方案详情文

智能文字提取功能测试中

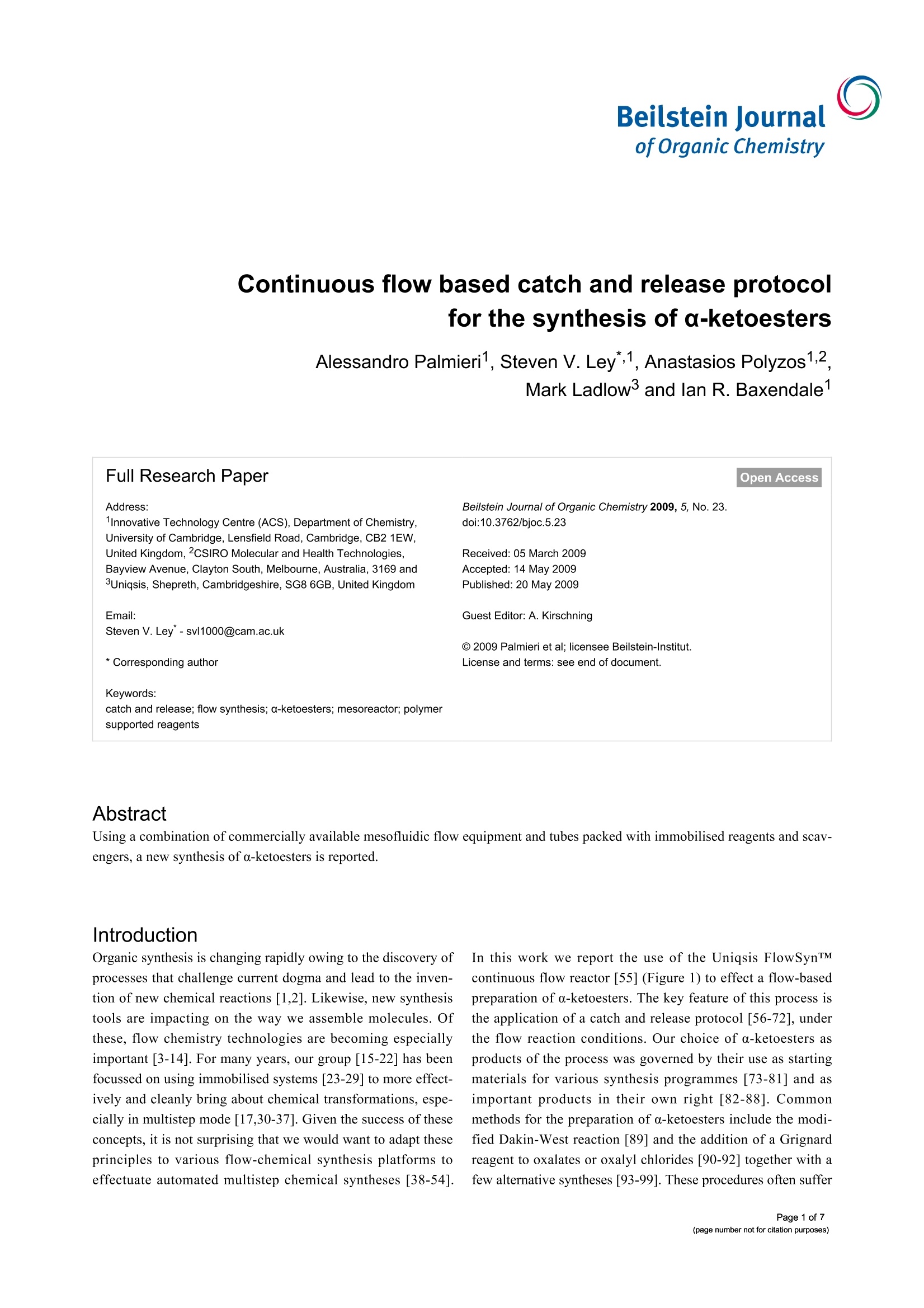

Beilstein JournalofOrganic Chemistry Beilstein Journal of Organic Chemistry 2009, 5, No. 23. Continuous flow based catch and release protocolfor the synthesis of a-ketoesters Alessandro Palmieri1, Steven V. Ley*,1, Anastasios Polyzos1.2,Mark Ladlow3 and lan R. Baxendale1 Address: Innovative Technology Centre (ACS), Department of Chemistry,University of Cambridge,Lensfield Road, Cambridge, CB2 1EW,United Kingdom, 2csIRO Molecular and Health Technologies,Bayview Avenue, Clayton South, Melbourne, Australia, 3169 andUniqsis, Shepreth, Cambridgeshire, SG8 6GB, United Kingdom Email: Steven V. Ley-svl1000@cam.ac.uk *Corresponding author Keywords: Organic synthesis is changing rapidly owing to the discovery ofprocesses that challenge current dogma and lead to the inven-tion of new chemical reactions [1,2]. Likewise, new synthesistools are impacting on the way we assemble molecules. Ofthese, flow chemistry technologies are becoming especiallyimportant [3-14]. For many years, our group [15-22] has beenfocussed on using immobilised systems [23-29] to more effect-ively and cleanly bring about chemical transformations, espe-cially in multistep mode [17,30-37]. Given the success of theseconcepts, it is not surprising that we would want to adapt theseprinciples to various flow-chemical synthesis platforms toeffectuate automated multistep chemical syntheses [38-54]. In this work we report the use of the Uniqsis FlowSynTMcontinuous flow reactor [55] (Figure 1) to effect a flow-basedpreparation of o-ketoesters. The key feature of this process isthe application of a catch and release protocol [56-72], underthe flow reaction conditions. Our choice of a-ketoesters asproducts of the process was governed by their use as startingmaterials for various synthesis programmes [73-81] and asimportant products in their own right [82-88]. Commonmethods for the preparation of a-ketoesters include the modi-fied Dakin-West reaction [89] and the addition of a Grignardreagent to oxalates or oxalyl chlorides [90-92] together with afew alternative syntheses [93-99]. These procedures often suffer Figure 1: The Uniqsis FlowSynTM continuous flow reactor comprising of a column holder and heating unit (A) and the reactor coil (B). A detailedimage of the reactor coil is shown on the right. from drastic conditions, restricted selectivity and poor yields.Our flow-based approach delivers a new and general method forthe preparation of a-ketoesters, which proceeds under mildconditions, with good functional group tolerability and gener-ates products in high purity. Results and Discussion The experimental set up for these transformations involves theuse of the Uniqsis FlowSynTM device [55]. The fully integratedinstrument employs a dual channel flow system, with eachchannel independently driven by a variable high-pressure pistonpump. The starting materials and reagents are dispensed fromsample loops (0.5-10 mL) and are united in a T-mixing pieceand then passed into either a coil or column reactor (Figure 1).The column reactor utilises adjustable glass columns with vari-able internal diameter (1-1.5 cm) and range in volume from6-83 mL (unpacked). The coil reactors are made from a selec-tion of materials including PTFE, PEEK, stainless steel orHastelloy@ and accommodate volumes from 2-20 mL. Thecolumn reactor (Figure 1, A) can be heated up to 150 °C and thecoil heater (Figure 1, B) up to 260C, over a range of flow ratesbetween 0.01-20 mL/min, and can be configured for multistepor parallel operation. Exiting products can be collected asaliquots using an automated fraction collector for reactionoptimisation or as a bulk sample for scale-up. In addition, product purification can be achieved as part of the overall flowprocess by in-line solid phase extraction (SPE) or alternativelyby diverting the flow stream into an attached HPLC system[100]. A series of preliminary experiments was carried out on the flowequipment to profile the reaction in terms of optimum reactiontemperature, concentration, residence time, solvent and stoi-chiometry. Following rapid screening of conditions, we fixedupon a set of reaction parameters for efficient synthesis ofa-ketoesters (Scheme 1). The overall reaction process proceedsin the flow apparatus via nitroolefinic esters 1 as substrateswhich are captured onto a benzylamine polymer 2 (Quad-raPureTM QP-BZA polymer, loading 5.5 mmol/g, 4 equiv) togive 3 to effect product clean-up. In this way the immobilisedspecies 3 can be washed and any solution phase impurities(resulting from the formation of the nitroolefinic ester - seelater) are directed to waste (step 1). Next the column is treatedwith a flow stream of tetramethylguanidine (TMG; step 2) tocause elimination of nitrous acid and produce the corres-ponding enamino acid esters, which remain attached to thepolymer support. Finally, after flow-washing (step 3), the solidsupported species is hydrolysed, liberating a-ketoester product4 by flowing aqueous acetic acid (step 4) through the in-linecolumn. The overall route constitutes a new flow chemistry Scheme 1: General procedure for the flow synthesis of a-ketoester products 4a-j. example of the catch-react-and-release concept that we haveused successfully in other synthesis programmes [101-103]. The nitroolefinic esters 1 were originally formed in a separatebatch reaction from a Henry coupling of appropriate nitrocompounds with ethyl glyoxalate over AmberlystTM 21 (A21)resin to give the corresponding nitroalkanol 5 [104]. This wasfollowed by treatment of 5 with methanesulfonyl chloride(MsCl) or trifluoroacetic anhydride (TFAA) to promote thebase-catalysed dehydration, affording the nitroolefinic esters 1(Scheme 2) [105]. As we have deliberately constructed thissequence for implementation in a continuous flow process, theintermediate nitroalkanols 5 were not isolated and the nitrool-efinic esters were used without further purification. The average yield for the nitroolefins 1a-j prepared as described in Scheme2 was approximately 60% by LCMS. Impurities were readilyremoved following immobilisation of nitroolefinic esters 1 onthe QP-BZA resin. In addition, the flow synthesis of two representative compoundswas undertaken to allow for the complete generation ofa-ketoester products in flow from the starting nitroalkanes(Scheme 3). As shown in Table 1, we demonstrate that thesynthesis of the nitroolefinic esters was achieved under flowconditions in a clean and effective fashion. Moreover, thissynthesis demonstrates the first reported example of Henryreaction conducted in flow and we intend to elaborate on thisimportant transformation in future studies. R A21 NO2 0 MsCI R NO2 .OEt R OEt Et3N O2N OEt OH 5 1a-j Scheme 2: General procedure for the batch synthesis of nitroolefinic esters 1a-j. Table 1: Nitroolefinic esters 1a,c prepared under flow conditions (asdescribed in Scheme 3). Figure 2 illustrates the examples and yields of a-ketoesterproducts afforded by this new approach. While the list is notextensive, we have established that the process is tolerant ofboth aliphatic and aromatic substituted nitro-derivatives in thefirst step, and accommodates ester, acetate, acetal, nitrile andolefinic functionality in the final product. The process was reli-able over several runs and consistently afforded very cleanmaterial (≥97% by NMR). The yields while only moderate forthe overall process still equate to an average step conversion of68-78% per chemical iteration, given that the sequence is amultistep process (see Supporting Information for full experi-mental data). Conclusion In conclusion, we have demonstrated the versatility of theUniqsis FlowSynTM unit to achieve multi-step organic synthesisunder continuous flow-chemistry conditions. This was accom-plished by adapting the device to incorporate immobilisedreagents packed in flow tubes, enabling clean transformationswithout recourse to conventional product work-up or purifica-tion. The overall process delivers synthetically usefula-ketoester products in high purity from various nitroalkaneinputs and paves the way for more extended reaction sequences. Supporting Information Supporting Information File 1Supporting Information-Continuous flow based catch andrelease protocol for the synthesis of a-ketoesters[http://www.beilstein-journals.org/bjoc/content/supplementary/1860-5397-5-23-S1.doc] Acknowledgments We gratefully acknowledge financial support from the EPRSC(to I. R. Baxendale), the BP endowment (to S. V. Ley),University of Camerino and MIUR-Italy (to A. Palmieri) andCSIRO Capability Development Fund (CDF) (to A. Polyzos). References 1. Ley, S. V.; Baxendale,I. R. Nat. Rev.Drug Discovery 2002, 1,573-586.doi:10.1038/nrd871 2.Baxendale, I. R.; Hayward, J. J.;Ley, S. V.; Tranmer, G. K. ChemMedChem2007,2,768-788. doi:10.1002/cmdc.200700008 3.Baxendale, I. R.; Pitts, M. R. Chim. Oggi 2006,24(3),41-45. 4..Baxendale,I. R.;Ley,S. V. Heterogeneous Reactions. In NewAvenues to Efficient Chemical Synthesis, Emerging Technologies;Seeberger, P. H.; Blume, T., Eds.; Springer-Verlag: Berlin,Heidelberg, 2007; pp 151-185. ( 5. . Baxendale, I . R .; Hayward, J. J.;Ley, S. V.Comb. Chem. High Throughput Screening 2007,10,802-836. doi:10.2174/138620707783220374 ) 6. Baxendale,I. R.; Hayward, J. J.;Lanners, S.; Ley, S. V.; Smith, C. D.Heterogeneous Reactions. In Microreactors in Organic Synthesis andCatalysis; Wirth, T., Ed.; Wiley-VCH: Weinheim, 2008; pp84-122.Chapter 4.2. 7.Jas, G.; Kirschning, A. Chem.-Eur.J. 2003, 9, 5708-5723.doi:10.1002/chem.200305212 8. Hodge, P. Curr. Opin. Chem. Biol. 2003, 7,362-373.doi:10.1016/S1367-5931(03)00052-8 ( 9. Jahnisch, K.; Hessel,V.; Lowe, H. ; Baerns, M. Angew . Chem. 2004,116,410-451.doi:10.1002/ange.200300577Angew. Chem., Int. Ed.2004, 43, 406-446. ) ( doi:10.1002/anie.200300577. ) Figure 2: a-Ketoesters prepared and isolated yields. ( 10. K irschning, A.; Solodenko, W.; Mennecke, K . Chem.-Eur. J. 2006, 1 2, 5972-5990. doi:10.1002/chem.200600236 ) ( 11. A hmed-Omer, B.; Brandt, J. C . ; Wirth, T . Org. Biomol. Chem. 2007,5, 733-740. doi:10.1039/b615072a ) ( 12. M ason, B. P. ; Price, K. E.; Steinbacher, J. L.; B o gdan, A. R.; McQuade, D. T . Chem. Rev.2007,107,2300-2318. doi:10.1021/cr050944c ) ( 13. G ( lasnov,V. T . N.; K appe, C. O . M acromol.Rapid Commun. 2007, 28, 395-410. doi:10.1002/marc.200600665 ) ( 14. B enito-Lopez, F.;Egberink, R. J . M.; Reinhoudt, D. N.; Verboom, W. T etrahedron 2008, 64, 1 0023-10040. doi:10.1016/j.tet.2008.07.108 ) ( 15. L ey, S. V.; B axendale,I. R.; Bream, R. N.; Jackson, P. S . ;Leach, A. G.; Longbottom, D. A . ; N esi , M.; Scott, J. S.; Storer, R. I.; T aylor, S. J . J. Chem. Soc., Perkin Trans. 1 2000, 3815-4195. doi:10.1039/b006588i ) ( 16. 1 B axendale, I. R . ; Lee, A.-L.; Ley, S. V. J. Chem. So c ., Pe r kin Tra n s. 1 2002,1850-1857.doi:10. 1 039/b203388g ) ( 17. B axendale, I. R.; E rnst, M.; Krahnert, W.-R.; Ley, S. V. Synlett 2002, 1641-1644. d oi:10.1055/s-2002-34249 ) ( 18. L ey, S . V.; Baxendale, I . R . Chem. Rec. 2002,2, 377-388. doi:10.1002/tcr.10033 ) ( 19. B axendale, I. R.;Ley, S. V.; Nesi, M. ; Piutti, C. T e trahedron 2002, 58,6285-6304.doi:10.1016/S0040-4020(02)00628-2 ) ( 20. S torer, R. I.; Takemoto, T.; Jackson, P. S . ; Ley , S. V. Angew. Chem.2003,115,2625-2629.doi:10.1002/ange.200351413Angew. Chem., Int. Ed. 2003, 4 2,2521-2525. doi:10.1002/anie.200351413. ) ( 2 1 . Storer, R . I .; Takemoto, T.; Jackson,P. S . ; Brown, D . S . ; Baxendale, I. R.; Ley, S. V. Chem.-Eur. J.2004,10, 2 529-2547. doi:10.1002/chem.200305669 ) ( 22. B axendale, I. R.; Ley, S. V. I nd. Eng. Chem. Res. 2005, 44, 8588-8592.doi:10.1021/ie048822i ) ( 23. T h ompson, L. A. Curr. Opin. Chem. Biol. 2000, 4,324-337. doi:10.1016/S1367-5931(00)00096-X ) ( 24. Kobayashi, S. Curr. Opin. Chem. Biol.2000,4,338-345.doi:10.1016/S1367-5931(00)00097-1 ) ( 25. K irschning, A.; M onenschein, H.; Wittenberg, R. Chem.-Eur. J. 2 0 00, 6,4445-4450. doi:10.1002/1521-3765(20001215)6:24<4445::AID-CHEM4445>3.0.C O;2-W ) ( 26. K irschning, A .; Monenschein, H.; Wittenberg, R . Angew. Chem. 2001, 113,670-701. doi:10.1002/1521-3757(20010216)113:4<670::AID-ANGE6700>3.0.C O:2-G Angew. Chem., Int. Ed.2001, 40, 650-679.doi:10.1002/1521-3773(20010216)40:4<650::AID-ANIE6500>3.0.CO; ) ( 2-C. ) ( 27. S herrington, D. C . J. Polym. S ci., Part A: Polym. Chem. 2 001, 39,2364-2377. doi:10.1002/pola.1213 ) ( 28. H odge, P . Ind. E ng. C hem. Res. 2 0 05, 44, 8 5 42-8553. doi:10.1021/ie040285e ) ( 29. Solinas, A.; Taddei, M. Synthesis 2007,2409-2453. doi:10 . 1055/s-2007-983806 ) ( 30. B axendale, I. R.;Ley, S. V . Bioorg. Med. Ch e m. Let t . 2000, 10, 1983-1986. doi:10.1016/S0960-894X(00)00383-8 ) ( 31. Ley, S . V.; Baxendale, I. R.; B r usotti, G.; Caldarelli, M.; Massi,A.; Nesi, M. Farmaco 2002, 57,321-330. doi : 10.1016/S0014-827X(02)01210-7 ) ( 32. B axendale,I. R.; Brusotti, G.; Matsuoka, M .; Ley, S. V. .J . Chem. Soc., Perkin Trans . 1 2002, 143-154. doi:10.1039/b109482n ) ( 3 3. Baxendale, I. R.;Lee, A.-L.; Ley, S. V. Synlett2002,516-518. doi:10.1055/s-2002-20483 ) ( 34. Baxendale, I. R.; Ley, S. V.; Lumeras, W.; Nesi, M . Comb.Chem. High Throughput Screening 2002, 5, 197-199. ) ( 3 5. Baxendale, I. R.; Ley, S. V.; Sneddon, H . F. Synlett 2002, 775-777. doi:10.1055/s-2002-25333 ) ( 36. Baxendale, I. R .; Storer, R. I . ; Ley, S. V. Supported Reagents andScavengers in Multi-Step Organic Synthesis. In Polymeric Materials inOrganic Synthesis and Catalysis; Buchmeiser, M.R., Ed . ; Wiley-VCH: Weinheim, 2003; pp 53-136. d oi:10.1002/3527601856.ch2 ) ( 3 7. Baxendale, I. R.; L ey, S. V. Curr . Org . Chem. 2005, 9 , 1521-1534 doi:10.2174/138527205774370513 ) ( 3 8. B a xendale,I. R.; Deeley, J.; Griffiths-Jones, C. M.; Ley, S. V.;Saaby,S.; Tranmer, G. K. Chem. Commun. 2006,2566-2568. doi:10.1039/b600382f ) ( 39. B | aumann, M.; Baxendale, I. R. ; Ley, S. V . ; Smith, C. D.; ) Tranmer, G. K. Org. Lett. 2006, 8, 5231-5234. doi:10.1021/ol061975c ( 40. Smith, C. J . ;I g lesias-Siguenza, F. J.;Baxendale, I.R . ; Ley, S. V.Org. Biomol. Chem. 2007,5,2758-2761. doi:10.1039/b709043a ) ( 41. Smith, C. D.; Baxendale,I. R . ; Lanners, S.; H a yward, J. J.; Smith, S. C.; Ley, S. V. Org. Biomo l . Chem. 2007,5 , 1559-1561. doi:10.1039/b702995k ) ( 42. Hornung, C. H.; Mackley, M. R.; Ba x endale, I. R . ; Ley, S. V.Org. Process Res. Dev.2007,11,399-405.doi:10.1021/op700015f ) ( .43. Baumann, M.; Baxendale, I. R . ; Ley, S. V. S y nlett 2008, 2111-2114 doi:10.1055/s-2008-1078026 ) ( 44. Baumann, M.;Bax e ndale, I. R . ; L ey, S. V.;Nikbin, N.; S m ith, C. D. Org. Biomol. Chem. 2008, 6 , 1587-1593.doi:10.1039/b801634h ) ( 45. Baumann, M.; Baxendale, I. R.; Ley, S. V.; Nikbin, N.; Sm i th, C. D.;Tierney, J . P. Org. Biomol.Chem. 2008, 6,1577-1586. doi:10.1039/b801631n ) .46. Baxendale, I. R.; Ley,S. V.; Smith, C. D.; Tamborini, L.; Voica, A.-F. J. Comb. Chem. 2008, 10,851-857. doi:10.1021/cc800070a 47. Jas, G.; Kirschning, A. Chem.-Eur. J. 2003, 9,5708-5723. doi:10.1002/chem.200305212 48. Bernstein, D.; France, S.; Wolfer, J.; Lectka, T. Tetrahedron: Asymmetry 2005, 16, 3481-3483. doi:10.1016/j.tetasy.2005.09.014 49. Bonfils, F.; Cazaux, I.; Hodge, P.; Caze, C. Org. Biomol.Chem. 2006, 4, 493-497. doi:10.1039/b515241k 50. Wiles, C.;Watts, P.; Haswell, S. J. Tetrahedron Lett.2006, 47, 5261-5264. doi:10.1016/j.tetlet.2006.05.157 51. Drager, G.; Kiss, C.; Kunz, U.; Kirschning, A. Org. Biomol. Chem. 2007,5,3657-3664. doi:10.1039/b712804e 52. Burguete, M. I.; Cornejo,A.; Garcia-Verdugo, E.; Gil, M. J.; Luis, S. V.; Mayoral, J. A.; Martinez-Merino, V.; Sokolova, M. J. Org. Chem. 2007,72, 4344-4350. doi:10.1021/jo070119r 53. Solodenko, W.; Jas, G.; Kunz, U.; Kirschning, A. Synthesis 2007, 583-589. doi:10.1055/s-2007-965877 54. Odedra, A.; Geyer, K.; Gustafsson, T.; Gilmour, R.; Seeberger, P. H. Chem. Commun. 2008, 3025-3027.doi:10.1039/b803715a 55. Uniqsis web site. http://www.uniqsis.com (accessed Apr 6,2009). 56. Cohen, B. J.; Kraus, M. A.; Patchornik, A. J. Am. Chem. Soc. 1977, 99,4165-4167. doi:10.1021/ja00454a050 57. Cohen, B. J.; Kraus, M. A.; Patchornik, A. J. Am. Chem. Soc. 1981, 103,7620-7629. doi:10.1021/ja00415a034 58. Patchornik, A. In Proc. IUPAC, I. U. P. A. C., Macromol. Symp., 28th, 1982, University of Massachusetts, Amherst, July 12-16, 1982; IUPAC:Oxford, 1982; p 85. ( 59. B rown, S. D.; Armstrong, R. W . J. Am. Chem. Soc.1996, 118 , 6331-6332. doi:10.1021/ja961203j ) ( 60. H u, Y.; Baudart,S.; P o rco, J. A . , Jr. J. O rg. Chem. 1999, 64, 1049-1051.d o i:10.1021/jo981874v ) ( 6 1. S t uder, A. ; Ha d ida, S.; Ferritto, R.; Kim, S.-Y.; Jeger, P.; W ipf, P.; Curran, D. P. Science 1997,275,823-826. doi:10.1126/science.275.5301.823 ) ( .62. Flynn, D. L.; Crich , J. Z . ; Devra j , R.V.; Hockerman,S.L.; Parlow, J. J.; South, M. S.; Woodard,S. J. Am. Chem. Soc. 1997,119, 4 874-4881. doi:10.1021/ja963462e ) ( 63. Curran, D. P. Angew.Chem. 1998,110,1230-1255.doi:10.1002/(SICI)1521-3757(19980504)110:9<1230::AID-ANGE1230 >3.0.CO;2-Y Angew. Chem., I n t. Ed. 1 998,37, 11 7 4-1196.doi:10.1002/(SICI)1521-3773(19980518)37:9<1174::AID-ANIE1174>3 .0.CO;2-P. ) ( 64. B osanac, T. ; Yang, J . ; W ilcox, C. S. Angew. Chem. 2001, 11 3 , 1927-1931. ) ( doi:10.1002/1521-3757(20010518)113:10<1927::AID-ANGE1927>3.0. CO:2-# ) ( Angew. Chem., Int. E d. 2001, 4 0,1875-1879. ) ( doi:10.1002/1521-3773(20010518)40:10<1875::AID-ANIE1875>3.0. C O;2-5. ) ( 65. Ley, S. V.; M assi, A.; R odriguez, F . ; Horwell, D. C .; Lewthwaite, R. A.; Pritchard, M. C.; Reid, A. M. Angew. Chem. 2001, 113,1088-1090. doi:10.1002/1521-3757(20010316)113:6<1088::AID-ANGE10880>3.0. CO;2-# Angew. Chem., I n t. Ed. 2001, 40,1053-1055. doi:10.1002/1521-3773(20010316)40:6<1053::AID-ANIE10530>3.0.C O;2-D. ) ( 6 6. Galante, A . ; Lhoste, P.; S inou, D . Tetrahedron L e tt. 2001, 42, 5425-5427. doi:10.1016/S0040-4039(01)01055-3 ) ( 67. Y oshida, J.-i.; Itami, K. Chem. Rev. 2002, 102,3693-3716. doi:10.1021/cr0103524 ) ( . 68. Dobbs, A. P.; McGregor-Johnson, C . T e trahedron Lett. 2 002, 43, 2807-2810.doi:10.1016/S0040-4039(02)00322-2 ) ( 69. L an,P.; Porco, J. A . , Jr.; South, M. S.; Parlow, J. J. J. Comb.C h em.2003,5,660-669. doi:10.1021/cc030028h ) ( 70. S iu, J.;Baxendale, I.R.; L e wthwaite, R . A .; Ley, S.V.Org. Biomol. Chem. 2005, 3, 3140-3160. doi:10.1039/b503778f ) ( 71. C urran, D. P.; Wang, X.; Zhang, Q. J. Org. Chem. 200 5 , 70, 3716-3719. doi:10.1021/jo050116j ) ( 72. M othana, S.; Chahal,N.; V anneste, S.; Hall, D. G. J. Comb. Chem. 2007,9,193-196. doi:10.1021/cc060149s ) ( 73. A udrain,H.; Thorhauge, J.; Hazell, R. G .; Jorgensen, K. A J. Org. Chem. 2000, 65,4487-4497. doi:10.1021/jo9918596 ) ( 74. P eng, Z.-H.;Woerpel, K. A. Org. Lett. 2002,4,2945-2948. doi:10.1021/ol026343e ) ( 75. Y u,S.; Saenz, J.; Srirangam, J. K . J . Org. Chem. 2002, 67, 1699-1702. doi:10.1021/jo016131f ) ( 76. G riesbeck, A. G . ; Bondock, S.; Lex, J. O r g. Biomol. Chem. 2004, 2, 1113-1115. doi:10.1039/b401990c ) ( 77. S un, Y.; Wan, X.; Wang, J.; Meng, Q.; Zhang,H . ; Jiang, L .; Zhang, Z Org. Lett. 2005, 7,5425-5427.doi:10.1021/ol052212c ) ( 78. Zhang, W.;Shi, M. Chem. Commun. 2006, 1218-1220. doi : 10.1039/b516467b ) ( 79. H oward,B . E. ; Woerpel, K. A . Org. Lett. 2007, 9, 4651-4653. doi : 10.1021/ol702148x ) ( 80. K ratzer, R.; Nidetzky , B. Chem. Commun. 2007,1047-1049. doi:10.1039/b616475g ) ( 81. N t aganda, R.; Milovic, T.; Tiburcio, J.; T h adani, A. N. Chem. Commun. 2008,4052-4054.doi:10.1039/b808302a ) ( 8 2. P e et, N . P . ; Burkhart, J. P .; Angelastro, M . R.; G iroux, E. L .;Mehdi, S.; Bey, P . ; Kolb, M . ; Neises, B.; Schirlin, D. J. M ed. C h em.1990, 33,394-407.doi:10.1021/jm00163a063 ) ( 83. P a tel, D. V . ; Rielly-Gauvin, K.; R y ono, D. E. ; Free, C. A.; Smith, S. A.; Petrillo, E. W., Jr. J.Med.Chem. 1993,36, 2 431-2447. doi:10.1021/jm00069a001 ) ( 8 4. Li, Z .; Patil, G. S.; Golubski, Z. E.; Hori, H.; Tehrani, K.; F oreman, J. E . ;Eveleth, D. D . ; Bartus, R. T . ; P owers, J . C. J. Med. Chem. 1993,36, 3472-3480. doi:10.1021/jm00074a031 ) ( 8 5. Koutek, B. ; Prestwich, G. D.; Ho w lett, A. C.; Ch i n, S. A.; Sa l ehani, D.;Akhavan,N . ;D e utsch, D. G . J. Biol. Chem . 1994, 269,22937-22940 ) ( 86. Conde-Frieboes, K.; Reynolds, L. J.; Lio, Y.- C .; Hale, M. R.; Wasserman, H. H.; D e nnis, E. A . J . Am. C hem. S o c. 1996,118,5519-5525.d o i:10.1021/ja953553w ) ( 87. Otto,H.-H.; Schirmeister, T. Chem. Rev. 1997, 97,133-172. doi:10.1021/cr950025u ) ( 88. Choe, Y.; B r inen, L . S.; P rice, M. S.;Engel, J. C.;Lange,M.; G risostomi, C.; Weston, S . G.; Pallai, P . V.; Cheng, H.; Hardy, L. W.; H artsough, D . S.; McMakin, M.; Tilton, R. F.; Baldino, C. M.;Craik, C. S. Bioorg. Med. Chem. 2 005, 1 3 ,2141-2156.doi:10.1016/j.bmc.2004.12.053 ) ( 89. Buchanan, G. L. Chem. S oc. Rev.1988, 17,91-109. doi:10.1039/cs9881700091 ) ( 90. Nimitz, J. S .; Mosher, H. S. J. O rg. Chem. 1 9 8 1, 46, 21 1 -213. doi:10.1021/jo00314a057 91. Creary, X.; Mehrsheikh-Mohammadi, M . E . J. Org. Chem. 1986, 5 1, 2664-2668. doi:10.1021/jo00364a009 ) ( . 92. B abudri, F .; Fiandanese, V.; M archese, G.; P u nzi, A. T e trahedron 1996, 52, 13513-13520.doi:10.1016/0040-4020(96)00805-8 ) ( 9 3. W asserman, H. H.; Ives, J. L . J. Or g . Chem. 1985, 5 0 ,3573-3580doi:10.1021/jo00219a025 ) ( 94. Bulman Page, P. C.; Rosenthal, S. T et r ahedron Lett. 1986, 27, 1947-1950. d oi:10.1016/S0040-4039(00)84419-6 ) 95. Sakakura,T.; Yamashita, H.; Kobayashi, T.-a.; Hayashi, T.; Tanaka, M. J. Org.Chem. 1987,52,5733-5740. doi:10.1021/jo00235a017 96. Wong, M.-K.; Yu, C.-W.; Yuen, W.-H.; Yang, D.J. Org. Chem. 2001, 66,3606-3609.doi:10.1021/jo0015974 97. Li, L.-S.; Wu, Y.-L. Tetrahedron Lett. 2002, 43, 2427-2430. doi:10.1016/S0040-4039(02)00290-3 98. Ma, M.; Li, C.; Peng, L.; Xie, F.; Zhang,X.; Wang, J. Tetrahedron Lett. 2005,46,3927-3929. doi:10.1016/j.tetlet.2005.03.199 99. Shimizu,H.; Murakami, M. Chem. Commun.2007,2855-2857. doi:10.1039/b704105e 100.Baxendale, I. R.; Griffiths-Jones, C. M.; Ley, S. V.;Tranmer, G. K. Synlett 2006, 427-430.doi:10.1055/s-2006-926244 101.Baxendale, I. R.; Ley, S. V.; Smith, C. D.; Tranmer, G. K. Chem. Commun.2006,4835-4837.doi:10.1039/b612197g 102.Smith, C. D.; Baxendale,I. R.; Tranmer, G. K.; Baumann, M.; Smith, S. C.; Lewthwaite, R. A.; Ley, S. V. Org. Biomol. Chem. 2007, 5,1562-1568.doi:10.1039/b703033a 103.Griffiths-Jones, C. M.; Hopkin, M. D.; Jonsson, D.; Ley, S. V.; Tapolczay, D. J.; Vickerstaffe, E.; Ladlow, M. J. Comb. Chem. 2007, 9, 422-430.doi:10.1021/cc060152b . 104.Ballini, R.; Bosica, G.; Forconi, P. Tetrahedron 1996,52,1677-1684. doi:10.1016/0040-4020(95)00996-5 105.Ballini, R.; Fiorini, D.;Palmieri, A. Tetrahedron Lett. 2004, 45, 7027-7029. doi:10.1016/j.tetlet.2004.07.141 License and Terms This is an Open Access article under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/2.0), whichpermits unrestricted use, distribution,and reproduction inany medium, provided the original work is properly cited.The license is subject to the Beilstein Journal ofOrganicChemistry terms and conditions:(http://www.beilstein-journals.org/bjoc) The definitive version of this article is the electronic onewhich can be found at: doi:10.3762/bjoc.5.23 Page of (page number not for citation purposes)

关闭-

1/7

-

2/7

还剩5页未读,是否继续阅读?

继续免费阅读全文博盛技术(中国)有限公司为您提供《a-ketoesters中连续流动合成方法检测方案(化学合成仪)》,该方案主要用于基础有机原料中理化分析检测,参考标准《暂无》,《a-ketoesters中连续流动合成方法检测方案(化学合成仪)》用到的仪器有流动合成系统。

我要纠错

相关方案

咨询

咨询