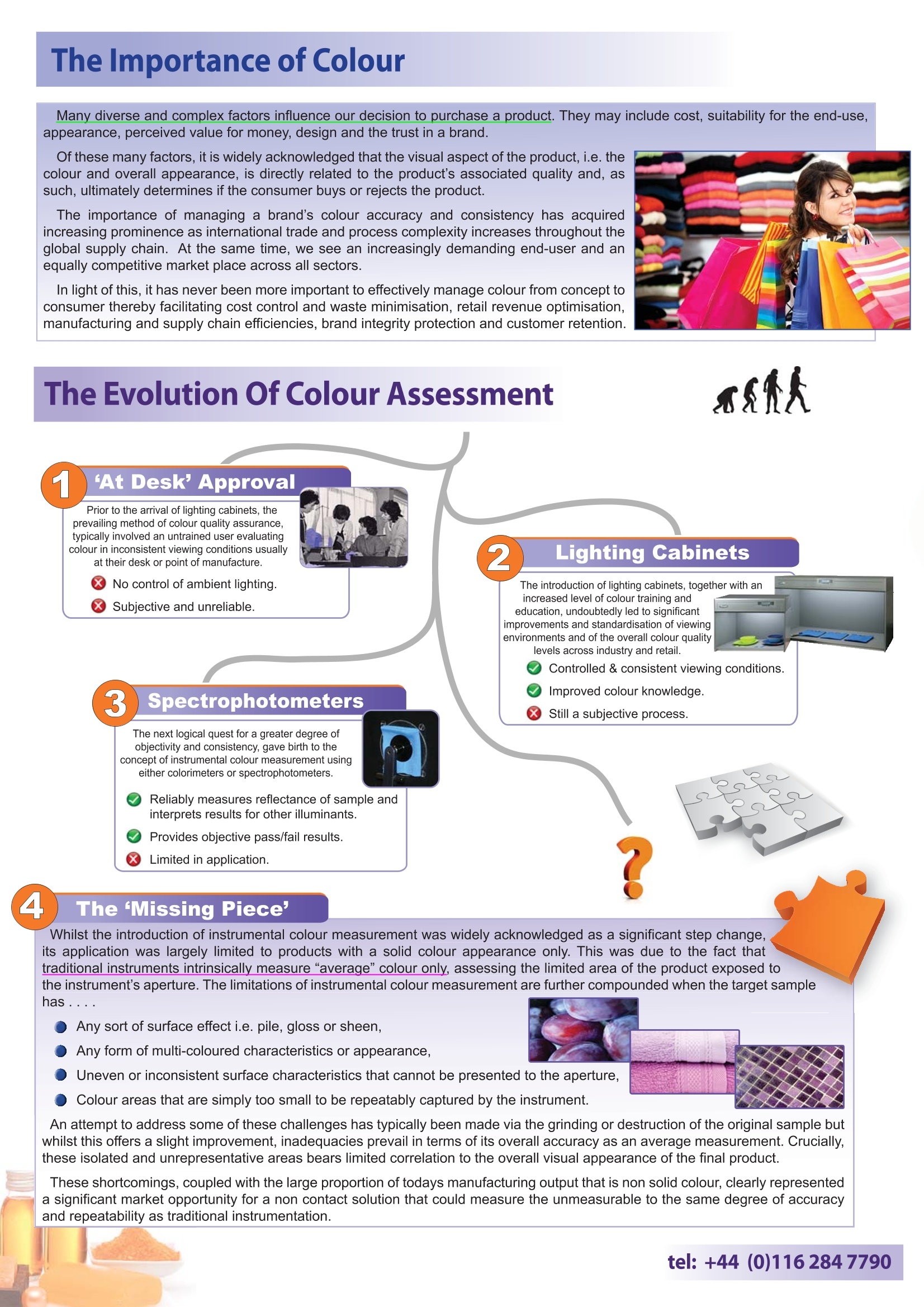

What DigiEye Offers You sheens :fabric Digi sye with pile Putting Colour in Context multi-coloured curved33 Measuring theunmeasurable The Importance of Colour Many diverse and complex factors influence our decision to purchase a product. They may include cost, suitability for the end-use,appearance, perceived value for money,design and the trust in a brand. Of these many factors, it is widely acknowledged that the visual aspect of the product, i.e. thecolour and overall appearance, is directly related to the product's associated quality and, assuch, ultimately determines if the consumer buys or rejects the product. The importance of managing a brand's colour accuracy and consistency has acquiredincreasing prominence as international trade and process complexity increases throughout theglobal supply chain. At the same time, we see an increasingly demanding end-user and anequally competitive market place across all sectors. In light of this, it has never been more important to effectively manage colour from concept toconsumer thereby facilitating cost control and waste minimisation, retail revenue optimisation,manufacturing and supply chain efficiencies, brand integrity protection and customer retention. The Evolution Of Colour Assessment 4 The ‘Missing Piece’ Whilst the introduction of instrumental colour measurement was widely acknowledged as a significant step change,its application was largely limited to products with a solid colour appearance only. This was due to the fact thattraditional instruments intrinsically measure “average”colour only, assessing the limited area of the product exposed tothe instrument’s aperture. The limitations of instrumental colour measurement are further compounded when the target samplehas.... Any sort of surface effect i.e. pile, gloss or sheen, Any form of multi-coloured characteristics or appearance, Uneven or inconsistent surface characteristics that cannot be presented to the aperture, Colour areas that are simply too small to be repeatably captured by the instrument. An attempt to address some of these challenges has typically been made via the grinding or destruction of the original sample butwhilst this offers a slight improvement, inadequacies prevail in terms of its overall accuracy as an average measurement. Crucially,these isolated and unrepresentative areas bears limited correlation to the overall visual appearance of the final product. These shortcomings, coupled with the large proportion of todays manufacturing output that is non solid colour, clearly representeda significant market opportunity for a non contact solution that could measure the unmeasurable to the same degree of accuracyand repeatability as traditional instrumentation. The DigiEye System was developed in response to this market demand, and provides a ‘best practice’combination oflighting and visual assessment principles, together with non-contact instrumental measurement for quantifiable and objectivequality control. Using controlled, consistent and defined illumination conditions, DigiEye captures and measures product colour andappearance with an amazingly high resolution and great precision. Controlled, consistent & enclosed lighting, totalelimination of ambient light. Objective colour measurement. Non-destructive sample measurement. Total visual consistency. DigiEye is a digital colour imaging system used by leading companies and organisations throughout the world,with applications within an increasingly diverse array of industry sectors. Included in the DigiEye System are; A characterised digital SLR camera, enabling capture of outstandingly detailed images,recording colour data at millions of points. A calibrated monitor and printer which provide highly accurate visual on-screenrepresentation of the product and printed colour accurate authentic representations ofthe product for use as master product standards. Samples are captured on a neutral grey background within the ‘DigiEye Cube’. To ensureconsistency and repeatability, this cube provides a totally controlled and defined lighting environmentwhich eliminates all ambient light. The lighting used within the cube closely matches the CIE D65lighting and can be used with angled & diffuse lighting. The two images of eyeshadow, (right), taken using the DigiEye system, illustrate the differing visualappearance obtained from using angled and diffuse lighting. ANGLED ILLUMINATIONHighlights surface details. Idealfor accurate appearance. Diffuse illumination is useful as it removes the specular reflections of products with glossy andcurved surfaces. This enables reliable colour measurement of product such as fruit, metallics, ceramicsand satin fabric. Angled illumination allows product with uneven surface structures and texture to beclearly displayed, measured and evaluated. The colour measurements are made in CIE colour space. Colour data can be presented in a widerange of specifications such as LAB, XYZ andLCH. Colour difference measurements can be assessedin a variety of industry standard equations such as CIELAB, CMC and CIEDE2000, with colourdifference information between standard and batch shown in both numerical and via an on-screenvisual format, including texture. DIFFUSE ILLUMINATION Flattens the images. Ideal forcolour measurement and QC. DigiEye Applications - What can it do? DigiEye Virtual Selection The DigiEye Virtual Selection application allows the user to assess the appearance of a product or substrate in a variety ofcolours without the need to manufacture all of the intended colour options as physical samples. Using just one sample, for example, an item of clothing or a mobile phone fascia(as illustrated), the user can accurately simulate other colours or colourcombinations onto this donor'image. As DigiEye individually retextures each pixel on the image the authenticappearance of the original image such as the detail and the areas of lightness &shadow,are retained. Having first captured the image of one prototype sample, thenew colours are applied using the DigiPix colour replacement application. New colours can originate from in-built colour libraries (Pantone, NCS etc),frommeasurements via DigiEye or a spectrophotometer, or by creating the colourusingthe colour slider functionality within the software. A calibrated monitor and printer allows the user to make onscreen and hardcopy assessments of the commerciality of the new colours, thereby negating theneed to physically prototype all the colour combinations within a range. This offersmajor associated benefits in terms of speed to market sampling and overall costreduction This process can be used for multiple product types in variousmarket sectors including Fashion Retail, Consumer Products, Print &Packaging, Personal Care, Flooring or any other area where samplingcosts are typically high, manufacturing timescales extended or when theprototyping timescales are under pressure. A further extension of the Virtual Selection application is thesubsequent use of the initial prototypes as photographic standards forongoing production. DigiEye Digital Standards DigiEye allows the generation of colour accurate, digital visual assessment standards. High resolution images are captured,within the DigiEye ‘Cube'under controlled and consistent illumination conditions. This ensures the images have a realisticappearance, which is repeatable, allowing objective comparisons. Once the digital standards are defined, they can be sharedwith the supply chain or multiple production sites electronically via full'or ‘satellite'systems or in hard copy format. The image format is colour managed for use with an ICC profile, which is produced by the team at VeriVide, using the client'sown products. This ensures colour accurate printing and gives the optimum visual accuracy. Digital photographic standards are particularly useful in establishingat the outset, the agreed standards for product colour and appearance. They can add further value by helping manage products withtransient properties such as food stuffs, and can prove usefulcontrolling the challenges of product shelf-life. These colour accurate images can bee used throughout theproduction process including areas where it may not be practical tohave instrumental equipment, such as ovens, freezers etc. Production tolerances can also be defined using these photographicstandards to help to ensure product meets the visual expectations ofthe customer. DigiEye Virtual Sampling Once the digital standards have been defined and shared with the supply chain, the opportunity of electronic sample submissionis available, from point of manufacture through to point of approval. Physical production samples can be produced to meet the defined tolerances and subsequently imaged in the DigiEye System forelectronic evaluation and sample submission using DigiEye’s QC Matrix package. This software provides clear and accurateinformation, allowing the user to make both numerical and visual assessments of their standard/batch colour differences on theirdesired product or substrate. This is supported by a clear indicator of the pass/fail status, and also includesa ‘virtual light box' allowing the user to toggle through up to three illuminants andcheck for any visual and numerical metamerism. The QC matrix can be sent via email to the point of approval where it isevaluated on a calibrated monitor. The solution optimises the files so that imagesize is no longer a constraint plus it is also fully compatible with all existing filesformats. DigiEye's various software selection tools enable theuser to measure the colour of the total sample orspecific area of interest to assess individual productelements in context within the colour of the total sample.This capability significantly extends the boundaries ofinstrumental measurement for the ‘non-measurables’. From a retail perspective, lingerie or any othermulti-component product can be addressed, similarlypatterns and prints, home furnishings, hard & softgoods, personal care items and cosmetics. Outside of the retail sector, the evaluation of thevarying surface characteristics of any industrial orconsumer product is an ongoing challenge. DigiEyeaddresses this challenge in two ways; The: Colour Clustering’function, whichgives the percentage of each colour on thevisible surface and The ‘Sort & Replace’method which alsogives a clear, visual representation of wherethese colours are within the sample. This processhas numerous proven applicationswithin many sectors, examples include industrial flooringmanufacturers (aggregate distribution for non-slip),wood producers for home flooring and kitchens (graindistribution) and also for multiple applications within thefood sector. Such applications include the quality controlcoatings on biscuits and cake, the percentage ofdifferent visual products in a mix, the assessment of thepercentage of visible fruit on the surface of yogurts andsauces- to name but a few. Traditionally these QC checks were limited tosubjective visual assessment methods. DigiEye offers Industry the opportunity to apply anobjective fixed numerical tolerance resulting in faster &more accurate decision making, fewer people involvedin that process and a higher production throughput. Colour Fastness grading for both change of shade and staining of adjacent fabric hastraditionally been undertaken by trained and experienced graders using a standardillumination cabinet and a set of grey-scales. Today, grading can now be achieved digitallyusing the Colour Fastness feature within DigiEye-DigiGrade By capturing images of treated samples together with the adjacent multi-fibre test fabricDigiGrade can be used to objectively evaluate change of the shade and the staining. Colour Fastness grading using DigiGrade can beundertaken with minimal training allowing the laboratoryteam to utilise their skills elsewhere and, as the systemalso allows multiple samples within a single image, anadditional benefit is the speed of the process overtraditional visual techniques. This can lead to a reductionin time to market for the manufacturer and an increasedlaboratory throughput. The images and results can be sent electronically,thereby saving the time and expense of shipping therelevant samples. The DigiGrade Colour Fastness6 1feature is mostcommonly used to evaluate wash fastness results;however, it is also capable of evaluating Crocking (dryand wet rubbing), change of shade for all products anddeterminingthe endpoint and final grade for lightfastness. DigiGrade is used by major retailers, throughout their supply chain and by independentand mill test houses around the world and is accepted as part of ISO 17025 UKASaccreditation (or the equivalent national body). DigiEye further expands the scope of the‘non-measurables’by offering aLarge Area Imaging system, known as the ‘DigiEye-LAI', for product largerthan that which can be accommodated within the standard illumination cube The booth can readily accept product within a field view of1300 mm x 1300 mm and offers optimised and controlledlighting across the whole target area. This has typicallyincluded full garments, print repeats, full-sized mannequins& models and even automotive wheels. An additional proven application for the LAl is use as an'lmaging Tool’ for web and catalogue photography. Thesystem is quick and easy to use, requires very littlepost-processing and gives the business direct control of theprocess, especially during the‘sale season'or when a quickresponse is necessary. Images can also be re-coloured using the DigiEye systemnegating the need for multiple colour sampling, usually atshort notice. The system has even been deployed as a warehouse QCtool by a major UK High Street Retailer for the visualassessment of incoming merchandise and to assist withfault identification and trouble shooting. Features >Benefits Non-contact colour measurement.surpassing the capabilities and Increases tremendously the types of product that cannow be accurately colour measured. restrictions of the spectrophotometer. A totally enclosed area for sampleimage capture. Eliminating the detrimental effects of ambient lighting.Controlled & consistent lighting ensuring controlled,reliable & repeatable results. Colour Clustering'-measurement of the differently coloured visibleelements in a product or sample. DigiEye can calculate the percentage of each visiblecolour, supplying quantifiable quality control data foreach element in context with the total sample. Visual consistency dacross multi-location productionunits and improvedl product reliability as colour dataandimagescan become part oftheproductspecifications. As the camera settings are largely controlled by theDigiEye Software, there is no requirement for priorphotographic knowledge. Measurement of colour as seen by the consumer, e.g.liquid within a transparent bottle, the appearance ofyogurts, eyeshadow within a clear container. Digitally change the on-screen colour of the product toassessthe alternate colours ofnew and existingproducts, e.g. changes in the colour of footwear or toassess different colour options of plastic products. Removes subjective manual visualassessment duringproduction. The system enables timely detection ofnon-standard product, creating opportunities for areduction in retailer returns & significant waste andcost reduction. Finally, a solution that canbridge the non-measurable'gap and still offer high-endinstrumental performanceand accurate visual &numerical colour data. 55 VeriVide Limited. Quartz CloseWarrens Business ParkEnderby, Leicester. LE19 4SGUnited Kingdom Tell::+44(0)116 2847790 Fax:+44 (0) 1162847799 enquiries@verivide.com www.verivide.com/digieyewww.digieye.co.uk The DigiEye Colour Measurement & Imaging System is manufactured in the UK by VeriVide Limited, the lighting and digital colour assessment specialists. O VeriVide Limited. Leicester. United Kingdom.All rights reserved. Reproduction in whole or in part is not allowed without the prior written consent of the copyrightowner. Some of the images contained herein, have not been generated using the DigiEye System; they are illustrative to represent the diverse array of product typesthat either have or could be colour measured using the DigiEye System. ( The information i n this leaflet i s believed t o be CE accurate and reliable and may be changed without notice. No par t of this document forms part of any contractor quotation. VeriVide L i mited is registered under BS EN I S O 9001 Certificate No. 3393. ) tel: +() email: enquiries@verivide.com 电子眼颜色测量系统对汽车内饰颜色控制的帮助 国内汽车市场刚性需求的状态没有改变,仍将长期处于刚性需求阶段,潜力巨大,许多地方政府也将汽车市场列为支柱产业的总方针,同时各地政府对汽车市场的支持力度不断加大,目前全国汽车年销售量已经超过2000万辆。 汽车的巨大销售量也带动了汽车行业整条生产链的发展,比如说汽车内饰。随着大家对汽车的购买力越来越高,也就对汽车产品更为挑剔,汽车内饰的品质也就成了各大汽车品牌用以吸引消费者的重要部分。汽车内饰是近年来国内新兴产业,主要分为汽车顶棚内衬装饰、侧围内护板和门内护板装饰、仪表板装饰、座椅装饰、地板装饰和内饰精品装饰。作为广大消费者来说最关注汽车内饰的两大特征是舒适和美观。 汽车内饰对于用户来说,是要与自己亲密接触时间最长的,是可以直接影响到自己的部分,尤其是它的颜色美观与否直接影响了用户的心情。考虑到内饰市场的大规模扩张与竞争,无论是汽车厂家、零部件生产厂家、原材料厂家都对颜色的设计与呈现提出了更高的要求。那么汽车内饰行业的生产链是如何保证颜色的一致性呢? 标准样板是内饰生产链上关于颜色统一评价的重要工具,是设计认可的关于颜色、触觉、结构、皮纹的复制品。标准色板的复制过程中,对于△E,△L*,△a*,△b*都有一定的要求。标准样板作为发放颜色的依据以及后期确认颜色的依据。 目前较多的零部件生产商对零部件与标准样板的色差效果评估采用的是多人目视评价,通过评价小组的颜色评定来进行产品等级分级。由于这种方式对人员的要求较高,受制于人眼观察能力,并且存在一些评价过程中的不稳定、不客观因素,因此,只能进行粗略的分级。随着内饰行业的发展,仪器测量方法也就被引入进来了,利用仪器法测量可以对色差较小的产品进行区分,并细分等级,对于在视觉上无法区分的产品与标准样板之间的色差只能通过仪器进行测量。利用仪器测量可以将△E,△L*,△a*,△b*的数值范围设定在一个更小的区间用以更严格的要求生产工艺,最终做出的产品一致性大大提高。 原材料厂家可以利用仪器法对内饰产品进行有效的管理,零部件厂家也能利用仪器测量进行来料检验及管理,不过对于汽车厂来说,所采购的产品为形状大小不一的零部件,如果用便携式的仪器进行测量,工作量巨大,并且对于特殊的形状无法准确测量,那么该如何对不规则的内饰产品进行快速批量的颜色测量就成为了各大汽车产关心的问题。 上海韵鼎公司为广大客户提供英国Vervide DigiEye智能数字电子眼,电子眼是一种最新式的颜色测量系统,在标准环境下,用经过校准的标准相机对样品拍照,并将图像转换成颜色数据L*a*b*的最新型仪器,可以检测各种状态的不规则、规则、杂色等样品的颜色效果。DigiEye已经写入ISO颜色测试标准。 DigiEye可使汽车零部件以真实面貌呈现在屏幕上,它是质量控制和科研分析的利器,能够帮助汽车厂商对大批量的零部件进行稳定的颜色质量分析,DigiEye利用校正色卡对仪器进行颜色校正,保证颜色测量数据的稳定性和真实性。 DigiEye数慧眼系统与众不同,它通过超高分辨率捕捉产品表面结构、颜色及外观的数字图像。这种测色方式非常准确且具有一致性,可重复性。 DigiEye获取信息比较全面,可获得样品外形、颜色、光泽、纹理结构、透明情况、色度数据、色差等,可用于测量产品在不同工艺下颜色外观的改变。不但能对产品进行整体的视觉分析,还能计算样品每个单一颜色的百分比,并对整个样品的任何位置都可提供质量控制的数据。此外,还具有颜色替换和分类、合格/不合格判定、定时自动测量功能等。 DigiEye可实现多台显示器共享软件平台,并可通过网络传递样品测试结果文件(包含颜色、形状、尺寸及表面构造)。可通过多处生产的样品与标样比较来实现可视化质量控制,从而使真实的颜色数字和影像成为产品规格的一部分。

关闭-

1/8

-

2/8

还剩6页未读,是否继续阅读?

继续免费阅读全文产品配置单

上海韵鼎国际贸易有限公司为您提供《汽车内饰中规则或不规则产品的颜色和色差检测方案(色差仪)》,该方案主要用于汽车内饰中理化分析检测,参考标准《暂无》,《汽车内饰中规则或不规则产品的颜色和色差检测方案(色差仪)》用到的仪器有测色电子眼Digieye。

我要纠错

推荐专场

相关方案

咨询

咨询