煤炭中重金属汞、总汞、固体汞检测方案(测汞仪)

检测样品 煤炭

检测项目 重金属汞、总汞、固体汞

方案详情文

智能文字提取功能测试中

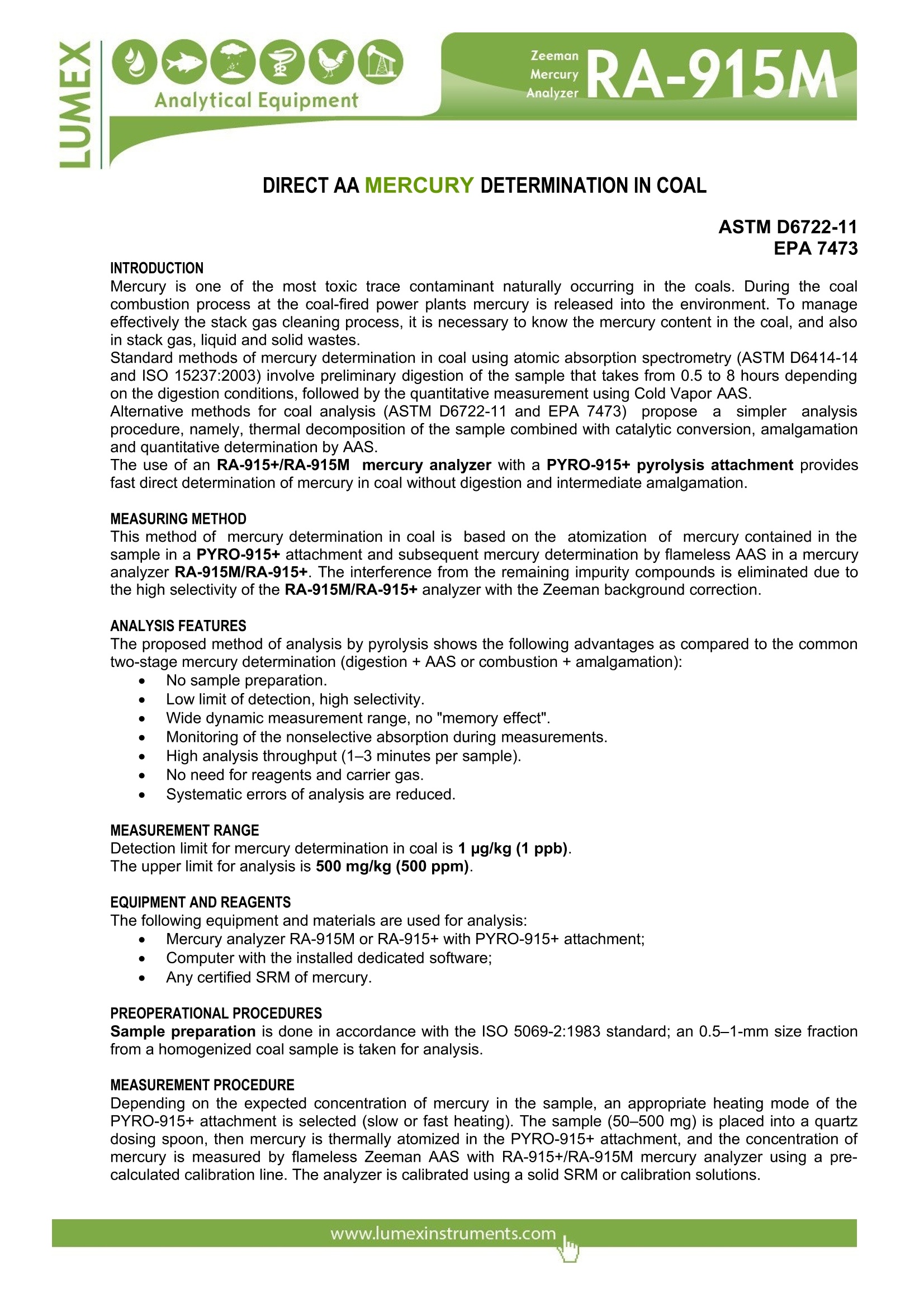

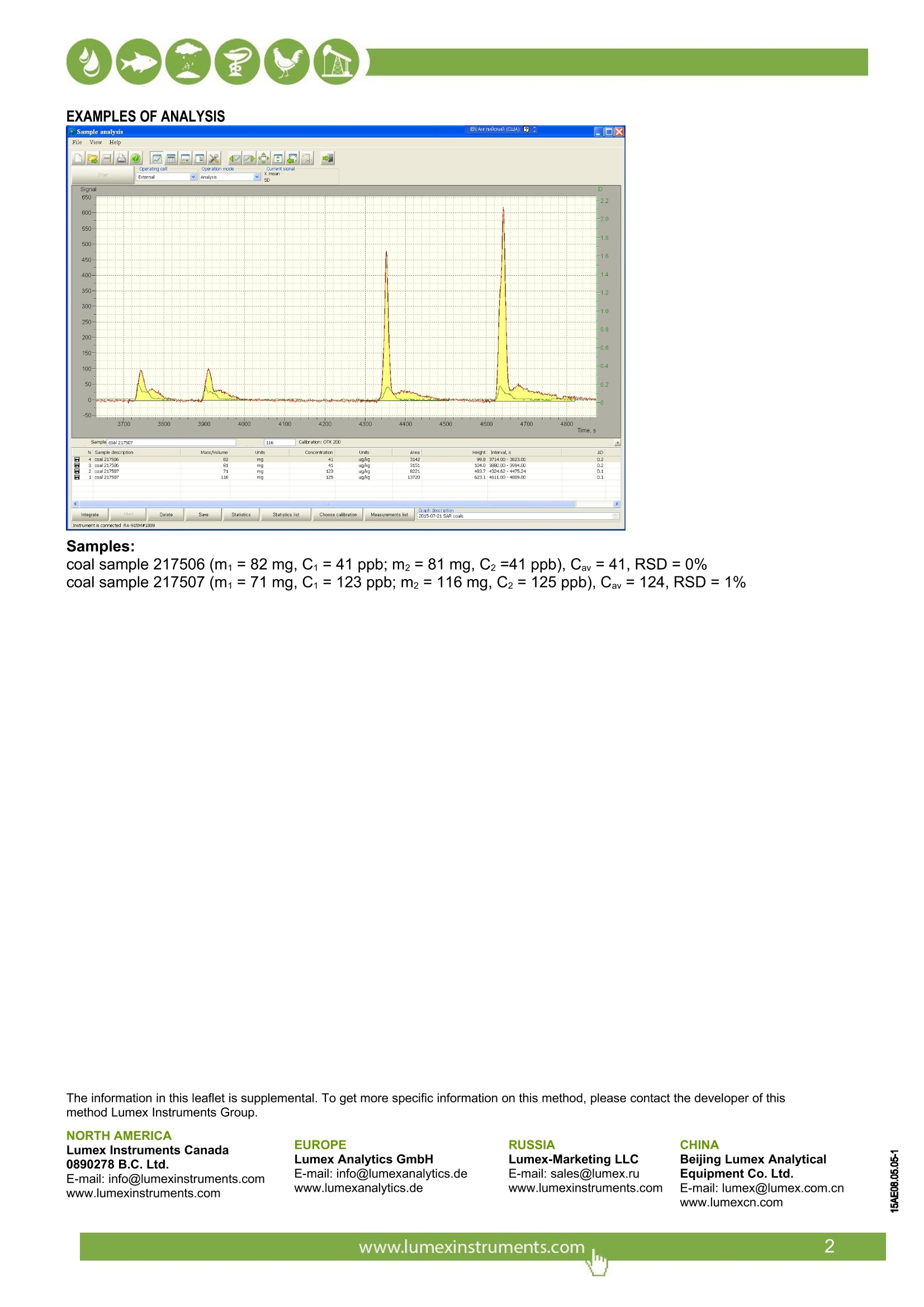

DIRECT AA MERCURY DETERMINATION IN COAL INTRODUCTION ASTM D6722-11 EPA 7473 Mercury is one of the most toxic trace contaminant naturally occurring in the coals. During the coal combustion process at the coal-fired power plants mercury is released into the environment. To manage effectively the stack gas cleaning process, it is necessary to know the mercury content in the coal, and also in stack gas, liquid and solid wastes. Standard methods of mercury determination in coal using atomic absorption spectrometry (ASTM D6414-14 and ISO 15237:2003) involve preliminary digestion of the sample that takes from 0.5 to 8 hours depending on the digestion conditions, followed by the quantitative measurement using Cold Vapor AAS. Alternative methods for coal analysis (ASTM D6722-11 and EPA 7473) propose a simpler analysis procedure, namely, thermal decomposition of the sample combined with catalytic conversion, amalgamation and quantitative determination by AAS. The use of an RA-915+/RA-915M mercury analyzer with a PYRO-915+ pyrolysis attachment provides fast direct determination of mercury in coal without digestion and intermediate amalgamation. MEASURING METHOD This method of mercury determination in coal is based on the atomization of mercury contained in the sample in a PYRO-915+ attachment and subsequent mercury determination by flameless AAS in a mercury analyzer RA-915M/RA-915+. The interference from the remaining impurity compounds is eliminated due to the high selectivity of the RA-915M/RA-915+ analyzer with the Zeeman background correction. ANALYSIS FEATURES The proposed method of analysis by pyrolysis shows the following advantages as compared to the common two-stage mercury determination (digestion + AAS or combustion + amalgamation): No sample preparation. Low limit of detection, high selectivity. Wide dynamic measurement range, no "memory effect". Monitoring of the nonselective absorption during measurements. High analysis throughput (1–3 minutes per sample). No need for reagents and carrier gas. Systematic errors of analysis are reduced. MEASUREMENT RANGE Detection limit for mercury determination in coal is 1 µg/kg (1 ppb). The upper limit for analysis is 500 mg/kg (500 ppm). EQUIPMENT AND REAGENTS The following equipment and materials are used for analysis: Mercury analyzer RA-915M or RA-915+ with PYRO-915+ attachment; Computer with the installed dedicated software; Any certified SRM of mercury. PREOPERATIONAL PROCEDURES Sample preparation is done in accordance with the ISO 5069-2:1983 standard; an 0.5–1-mm size fraction from a homogenized coal sample is taken for analysis. MEASUREMENT PROCEDURE Depending on the expected concentration of mercury in the sample, an appropriate heating mode of the PYRO-915+ attachment is selected (slow or fast heating). The sample (50–500 mg) is placed into a quartz dosing spoon, then mercury is thermally atomized in the PYRO-915+ attachment, and the concentration of mercury is measured by flameless Zeeman AAS with RA-915+/RA-915M mercury analyzer using a pre- calculated calibration line. The analyzer is calibrated using a solid SRM or calibration solutions. EXAMPLES OF ANALYSIS Samples: coal sample 217506 (m1 = 82 mg, C1 = 41 ppb; m2 = 81 mg, C2 =41 ppb), Cav = 41, RSD = 0% coal sample 217507 (m1 = 71 mg, C1 = 123 ppb; m2 = 116 mg, C2 = 125 ppb), Cav = 124, RSD = 1% The information in this leaflet is supplemental. To get more specific information on this method, please contact the developer of this method Lumex Instruments Group. NORTH AMERICA Lumex Instruments Canada 0890278 B.C. Ltd. E-mail: info@lumexinstruments.com www.lumexinstruments.com EUROPE Lumex Analytics GmbH E-mail: info@lumexanalytics.de www.lumexanalytics.de RUSSIA Lumex-Marketing LLC E-mail: sales@lumex.ru www.lumexinstruments.com CHINA Beijing Lumex Analytical Equipment Co. Ltd. E-mail: lumex@lumex.com.cn www.lumexcn.com ( 2 ) 汞是煤或煤炭中最常见的微量有害物之一。在燃煤电厂的燃煤工艺过程中,汞会被释放到环境中,从而造成环境污染。为了有效处理煤燃烧后烟道气体中的污染物质,就需要知道煤中的汞含量,以及烟道气,液体,固体废物中的汞含量。传统的方法通常使用原子吸收光谱法(ASTM D6414-14和ISO 15237:2003)来测定煤炭中的汞含量,光样品前处理就需要花费0.5到8小时不等(具体根据处理条件),然后再使用冷蒸汽原子吸收法对吸附的汞含量进行测定。目前有一种煤分析的替代方法(ASTM D67 22-11和EPA 7473),提出了一种更简单的分析程序,即样品的热分解结合催化转化、合并和AAS的定量测定。RA-915M汞分析仪配合PYRO-915+热解附件提供了无需消解可直接快速测定煤中汞的方法。

关闭-

1/2

-

2/2

产品配置单

LUMEX INSTRUMENTS (鲁美科思分析仪器)为您提供《煤炭中重金属汞、总汞、固体汞检测方案(测汞仪)》,该方案主要用于煤炭中重金属汞、总汞、固体汞检测,参考标准《暂无》,《煤炭中重金属汞、总汞、固体汞检测方案(测汞仪)》用到的仪器有LUMEX应急便携测汞仪RA-915M(汞分析仪)、LUMEX连续在线烟气汞监测仪OLM915J、LUMEX便携烟气汞采样系统OLM30B、LUMEX便携气苯分析仪BA-15(测苯仪)、LUMEX石墨炉原子吸收MGA-1000。

我要纠错

推荐专场

烟气汞连续监测系统(Hg-CEMS系统)

更多相关方案

咨询

咨询