方案详情文

智能文字提取功能测试中

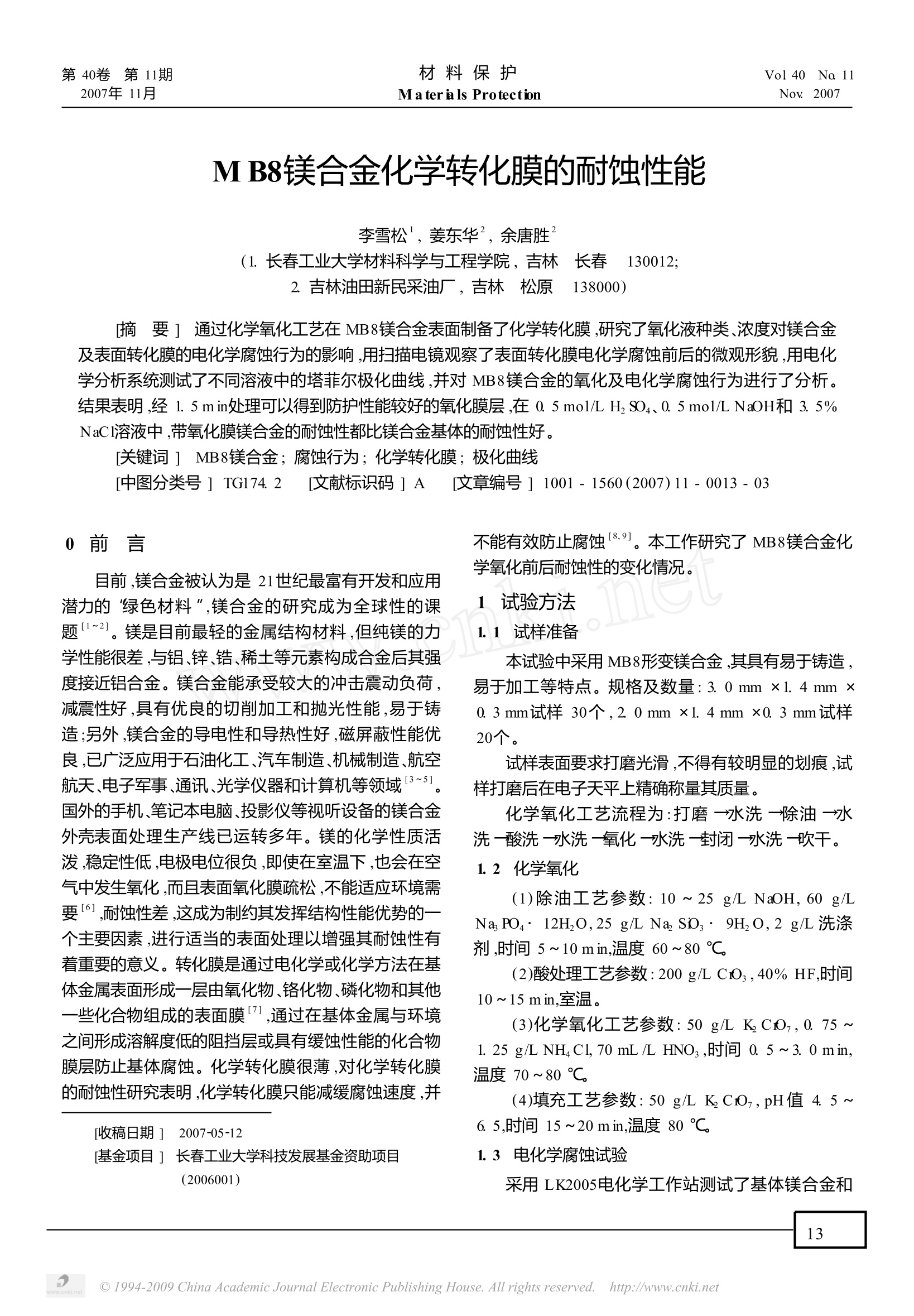

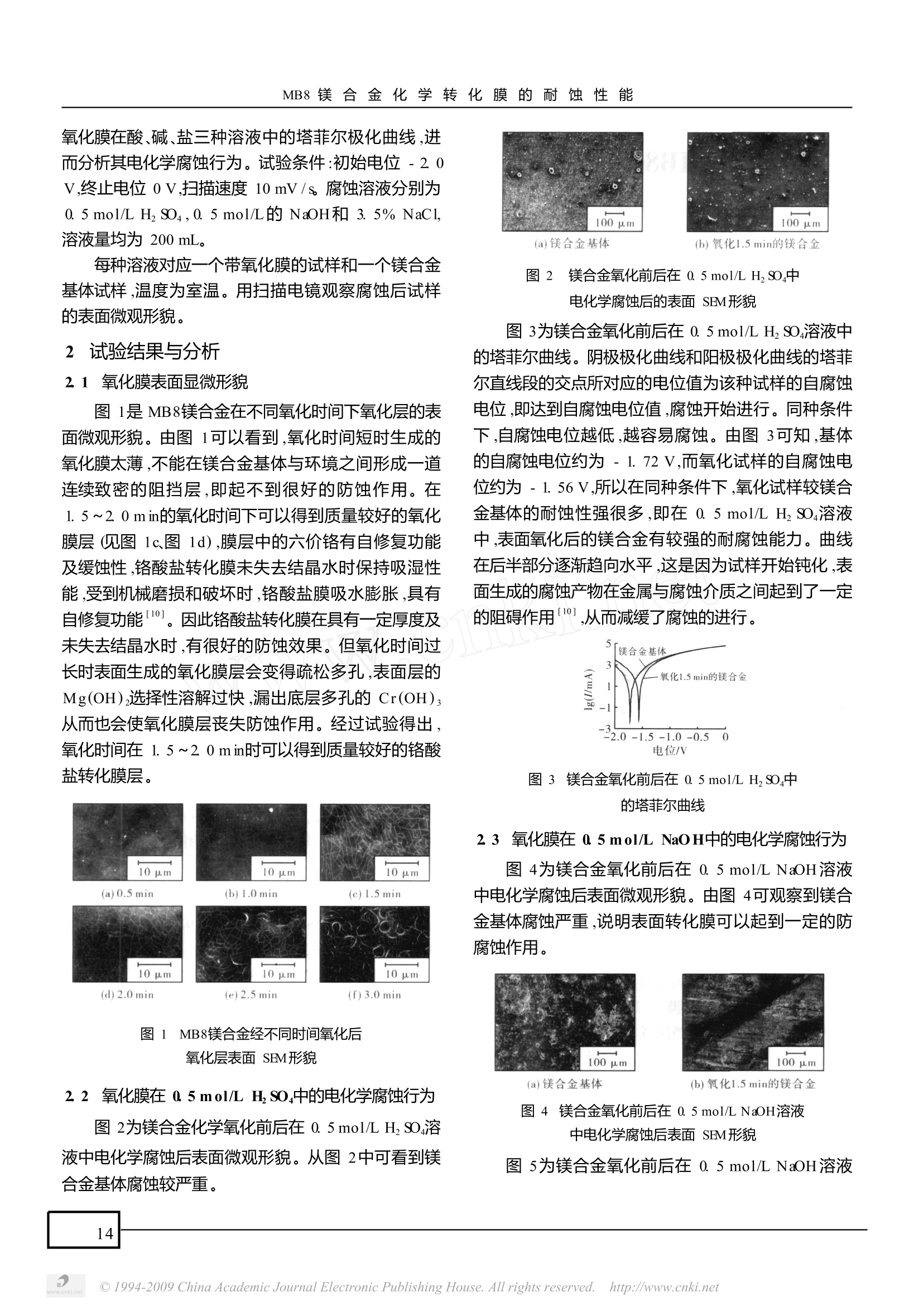

材料 保 护Materals ProtectionVol 40 No 11Nov 2007第40卷 第11期2007年11月 MB8镁 合 金 学 转 化 膜 的 耐 蚀 性 能 MB8镁合金化学转化膜的耐蚀性能 李雪松,姜东华,余唐胜 (1.长春工业大学材料科学与工程学院,吉林 长春 130012:2吉林油田新民采油厂,吉林 松原 138000) 摘 要1 通过化学氧化工艺在MB8镁合金表面制备了化学转化膜,研究了氧化液种类、浓度对镁合金及表面转化膜的电化学腐蚀行为的影响,用扫描电镜观察了表面转化膜电化学腐蚀前后的微观形貌,用电化学分析系统测试了不同溶液中的塔菲尔极化曲线,并对MB8镁合金的氧化及电化学腐蚀行为进行了分析。结果表明,经1.5min处理可以得到防护性能较好的氧化膜层,在 0.5mol/L H, SO4、0. 5mol/L NaOH和3.5%NaCl溶液中,带氧化膜镁合金的耐蚀性都比镁合金基体的耐蚀性好。 [关键词1 MB8镁合金;腐蚀行为;化学转化膜;极化曲线 [中图分类号]TG174.2 [文献标识码]A [文章编号]1001-1560(2007)11-0013-03 0 前 言 目前,镁合金被认为是21世纪最富有开发和应用潜力的“绿色材料”,镁合金的研究成为全球性的课题1~2]。镁是目前最轻的金属结构材料,但纯镁的力学性能很差,与铝、锌、锆、稀土等元素构成合金后其强度接近铝合金。镁合金能承受较大的冲击震动负荷,减震性好,具有优良的切削加工和抛光性能,易于铸造;另外,镁合金的导电性和导热性好,磁屏蔽性能优良,已广泛应用于石油化工、汽车制造、机械制造、航空航天、电子军事、通讯、光学仪器和计算机等领域13~51国外的手机、笔记本电脑、投影仪等视听设备的镁合金外壳表面处理生产线已运转多年。镁的化学性质活泼,稳定性低,电极电位很负,即使在室温下,也会在空气中发生氧化,而且表面氧化膜疏松,不能适应环境需要6],耐蚀性差,这成为制约其发挥结构性能优势的一个主要因素,进行适当的表面处理以增强其耐蚀性有着重要的意义。转化膜是通过电化学或化学方法在基体金属表面形成一层由氧化物铬化物、磷化物和其他一些化合物组成的表面膜,通过在基体金属与环境之间形成溶解度低的阻挡层或具有缓蚀性能的化合物膜层防止基体腐蚀。化学转化膜很薄,对化学转化膜的耐蚀性研究表明,化学转化膜只能减缓腐蚀速度,并 ( [收稿日期] 2007-05-12 ) ( [基金项目] 长春工业大学科技发展基金资助项目 (2006001) ) 不能有效防止腐蚀18,9]。本工作研究了MB8镁合金化学氧化前后耐蚀性的变化情况。 1 试验方法 1.1 试样准备 本试验中采用MB8形变镁合金,其具有易于铸造,易于加工等特点。规格及数量:3.0mm×1.4mm ×0.3mm试样30个,2.0mm ×1. 4 mm X0. 3 mm试样20个。 试样表面要求打磨光滑,不得有较明显的划痕,试样打磨后在电子天平上精确称量其质量。 化学氧化工艺流程为:打磨→水洗→除油→水洗-酸洗一水洗一氧化→划洗-封闭→水洗一吹干。 1.2 化学氧化 (1)除油工艺参数:10~25 g/L NaOH, 60 g/LNag PO4 ·12H,O,25 g/L Na SOs ·9H,O,2 g/L 洗涤剂,时间5~10min,温度 60~80℃。 (2)酸处理工艺参数:200 g/L Ci0,40% HF,时间10~15 min,室温。 (3)化学氧化工艺参数:50 g/L K C10,,0.75~1.25 g/L NH C1, 70 mL /L HNO3,时间0.5~3.0min,温度70~80℃。 (4)填充工艺参数:50 g/L K, CiO,,pH值4.5~6.5,时间15~20min,温度 80℃。 1.3 电化学腐蚀试验 ( 采用LK2005电化学工作站测试了基体镁合金和 ) 氧化膜在酸、碱、盐三种溶液中的塔菲尔极化曲线,进而分析其电化学腐蚀行为。试验条件:初始电位-2.0Ⅴ,终止电位0V,扫描速度 10mV/s。腐蚀溶液分别为0.5 mol/L H, SO4,0. 5mol/L的 NaOH和3.5% NaCl,溶液量均为200mL。 每种溶液对应一个带氧化膜的试样和一个镁合金基体试样,温度为室温。用扫描电镜观察腐蚀后试样的表面微观形究。 2 试验结果与分析 21 氧化膜表面显微形貌 图1是MB8镁合金在不同氧化时间下氧化层的表面微观形貌。由图1可以看到,氧化时间短时生成的氧化膜太薄,不能在镁合金基体与环境之间形成一道连续致密的阻挡层,即起不到很好的防蚀作用。在1. 5~2.0min的氧化时间下可以得到量量较好的氧化膜层(见图1c、图1d),膜层中的六价铬有自修复功能及缓蚀性,铬酸盐转化膜未失去结晶水时保持吸湿性能,受到机械磨损和破坏时,铬酸盐膜吸水膨胀,具有自修复功能,。因此铬酸盐转化膜在具有一定厚度及未失去结晶水时,有很好的防蚀效果。但氧化时间过长时表面生成的氧化膜层会变得疏松多孔,表面层的Mg(OH),选择性溶解过快,漏出底层多孔的 Cr(OH)从而也会使氧化膜层丧失防蚀作用。经过试验得出,氧化时间在1.5~2.0min时可以得到质量较好的铬酸盐转化膜层。 图1 MB8镁合金经不同时间氧化后氧化层表面 SEM形貌 2.2 氧化膜在 0.5mol/L H SO中的电化学腐蚀行为 图2为镁合金化学氧化前后在 0.5mol/L H SO溶液中电化学腐蚀后表面微观形。从图2中可看到镁合金基体腐蚀较严重。 图2 镁合金氧化前后在 0.5 mol/L H, SO4中电化学腐蚀后的表面 SEM形貌 图3为镁合金氧化前后在0.5 mol/L HSO溶液中的塔菲尔曲线。阴极极化曲线和阳极极化曲线的塔菲尔直线段的交点所对应的电位值为该种试样的自腐蚀电位,即达到自腐蚀电位值,腐蚀开始进行。同种条件下,自腐蚀电位越低,越容易腐蚀。由图3可知,基体的自腐蚀电位约为-1.72V,而氧化试样的自腐蚀电位约为-1.56Ⅴ,所以在同种条件下,氧化试样较镁合金基体的耐蚀性强很多,即在 0.5 mol/L HSO溶液中,表面氧化后的镁合金有较强的耐腐蚀能力。曲线在后半部分逐渐趋向水平,这是因为试样开始钝化,表面生成的腐蚀产物在金属与腐蚀介质之间起到了一定的阻碍作用[10],从而减缓了腐蚀的进行。 图3镁合金氧化前后在 0.5 mol/L H, SO中的塔菲尔曲线 23 氧化膜在 0.5mol/L NaOH中的电化学腐蚀行为 图4为镁合金氧化前后在 0.5 mol/L NaOH溶液中电化学腐蚀后表面微观形貌。由图4可观察到镁合金基体腐蚀严重,说明表面转化膜可以起到一定的防腐蚀作用。 图44镁合金氧化前后在 0.5 mol/L NaOH溶液 中电化学腐蚀后表面 SEM形貌 图5为镁合金氧化前后在0.5 mol/L NaOH溶液 中腐蚀电位与腐蚀电流的关系曲线。从图5可看出,在0.5 mol/L NaOH溶液中基体镁合金的自腐蚀电位为-1.30V,而有氧化膜镁合金的自腐蚀电位约为-0.60V,说明表面氧化后镁合金的自腐蚀电位正移,即耐蚀性能提高,起到了很好的防护作用。 图55钉镁合金氧化前后在 0.5mol/LNaOH中的塔菲尔曲线 2.4 氧化膜在3.5%NaCl溶液中的电化学腐蚀行为 图6为镁合金化学氧化前后在3.5%NaCl溶液中电化学腐蚀后的表面微观形貌。从图6可以看到,基体镁合金较有氧化膜层的镁合金腐蚀严重得多,这是因为 C1对镁合金基体有很强的腐蚀作用,而表面氧化后,氧化膜层可有效阻碍 C1与镁合金基体的接触从而起到很好的防护作用。 图6镁合金氧化前后在3.5% NaCl中电化学腐蚀后表面SEM形貌 图7为镁合金基体和氧化1.5min的镁合金在3.5%NaCl溶液中腐蚀电位与腐蚀电流的关系曲线。 图7 镁合金氧化前后在3.5%NaCl中的塔菲尔曲线 由图7可知,基体的自腐蚀电位约为-1.40V,而氧化试样的自腐蚀电位约为-1.20V,故氧化试样较镁合金基体的耐蚀性强。试验中可观察到镁合金基体 在3.5%NaC1中反应非常剧烈,而且从开始即被剧烈腐蚀,没有钝化现象产生,可见镁合金基体在盐环境中的腐蚀很严重,而表面氧化后反应则比较缓慢,可见表面氧化膜层提高了镁合金在盐溶液中的自腐蚀电位,从而也使其在盐溶液中具有较好的防护性能。 3 结 论 (1)采用在镁合金表面形成铬酸盐转化膜的技术可大大提高MB8形变镁合金的耐蚀性能,氧化时间在1.5~2.0min时得到的转化膜层防护性能最好。 (2)带化学转化膜层的MB8镁合金在酸、碱、盐溶液中耐电化学腐蚀性均有不同程度的提高。由塔菲尔曲线测得,在 0.5 mol/L HSO4溶液中自腐蚀电位由-1.72V正移到-1.56V,在 0. 5 mol/L NaOH溶液中自腐蚀电位由-1.30V正移到-0.60V,在3.5%NaCl溶液中自腐蚀电位由-1.40V正移到-1.20V。 ( 参 考 文 献 ) ( [1] 终丽红.汽车制造业使用镁的现状与潜力[J].有色金 属,2002(8):12~15. ) ( [2] 朱祖芳.有色金属的耐腐蚀性及其应用[M].北京:化学 工业出版社,1995:98~120. ) ( [3] 刘 正,张 奎,曾小勤.镁基轻质合金理论基础及其应 用[M].北京:机械工业出版社,2002:1~13. ) ( [4] Song GL , Atrens A, Dargusch M. Influence ofM iciostruc- ture on the Corrsion of Die-CastMB81[J]. Coriosion Sci-ence, 1999, 41(2):249~273. ) ( [5] 钟 皓,刘培英,周铁淘.镁及镁合金在航空航天中的应 用及前景[J].航空工程与维修,2002(4):41~42. ) ( [6] Nakatsugawa I, M a rtin R, Knystautas E J. m p roving Corm-sion Resistance of MB8 Magnesium A lloy by Nitrogen b nmplantation[J]. Coriosion, 1996,52(12):921~926. ) ( [7] 曾爱平,薛 颖,钱宇峰,等.镁合金表面改性新技术 [J].材料导报,2000,14(3):19~20. ) ( [8] M akar G L, Kruger J. Corrsion ofMagnesium [J] . ntema-tionalMaterials Reviews, 1993,38(3) : 138~153. ) ( [9] B aril G , Pebere N. T he c o rr sion ofpure magnesium in aerated and s odium su lphate solution [ J] . C orrsion S c ience, 2001,43:471 ~ 484. ) ( [10] 周学华,陈秋华,卫中领,等.镁合金的化学转化膜[J]. 腐蚀与防护,2004,25(11):46~51. ) JournalofMaterials Protection (Monthly,Started in 1960) ISSN 1001-1560 Nov. 2007 Vol.40 No.11 Serial No.346 Contents & Abstracts Corrosion Behavior of Deformed Copper Alloy in SO, andNaCl Fog ZHENG Mao-sheng,ZHANG Ya-ni, ZI Jin-lei, SUN Sheng-ying(School of Materials Science and Engineering, Xi’an Jiao-tong University, Xi’an 710049,China). Cailiao Baohu 2007,40(11),01~03(Ch). The service life of material has close rela-tion with its corrosion resistance. Thus, the investigation on cor-rosion behavior is important for the better use of the material. Thecorrosion behavior of copper alloy deformed with different tech-niques in SO, and NaCl fog corrosion environment was investiga-ted using SEM and weight- loss measurements. The resultsshowed that the weight-loss rate of alloy increased with exposuretime in NaCl fog environment, and the cold worked sample speci-men had higher corrosive rate than non-cold worked specimen.When exposure time was up to 12 days, the margin for weight-loss was 1.68 g/m’ which was between two kinds of specimens.In contrast, the weight-loss rate decreased with the exposure timein SO, corrosion environment, and the celd worked specimensample had lower corrosion rate than non-cold worked one. Inaddition, when exposure time was up to 4 days, the margin forweight-ioss was 3. 826 g/’m’which was between two kinds ofsamples. Key words: deformed copper alloy; corrosion resistance; deformprocess;coatings Electrodeposition and Wear Resistance Characterization ofNi-W-Co-CB, Composite Coatings XU Chang-qing, TIAN Jing, LI Gui-jiang (College of MaterialsScience, Hebei University of Technology, Tianjin 300130, Chi-na). Cailiao Baohu 2007,40(11),04~05(Ch). The abrasivewear behaviors of electrodeposited Ni-W-Co-CBcomposite coat-ings were examined. The results showed that the wear resistance ofthe Ni-W-Co-CB composite coating was good,the content of CBparticles and the loads had great effect on the wear resistance ofthe coatings. Some CB. particles were removed away during thefriction process. In the condition of oil lubrication, the antiwear a-bility of the Ni-W-Co-B.C coating was better than that ofNi-W-Co. The best sliding wear resistance was obtained withNi-W-Co-CB. composite coatings containing 20% CB particles.Key words: Ni-W-Co-CB. composite coatings; electrocompos- ite;wear resistance;oil lubrication; 45 steel Effects of Rare Earth Elements on the Corrosion Property ofAZ31 Magnesium Alloy YU Kun,LI Wen-xian,WANG Ri-chu, CHAO Guo-hui( Schoolof Materials Science and Engineering, Central South University,Changsha 410083, China). Cailiao Baohu 2007,40(11),06~09(Ch). The rare earth cerium and neodymium were added inAZ31 magnesium alloy to improve its corrosion resistance. Thecorrosion behaviors of such alloy were measured through salt spraytest and potentiodynamic polarization test. The surface of speci-mens was observed by using Nikon990 digital camera, Polyvar-MET optical microscope with VSM2000 quantitative analysis sys-tem and JEOL scanning electron microscopy. The potentiodynam-ic polarization curve was measured by using Solartron 1287 poten-tiostat system with a scanning rate of 5 mV/s. The data were col-lected and analyzed using Corrware and Corrview software. Theresults showed that the corrosion rate of alloys with Ce or Nd ad- dition decreased about a half in the salt spray test. And the corro-sion electrical current also decreased to 0. 12 p.A/cm’ and 0.10pA/cm’, being less than half of the compared AZ31 alloy (0.30pA/cm). The rare earth Ce and Nd could improve the corrosionresistance of solid solution (Mg) and make the second phase B(MgAl 2) compound dispread more uniformly, so the corrosionresistance of AZ31 alloy was increased due to the addition of therare earth element. Key words: AZ31 magnesium alloy; rare earth;corrosion resist-ance;salt spray corrosion; potentiodynamic polarization Effects of Al,O, Content on Microstructure and Properties ofNi-Al,O, Composite Coatings Electrodeposited with ReversePulses SHI Shu-yun, CHANG Li-min (Environmental Engineering Col-lage, Jilip Normal Univer ity, Siping 136000, China). CailiaoBaohu 2007,40(11),10~12(Ch). In order to study the effectsofAl,0g on microeucture and properties of Ni-Al,Os compositeeesings electrodeposited with reverse pulses,Ni-Al,0, compositecoatings, Ni-Al, Og composite coatings were prepared by directcurrent (DC) and reverse pulse electrodeposite (PRC) tech-nique. The microstructure and properties of Ni-Al,Os compositecoatings were studied by XRD, SEM, micro-hardness test, andresidual stress meter. The results showed that both DC and PRCcoatings appear single phase of Ni matrix with face center cubic(fce) structure. With the increase of the Al, O particles content,there was crystal preferential orientation along (110) and (220)crystal face, the distribution of Al,O, in the coatings was uniformand the coatings were smooth surface with the fine and compactcrystal of Ni matrix, and the hardness and wear resistance of thecomposite coatings were increased. When the Al, 0s particlescontent was 5.81% in coatings, the microstructure and propertiesof coatings were the best. The hardness (491 HV) and wear re-sistance of Ni-Al, Os composite coatings deposited by PRC werebetter than that by DC,while micro-residual stress of coatings waslower. Key words: bidirectional pulse; electrodeposited; Ni-Al,0, com-posite coating; microstructure; properties Corrosion Behavior of Conversion Film of MB8 MagnesiumAlloy LI Xue-song,JIANG Dong-hua,YU Tang-sheng (1. Materials Science and Engineering College, Changchun University of Tech-nology, Changchun 130012,China; 2. Xinmin Petroleum Produc-tion Factory , Jilin Petroleum Group , Songyuan 138000,China).Cailiao Baohu 2007,40 (11), 13 ~15( Ch). The influences ofsolution type and solution concentration on the corrosion behaviorof the conversion film on MB8 magnesium alloy surface were stud-ied. The morphology of the surface conversion film was observedby scanning electron microscope. The Tafle curve was measuredby electrochemical analysis system in different solutions. The oxi-dation of MB8 magnesium alloy and electrochemical corrosion be-havior were analyzed from the view points of corrosion pattern andsurface film state. The results showed that the oxidation film withbetter corrosion resistance behavior may be obtained after oxidi-zing for 1.5 min. And in 0. 5 mol/L H,SO solution, the self-corrosion potential changed from -1. 72 V to -1.56 V; in3.5% NaCl solution, the self- corrosion potential changed from -1. 4 V to -1. 2 V; and also the self- corrosion potentialchanged from -1.3 V to -0.6 V in the 0.5 mol/L NaOH solu-tion. Thus, the magnesium alloys with oxidation film had bettercorrosion resistance behavior compared with magnesium alloy ma-trix Key words: MB8 magnesium alloy; corrosion behavior; conver-sion film; polarization curve The Drag Reduction Performance of Low Surface EnergyCoating LAN Jia-yong, LIU Xiu-sheng, ZHANG Ying-ping, ZENG Yue-lian, XIE He-ping, SHUN Jia-feng(Wuhan Researrch Instituteof Materials Protection, Wuhan 430030, China). Cailiao Baohu2007,40(11),16~18(Ch). A longer fluorocarbon chain copol-ymer FC-1 with hydroxyl group was synthesized,and it was addedinto FEVE fluorocarbon coating as an additive. The results showedthat the film had good hydrophobic performance. The contact anglewas approaches to 128 degree. At the same time, a test devicewas done by pressure difference drag reduction testing. The dragreduction properties of epoxy resin, epoxy asphalt, and low sur-face energy interior pipe coating were studied by the device. Alsothe drag-reduction mechanism of different coatings was analyzed.Key words: low surface energy; fluorocarbon chain copolymerdrag reduction;contact angle ;difference pressure Hot Corrosion Resistance of HVFS Sprayed Fe-Al/SiCComposite Coatings LIU Shuang',XU Run-sheng’,LIU Xiao-ming’(1. Shandong E- lectric Power Research Institute, Jinan 250002, China; 2. InterMongolia Electric Research Institute, Hohho: 01001, China).Cailiao Baohu 2007,40(11),19~21(Ch). Fe. Al/SiC compos-ite coating was maie by HVFS. hhe hot coresive dynanics ruleof Fe-Al/SiC comosite coating and 20 steel was researched at650 ℃. The compositions and the products of coating after hotcorrosion were analyzed by SEM, EDS and XRD. It indicatedthat the matrix of Fe-Al/SiC composite coating was Fe-Al phase(Fe,Al,FeAl) and SiC hard phase distributed all over the coat-ing, and the coating displayed the typical layers structure charac-teristics. Fe-Al/SiC composite coating possesses good hot corro-sion resistance. The weight gain of Fe-Al/SiC composite coatingafter 150 h corrosion test was about 30% of 20 steel under thesame test condition. The weight increasing was due to the deposi-tion of iron oxide. Key words: high velocity flame spraying (HVFS); Fe-Al/SiCcomposite coating;hot corrosion;20 steel Effects of a Small Quantity of Tin, Zinc on the CorrosionResistance of Pure Copper in Weak-Acid Solution ZHANG Rong-jun,ZHANG Tian-ming(School of Machine Engi-neering, Chang’an University, Xi’an 710064, China). CailiaoBaohu 2007,40(11),22~23(Ch). Three cast copper alloysCu-5Sn, Cu-5Zn and Cu-5Sn-5Zn were prepared by adding tinand zinc in pure copper. Corrosion resisting properties of Cu,Cu-5Sn, Cn-5Zn and Cu-5Sn-5Zn were investigated by anodicpolarization test in weak- acid solution (pH=6) and constantcurrent deoxidization in 0. 1 mol/L KCl solution. The resultsshowed that the passive current density of Cu - 5Sn andCu-5Sn-5Zn was about 30% and 50% of pure copper, respec-tively. Copper alloys with the element tin improved the corrosiveresistance of pure copper in weak-acid solution. The passive cur-n.5'rent density of Cn-5Zn was same as that of pure copper. The ad-ditive zinc increased copper alloys’ thickness of passivating filmand was indistinctive on improving corrosion resistance of purecopper in weak-acid solution. Key words:copper; corrosion resistance; tin; zinc;corrosion be-havior Preparation of Foamed Fe-Cr-Ni Alloy by ElectrodepositionLI Hua-fei,ZHANG Xi-sheng (Institute of Equipment and Con- trol of Chemical Process, Huazhong University of Science and Technology, Wuhan 430074, China). Cailiao Baohu 2007, 40(11),24~26(Ch). Fe-Cr-Ni foamed-alloy was prepared withpolyurethane sponge as substrate by a series of processes of elec-troless Ni plating, Fe-Cr alloy electrodeposition, and sintering.The effects of process conditions especially the current density,the [Cr*]/[Fe*] and pH value in the bath on the film qualityand the composition of Cr in the film were investigated. The opti-mized processes of Fe-Cr alloy electrodeposition were obtained.The prepared foamed-alloy was analyzed by X-ray fluorescence(XRF), which was composed of 18%~ 20% Cr,8%~10% Niand 70%~74% Fe, and it approached to that of 18-8 typestainless steel. Key words:Fe-Cr-Ni alloy;foamed metal;electrodeposition Process of Blackening Passivation for Zinc-Iron Alloy andTin Surface at Room Temperature ZENG Xiao-jun, XU Hua, ZHANG Guo-qing(The Departmentof Chemistry & Material Engineering, Changshu Institute of Tech-nology, Changshu 215500, China). Cailiao Baohu 2007, 40(11),27~29(Ch). The optimal formulation and technologicalprocess for chemical black coloring of zinc-iron alloy and tin sur-faces present together were investigated. The influences of thecomponents in the passivating solution on film-forming rate, cor-rosion resistance and abrasive resistance were srudied. The opti-mal formelation and iechnological precess for chemnical black colo-ring of zinc-iron lloy and tin surfaces were 3.0 ~5.0 g/LNa0H,9.0~10.0 gT HCOOH,30 0~35.0 g/L CrO,,0. 1 ~0.3 g1HCHC,0.2-0.3/LHPO,pH value of 1.5 ~2.0,temperature ef 15-25C,passivation time of 8~ 12 min. Thepassive film obtained with this formulation had bright black sur-face, uniform color, high corrosion resistance and abrasive resist-ance and good adhesion. The passivating solution had advantagesof non-silver salt blackening reagent, light pollution, stable prop-erties and long life-span. Key words: zinc-iron alloy; tin; blackening passivation; roomtemperature Techniques of Carbonly Iron Powder Coated with Co-B Al-loy Using Electroless Plating GONG Jian - hui, QIU Tai, SHEN Chun- ying, LI Xiao- yunYANG Jian (Department of Materials Science and Technology,Nanjing University of Technology, Nanjing 210009,China). Cail-iao Baohu 2007,40(11),30~33(Ch). Carbonyl iron powders(CIP) coated with Co-B alloy have obtained by improved electro-less plating, the reaction rate can be controlled, by usingCoSO·7H,0 as complex ions, NaBH, as reducing agent, andNa,CH,0。 ·2H,0 as chelating agent. The relations among goldcomplex ions, reducing agent, chelating agent, pHvalue, tem-perature, and plating rate were analyzed by orthonogal test. Theempirical optimal conditions were obtained. Additionally, thesurface morphology of the synthesized particles before and afterplating was examined using scanning electron microscope.Key words: electroless plating; Co- B alloy; carbonyl iron pow- der; orthonogal test ZHONG Ping, HAN Xiao-peng’, XIAO Xing',ZHANG Fu-an(1. Department of Chemistry and Chemical Engineering,Xiangtan 411104, China; 2. Wuhan Institute of Materials Pro-tection, Wuhan 430030, China; 3. Shahu Wastewater Treat-ment Factory of Wuhan, Wuhan 430077,China). Cailiao Bao-hu 2007,40(11),34~36(Ch). A lead-free cathodic elec-trophoresis paint curable at low temperatures was prepared. Itscoating formulations were investigated, and the properties ofthe coatings were tested. The experimental results showed thatthe combination of the prepared curing resin and the selectedcompound catalyst could decrease the temperature required to China Academic Journal Electronic Publishing House. All rights reserved. http://www.cnki.net

关闭-

1/5

-

2/5

还剩3页未读,是否继续阅读?

继续免费阅读全文产品配置单

天津市兰力科化学电子高技术有限公司为您提供《镁合金化学转化膜中耐蚀性能检测方案(电化学工作站)》,该方案主要用于镁中可靠性能检测,参考标准《暂无》,《镁合金化学转化膜中耐蚀性能检测方案(电化学工作站)》用到的仪器有LK2005A电化学工作站。

我要纠错

推荐专场

相关方案

咨询

咨询