方案详情文

智能文字提取功能测试中

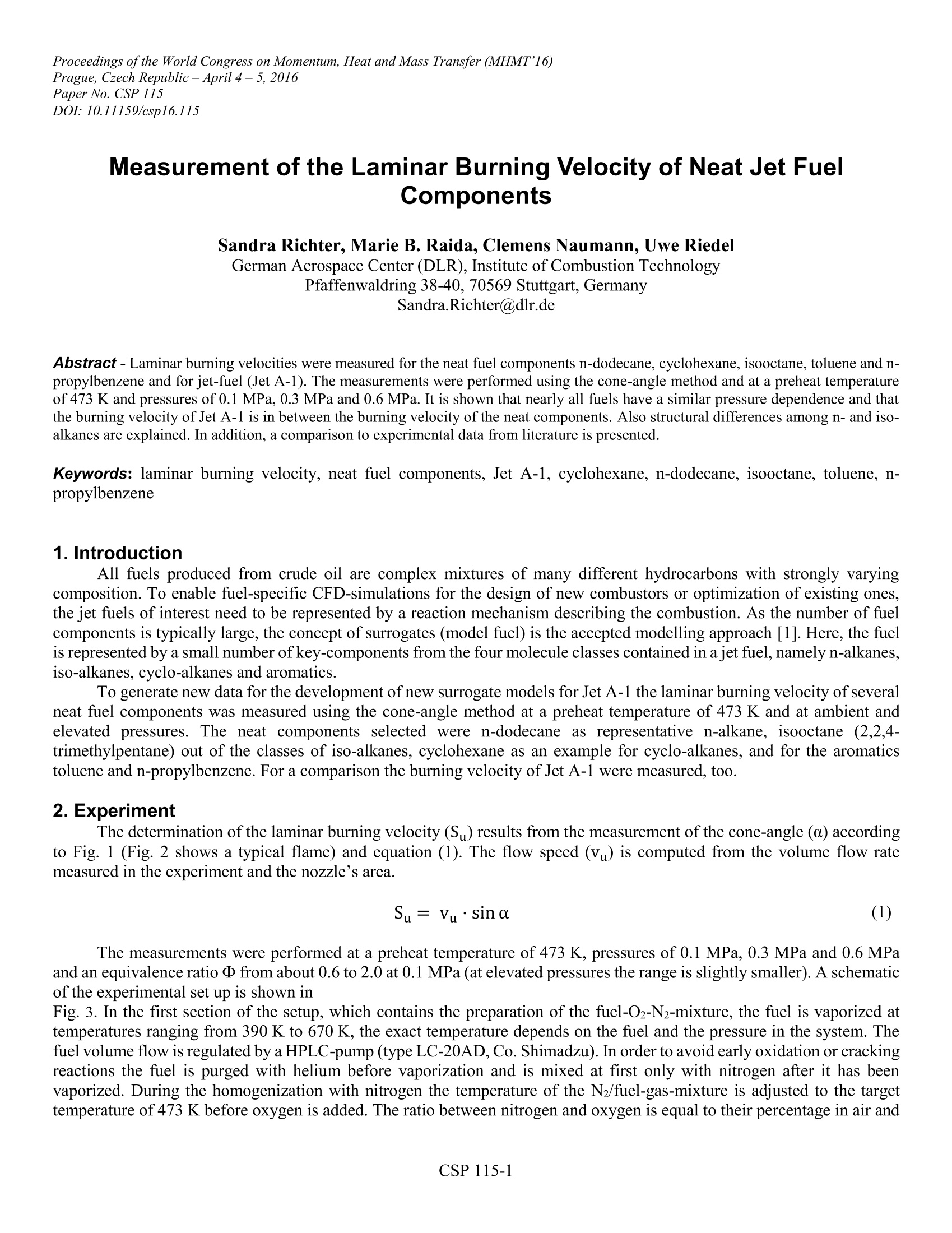

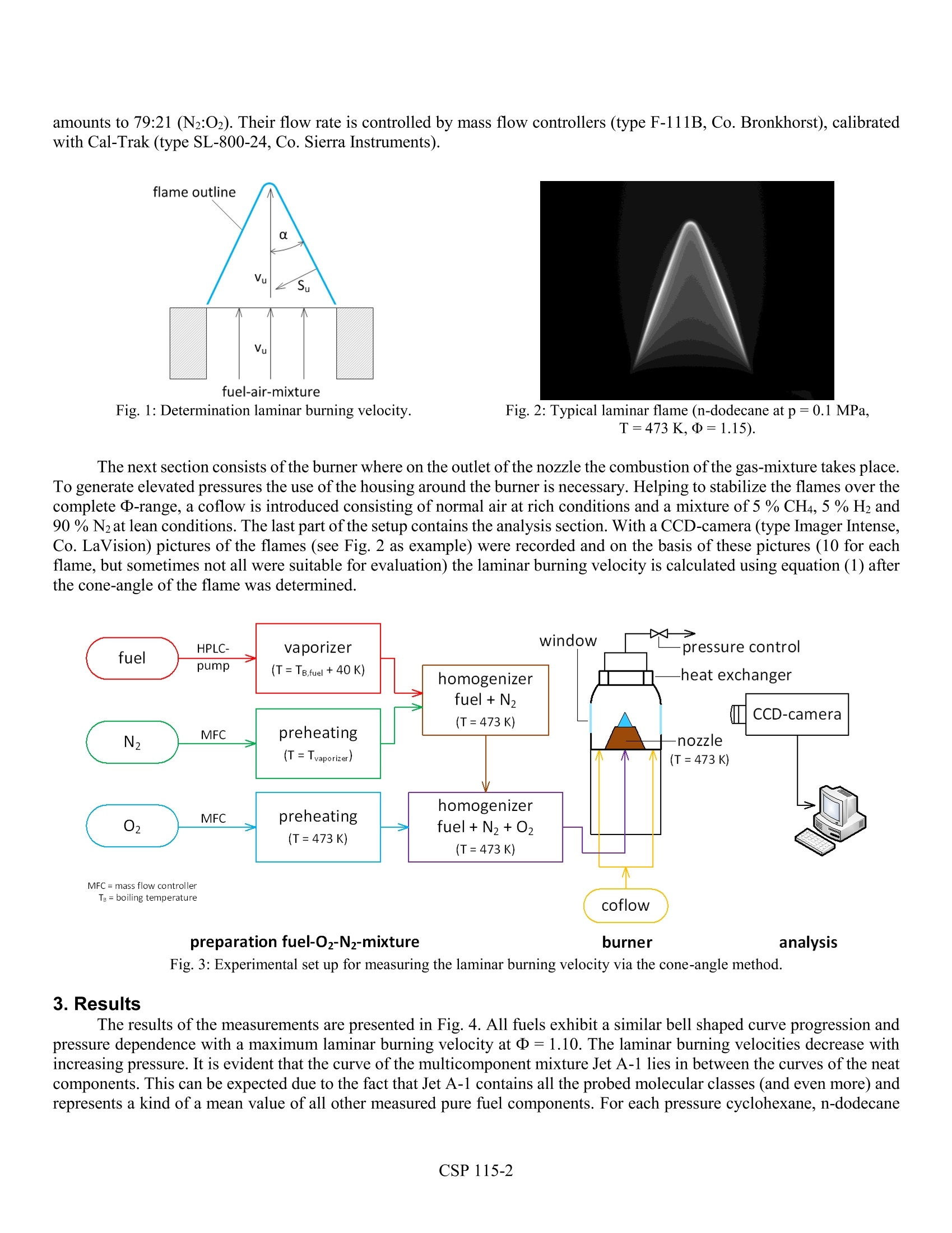

Proceedings of the World Congress on Momentum, Heat and Mass Transfer (MHMT16)Prague, Czech Republic-April 4-5,2016Paper No. CSP 115DOI:10.11159/csp16.115 Measurement of the Laminar Burning Velocity of Neat Jet FuelComponents Sandra Richter, Marie B. Raida, Clemens Naumann, Uwe Riedel German Aerospace Center (DLR), Institute of Combustion TechnologyPfaffenwaldring 38-40, 70569 Stuttgart, Germany Sandra.Richter@dlr.de Abstract-Laminar burning velocities were measured for the neat fuel components n-dodecane,cyclohexane, isooctane, toluene and n-propylbenzene and for jet-fuel (Jet A-1). The measurements were performed using the cone-angle method and at a preheat temperatureof 473 K and pressures of 0.1 MPa, 0.3 MPa and 0.6 MPa. It is shown that nearly all fuels have a similar pressure dependence and thatthe burning velocity of Jet A-1 is in between the burning velocity of the neat components. Also structural differences among n- and iso-alkanes are explained. In addition, a comparison to experimental data from literature is presented. Keywords: laminar burning velocity, neat fuel components, Jet A-1, cyclohexane, n-dodecane, isooctane, toluene, n-propylbenzene 1.Introduction All fuels produced from crude oil are complex mixtures of many different hydrocarbons with strongly varyingcomposition. To enable fuel-specific CFD-simulations for the design of new combustors or optimization of existing ones,the jet fuels of interest need to be represented by a reaction mechanism describing the combustion. As the number of fuelcomponents is typically large, the concept of surrogates (model fuel) is the accepted modelling approach [1]. Here, the fuelis represented by a small number of key-components from the four molecule classes contained in a jet fuel, namely n-alkanes,iso-alkanes, cyclo-alkanes and aromatics. To generate new data for the development of new surrogate models for Jet A-1 the laminar burning velocity of severalneat fuel components was measured using the cone-angle method at a preheat temperature of 473 K and at ambient andelevated pressures. The neat components selected were n-dodecane as representative n-alkane, isooctane (2,2,4-trimethylpentane) out of the classes of iso-alkanes, cyclohexane as an example for cyclo-alkanes, and for the aromaticstoluene and n-propylbenzene. For a comparison the burning velocity of Jet A-1 were measured, too. 2. Experiment The determination of the laminar burning velocity (Su) results from the measurement of the cone-angle (a) accordingto Fig. 1 (Fig. 2 shows a typical flame) and equation (1). The flow speed (vu) is computed from the volume flow ratemeasured in the experiment and the nozzle’s area. The measurements were performed at a preheat temperature of 473 K, pressures of 0.1 MPa, 0.3 MPa and 0.6 MPaand an equivalence ratio from about 0.6 to 2.0 at 0.1 MPa (at elevated pressures the range is slightly smaller). A schematicof the experimental set up is shown in Fig. 3. In the first section of the setup, which contains the preparation of the fuel-O2-N2-mixture, the fuel is vaporized attemperatures ranging from 390 K to 670 K, the exact temperature depends on the fuel and the pressure in the system. Thefuel volume flow is regulated by a HPLC-pump(type LC-20AD, Co. Shimadzu). In order to avoid early oxidation or crackingreactions the fuel is purged with helium before vaporization and is mixed at first only with nitrogen after it has beenvaporized. During the homogenization with nitrogen the temperature of the N2/fuel-gas-mixture is adjusted to the targettemperature of 473 K before oxygen is added. The ratio between nitrogen and oxygen is equal to their percentage in air and amounts to 79:21 (N2:O2). Their flow rate is controlled by mass flow controllers (type F-111B, Co. Bronkhorst), calibratedwith Cal-Trak (type SL-800-24, Co. Sierra Instruments). Fig. 1: Determination laminar burning velocity. Fig. 2: Typical laminar flame (n-dodecane at p=0.1 MPa,T=473 K,D=1.15). The next section consists of the burner where on the outlet of the nozzle the combustion of the gas-mixture takes place.To generate elevated pressures the use of the housing around the burner is necessary. Helping to stabilize the flames over thecomplete D-range, a coflow is introduced consisting of normal air at rich conditions and a mixture of5 % CH4, 5% H and90 % N2at lean conditions. The last part of the setup contains the analysis section. With a CCD-camera (type Imager Intense,Co. LaVision) pictures of the flames (see Fig. 2 as example) were recorded and on the basis of these pictures (10 for eachflame, but sometimes not all were suitable for evaluation) the laminar burning velocity is calculated using equation (1) afterthe cone-angle of the flame was determined. preparation fuel-O2-N2-mixture burner analysis Fig. 3: Experimental set up for measuring the laminar burning velocity via the cone-angle method. 3.Results The results of the measurements are presented in Fig. 4. All fuels exhibit a similar bell shaped curve progression andpressure dependence with a maximum laminar burning velocity at =1.10. The laminar burning velocities decrease withincreasing pressure. It is evident that the curve of the multicomponent mixture Jet A-1 lies in between the curves of the neatcomponents. This can be expected due to the fact that Jet A-1 contains all the probed molecular classes (and even more) andrepresents a kind of a mean value of all other measured pure fuel components. For each pressure cyclohexane, n-dodecane and n-propylbenzene have a higher burning velocity than Jet A-1, whereas the isooctane burning velocities are always lower.Only toluene differs from the typical pressure curve as it is shown in the lower right picture of Fig. 4. Between 0.1 MPa and0.3 MPa a stronger decrease is visible for toluene than for the other fuel components. The nearly constant difference from about 10 cm/s at the maximum between n-dodecane and isooctane reveals thedependence of the burning velocity on molecular structure. Since iso-alkanes have a tertiary carbon-atom (or yet a quaternaryC-atom as in the case of isooctane) they form considerably more stable intermediates than n-alkanes. Hence iso-alkanes havea lower reactivity and this results in a lower laminar burning velocity, as can be concluded in the measurements presented. For the evaluation of the experiment also an error analysis was performed. We consider the variation of the cone-angle, of the observed pressure, temperature, and flow rates in the error analysis. The variation of the cone-angle has themajor influence of the total error. The errors were calculated to be in a range from 2 to 11 % depending on the pressure andthe fuel-air-equivalence ratio. In general they rise with increasing pressure and deviation from stoichiometric conditionswhere the errors have the lowest values. In detail this means for the stoichiometric region that at 0.1 MPa the relative erroris about 2 to 4%, at 0.3 MPa the error can grow up to 6 % and at 0.6 MPa up to 11 %. p (MPa) Fig. 4: Experimental results for the laminar burning velocity at different pressures (lines to guide the eye): top left- 0.1 MPa, top right-0.3 MPa, bottom left- 0.6 MPa, bottom right -pressure dependence at =1.10. 4. Comparison to Literature Values Finally a short comparison should be given how the data obtained are comparable to data available in the literature.This comparison is performed for the neat jet fuel components at a pressure of 0.1 MPa except for the componentcyclohexane, because no other experimental data at a preheat temperature of 473 K are available. A graphical comparison isshown in Fig. 5. The upper left picture shows our measurements for n-dodecane compared to data from Kumar and Sung(2007) [2]. They have performed their measurements in a counterflow twin-flame configuration to measure the laminar flamespeed vs. the stretch rate (a) and used a linear extrapolation for the evaluation of Sy(a=0). In the lean region there is a goodagreement between the experimental values, in the slightly rich region a difference up to 8 cm/s appears. In this group alsomeasurements with isooctane [3] and toluene [4] were performed. Whereas a similar deviation occurs for isooctane the valuesfor toluene show an opposite characteristics though there is a better match in the lean and rich regime. In the stoichiometricregion the difference is smaller than 4 cm/s. Hui et al. [5] have performed measurements of several aromatic substances using also the counterflow twin-flametechnique but a non-linear extrapolation approach for evaluating s(a=0). Their data for toluene are lower than our datapresented here and also lower than the data from Kumar and Sung (2010) [4], especially in the stoichiometric and rich regime.In contrast to toluene the data for n-propylbenzene of our measurements are in good agreement with the data from Hui et al.[5] and show a maximum deviation of about 3 cm/s. Toluene this work (T=473 K) o0o D Hui et al (T=470K)Kumar,Sung 2010 (T=470 K) e 0a o p=0.1MPa 0.5 1.0 1.5 2.0 Fig. 5: Comparison of the measured laminar burning velocity with experimental results from literature: top left -n-dodecane [2], topright-isooctane [3, 6], bottom left-n-propylbenzene [5],bottom right-toluene [4, 5]. With respect to isooctane, additional data from Galmiche et al.[6] are available. They performed their measurementswith a spherical flame and also used non-linear extrapolation.Compared to both, our own data and data from Kumar et al.[3], the measurements performed by Galmiche et al.[6] result in lower values. This trend is recognized in [6] and attributedto the composition of the air used in this specific experiment (20.5 % O2 and 79.5 %N2 instead of 21 % and 79 %). 5. Summary and Conclusion Measurements ofthe laminar burning velocity for five neat jet fuel components and Jet A-1 were performed at preheattemperature T = 473 K and different pressures (0.1 MPa, 0.3 MPa and 0.6 MPa) for a wide range of the fuel-air equivalenceratio. The analysed neat fuel components were n-dodecane, isooctane, cyclohexane, toluene, and n-propylbenzene. Theexperimental results, which were collected using the cone-angle method, show that the burning velocities of the purecomponents differ to some extend considerably from those of Jet A-1. This behaviour was expected due Jet A-1 is a mixtureof various hydrocarbons. Furthermore, it is shown that all investigated fuels have a similar pressure dependence, excepttoluene. A comparison with literature data for n-dodecane, isooctane, toluene, and n-propylbenzene shows consistent resultssince the relative deviations are predominantly smaller than 10 %. References ( [ 1 ] T . E dwards and L . Q . Maurice,“S u rrogate Mixtures to Represent Complex Aviation and Rocket Fue l s,” Journal ofPropulsion and Power, vol. 1 7, no. 2, pp. 461-466,2001. ) ( [2]K K . Kumar and C.-J. Sung,“L a minar flame speeds and e xtinction limi t s of p re h eated n-d e cane/O2/N2 and n-dodecane/O2/N2 mixtures,”Combustion and Flame, vol. 15 1 , no. 1-2, pp.209-224,2007. ) ( [3]F K . K umar, J . E. Freeh, C.-J. Sung and Y. Huang“La m inar Flam e Speeds of Preheated iso-Octane/O2/N2 and n-Heptane/O2/N2 Mixtures,”Journal of Propulsion and Power, vol. 2 3 ,no. 2 , pp. 4 28-436, 2007. ) ( [4]K K. K umar a n d C . J. Sung,“F l ame Pro p agation and Ext i nction Characteristics of Neat Surrogate Fuel Components,"Energy Fuels, vol. 24, no. 7, pp. 3840-3849,2010. ) ( [5] X. H ui, A. K . Das, K. Kumar, C.-J. Sung, S. Dooley and F. L.Dryer,“Laminar flame speeds and extinction stretch ratesof selected aromatic hydrocarbons,"Fuel, vol. 97, pp.695-702, 2012. ) ( [6]B. Galmiche, F. H alter and F . Foucher,“Effects of high pressure, high temperature and dilution on laminar burningvelocities and M arkstein lengths of iso-octane/air mixtures,” Co m bustion and Flame, vol. 1 5 9, n o . 11, pp . 3286-3 2 99,2012. ) CSP Laminar burning velocities were measured for the neat fuel components n-dodecane, cyclohexane, isooctane, toluene and n-propylbenzene and for jet-fuel (Jet A-1). The measurements were performed using the cone-angle method and at a preheat temperature of 473 K and pressures of 0.1 MPa, 0.3 MPa and 0.6 MPa. It is shown that nearly all fuels have a similar pressure dependence and that the burning velocity of Jet A-1 is in between the burning velocity of the neat components. Also structural differences among n- and iso-alkanes are explained. In addition, a comparison to experimental data from literature is presented.

关闭-

1/5

-

2/5

还剩3页未读,是否继续阅读?

继续免费阅读全文产品配置单

北京欧兰科技发展有限公司为您提供《火焰,燃料喷射燃烧中速度检测方案(CCD相机)》,该方案主要用于天然气/燃气中速度检测,参考标准《暂无》,《火焰,燃料喷射燃烧中速度检测方案(CCD相机)》用到的仪器有德国LaVision PIV/PLIF粒子成像测速场仪、PLIF平面激光诱导荧光火焰燃烧检测系统。

我要纠错

推荐专场

相关方案

咨询

咨询