芳香族芽孢杆菌合成的(3-羟基丁酸酯)-(4-羟基丁酸酯)聚合物(PHA聚羟基脂肪酸酯) 样品的提取

检测样品 可降解材料

检测项目 含量

方案详情文

智能文字提取功能测试中

不同单体组成对芳香族芽孢杆菌合成的广泛应用的(3-羟基丁酸酯)-(4-羟基丁酸酯)聚合物(PHA聚羟基脂肪酸酯)性能的影响Effects of Differing Monomer Compositions on Properties of P(3HB-co-4HB) Synthesized by Aneurinibacillus sp. H1 for Various Applications2 of 12Polymers 2022, 14, 2007 Polymers 2022, 14, 20073 of 12 Citation: Pospisilova, A.; Vodicka, J.; Trudicova,M.; Juglova, Z.; Smilek, J.; Mencik, P.;Masilko, J.; Slaninova, E.; Melcova, V.; Kalina,M.; et al. Effects of DifferingMonomer Compositions on Properties of P(3HB-co-4HB) Synthesized by Aneurinibacillus sp. H1 for Various Applications. Polymers 2022, 14, 2007. https://doi.org/10.3390/polym14102007 Academic Editors: Ben Bin Xu and Sneh Punia Bangar Received: 15 April 2022 Accepted: 10May 2022 Published: 13May 2022 Publisher’sNote:MDPI stays neutral with regard to jurisdictional claims in publishedmaps and institutional affil-iations. Copyright: © 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution(CC BY) license(https://creativecommons.org/licenses/by/4.0/). zuzana.juglova@vut.cz(Z.J.); smilek@fch.vut.cz(J.S.);mencik@fch.vut.cz(P.M.);masilko@fch.vut.cz(J.M.); xcslaninovae@fch.vut.cz(E.S.); xcmelcova@fch.vut.cz(V.M.); kalina-m@fch.vut.cz(M.K.); obruca@fch.vut.cz(S.O.)* Correspondence: sedlacek-p@fch.vut.cz; Tel.:+420-541-149-486 Abstract: Films prepared frompoly(3-hydroxybutyrate-co-4-hydroxybutyrate) copolymers produced by Aneurinibacillus sp.H1 using an automatic filmapplicatorwere homogeneous and had a defined thickness,which allowed a detailed study of physicochemical properties. Their propertieswere com-paredwith those of a poly(3-hydroxybutyrate) homopolymer filmprepared by the same procedure, which proved to be significantlymore crystalline by DSC and XRD. Structural differences between samples had amajor impact on their properties. With increasing 4-hydroxybutyrate content, the ductility and release rate of themodel hydrophilic active ingredient increased significantly. Other observed properties, such as the release of the hydrophobic active substance, the contact anglewith water and ethylene glycol, or the surfacemorphology and roughness,were also affected by the composition. The identified properties predetermine these copolymers forwide use in areas such as biomedicine or smart biodegradable packaging for food or cosmetics. The big advantage is the possibility of fine-tuning properties simply by changing the fermentation conditions. Keywords: polyhydroxyalkanoates(PHA); P(3HB-co-4HB); Aneurinibacillus sp. H1; mechanical properties; surfacemorphology; crystallinity; active ingredients release 1. Introduction In the course of the last two centuries, plastics have become an inseparable part of human life. The robustness of thesematerials ensureswide-scale applicability as long-life products. The great variety of itsmechanical properties also favours its use in consumer products, such as packages or coatings. However, environmental aspects have played an in-fluential role against petrochemical plastics within the last decades. Therefore, a generation of biodegradable polymers has become a very promising substitute for commercial plastics, especially in the consumption segment. Amongst these polymers, polyhydroxyalkanoates (PHA) attract great attention due to their biocompatibility and full biodegradability[1]. PHAs are a class of polymersthatcover a wide range of polymers, including homopoly-mers and copolymers composed of a large variety ofmonomers.Numerousmonomeric compositions provide great variability in physical andmechanical properties, facilitating several applicability directions. Until now,more than 150 differentmonomers of PHA have been described; however, only a fewof themare relevant to large-scale applications due to production availability and the final impact on the final product properties[2]. The properties of PHAmaterials are also reflected in the ratio of themonomers in the polymer chain. Hence,material properties could be tailored to specific requirements by managing the polymer composition. However, adjusting themonomer ratio of copolymers is possible,which is quite unique for the biotechnological production of PHA. Fortunately, a thermophilic bacterial strain, Aneurinibacillus sp.H1 has appeared as this kind of optimal producent if cultivation conditions are controlled[3]. Aneurinibacillus is a remarkable producent of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) copolymer able to incorporate 4-hydroxybutyrate(4HB) units up to 90mol.%by utilising 1,4-butanediol as a precursor, while themonomer ratio in the final copolymer ismirrored to carbon sources(precursor) ratio in themedium[3]. In addition, this thermophilic bacterial strain is also able to produce terpolymers consisting of 3-hydroxybutyrate, 4-hydroxybutyrate, and 3-hydroxyvalerate and does not produce toxic endotoxins[3]. These copolymers seem to be suitable poly-mers for thin-film production due to their favourablematerial properties for different applications[4,5]. Polymerfilmsrepresent a large segmentof the industry where the annual consumption of thesematerials in the EU reaches dozens ofmegatons. Films are used in packaging, such as insulation or protective layers for sensitive surfaces[6]. The vastmajority are made of conventional polymers, especially polyethylene and polypropylene.However, in some segments, there is a demand for biodegradable and biobased alternatives inwhich PHAs could be applied.Materials of various chemical, optical, andmechanical properties are used[7].Of the mechanical ones, tear strength, elongation at break, modulus of elasticity, impact strength, tear resistance, and tear propagation are themost important. However, the properties of films also largely depend on additives, surfacemodifications, andmanufacturingmethods[8]. Films are usuallymade by thermoplastic film-forming or solution casting,where the latter option is advantageous for thermally unstable or very high-meltingmaterials[8]. Of the conventional plastics, this applies to cellulose acetate, polyimide, and polycarbonate[9]. The advantage of solution casting is also the possibility of adding temperature-sensitive additives directly during filmproduction. Such additives may improve the physical properties of the filmormay be added as active ingredients for sustained release. Within this paper,we introduce two different P(3HB-co-4HB) copolymer films pro-duced by the employment of Aneurinibacillus sp. H1 in targeted cultivations and formed by amulti-layer solution casting technique. This production represents amodelmanufacture of suchmaterials, aiming at an exploration of basic applicability options. As a reference, a homopolymer of 3-hydroxybutyratewas produced by thewell-described bacterium Cupri-avidus necator and further investigated to evaluate the advantages of 4HB incorporation in the polymer chain. Besides the basic physical andmechanical properties, the active ingredient release kinetics is also shown on rhodamine 6G andNile red. The dyes pose as lowmolecular solutes, representing active ingredients inmedicine or active packaging. The outputs of this research should serve as background for further particular research with respect to specific applications. 2.Materials andMethods The polymermaterials used for this study correspond tomaterial used for degradation tests published previously[8]. Thematerials productionwas provided by the same proce-dures. We also introduce some properties relevant to this study,whichwere previously presented in stated paper, especially the film thickness(determined bymechanical pro-filometry) and averagemolecularweight(determined by size exclusion chromatography). 2.1. PHA Production Preparation of the PHAs and polymer filmswas previously described in[10]. For the purpose of PHAs production, two bacterial strains were employed—Cupriavidus necator H16for P(3HB) biosynthesis and Aneurinibacillus sp.H1 for copolymers of 3-hydroxybutyrate and 4-hydroxybutyrate production. To prepare the inoculum, complexmedia nutrient broth(10 g/L beef extract, 10 g/L peptone, 5 g/LNaCl)were used for bacterial growth. Mediawere incubated at 30 ◦C and 45 ◦C for Cupriavidus and Aneurinibacillus, respec-tively, while shaking at 180 rpm for 24 h. Afterwards, mineral salt medium(MSM) was used for PHA production. The inoculum ratiowas 10 vol.%. MSM for C. necator consisted of the following: KH2PO4, 1.02 g/L;(NH4)2SO4, 1.0 g/L;Na2HPO4·12H2O,11.1 g/L,MgSO4·7H2O, 0.2 g/L; trace element solution(TES, composition see Table S1, SupplementaryMaterials), 1mL/L; as a carbon source, 20 g/L of fructose has been used. As theMSMfor Aneurinibacillus, the following componentswere used:Na2HPO4·12H2O,9.0 g/L; KH2PO4, 1.5 g/L; MgSO4·7 H2O, 0.2 g/L; NH4NO3, 1.0 g/L; CaCl2·2 H2O,0.02 g/L; FEIIINH4citrate, 0.0012 g/L; Tryptone, 0.5 g/L andmicroelement solution(MES, composition see Table S2, SupplementaryMaterials), 1mL/L. To produce P(3HB-co-4HB) copolymer, 1,4-butanediol and glycerol in the following two different ratioswere used:4 g/L of 1,4-BD and 6 g/L of glycerol for lower 4HB-content polymer production, 4 g/L of 1,4-BD and 2 g/L of glycerol for polymer richer in 4HB. Productionswere performed in 100mL Erlenmeyer flasks(250mL) incubated at 30 ◦C(Cupriavidus necator) and 45 ◦C (Aneurinibacillus) for 72 h under shaking of 180 rpm. Grownmediawere centrifuged(4800× g, 10min) in order to collect bacterial cells, the biomasswas dried at 70 ◦C in Petri dishes. Acquired biomasseswere determined gravimetrically as the cell drymass(CDM). The PHA content andmonomeric compositionwere determined by gas chromatography as described by Obruca et al.–see Ref.[11]. To obtain the polymers, chloroformextractions were carried out at the SOXTHERM® automatic extraction system(C. Gerhardt Analytical systems, Königswinter, Germany). 2.2. Films Production Preparation of the PHAs and polymer filmswas previously described in[10]. Briefly, extracted polymeric materials were dissolved in chloroform to 5% w/w concentration. Viscous solutionswere filtered through 5 µm-nylon filters. To generate films, an automatic filmapplicator(QTC Sheen, Capelle aan den IJssel,Netherlands)was employed. Each film was prepared by application of two layers of solution(120 µmthickness). After solvent evaporation, filmthicknesswas determined bymechanical profilometry(Bruker, Billerica, MA, USA). 2.3. Size Exclusion Chromatography Themethod for the averagemolecularweight determinationwas described previ-ously[10]. Samples of filmswere dissolved in HPLC-grade chloroformat a concentration of 1.5mg/mL. The solutionswere filtered through 0.45 µmnylon filters and injected(100 µL) into the size exclusion chromatography system(Infinity 1260 systemwith PLgelMixed-C column, Agilent, Santa Clara, CA, USA) coupledwith themulti-angle light scattering detector(DawnHeleos II,Wyatt Technology, Santa Barbara, CA, USA) and differential refractometer(Optilab T-rEX,Wyatt Technology, Santa Barbara, CA, USA). Themobile phase(HPLC-grade chloroform)was pre-filtered through 0.02 µmmembrane filters. The flowratewas adjusted to 0.6mL/min. The rawdatawere processed in ASTRA software (version 7.3.2,Wyatt Technology, Santa Barbara, CA, USA), theweight-averagemolecular weight(Mw)was calculated by using Zimmequation. 2.4. Atomic ForceMicroscopy Surfacemorphology of P3HB and copolymers P3HB-co-4HBwas determined by QI mode(quantitative imagingmode) using JPKNanowizard 4 AFM(Bruker, Billerica,MA, USA). Rectangular geometry TESPA-V2(radius 7 nm, resonance frequency 312 kHz, spring constant 33N/m)was used for the surface imaging of films. Spring constant aswell as resonance frequency were experimentally determined during calibration(free oscillation of the probe far enough fromthe sample surface in the air). P3HB or appropriate copolymers were placed onmicroscope slide(dried beforemeasurement) andmeasured in tapping mode under air condition. The following parameterswere chosen: setpoint–2.7 nN, Z-speed–50mm/s, scan size–50mm, resolution–512 × 512. Images of surface topography were subsequently processed in JPK DP Data Processing softwarewith the following steps:line levelling–linear; smooth QI images–no, interpolation–yes. The surfaces of P3HB and copolymerswith 4HBwere imagined in pixel difference 3Dmode. No further image adjustmentswere carried out. 2.5. Contact AngleMeasurements Sessile drop test was performed on See System E/S(Advex Instruments, Brno, Czech Republic). In total, 5 µL drop of the respective solventwas placed on a polymer film surface using amicrosyringe. Contact angleswere calculated automatically by the implemented software, See System7.0(Advex Instruments, Brno, Czech Republic). Each measurementwas repeated seven times. 2.6. Tensile Tests The elongation at break, Young’smodulus, and the tensile strengthwere determined using the universal testingmachine Zwick Z 010(ZwickRoell GmbH& Co., Ulm,Germany) at ambient conditions. Average values of at least sevenmeasurementswere reported. Measurementswere carried out using the load indicatorwith amaximal tensile force of 10N andwith pneumatic grips. Pre-loadwas 0.1N and the deformation ratewas 5mm/min. The 5A double-paddle testing sampleswere cut fromthe films and heated to110 ◦C for 1 h in order to remove residual solvent and enhance crystallisation. Thickness of each specimenwasmeasured before the tensile test. 2.7. X-ray Diffractometry(XRD) XRD patternswere collected using the X-ray diffraction analyzer EMPYREAN(PANa-lytical,Malvern, UK) in a central focusing arrangementwith Bragg-Brentano parafocusing optics using CuKα radiation(range: 5–90◦ second, step: 0.013◦ second, voltage: 40 kV, current 30mA), ADS: 10mm,time per step: 96 s,withoutmonochromator. 2.8. Active Ingredients Release Kinetics Active ingredients release kineticswasmodelledwith two different dyes–hydrophilic Rhodamine 6G and hydrophobicNile red. As a polar environment for Rhodamine release, distilled water was selected. For hydrophobic eluate release, water solution of polyoxyethy-lene(20) oleyl ether(Brij®O20, Sigma Aldrich, St.Louis, MO, USA) was used as the solubilizing agent. Dyewas added to polymer solution to consequential concentration of 1 g/L. Subsequently, filmswere prepared as described above. Pieces of 2.6 × 2.6 cm-coloured films were incubated in solvent for 48 h. Amount of released dye was determined spectrometrically at 524 nmfor Rhodamine and 561 nmforNile red detection. 3. Results andDiscussion 3.1. PHA Films Production The PHA productivity of Aneurinibacillus sp. H1 is generally lower than that of C. necator. Compared to C. necator, Aneurinibacillus sp. H1 reaches lower cell drymass/biomass yields, and the obtained biomass is quite poor in PHA content as compared to C. necator(see Table 1). Furthermore, produced copolymers dispose of a significantly lower average molecularweight than homopolymers,which is given by the difference in PHA synthase types of the respective producents and their general biological dissimilarity(as proposed in[12]), and possible polymerization termination by glycerol[13,14]. On the other hand, manipulating themonomer composition is expected to broaden the range of accessible physical andmaterial properties(crystallinity, ultimate tensile strength), resulting in higher applicability. In addition, thermophilic strains(or generally extremophiles) offer numerous advantages for biotechnological productions if employed, such as lower sterility require-ments and fewer cooling needs[15],which partially offset lower process yields, although the production cost is also affected by lower PHA content in the biomass. Hereby,we present basal differences in physical properties in order to illustrate themotivation of P(3HB-co-4HB) production by Aneurinibacillus sp.H1, sincewe are able to set the physical properties of the product by a simple choice of cultivation strategy. Accordingly,wewould like to point out the first two columns of Table 1 as the key results presented here. Therefore, not all of the stated aspects are accountable or projectable in the final production costs and the stimulus of P(3HB-co-4HB) copolymer production by Aneurinibacillus sp.H1 should definitely follow the requirements on final product properties(purposes) presented in this paper. Table 1. Results of polymers production–also in[10]. Sample Substrate CDM(g/L) PHA(%per CDM) Mw(kDa) Crystallinity+ (%) P3HB fructose 9.06 ± 0.24 76.82 ± 12.44 481.26 ± 11.62 59 P(3HB-co-36%4HB)* 1,4-(B2D:3:)GLY 1.28 ± 0.53 29.46 ± 3.67 127.14 ± 1.73 36 P(3HB-co-66%4HB)* 1,4-(B2D:1:)GLY 1.82 ± 0.18 32.09 ± 3.16 174.13 ± 4.27 43 1,4-BD= 1,4-butanediol; GLY= glycerol; CDM= cell drymass;Mw=weight averagemolecularweight;* Copoly-mer composition determined by GC-FID;+ Counted frommelting enthalpies(146 J/g and 110 J/g for 100%crystalline P3HB and P4HB, respectively[12]). 3.2. Surface Characteristics The filmswere prepared using a film applicatorwith a controlled thickness of the solution layer. This enabled us to prepare uniformand well-defined filmswith good control over the film thickness(Table 2). Certain dissimilaritieswere observed by AFM,where different copolymers had slightly different surfacemorphologies(see Figure 1). This could be caused by differences inmolecularweight, crystallinity, and rate of crystal formation. Table 2. Data frommechanic profilometry. Sample FilmThickness(µm) Roughness Ra(µm) P3HB 10.96 ± 1.11 0.35 P(3HB-co-36%4HB) 11.12 ± 1.37 0.67 P(3HB-co-66%4HB) 11.09 ± 0.57 0.20 P3HB P(3HB-co-36 mol.% 4HB) P(3HB-Co-66 mol.%4HB) Figure 1. AFM surfacemorphology of prepared films illustrating the differences in the surface roughnesses of P3HB, P(3HB-co-36mol.%4HB) and P(3HB-co-66mol.%4HB). 3.3. Contact Angle The contact angle is a basic indicator of thewettability and a goodmeasure of the hydrophilicity of thematerial. It is affected by surface free energy, liquid surface tension, and roughness[16]. The interaction of thematerialwith solvents plays amajor role in a number of technological steps involved in film production and use, such as cleaning, gluing, printing, and dyeing[17]. The contact angles of the tested PHA are presented in Figure 2. Figure 2. Contact angles of prepared films suggesting differences in the surfacewettability of the homopolymer and the copolymers films. Both P3HB and P(3HB-co-4HB) copolymers have been confirmed to be relatively hydrophobicmaterials that have a rather high contact anglewhen in contactwith polar liquids(water and ethylene glycol, see Figure 3). The results are comparablewith data obtained by other authors on similar PHAs[18–21]. P3HB and P(3HB-co-4HB)s are similar to synthetic polymers,which are commonly used in filmtechnology[22], and significantly differ fromother natural polymers(polysaccharides, proteins, nucleic acids, etc.) that are highly hydrophilic. This canmake the PHAs a suitable alternative to synthetic plastics in applicationswhere surface hydrophobicity plays an important role. An example could be the packaging of hydrophilic foodstuffs—hydrophobic packaging is generallymore advantageous than hydrophilic because strong adhesion of the content to packagingmay lead to impaired product acceptability and increasedwaste[16]. Figure 3. Images fromwater contact anglemeasurements representing high hydrophobicity of all tested films–P3HB, P(3HB-co-36mol.%4HB) and P(3HB-co-66mol.%4HB). 3.4. Tensile Test Tensile testing(Table 3) showed the dependence ofmechanical properties on the content of 4HB in the copolymer, as apparent fromFigure 4.With increasing 4HB content, the films weremore ductile, which can be attributed to substantially lower crystallinity.We have seen that the samples change significantly over time. Immediately after preparation, all samples weremuch less stiff than after several days of storage at roomtemperature(data not shown). The properties did not seemto stabilize within two weeks of storage. Fromthe perspective of filmapplications, it is important to estimate the properties of the polymer in theweeks tomonths after preparation. Therefore, to ensure complete crystallisation and removal of residual solvent, the sampleswere pre-treated by heating at 110 ◦C for 1 h. We assume that thismay explain the difference between our data and the results of other authors,who usually observedmuch higher ductility. The authors pre-treated samples by prolonged storage at room temperature[23–26] or did not specify the pre-treatment procedure[27,28]. Another reasonmay be the differentmonomer sequence of the copolymers, differentmolecularweight, or different parameters of themeasurement. Anyway, the copolymers aremore ductile than pure P3HB, retain their ductility even after a long time, and the degree of ductility is adjustable by the 4HB content, which depends on the fermentation conditions. This is beneficial for the fine-tuning of properties in applicationswhere the ductility ofmaterial and its control is crucial. Table 3. Results fromthe tensile tests. Sample Et(MPa) σm(MPa) εm(%) P3HB P(3HB-co-36%4HB) 2000 ± 167 161 ± 14.7 20.4 ± 1.82 6.72 ± 0.667 1.3 ± 0.12 5.3 ± 0.91 P(3HB-co-66%4HB) 210 ± 35.8 13.8 ± 3.63 180 ± 52.0 strain (cm) Figure 4. Typical stress−strain curves demonstrating differences in ducilities of the tested homopoly-mer(P3HB) and the P(3HB-co-4HB) copolymers films. 3.5. X-ray Diffraction Patterns The obtained diffraction patterns(see Figure 5) revealed that all materials were semicrystallinewith characteristic diffractions for crystalline phases and a broad back-ground band attributable to the amorphous fraction. The ratio between P3HB and P4HB crystallites gradually shifted with changing copolymer composition, confirming the copoly-mer composition found by the GC-FIDmethod. The diffraction patterns correspondwell with previously described data[12] obtained onmaterials produced by the samemicroor-ganismas in this work. Other authors(see Ref.[26]) achieved slightly different patterns for the copolymers,with a substantially lower ratio of P3HB crystallites in the P(3HB-co-66%4HB) copolymer. It reveals that not only copolymer composition determines polymer properties–other factors, such as distribution of the monomers in the polymer chains (randomor block) ormolecularweight,may also affect the properties. dom or block) or molecular weight, may also affect the properties. 2θ(°) P3HB P(3HB-co-36%4HB) P(3HB-co-66%4HB) Figure 5. X-ray Diffraction patterns indicating different crystallinemorphology of P3HB and the Fi gP(u3rHe B5-.c oX-4-rHaBy) cDoipfforlaycmtieorns. patterns indicating different crystalline morphology of P3HB and the P(3HB-co-4HB) copolymers. 3.6. Active Ingredients Release Kinetics 3.6. ActBiivoep Ionlygrmeedrise rnetcs eRntellye atsoeo kK ia npetoiscistion among potential reservoirs for active ingredients’rel eBaisoe.poTlyhemsee rss yrsteecemns tlfiyn tdo aopk pali cpaotisoitniso inn apmacoknagg ipnog tteencthianlo lroegsieersv, osiurcs hf oars aaccttiivvee ionrgredi-intelligent packaging of foods, cosmetics, pharmaceuticals, or other consumer products. en tCso’ nrceulerraesnet.l yT, htehsees es ypsotleymmse rfsi nads aacptpivliec iantigornesd iienn tp arecskeargvionirgs taerce hpnootleongtiieals, msautcrihc aess faocrtive or in ttehlel iignegnret dpieanctk raeglienasge oinf fvoaoridosu, s ceonsvmireotnicms,e npthsa(argmriaccueltuutircala, lss,y notrh eottihc,e rp hcyosniosluogmiec,r eptcr.o).ducts. C oSnevceurrarl ernetqluyi,r tehmeesnet sp aorley pmute rosn ams aatrcitcievse fionr garcetidviee inntg rreesdieernvt orierlse aasree. Ipn ogteennetiraall , tmhaetrmicatersi xfor the insghreoudlied nbt er ealbelae steo ihno lvda rhiioguhs aemnvoiurnotns mof etnhtes i(naggrreidciueltntu raanl,d soypnttihmeatlilcy, rpehleyassieo ltohgeicw, heotlce.). Sev- er aalm roeuqnut iorfe tmhee inntsg raerdei epntu it n otnh e mdaetfirinceeds tifomre apcetriivoed i(ntog reensduieren tn ro eilnegarseed.i Ienn tgweansetirnagl,) . thTeh ematrix sh roatuel do f bine garebdliee tnot rheloelads e hsitgroh naglmy oduenpetsn dosf otnh et hienmgraetrdiix epnrto apenrdti eos.p tTihmuasl,lwy er ealsesausmee tthhea twhole a mthoeumnto noof mthere cionmgrpeodsiiteiontn ionf ttehstee dd ePfiHnAesd wtiillm der ipvee rtihoed fi(ntaol reenlseausree bneoh aivnigoruer.dient wasting). The ratReh oofd ianmgirneed’is esnttr urcetlueraes ec ostmrboinngelsy adroepmeanticd sr ionng st haen dm paotrsiitxi vper ochpaerrgtiee,s.w Thihcuh si,s wane aal-ssume ogous to common pharmaceuticals, for instance, antibiotics or anaesthetics[29,30]. The th raet stuhltes omf orhnoodmaemri nceo rmelpeoasseit(isoene oFif gtuerset e6)d sPhoHwAas cwleiallr ddirfifveree tnhcee ifni nbaolt rh etlheea sceo ubreseh aofv ieoluu-r.tion Rahnod dtahem oivneer’asl ls tarmuoctuuntr eo fc doyme rbeilneeass eadr foomr hatoicm oripnoglys maenrds apnods ictoipvoel ychmaerrgs. e,A pwphaircehn tilsy ,analo-gotuhse tcor ycsotamllimneonm oprhpahromloagcye ouft ibcoatlsh , cfoopr oilnysmtaenrsc ies, amnutcibhiomtoicrse foarv aonuraaebslteh feotir chsy[d2r9o,3p0h]i.l icThe re- su llotsw -omf orlhecoudlaar msiunbes traenlceeas sreel(esaesee tFhiagn uhreo m6)o psohloywm era sctrleuactru rdei fsfienrcee nfcacei liitna tbeso tfha stt heleu tcioonurse of el tuot itohne aaqnude othues eonvveirroalnl maemnto. uTnhte o4f HdBy ceo rnetleenat sien dt hfeo rp ohloymmeorpmolaytrmixe orsb vainoud slcyo epnohlyanmceesrs. Ap- patrhee nutlsya,b tilhitey corfy tsthae llhiynde rompohrilpich oalcotigvye ionf gbroetdhie cnot paonldy emnesrusr eiss tmheu rcehl emasoe roe f fsaivgoniufircaabnltel yfor hy- drhoipghheilri ca mloowun-tms oofl etcheu lianrg rseudbiesntta.nMceosr eroevleera, steh et hraatne ohf oremleoapseo lisy pmreerd iscttraublcet ubry es shiifnticne g ftahceilitates fas3tHl eBol:wu4)t iHroBeln re taaots ieto h. oeOf ian nqtguhree edooiuteshn eter snh. vaTihrneod, ln Pinm3eeHanBr t r. seThghoreews better retention of the solute and a stable(ss 4siHonB (cdoenpteenndt einnc te hoef pwo/lyw moen r √mt, aFtirigxu roeb 6v)iously enhances the usability of the hydrophilic active ingredient and ensures the release of sig-confirmed that diffusion is the rate-limiting step. The diffusion is apparently driven by ni fdiicfafenrtelnyt hdiigffhuesri oan mcoouefnfitcsi eonf tts hDe ifnorg irneddiiveindt.u aMlomraetorivceers,, tahs eo rbasteer voef dr eolne adsieff iesr epnrt ecduircvtaeble by sh silfotipnegs. tThhee 3seH aBr:e 4thHe Ba srpateicot.s tOo nc otnhsei doetr hienrd ihvaidnuda, llPy 3foHr Bi nsthenodwesd baeptptleirc arteitoenns.t iTohne roefl tehasee solute an frdo am stPa(3blHeB(-sclo-o6w6)% r4elHeBa)s ies omf oirne grraepdidi ewnittsh. inT hthee l ifinresta 6r hr ecgormespsairoend t(od eP(p3eHnBd-econ-c3e6 %of 4wH/Bw), on √t, Fi gwuhriles t 6t)h ec oonthfierr mdeodm itnhaatte s diinf ftuhse ifoonll oisw tinhge “rpaltaet-eliaum”i tpinhgas es.t eTph. oTughhe, idt iifsf unsoit opno sissi balpe ptoarently dr fiovremn ublayt e dsitfrfiecrt ecnotn cdliufsfiuosniso anb coouet ftfhiec ipehnetns oDm feonra iinn dtihve ipdluatael aum apthraiscee ss,i nacse othbes edrevveiadt ioonn sdiffer- enatr ec uqruvitee shliogphe isn. tThhise speh aasree. the aspects to consider individually for intended applications. The release from P(3HB-co-66% 4HB) is more rapid within the first 6 h compared to P(3HB-co-36%4HB),whilsttheotherdominatesinthefollowing “plateau” Rhodamine 一 P(3HB-co-66%4HB) ●P3HB ■IIP(3HB-co-36%4HB) ▲P(3HB-co-66%4HB) Figure 6. Results fromactive ingredients release tests highlighting the differences in rhodamine and Nile red release fromthe homopolymer P3HB and the P(3HB-co-4HB) copolymers. Nile red as hydrophobic active ingredient representsmodel of typical pharmaceutical ingredient(e.g., analgesic),where lowwater solubility is very common. Compared to rhodamine release,Nile red release did not reach high values of the final amount of solute release(Figure 6). Even though this conclusion is justified(due to lowdye polarity), the final amount of the releasedNile red is surprising since itwould be expected to appear up to 10%. The final concentration of approximately 2.9 µMand 2.3 µMof releasedNile red fromthe homopolymer and copolymers respectively approaches themaximal solubility in water–approx. In total, 3 µM(according to Ref.[31]). Probably, thematrix–water systems achieved equilibriumafter the solvent saturation, so this resulted in limited the elution. Obviously, not even the presence of the high-molecularwetting agent contributed to the hydrophobic dye release. The rate of release ofNile redwithin the exponential phase is basically the same for copolymers and homopolymer as shown on the Figure 6. Only very slight differences are observable in the time dependence,where homopolymer reports very short “lag time”compared to copolymers, and former incline to plateau phase of P(3HB-co-66% 4HB). For this reason, the regressions(square root dependence) are not displayed. Though, the differences between homopolymer and copolymer are almost insignificant compared to Rhodamine release. The diffusion rate is generally influenced by diffusion coefficient D and the concentration gradient as themain stimuli. Though, the homopolymer consisting of higher number of crystalline regions potentially retaining the hydrophobic dyemight representsmatrix reducing D, the high-crystalline regions are capable aggregate the dye duringmatrix formation(load) so cumulating local over-gradients possibly compensating diffusivity deficiency. 4. Conclusions Within this study, we have applied the previously described model of P(3HB-co-4HB) copolymer production by the thermophilic bacterium Aneurinibacillus sp. H1(see Refs.[3,12]) to adjust selected product properties via different cultivation strategies. Com-pared to P3HB production by C. necator, the productivity of the copolymer synthesis is considerably lower. On the contrary, manufactured copolymers showed a significant advance inmechanical properties as they incorporated a higher number of 4HB units. Elongation at break of P(3HB-co-66% 4HB) reached about a hundred times higher val-ues than P3HB,which predetermines this copolymer for the production of high-value packaging technology(active, smart, or bioresorbed coatings), for instance for foodstuffs, cosmetics, and consumer products,where high flexibility of foils is required. Further, the surface of copolymers appears slightly less hydrophobic as the contact angleswithwater and ethylene glycol are gently lower compared to homopolymers. This ensures higher reactivity of the surface on the interfacewithwater environments, possibly broadening the applicability of copolymers in biomedicine(degradable soft tissue implants and scaf-folds, surgical sutures, repair patches, etc.). Suitability for in vivo applicabilitywas also confirmed by active ingredients release testing, where copolymers showed rapid ingredient releasewhen releasing both hydrophilic and hydrophobic low-molecular ingredients. In addition, the release of hydrophilic rhodamine fromcopolymermatricesmight prevent wasting of the active ingredient since thematrices allowhigh effective leaching of the dye. Themodelling of copolymer content as a reservoir could be beneficially used for various kinetics of in vivo drug release or active packaging. In our previous study(see Ref.[10]), we reported the high biodegradability of tested copolymers in simulated physiological environments and found no cytotoxicity of the degradation products. A combination of these outputs shows great usability of tested P(3HB-co-4HB) copolymers in biomedicine and foodstuff or cosmetics packaging. SupplementaryMaterials: The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/polym14102007/s1, Table S1: Composition ofmicroelement solution(MES); Table S2: Composition of trace element solution(TES). Author Contributions: Conceptualization,methodology and supervision, S.O. and P.S.; investigation, A.P., J.V.,M.T., Z.J., J.S., P.M., J.M., E.S., V.M. andM.K.;writing—original draft preparation, A.P. and J.V.;writing—reviewand editing, J.S.,M.K., S.O. and P.S.; visualization, A.P., J.V., Z.J. and P.S.; project administration and funding acquisition, J.V. All authors have read and agreed to the published version of themanuscript. Funding: This investigationwas funded by the grant FCH-K-21-7008 providedwithin the project Quality Internal Grants of BUT(KInG BUT), Reg.No. CZ.02.2.69/0.0/0.0/19_073/0016948,which is resourced fromthe OP RDE,Ministry of education youth and sports, Czech Republic. Informed Consent Statement:Not applicable. Data Availability Statement: The data that support the findings of this study are available fromthe corresponding author, P.S., upon reasonable request. Acknowledgments: The authors express their acknowledgments toMonikaWikarska for assisting with active ingredients release kinetics experiment. Conflicts of Interest: The authors declare no conflict of interest. The funders had no role in the design of the study; in the data collection, analyses, or interpretation; in themanuscriptwriting, or in the decision to publish the results. References 1. Meereboer, K.W.;Misra,M.;Mohanty, A.K. Reviewof recent advances in the biodegradability of polyhydroxyalkanoate(PHA) bioplastics and their composites. Green Chem. 2020, 22, 5519–5558.[CrossRef] 2. Koller,M.;Mukherjee, A. A NewWave of Industrialization of PHA Biopolyesters. Bioengineering 2022, 9, 74.[CrossRef][PubMed]3. Pernicova, I.;Novackova, I.; Sedlacek, P.; Kourilova, X.; Kalina,M.; Kovalcik, A.; Koller,M.;Nebesarova, J.; Krzyzanek, V.; Hrubanova, K.; et al. Introducing the newly isolated bacteriumaneurinibacillus sp. H1 as an auspicious thermophilic producer of various polyhydroxyalkanoates(PHA) copolymers-1. Isolation and characterization of the bacterium. Polymers 2020, 12, 1235.[CrossRef][PubMed] 4. Philip, S.; Keshavarz, T.; Roy, I. Polyhydroxyalkanoates: Biodegradable polymerswith a range of applications. J. Chem. Technol. Biotechnol. 2007, 82, 233–247.[CrossRef] 5. Huong, K.H.; Sevakumaran, V.; Amirul, A.A. P(3HB-co-4HB) as high value polyhydroxyalkanoate: Its development over recent decades and current advances. Crit. Rev. Biotechnol. 2021, 41, 474–490.[CrossRef] 6. Shen, L.;Worrell, E. Plastic Recycling. In Handbook of Recycling; Elsevier: Amsterdam, TheNetherlands, 2014; pp. 179–190. 7. Luo, Z.;Wu, Y.-L.; Li, Z.; Loh, X.J. Recent Progress in Polyhydroxyalkanoates-Based Copolymers for Biomedical Applications. Biotechnol. J. 2019, 14, 1900283.[CrossRef] 8. Sosa-Hernández, J.E.; Villalba-Rodríguez, A.M.; Romero-Castillo, K.D.; Zavala-Yoe, R.; Bilal, M.; Ramirez-Mendoza, R.A.; Parra-Saldivar, R.; Iqbal,H.M. Poly-3-hydroxybutyrate-based constructswith novel characteristics for drug delivery and tissue engineering applications—A review. Polym. Eng. Sci. 2020, 60, 1760–1772.[CrossRef] 9. Schmitz, P.; Janocha, S. Films. In Ullmann’s Encyclopedia of Industrial Chemistry;Wiley-VCH Verlag GmbH& Co. KGaA:Weinheim, Germany, 2000. 10. Vodicka, J.; Wikarska, M.; Trudicova, M.; Junglova, Z.; Pospisilova, A.; Kalina, M.; Slaninova, E.; Obruca, S.; Sedlacek, P. Degradation of P(3HB-co-4HB) Films in Simulated Body Fluids. Polymers 2022, Forthcoming. 11. Obruca, S.; Benesova, P.; Oborna, J.;Marova, I. Application of protease-hydrolyzed whey as a complex nitrogen source to increase poly(3-hydroxybutyrate) production fromoils by Cupriavidus necator. Biotechnol. Lett. 2014, 36, 775–781.[CrossRef] 12. Sedlacek, P.; Pernicova, I.;Novackova, I.; Kourilova, X.; Kalina,M.; Kovalcik, A.; Koller,M.;Nebesarova, J.; Krzyzanek, V.; Hrubanova, K.; et al. Introducing the newly isolated bacteriumAneurinibacillus sp.H1 as an auspicious thermophilic producer of various polyhydroxyalkanoates(PHA) copolymers-2.Material study on the produced copolymers. Polymers 2020, 12, 1235.[CrossRef] 13. Zhu, C.; Chiu, S.;Nakas, J.P.;Nomura, C.T. Bioplastics fromwaste glycerol derived frombiodiesel industry. J. Appl. Polym. Sci.2013, 130, 1–13.[CrossRef] 14. Tsuge, T.;Hyakutake,M.;Mizuno, K. Class IV polyhydroxyalkanoate(PHA) synthases and PHA-producing Bacillus. Appl. Microbiol. Biotechnol. 2015, 99, 6231–6240.[CrossRef][PubMed] 15. Urbieta,M.S.; Donati, E.R.; Chan, K.G.; Shahar, S.; Sin, L.L.; Goh, K.M. Thermophiles in the genomic era: Biodiversity, science, and applications. Biotechnol. Adv. 2015, 33, 633–647.[CrossRef][PubMed] 16. Meiron, T.S.; Saguy, I.S.Wetting properties of food packaging. Food Res. Int. 2006, 40, 653–659.[CrossRef] 17. Karbowiak, T.; Debeaufort, F.; Voilley, A. Importance of surface tension characterization for food, pharmaceutical and packaging products: A review. Crit. Rev. Food Sci. Nutr. 2006, 46, 391–407.[CrossRef][PubMed] 18. Xu, K. Biodegradable block poly(ester-urethane)s based on poly(3-hydroxybutyrate-co-4- Ou, W.; Qiu, H.; Chen, Z.; hydroxybutyrate) copolymers. Biomaterials 2011, 32, 3178–3188.[CrossRef][PubMed] 19. Chen, Z.; Cheng, S.; Xu, K. Block poly(ester-urethane)s based on poly(3-hydroxybutyrate-co-4-hydroxybutyrate) and poly(3-hydroxyhexanoate-co-3-hydroxyoctanoate). Biomaterials 2009, 30, 2219–2230.[CrossRef] 20. Sharma, P.; Ahuja, A.; Izrayeel, A.M.D.; Samyn, P.; Rastogi, V.K. Physicochemical and thermal characterization of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) films incorporating thyme essential oil for active packaging ofwhite bread. Food Control 2022, 133, 108688.[CrossRef] 21. Volova, T.G.; Golubev, A.I.;Nemtsev, I.V.; Lukyanenko, A.V.; Dudaev, A.E.; Shishatskaya, E.I. Laser processing of polymer films fabricated fromphas differing in theirmonomer composition. Polymers 2021, 13, 1553.[CrossRef] 22. Busscher,H.J.; van Pelt, A.W.J.; de Jong,H.P.; Arends, J. Effect of spreading pressure on surface free energy determinations by means of contact anglemeasurements. J. Colloid Interface Sci. 1983, 95, 23–27.[CrossRef] 23. Volova, T.; Kiselev, E.;Nemtsev, I.; Lukyanenko, A.; Sukovatyi, A.; Kuzmin, A.; Ryltseva, G.; Shishatskaya, E. Properties of degradable polyhydroxyalkanoateswith differentmonomer compositions. Int. J. Biol.Macromol. 2021, 182, 98–114.[CrossRef][PubMed] 24. Doi, Y.; Segawa, A.; Kunioka,M. Biosynthesis and characterization of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) in Alcali-genes eutrophus. Int. J. Biol.Macromol. 1990, 12, 106–111.[CrossRef] 25. Chanprateep, S.; Buasri, K.;Muangwong, A.; Utiswannakul, P. Biosynthesis and biocompatibility of biodegradable poly(3-hydroxybutyrate- co-4-hydroxybutyrate). Polym. Degrad. Stab. 2010, 95, 2003–2012.[CrossRef] 26. Saito, Y.; Doi, Y.Microbial synthesis and properties of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) in Comamonas acidovorans. Int. J. Biol.Macromol. 1994, 16, 99–104.[CrossRef] 27. Huong, K.H.; Azuraini,M.J.; Aziz, N.A.; Amirul, A.A.A. Pilot scale production of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) biopolymerswith highmolecularweight and elastomeric properties. J. Biosci. Bioeng. 2017, 124, 76–83.[CrossRef] 28. Huong, K.H.; Elina, K.A.R.; Amirul, A.A. Production of highmolecularweight poly(3-hydroxybutyrate-co-4-hydroxybutyrate) copolymer by Cupriavidusmalaysiensis USMAA1020 utilising substratewith longer carbon chain. Int. J. Biol.Macromol. 2018,116, 217–223.[CrossRef] 29. Gunasekaran, P.; Rajasekaran, G.;Han, E.H.; Chung, Y.H.; Choi, Y.J.; Yang, Y.J.; Lee, J.E.; Kim,H.N.; Lee, K.; Kim, J.S.; et al. Cationic Amphipathic Triazineswith Potent Anti-bacterial, Anti-inflammatory and Anti-atopic Dermatitis Properties. Sci. Rep.2019, 9, 1292.[CrossRef] 30. Narahashi, T.; Yamada,M.; Frazier, D.T. Cationic Forms of Local Anaesthetics block Action Potentials fromInside theNerve Membrane. Nature 1969, 223, 748–749.[CrossRef] 31. Greenspan, P.; Fowler, S.D. Spectrofluorometric studies of the lipid probe, nile red. J. Lipid Res. 1985, 26, 781–789.[CrossRef]

关闭-

1/12

-

2/12

还剩10页未读,是否继续阅读?

继续免费阅读全文产品配置单

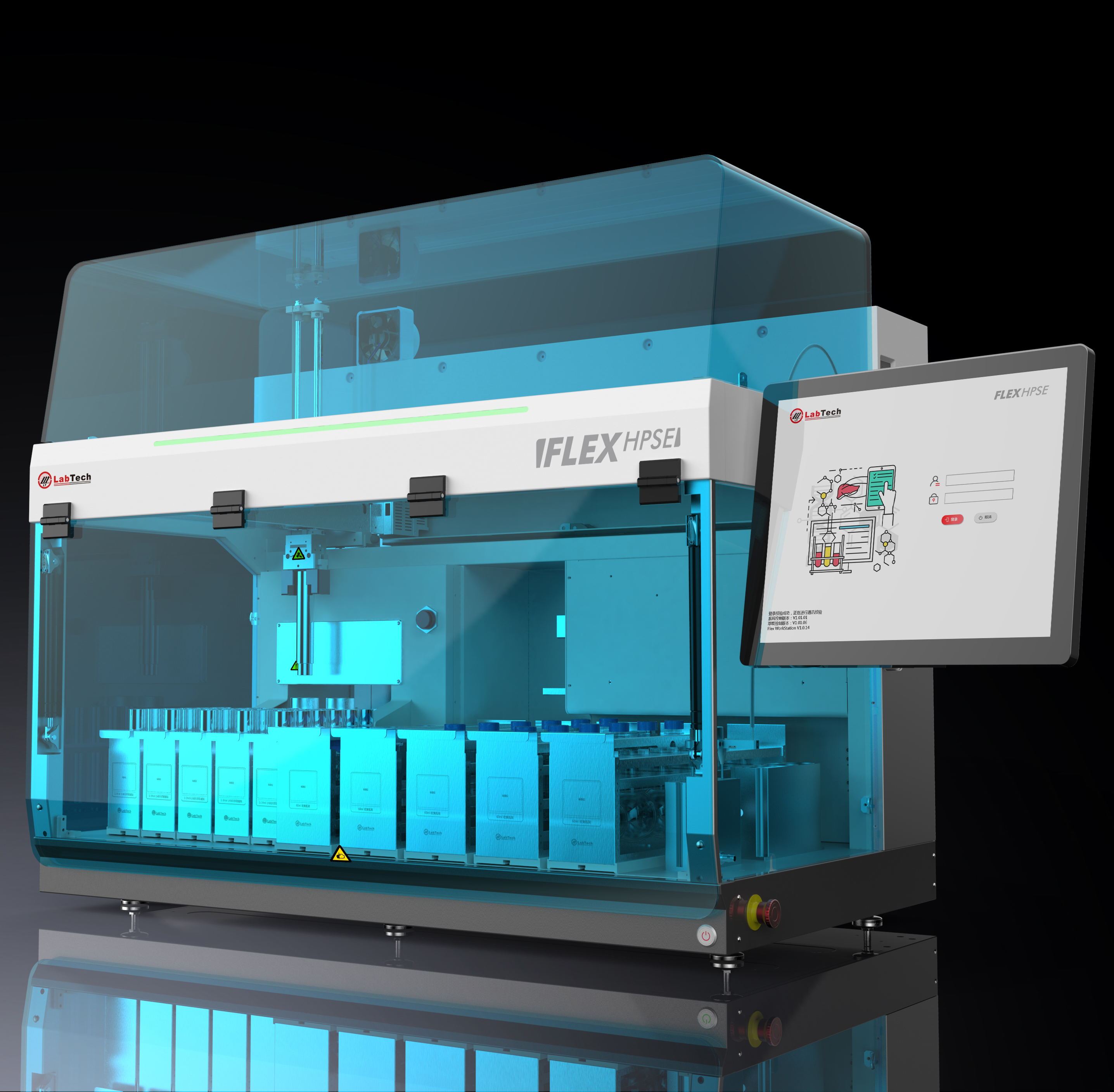

中国格哈特为您提供《芳香族芽孢杆菌合成的(3-羟基丁酸酯)-(4-羟基丁酸酯)聚合物(PHA聚羟基脂肪酸酯) 样品的提取》,该方案主要用于可降解材料中含量检测,参考标准《暂无》,《芳香族芽孢杆菌合成的(3-羟基丁酸酯)-(4-羟基丁酸酯)聚合物(PHA聚羟基脂肪酸酯) 样品的提取》用到的仪器有格哈特全自动快速溶剂萃取仪Sox416、德国加液器MM、滤纸筒。

我要纠错

推荐专场

快速溶剂萃取设备/快速溶剂萃取仪

更多相关方案

咨询

咨询