方案详情文

智能文字提取功能测试中

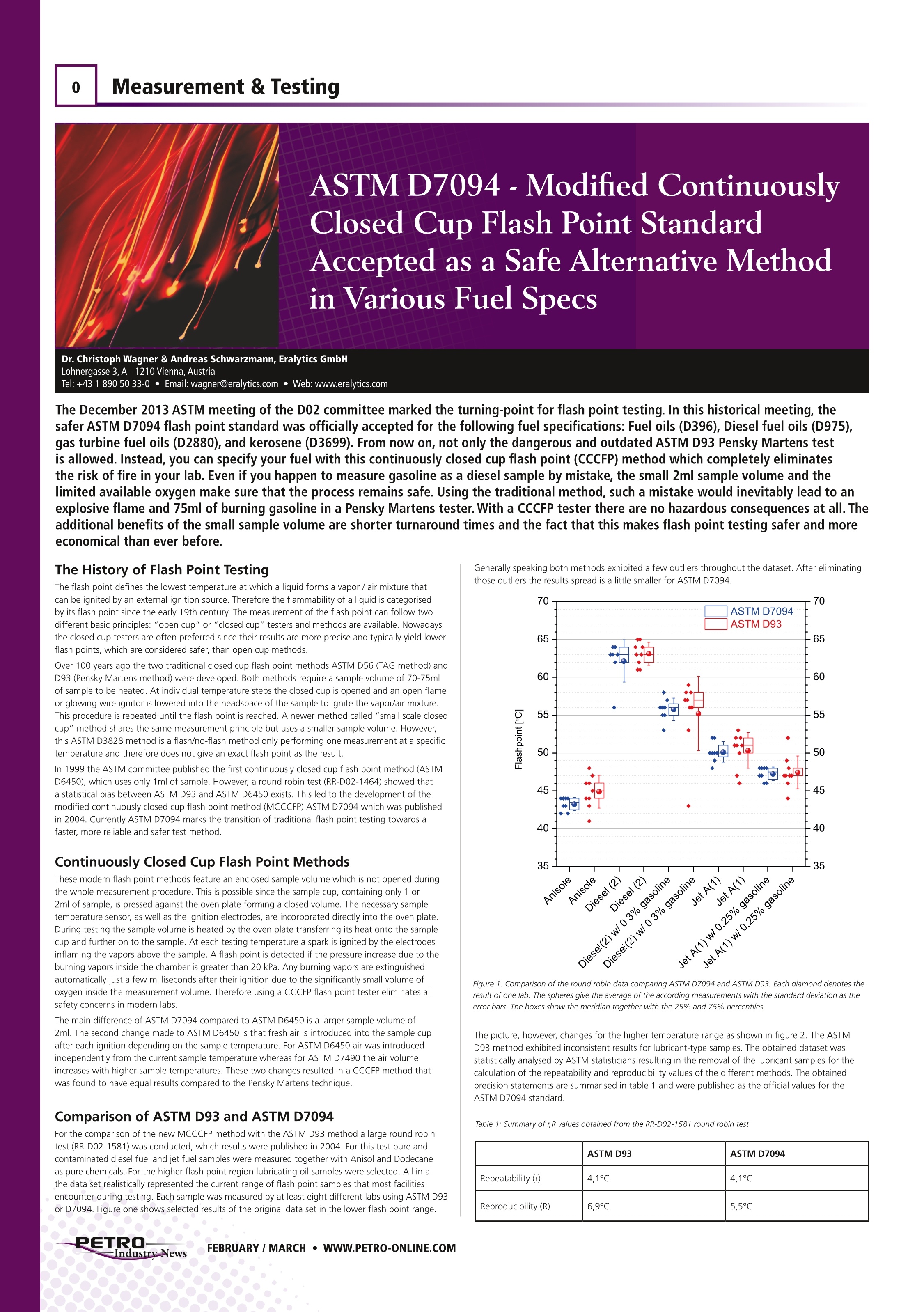

0Measurement & Testing ASTM D7094 -Modified ContinuouslvClosed Cup Flash Point Standard Accepted as a Safe Alternative Methodin Various Fuel Specs Dr. Christoph Wagner & Andreas Schwarzmann,Eralytics GmbH Lohnergasse 3,A-1210 Vienna,Austria Tel:+43 1 890 50 33-0·Email:wagner@eralytics.com·Web: www.eralytics.com The December 2013 ASTM meeting of the D02 committee marked the turning-point for flash point testing. In this historical meeting, thesafer ASTM D7094 flash point standard was officially accepted for the following fuel specifications: Fuel oils (D396), Diesel fuel oils (D975),gas turbine fuel oils (D2880), and kerosene (D3699). From now on, not only the dangerous and outdated ASTM D93 Pensky Martens testis allowed. Instead, you can specify your fuel with this continuously closed cup flash point (CCCFP) method which completely eliminatesthe risk of fire in your lab. Even if you happen to measure gasoline as a diesel sample by mistake, the small 2ml sample volume and thelimited available oxygen make sure that the process remains safe. Using the traditional method, such a mistake would inevitably lead to anexplosive flame and 75ml of burning gasoline in a Pensky Martens tester. With a CCCFP tester there are no hazardous consequences at all. Theadditional benefits of the small sample volume are shorter turnaround times and the fact that this makes flash point testing safer and moreeconomical than ever before. The History of Flash Point Testing The flash point defines the lowest temperature at which a liquid forms a vapor / air mixture thatcan be ignited by an external ignition source. Therefore the flammability of a liquid is categorisedby its flash point since the early 19th century. The measurement of the flash point can follow twodifferent basic principles: "open cup" or "closed cup"testers and methods are available. Nowadaysthe closed cup testers are often preferred since their results are more precise and typically yield lower. flash points, which are considered safer, than open cup methods. Over 100 years ago the two traditional closed cup flash point methods ASTM D56 (TAG method) andD93 (Pensky Martens method) were developed. Both methods require a sample volume of 70-75mlof sample to be heated. At individual temperature steps the closed cup is opened and an open flameor glowing wire ignitor is lowered into the headspace of the sample to ignite the vapor/air mixture.This procedure is repeated until the flash point is reached. A newer method called "small scale closedcup" method shares the same measurement principle but uses a smaller sample volume. However,this ASTM D3828 method is a flash/no-flash method only performing one measurement at a specifictemperature and therefore does not give an exact flash point as the resultIt In 1999 the ASTM committee published the first continuously closed cup flash point method (ASTMD6450), which uses only 1ml of sample. However, a round robin test (RR-D02-1464) showed thata statistical bias between ASTM D93 and ASTM D6450 exists. This led to the development of themodified continuously closed cup flash point method (MCCCFP) ASTM D7094 which was publishedin 2004. Currently ASTM D7094 marks the transition of traditional flash point testing towards a faster, more reliable and safer test method. Continuously Closed Cup Flash Point Methods These modern flash point methods feature an enclosed sample volume which is not opened during the whole measurement procedure. This is possible since the sample cup, containing only 1 or2ml of sample, is pressed against the oven plate forming a closed volume. The necessary sampletemperature sensor, as well as the ignition electrodes, are incorporated directly into the oven plateDuring testing the sample volume is heated by the oven plate transferring its heat onto the samplecup and further on to the sample. At each testing temperature a spark is ignited by the electrodesinflaming the vapors above the sample. A flash point is detected if the pressure increase due to theburning vapors inside the chamber is greater than 20 kPa. Any burning vapors are extinguishedautomatically just a few milliseconds after their ignition due to the significantly small volume ofoxygen inside the measurement volume. Therefore using a CCCFP flash point tester eliminates allsafety concerns in modern labs The main difference of ASTM D7094 compared to ASTM D6450 is a larger sample volume of2ml. The second change made to ASTM D6450 is that fresh air is introduced into the sample cupafter each ignition depending on the sample temperature. For ASTM D6450 air was introducedindependently from the current sample temperature whereas for ASTM D7490 the air volumeincreases with higher sample temperatures. These two changes resulted in a CCCFP method thatwas found to have equal results compared to the Pensky Martens technique. Comparison of ASTM D93 and ASTM D7094 . For the comparison of the new MCCCFP method with the ASTM D93 method a large round robintest (RR-D02-1581) was conducted, which results were published in 2004. For this test pure andcontaminated diesel fuel and jet fuel samples were measured together with Anisol and Dodecaneas pure chemicals. For the higher flash point region lubricating oil samples were selected. All in allthe data set realistically represented the current range of flash point samples that most facilitiesencounter during testing. Each sample was measured by at least eight different labs using ASTM D93or D7094. Figure one shows selected results of the original data set in the lower flash point range. Generally speaking both methods exhibited a few outliers throughout the dataset. After eliminatingthose outliers the results spread is a little smaller for ASTM D7094 Figure 1: Comparison of the round robin data comparing ASTM D7094 and ASTM D93. Each diamond denotes theresult of one lab.The spheres give the average of the according measurements with the standard deviation as theerror bars. The boxes show the meridian together with the 25% and 75% percentiles. The picture, however, changes for the higher temperature range as shown in figure 2. The ASTMD93 method exhibited inconsistent results for lubricant-type samples. The obtained dataset wasstatistically analysed by ASTM statisticians resulting in the removal of the lubricant samples for thecalculation of the repeatability and reproducibility values of the different methods. The obtainedprecision statements are summarised in table 1 and were published as the official values for theASTM D7094 standard. Table 1: Summary of r,R values obtained from the RR-D02-1581 round robin test ASTM D93 ASTM D7094 Repeatability (r) 4,1℃ 4,1°℃ Reproducibility (R) 6,9°C 5,5°℃ Figure 2: Round robin data for the higher flash point region. 70 +7060- -6050- 二-50The ASTM statisticians concluded that "a small amount of sample specific bias" was detected "whichis random" and does not need to be corrected between the two methods. The second important40 -40conclusion from this large round robin test is that the actually stated r,R values of ASTM D93 in thestandard itself overestimate the repeatability and reproducibility of samples modern fuel testing labs oa30-30are facing. Figure 3 summarises all samples evaluated during this round robin test and includes thereproducibility values obtained from the test itself as well as the calculated R values according to the ASTM D93 method. What can clearly be seen is that the new and safe flash point method always 20 -20falls within the precision statement even for the smaller calculated R values of ASTM D93.ERAFLASHFrom figure 3 it can be seen that both methods deliver equal results and that there is no statistical 1010D93bias observed using ASTM D7094. The obtained reproducibility for the new method was actuallyD3828better than for the Pensky Martens method. This fact is of course important if results from two0 0different labs should be compared in case of a dispute. This favorable outcome was finally recognised at the ASTM meeting in December 2013 by officially accepting ASTM D7094 as an alternativesel method in the following fuel specifications: Fuel oils (D396), Diesel fuel oils (D975), Gas turbine fuel DieJet (2)oils (D2880) and Kerosene (D3699). Diesel-BlkDiesel B3Diesel B6Diesel B11Diesel B20100 -100ASTM D7094ASTM D9375- -7550 -50With its move in December 2013ASTM finally paves the way for aonew era of safe flash point testingcNow it is officially possible tospecify fuels according to ASTM25- -25 D7094. This effectively eliminatesthe need to use large samplevolumes in combination with openflames in laboratories with a lotof potentially flammable samples.0 -0 Not only is ASTM D7094 the safestDodecanAnisoleDiesel (1)Diesel (2)Diesel (3)Diesel(1) w/0.5% gasolineDiesel(2) w/ 0.3% gasolineJet A(1) w/ 0.25% gasolineJet A(2) w/0.4% gasolineJet A(2) w/0.7% gasolineJet A(2) w/ 2.0% Biodieselpossible way to measure the flashpoint of fuel samples, due to thereduced sample volume it is alsofaster than the Pensky Martenstechnique. There is no longer aneed to stick with a 100 year-old technique and fuel testingFigure 3: Average values of all participating labs of the round robin test. Colored error bars mark the reproducibility. laboratories can finally upgrade tothe 21st century.ERAFLASH by eralytics is a state-of-the-art CCCFP flash pointtester that fully complies with the (R) values obtained from the round robin test itself whereas the black error bars show the calculated R valueaccording to ASTM D93. .ERAFLASH-a New Era of Flash Point Testing ERAFLASH, produced by eralytics, is a continuously closed cup flash point tester that can measureflash points according to ASTM D6450 as well as ASTM D7094. It was developed by Mr. AndreasSchwarzmann and Dr. Roland Aschauer, both long term members of the ASTM 02.08 flammabilitygroup. Their combined knowledge led to an industry-leading flash point tester that fully convincedlaboratory managers of leading refineries, lube oil manufacturers and independent oil and petroleumtesting organisations all over the world. ERAFLASH uses a patented PBT-Peltier Boost Technology to cover a temperature range of -25 to420C (-13 to 788°F) within a single analyser. This innovative technology lifts the Peltier elementsfrom the measurement cell as soon as a potentially harmful temperature for the elements is reachedto disconnect them from the oven plate. From there on three powerful heating rods solely take over the heating. During the cool down phase the Peltier elements are pre-cooled and lowered as soon aspossible to start actively cooling down the measurement cell and cup. This significantly reduces theturnaround time of ERAFLASH compared to other traditional closed cup testers. The PBT allows ERAFLASH to cool the sample cell from 200C to 100℃ in less than 80 seconds.Even in the low temperature range, the unit can cool from room temperature to 5℃ in around 100seconds without an external cooling supply. During heat up the Peltiers support the heating rods to allow unmatched heating rates, which is.especially advantageous for high temperature samples. Starting at room temperature, 100℃ is reached00°Ccin less than 50 seconds and for a temperature of 200℃ only an additional 70 seconds are needed. In the past, cleaning flash point testers often took a long time and also involved replacing sensorsor other elements of the analyser. With ERAFLASH this is different due to its CPT-ContaminationPrevention Technology. This includes sealed ceramics and self-cleaning electrodes which minimisesany required cleaning. A well designed oven plate effectively eliminates sample splashing at themoment of ignition further reducing contamination of the oven plate. These two technologies make ERAFLASH a fast and reliable analyser which requires a minimum ofcleaning and maintenance. But ERAFLASH also delivers on-spot measurement results which was provenin a very recent round robin test. Figure 4 combines results from seven different ERAFLASH instrumentsoperated in seven labs with the reference values from ASTM D93 and D3828. The evaluation of thesesamples gave an excellent repeatability of 2.3℃ and a reproducibility of 3.3C for ERAFLASH. Figure 4: Average flash points of different fuel samples including Diesel/FAME blends from 3 to 20 Vol% measuredwith ERAFLASH using ASTM D7094 are shown together with the reference values according to ASTM D93/D3828. The error bars state reproducibilities. For ERAFLASH the obtained values from this round robin test areplotted in blue. The red error bar for D93 is the R value obtained from RR-D02-1581. Black error bars give thepublished R values from the according standards. Conclusion Figure 5: ERAFLASH analyser with the 2ml sample cup for ASTMD7094 compliant measurements latest flash point methods. With its full-color touch screen operating the analyser is intuitive and easy. In addition to the inherent advantages of CCCFP testers ERAFLASH offers fastest heating and coolingrates and an unmatched temperature range due to the patented PBT design. A fully heat insulatedsample cup allows safe sample cup removal moments after the measurement; even if the flash points. are above 200℃. In combination with the PBT design this helps to further reduce the turnaroundtime of ERAFLASH compared to other CCCFP testers significantly. The full aluminum housing and therugged design of ERAFLASH makes it the ideal choice for stationary as well as mobile laboratories -PETRO-Industry NewsFEBRUARY/MARCH·WWW.PETRO-ONLINE.COM 闪点测试的历史 闪点的定义是指液体形成蒸汽和空气的混合物,并可由外部火源点燃的最低温度。因此,自十九世纪早期以来液体的可燃性一直用闪点进行分类。闪点的测量可以遵循两个不同的基本原则:“开杯”或“闭杯”测试仪和方法。如今闭杯试验器往往是首选,因为他们的结果是更准确的,而且一般闪点较低,相比开口法而被认为是更安全的。 100多年以前,两个传统的闭杯闪点测试方法ASTM D56(泰格法)和ASTM D93(宾马法)被发明。这两种方法都需要70-75ml的样品来进行加热,在测试的过程中测试腔会被打开,在样品顶部伸入一根燃烧的灼热电线对混合气体进行点燃。此过程会反复重复直到达到闪点的温度。一种被称作“微量闭杯”的新方法ASTM D3828采用也还是上述的测量原理,只不过用的小样品量而已。不管怎样,这个方法只是一种执行一个特定温度的闪点/非闪点测试方法,因此不能给出一个确切的闪点结果。 1999年ASTM正式颁布第一个“连续闭杯闪点测试方法”ASTM D6450,只需要1ml的样品量。但是一个循环对比试验(RR-D02-1464)表明ASTM D6450和ASTM D93之间存在统计学上的偏差。这就使得ASTM在2004年又颁布了修正的连续闭杯闪点测试方法(MCCCFP)ASTM D7094。现在ASTM D7094表明闪点测试方法正向着更快速、更准确、更安全的方向发展。 连续闭杯闪点测试方法这种现代的闪点测试方法主要特征就是在整个的测试过程中都是完全封闭的。这是由于只含有1ml或2ml样品的样品杯,和顶部加热陆判形成一个封闭的空间。样品温度传感器、压力传感器,以及点火电极,都被包裹在密闭空间中。在测试过程中,陆判的温度传到样品杯上,从而使样品被加热。每隔一定的测试温度,电极产生火花去点燃样品上方的蒸汽。当蒸汽燃烧并使当腔体内得压力变化瞬间升高超过20KPa时,此时的温度即为闪点。由于小体积的测试腔内氧气量有限,燃烧的蒸汽会在几毫秒内自动熄灭。因此现代实验室采用连续闭杯闪点测试仪器会排除一切危险因素。 ASTM D7094和ASTM6450之间最大的区别就是前者采用更大的2ml样品量。第二个相对于ASTM D6450的改变就是新鲜空气引入样品杯,取决于每次点火后样品的温度。ASTM D6450空气引入是和当前的样品温度无关的,而ASTM D7094中引入的空气量是随着样品温度的升高而增多的。这两个变化使得连续闭杯闪点测试方法和宾斯基马丁技术相比有着相同的测试结果。 ASTM D93和ASTM D7094之间的对比 ERAFLASH 全自动闪点仪大通量十倍微量连续闭杯闪点仪ERAFLASH S10

关闭-

1/2

-

2/2

产品配置单

培安有限公司为您提供《燃料油、柴油、燃气轮机燃油和煤油中闪点检测方案(闪点仪)》,该方案主要用于柴油中理化分析检测,参考标准《暂无》,《燃料油、柴油、燃气轮机燃油和煤油中闪点检测方案(闪点仪)》用到的仪器有Eraflash S10 全自动十杯微量闪点仪。

我要纠错

相关方案

咨询

咨询