方案详情文

智能文字提取功能测试中

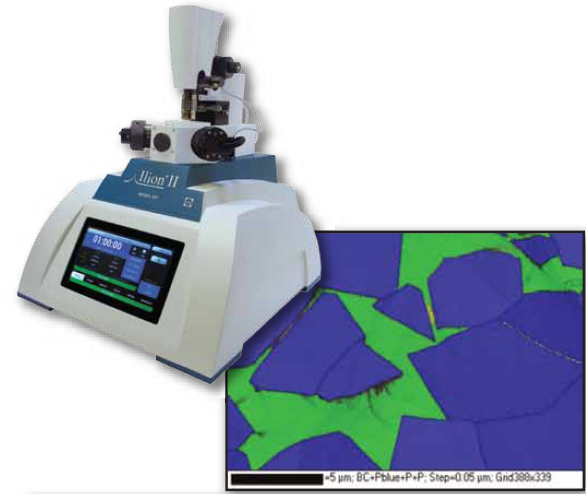

thermoscientific 01c lilHa STap- 8x81? B.s. 0 rtensty fsti ig duats 0Oviprt.wakkin a i thelor roe0g 0 0 0 6 8. 4. a a.4. Vorks derection: sihrat. badgyourd thom imanp:a B. 0Vods detectinrc top hat. tresniding 0 B. 4, 0Vtids dehection: mark dre tourdary roids 0Virt detectorc corbnevaits 0 0 B. 4. 0 Wnais. sae 0 8.4. Real Avizo Software forMaterials Research Materials characterization and quality control Industrial applications require stronger, lighter, cleanerand safer materials every day. For new developments or for better characterization ofexisting materials, Thermo ScientificT M AvizoTM Softwareallows for a better understanding of structure, propertiesand performance. No matter what modality is used to acquire digitaldata, Avizo Software provides optimized workflowsfor materials characterization. It also features imageprocessing tools, simulation modules and capabilitiesfor advanced defect analysis. ( On the cover: Porosity and permeability analysis of fiber r einforced concrete.Courtesy of EMPA. ) Ceramics, glasses and porous media Metals, alloys and powders (Composites, polymers and fibrousmaterials Biomaterials Batteries Additive manufacturing Semiconductors Food and agriculture From sample to knowledge From straightforward visualization and measurement to advanced imageprocessing, quantification, analysis and reporting, Avizo Software providesa comprehensive, multimodality digital lab for advanced 2D/3D materialscharacterization and quality control. Digital workflow Data acquisition Import Filtering and Visualization ·X-ray tomography: CT,micro-/nano-CT ·Raw images pre-processing ·Interactive high-quality ·Multi-modality Noise reduction visualization ·Electron Microscopy· Synchrotron · Very large data · Image artifact ●Direct manipulation of reduction objects ·Background correction Specialized tools Fiber analysis Porous materialscharacterization Meshing for FEA/CFD Simulation of physical properties ·Individual fiberextraction · Generation of 3D · Fiber statistics(per fiber andlocal): Orientation,distribution/densitv.length, ... · Pore & throat sizedistribution, poreconnectivity,pore shape mesh direct from 3D ·Absolute permeability images Thermal conductivity ·Extremely fast · Electrical resistivity generation ·Graph modelgeneration · Molecular diffusivity · Large dataset handling Courtesy of EMS Grivory ·Tortuosity andpermeabilitymeasurements forporous media · Export to FE-solvers Courtesy of Dominique BernardICMCB-CNRS Courtesy of Zellwerk GmbH Segmentation Measurement Presentation ·Automatic and and analysis ·Snapshots and 3D supervised ·200+ measures videos segmentation available · Advanced algorithms · Custom measures presentation scenario · Statistics ·3D stereo devices oEocconoco Materials deformationanalysis Recipe for automaticanalysis Amira-Avizo Python · 3D internaldisplacement andstrain measurements ·Design and performadvanced dataanalysis scenario asan automated high-level workflow · Access to hundredsof scientific algorithmsfrom the Pythoneco-system Ultra-efficient memory Courtesy of L. Laiarinandrasana & T.Morgeneyer (Centre des MateriauxMines ParisTech), and L. Helfen(European Synchrotron RadiationFacility; Karlsruhe Institute ofTechnology) management · Increase productivitywhile keeping fullpower and flexibility ofcomprehensive dataanalysis toolset · Fully compliant withPython scriptingconventions Avizo Software for materials research Avizo Software provides a reliable, fully automatable solution for both researchand industrial entities, allowing them to innovate faster, reduce time to market, andproduce more reliable and better performing materials. Characterization of porous material depends on the size,distribution, and shape of pores and possibly the channelsconnecting them. For other materials, such as ceramic or glass,understanding the distribution of the different particle types is ofupmost importance for estimating performance of the material.Porosity, tortuosity and permeability are some of the importantparameters that help characterize the material. Avizo Software provides an advanced workflow for pore networkcharacterization and particles analysis, including quantificationof pores or particles in the material, their volume distribution,shape and distance, as well as computation of material physicalproperties such as porosity, tortuosity or permeability. Metals, alloys and powders Transportation, energy production, machinery, building materialsand consumer products require development of metals thatare lighter, stronger and more durable. New manufacturingtechniques such as additive manufacturing require thedevelopment of new types of metal powders. Avizo Software helps expose the structure-property relationshipin metals and alloys. It enables you to fully understand theproperties of steel and alloys, in order to quantify their structureand composition, as well as possible defects such as unwantedinclusions. Its advanced set of quantification capabilities allowsyou to measure the quality of metal powder used for additivemanufacturing or to quantify grains distribution, just to name twoexamples. Sphericity and size distribution of each grain can bemeasured to assess quality and better understand properties. Avizo Software's multi-modality support allows for the fusionof data coming from different EM detectors. It can merge, forexample, SEM backscattered images with EDS or EBSD imagesof the sample, providing an even more efficient workflow fromdata to knowledge. Its multi-resolution support facilitates apowerful correlative workflow, from discovering areas of interestat the macro level to analyzing the sample at the nanoscale. Learn more at thermofisher.com/amira-avizo Composites, polymers and fibrous materials Composite materials are making their way into many differentapplication areas, ranging from aerospace to automotive andconstruction. Their properties improve stiffness and strength andallow for design of lightweight components at a reasonable cost. Avizo Software allows for analysis of the fibers that reinforcecomposite materials, computing length, orientation and density.It also detects matrix defects such as voids or foreign debris,cracking or delamination, and richness or dryness. AvizoSoftware can analyze pore networks for the latest micro-and/or nano-porous composites, allowing researchers to gain abetter understanding of the material properties and performimproved quality control on industrial parts made of compositematerial. Analysis of deformations of the material under physicalconstraints allows also for damage prediction of deficiencies. Biomaterials Recent progress in manufacturing and characterization ofbiomaterials has led to innovative development in tissueengineering and scaffold techniques. Avizo Software can be used to characterize such highly porousmedia, while also quantifying pore distribution and size as wellas high interconnectivity of the porous network. From there,mechanical strength and effective surface for cell attachmentcan be determined. Furthermore, Avizo Software can beused to validate experiments by generating Finite ElementAnalysis models and collaborating with FEA solvers, as wellas performing deformation analysis from a material samplesubjected to physical constraints. Evolution of damage during fatigue of woven composites. Innovative interconnected porous biomaterial for tissue engineering.Courtesy of Prof. A. Largeteau and Dr. Mythili Prakasam, Institute ofCondensed Matter Chemistry in Bordeaux and University of Bordeaux, France. Batteries Battery and Solid Oxide Fuel Cell (SOFC) manufacturers needto refine their manufacturing process and increase productlifespan. They also need to reduce the weight and size of theirenergy storage devices as well as increase charge capacitywhile lowering production costs, ensuring safety and making theproduct healthier for the environment. Thanks to advanced image processing and segmentationtechniques, Avizo Software makes it possible to extractkey quantitative parameters of the microstructure andmacrostructure of the involved materials. At the macro level,Avizo Software can be used to assess the quality of themanufacturing process, looking into packaging, checkingsolder points, and detecting possible leakage or porosity anddelamination. It can also examine the aging process,looking intofoil, cathode and anode morphological changes or core leakage.At the microscopic level, Avizo Software allows for the estimationof the tortuosity and permeability of the porosity structure ofelectrode and separator; thus, effective transport parameterscan be further used in the electrochemical performancesimulation. Quantification of triple phase boundary (TPB), phasedistribution and connectivity further allows for characterization ofthe cell's performance. Additive manufacturing Additive manufacturing has emerged as a very promisingmanufacturing technique, allowing advanced design of complexindustrial parts that used to require numerous sub-parts to beassembled together in the past and allowing for production oflighter and stronger innovative parts. Quality of the powder isessential to integrity of the part, and defect analysis is necessaryfor final quality check of a material sample or a produced part. Avizo Software offers a complete range of tools from pre to-post printing quality control of industrial parts. Powder can beanalyzed within Avizo Software to provide information such asshape and volume distribution, but also detection of pores orinclusions in the grain that can lead to important defect in the finalpart. Advanced automated defect detection can be applied ona sample or the final part to look for pores such as gas bubbles,inter-layers cracks, or lack of powder fusion for instance. Additively manufactured scaffold inspection. A common issue in 3D printingis porosity in the printed parts and deviation from the ideal shape as defined bythe CAD file. A 3D printed scaffold was scanned with a Thermo Scientific HeliScan microCTand analyzed with Avizo Software to find the segment with the highest amountof porosity, for further study with a PlasmaFIB instrument. Thickness of thesegments was also monitored and compared to the CAD file. Battery Cathode. Active materialconnectivity analysis.Data acquisition: Thermo ScientificHeliosTM PFIB DualBeamTM. Li-ion cylindrical cell. Inspection of battery's structure.Courtesy of Paul Shearing’s group,University College London. Dataacquisition: Thermo Scientific HeliScanTM microCT. Ti64 powder analysis- Grain separation, porosity and sphericity analysis.Data acquisition: Thermo Scientific HeliScan microCT. Semiconductor device manufacturers and designers routinelypush the boundaries of physics. Defect detection and failureanalysis, performance and process evaluation, and materialscharacterization are key to successful commercialization of newelectronic device. Avizo Software's advanced 3D visualization and imageprocessing tools allow for fast detection of defects such as issueslinked to voids in the solder balls of a Ball Grid Array (BGA). Food and agriculture 3D imaging techniques, such as X-ray micro-computedtomography (micro-CT), scanning electron microscopy (SEM),and magnetic resonance imaging (MRI), provide insights intofood structure and how it changes in various situations, includingprocessing operations. Avizo Software's comprehensive food and seeds analysis toolsetmakes it easy to perform microstructural characterization andbetter understand the relation of microstructure to propertiesneeded in food engineering, chemistry, microbiology and safety. Dedicated to Thermo Scientific TEM,SEM, FIB, DualBeam, and microCTsystems, as well as Thermo Scientificcorrelative workflows, Avizo Softwarefor Thermo Scientific Systems editionhas been developed to fit with ThermoScientific systems data acquisition andspecific workflows. Segmentation of voids inside solder balls of a BGA-Ball Grid Array. Analysis of bubles in ice cream. Courtesy of Irstea. Import and process image data · Handle any modality, at any scale, of any size: - X-ray tomography: CT, micro-/nano-CT -Electron Microscopy - Synchrotron ·Support for multi-data/multi-view, multi-channel, time series,very large data ·Scaling, calibration, conversion, re-sampling · Image enhancement, comprehensive filtering and convolution,Fourier frequency transforms ·Artifact reduction algorithms · Advanced multi-mode 2D/3D automatic registration · lmage stack alignment, arithmetic, correlation, fusion Visualize and explore ·Interactive high-quality volume ·Orthogonal, oblique, cylindrical and curved slicing ·Contouring and iso-surface extraction ·Maximum Intensity or other types of projections · Vector and tensor visualization Segment Thresholding and auto-segmentation, object separation,automatic labeling ·Region growing, snakes, interpolation, wrapping, smoothing·Morphological processing, including watershed and basins ·Machine Learning-based segmentation ·Automatic tracing of individual fibers · Skeletonization ·3D surface reconstruction ·Grid generation for FEA/CFD Analyze and quantify ·Intuitive recipe creation, customization, automated replay ·Built-in measurements, including counts, volumes,areasperimeters, aspect ratios and orientations · User-defined measures ·Results viewer with spreadsheet tool and charting · Automatic individual feature measurements, 3D localizationand spreadsheet selection ·Automated statistics, distribution graphs · Feature filtering using any measurement criterion ·Data registration, deformation, comparison andmeasurements ·Porosity detection and measurement ·Fiber analysis ·Pre-processing for structural and flow simulations · Import of CAD models for actual/nominal comparison Present · Animation and video generation ·Advanced key frame and object animation ·Mix images, geometric models, measurements andsimulations ·Annotations, measures legends, histograms and curve plots·Export spreadsheets, 3D models, high-quality images Simulate Image-to-simulation workflows: ·3D image-based meshing for Finite Element and CFD ·Porosity/pore connectivity analysis and skeletonization forPore Network Modeling ·Direct 3D image-based simulation: absolute permeability,molecular diffusivity, electrical resistivity, and thermalconductivity computation ·MATLABTM bridge Professional services We offer a comprehensive set of professional services. From training to consulting orcustom development, our professional services experts are dedicated to helping youmaximize your productivity with Avizo Software. Our custom training is designed to provide you with immediateand practical skills while keeping your specific goals in sight.We can help you quickly and effectively master all of AvizoSoftware's capabilities through focused training. Various courses can be arranged, with typical durations rangingfrom one to three days. We can customize our training to best fityour needs. The training can be arranged on-site at your locationor may also be delivered at one of our facilities. Consulting Our experts will help you get the best out of the constantinnovations introduced in Avizo Software so you can benefit fromthem in your daily work. We are your partner in creating solutions using Avizo Software.Custom-made consulting sessions can be performed at yourfacilities or remotely, depending on your needs. Our consultantscan help you analyze your specific tasks and workflows andleverage your knowledge and specific expertise to get themimplemented in Avizo Software. Custom development With 30 years of experience in 3D and image processingand hundreds of projects delivered to small and largeorganizations, we can provide you with a solution tailored to fityour specific needs. We have the ability to customize and expand our softwaresolutions at various levels, including, but not limited to: ·Building simple push-button solutions from entire workflows · Integrating specific workflows ·Implementing our solutions into an existing process ·Creating support for custom file formats Find out more at thermofisher.com/amira-avizo Open and closed porosity analysis. Courtesy of Zellwerk GmbH. ndustrial applications require stronger, lighter, cleaner and safer materials every day.For new developments or for better characterization of existing materials, Thermo Scientific™ Avizo™ Software allows for a better understanding of structure, properties and performance.

关闭-

1/12

-

2/12

还剩10页未读,是否继续阅读?

继续免费阅读全文产品配置单

北京欧波同光学技术有限公司为您提供《材料研究中材料表征和质量控制的 Avizo 软件检测方案(扫描电镜)》,该方案主要用于合金中材料表征和质量控制的 Avizo 软件检测,参考标准《暂无》,《材料研究中材料表征和质量控制的 Avizo 软件检测方案(扫描电镜)》用到的仪器有Apreo 2超高分辨场发射扫描电镜、赛默飞(原FEI)Helios 5 DualBeam 双束扫描电镜、赛默飞(原FEI)Scios 2 DualBeam 双束扫描电镜、赛默飞 Talos F200X S/TEM 透射电子显微镜、宽束氩离子抛光系统Gatan 697 Ilion II、赛默飞(FEI)Axia ChemiSEM 智能型钨灯丝扫描电镜。

我要纠错

相关方案

咨询

咨询