方案详情文

智能文字提取功能测试中

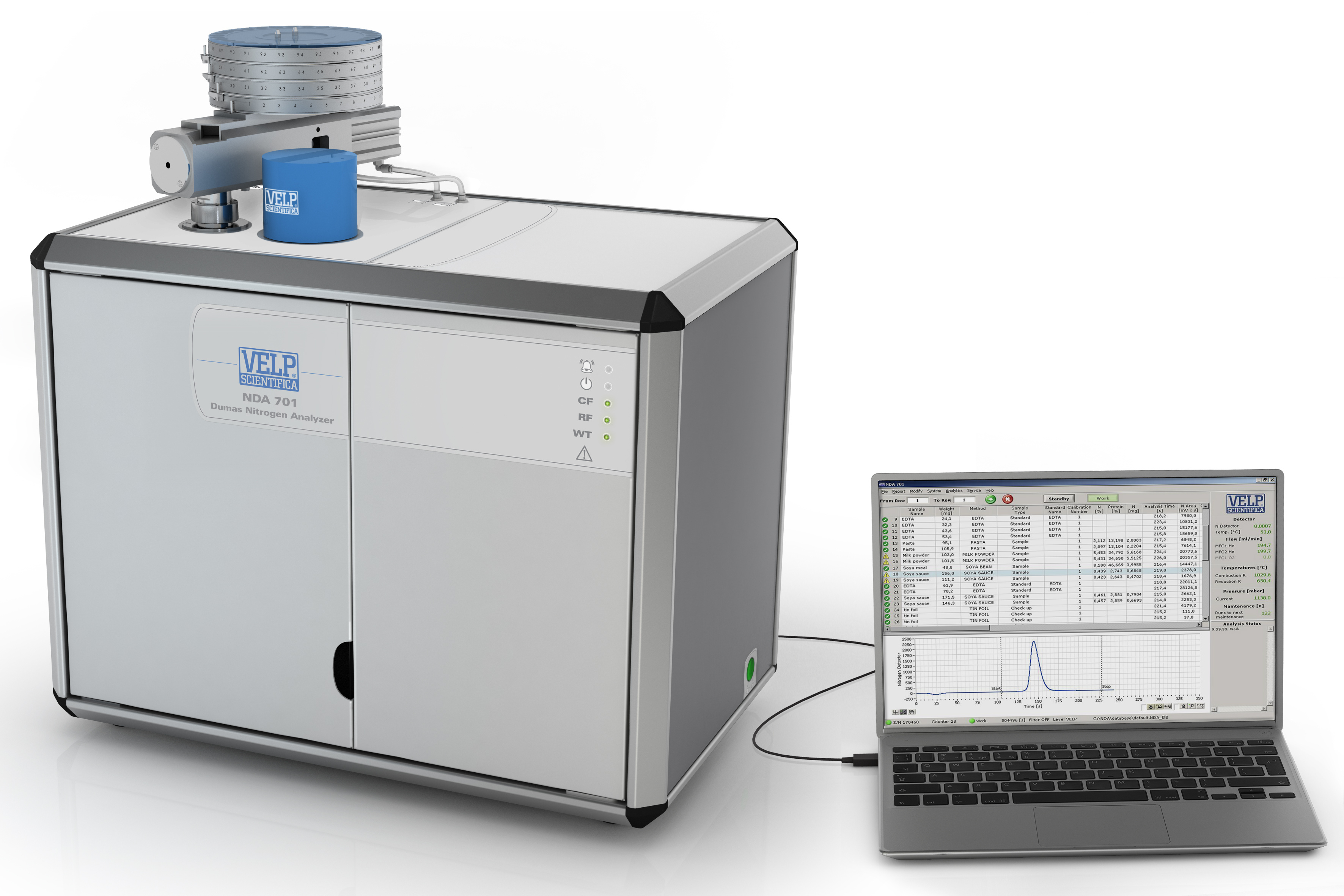

APPLICATION NOTEF&F-D-007-2014/A3 N/PROTEIN DETERMINATION IN MALTDUMAS COMBUSTION METHOD N/Protein Determination in Maltaccording to the Dumas method (He/Ar as Carrier) Reference: AOAC 997.09 Nitrogen in Beer, Wort, and Brewing Grains Protein (Total) Tested with VELP Scientifica NDA 702 Dual Carrier Gas Dumas Nitrogen Analyzer (Code F30800080) Introduction Beer is the product of the alcoholic fermentation by yeast of extracts of malted barley. The production of alcohols other than ethanol is linked with nitrogen uptake by yeast. The yeast requires nitrogen in order to make protein and other nitrogenous cell components For this reason the monitoring of the protein content during the brewing process is important to ensure the survival,.growth, and productivity of the yeast used to convert sugars to ethanol and carbon dioxide. Moreover the protein content is an important criteria in evaluating the quality of beer: water-soluble barley proteins playa major role in the formation, stability, and texture of head foams. Protein Determination in barley malt The Dumas method starts with a combustion furnace (CF) to burn thesample, obtaining elemental compounds. Water is removed by a first physical trap (WT1- DriStepTM), placed afterthe combustion, and a second chemical one (WT2). Between the two, theelemental substances passed through a reduction furnace (RF). The auto-regenerative CO2 adsorbers (CO2) let pass only the elementalnitrogen that is detected by the LoGas TM innovative Thermal ConductivityDetector (TCD) with no requirement for a reference gas. The NDA 702 is controlled via PC through the intuitive DUMASoftTM. NDA 702 Preliminary Operations (daily) Follow the operating manual to start the NDA 702 and check that the following parameters are set: Temperature Combustion reactor (Code A00000158):1030C Temperature Reduction reactor (Code A00000226): 650°C Flow rate MFC1 (He/Ar): 190 ml/min Flow rate MFC2 (He/Ar): 220 ml/min Condition the system by testing 2 EDTA standard (Code A00000149) and 3 to 5 empty tin foils (Code A00000153) asCheck up. Verify the calibration curve with one or more tests as Standard by testing the same standard used for the curve creation. Sample Preparation Using a spatula, put ~ 200 mg of finely grinded sample directly into the tin foil. Close the tin foil, obtaining a capsule and load the capsule into the autosampler. Analysis Procedure Fill the following fields in the database: Sample name, Weight, Method, Sample type, Calibration number The CEREAL MEAL 1 method shows the following parameters: Protein factor:6.25O2 flow rate:400 ml/minO2 factor: 1.6 ml/mg Press to start the analysis. Analysis time: from 3 minutes for one run. Typical Results on Barley Malt The obtained results are in accordance with the expected value. Results have been obtained with the followingcalibration curve: in a range of 0 - 9.46 mg N with 5 measurements of EDTA standard (N%=9.57) (Code A00000149).The data obtained are included in the tolerance admitted by the EDTA certificate. HELIUM as Carrier Gas ARGON as Carrier Gas Sample quantity (mg) Protein% Sample quantity (mg) Protein % 199.94 10.490 200.87 10.416 200.94 10.197 201.63 10.348 200.72 10.284 200.39 10.542 200.00 10.266 200.25 10.192 200.72 10.099 200.85 10.297 200.70 10.340 201.10 10.164 200.87 10.028 201.41 10.473 202.16 9.943 200.12 10.203 200.40 10.150 200.15 10.160 202.50 10.047 201.15 10.372 Average ± SD 10.184±0.165 10.317±0.136 RSD%* 1.618 1.316 Protein Expected Value:9.8-10.8% Protein Factor: 6.25 *RSD%=(Standard Deviation * 100)/ Average Conclusion Results are extremely reliable and reproducible, as demonstrated by the RSD, by using helium or argon as carrier gas,with the same conditions (method and sample weight) since the goal is to obtain < 2.0% relative standard deviation, asrequested by official methods. 啤酒是大麦麦芽提取物经酵母酒精发酵而成。酒精以外的其他酒精的生产与酵母对氮的吸收有关。酵母需要氮来制造蛋白质和其他含氮细胞成分。因此,在酿造过程中对蛋白质含量的监测对于确保用于将糖转化为乙醇和二氧化碳的酵母的生存、生长和生产力是很重要的。此外,蛋白质含量是评价啤酒品质的重要标准,水溶性大麦蛋白质对啤酒头部泡沫的形成、稳定性和质地起着重要作用。参考标准:AOAC 997.09啤酒、麦汁和酿造谷物蛋白质中的氮(总)检测仪器:NDA702杜马斯双载气定氮仪检测结果:所得结果与期望值基本一致。通过以下校准曲线获得了结果:在0 9.46 mg N范围内测量5次EDTA标准(N% = 9.57)(代码A00000149)。获得的数据包含在EDTA证书认可的公差中。结 论:RSD表明,在相同的条件(方法和样品重量)下,以氦或氩作为载气,其结果非常可靠和可重复性,因为其目标是获得官方方法要求的< 2.0%的相对标准偏差。

关闭-

1/3

-

2/3

还剩1页未读,是否继续阅读?

继续免费阅读全文产品配置单

北京盈盛恒泰科技有限责任公司为您提供《麦芽中N/蛋白质检测方案(氮磷钙测定仪)》,该方案主要用于生物发酵中营养成分检测,参考标准《暂无》,《麦芽中N/蛋白质检测方案(氮磷钙测定仪)》用到的仪器有VELP-NDA702杜马斯定氮仪。

我要纠错