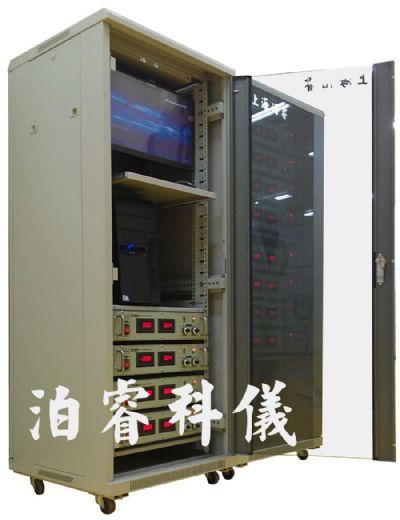

Electrical continuity, Insulation continuity, Grounding continuity test system

Perform standards: IEC 61215-2:2016 “electrical continuity for TC200 thermal cycling test and humidity-freeze test” condition, and UL 1703-2015 “Insulation continuity and grounding continuity” condition.

DC power current / voltage output: 25A / 60V or 10A / 100V

IEC 61215-2:2016

During the thermal cycling test set the continuous current flow during the heat up cycle to module Imp current at temperature from -40°C to 80°C. During cool down, the -40 °C dwell phase and temperatures above 80 °C the continuous current shall be reduced to no more than 1.0 % of the measured STC peak power current to measure continuity.

During the humidity freeze test set the continuous current flow to no more than 0.5% of the measured STC peak power current.

Note: During the 50 thermal cycle test no current flow is required.

| Module type | Imp | TC 200 Thermal Cycling | Humidity-Freeze |

| 1.58×0.808m monocrystalline | 5.20A | Provide Im over 25°C Provide 0.1~0.5A below 25°C | Provide current during the whole test |

| 2×1m polycrystalline | 7.66A | Provide Im over 25°C Provide 0.1~0.5A below 25°C | Provide current during the whole test |

| 1.4×1.1m Thin-film | 1.66A | Provide current during the whole test | Provide current during the whole test |

| 2.6×2.2m Thin-film | 2.66A | Provide current during the whole test | Provide current during the whole test |

UL 1703-2015

Temperature Cycling Test and Humidity Test shall not result in:

1) Loss of circuit continuity;

2) Accessibility of parts that involves a risk of electric shock, such as by delamination or separation of materials;

3) A reduction in the resistance between parts involving a risk of electric shock and an accessible part such that the module or panel is not in compliance with leakage current test, Section 21;

Temperature Cycling Test shall not result in:

4) Reduction in the thickness of the wall of a nonmetallic wiring compartment below required values;

5) Reduction in the volume of a nonmetallic wiring compartment below required values; or

6) A gap greater than 1/16 in (1.6 mm) or an increase of 1/16 in or more in an existing opening between nonmetallic wiring compartment walls and the cover;

b) The module or panel shall comply with dielectric voltage-withstand test, section 26, at 50°C or higher and also at room temperature;

c) Immediately following the dielectric voltage-withstand test, the module or panel shall comply with leakage current test, section 21;

d) Following the leakage current test, the module or panel shall comply with wet insulation-resistance test, section 27;

e) A module or panel with a wiring compartment as described in 13.1.6 shall comply with Wiring Compartment Securement Test, Section 42, following the wet insulation-resistance test; and

f) A module or panel with a wiring compartment as described in 13.1.6 shall comply with Wet Insulation-Resistance Test, Section 27, following the wiring compartment securement test.

Humidity Test shall not result in:

4) Corrosion of metal parts;

5) Reduction in the thickness of the wall of a nonmetallic wiring compartment below required values;

6) Reduction in volume of a nonmetallic wiring compartment below required values; or

7) A gap greater than 1.6mm or an increase of 1.6mm or more in an existing opening between nonmetallic wiring compartment walls and the cover.

b) Immediately following the test, the module or panel shall comply with dielectric voltage-withstand test, section 26.

c) The module or panel shall comply with Leakage Current Test, Section 21, immediately following the dielectric voltage-withstand test;

d) Following the leakage current test, the module or panel shall comply with wet insulation-resistance test, section 27;

e) A module or panel with a wiring compartment as described in 13.1.6 shall comply with Wiring Compartment Securement Test, Section 42, following the wet insulation-resistance test; and

f) A module or panel with a wiring compartment as described in 13.1.6 shall comply with wet insulation-resistance test, section 27, following the wiring compartment securement test.

相关产品

仪器对比

仪器对比

关注

关注