方案详情文

智能文字提取功能测试中

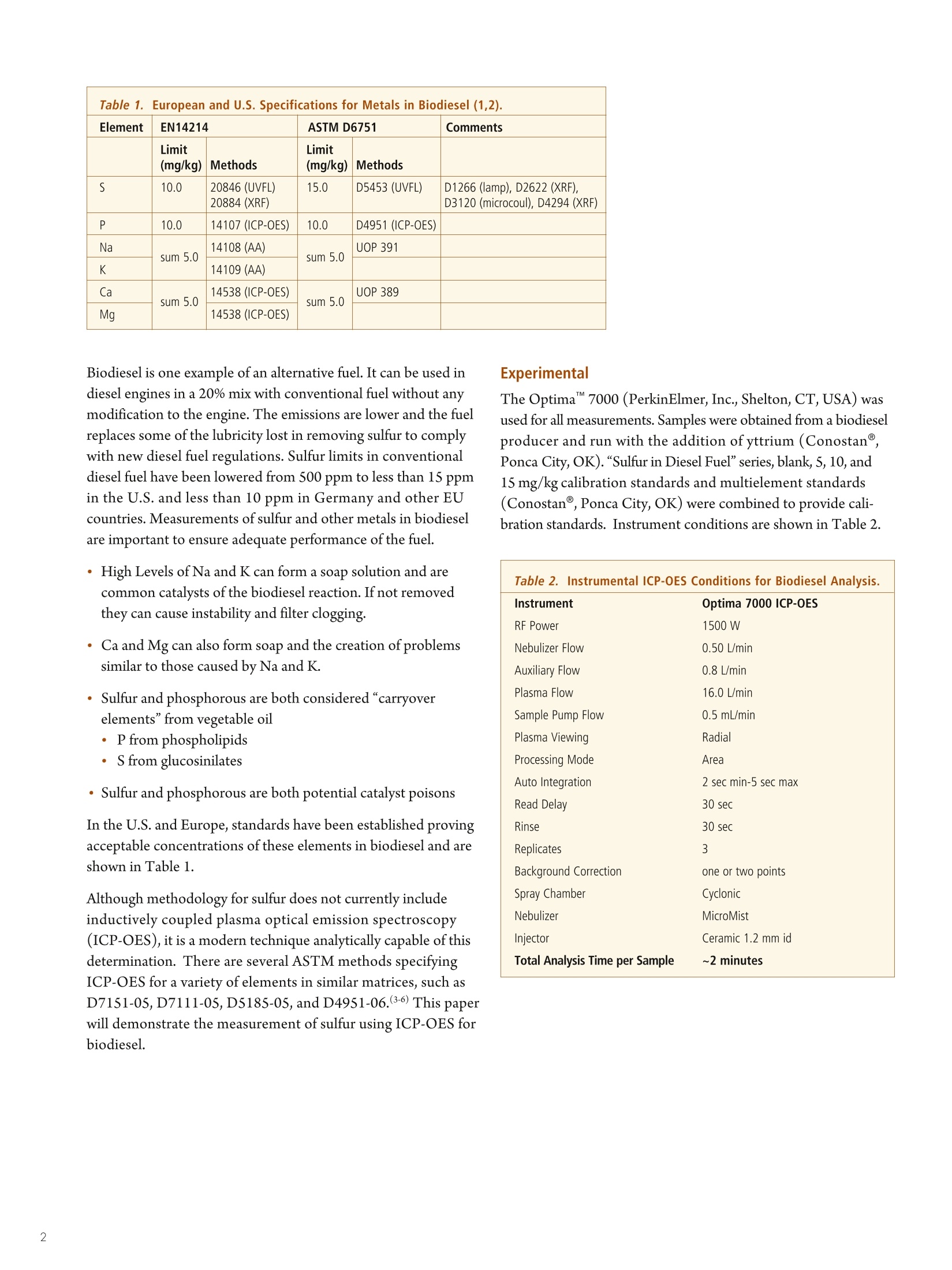

The Analysisof Biodieselfor InorganicContaminants.including Sulfur,by ICP-OES The alternative fuels market has been growing over the past fewyears and is expected to continue. Biodiesel production increasedfrom 9 million tons/year in 2007 to 11.1 milmliillonIC tons/year in 2008,an increase of almost 20%. Although the fluctuating price ofconventional petroleum-based fuel influences the rate of develop-ment and acceptance, it is generally acknowledged that petroleum-based fuel will run out. Governments around the world,such asthe U.S., Brazil, China, and India have set goals for increasedbiofuel use and research into processing of raw materials thatminimize competition with food and water is continuing. Table 1. European and U.S. Specifications for Metals in Biodiesel (1,2). Element EN14214 ASTM D6751 Comments Limit (mg/kg) Methods Limit(mg/kg) Methods S 10.0 20846 (UVFL)20884 (XRF) 15.0 D5453 (UVFL) D1266 (lamp), D2622 (XRF),D3120 (microcoul), D4294 (XRF) P 10.0 14107 (ICP-OES) 10.0 D4951 (ICP-OES) Na sum 5.0 14108 (AA) UOP 391 K 14109 (AA) sum 5.0 Ca sum 5.0 14538 (ICP-OES) sum 5.0 UOP 389 Mg 14538 (ICP-OES) Biodiesel is one example of an alternative fuel. It can be used indiesel engines in a 20% mix with conventional fuel without anymodification to the engine. The emissions are lower and the fuelreplaces some of the lubricity lost in removing sulfur to complywith new diesel fuel regulations. Sulfur limits in conventionaldiesel fuel have been lowered from 500 ppm to less than 15 ppmin the U.S. and less than 10 ppm in Germany and other EUcountries.Measurements of sulfur and other metals in biodieselare important to ensure adequate performance ofthe fuel. · High Levels of Na and K can form a soap solution and arecommon catalysts of the biodiesel reaction. If not removedthey can cause instability and filter clogging. ·Ca and Mg can also form soap and the creation of problemssimilar to those caused by Na and K. · Sulfur and phosphorous are both considered"carryoverelements" from vegetable oil· P from phospholipids· S from glucosinilates ·Sulfur and phosphorous are both potential catalyst poisons In the U.S. and Europe, standards have been established provingacceptable concentrations of these elements in biodiesel and areshown in Table 1. Although methodology for sulfur does not currently includeinductively coupled plasma optical emission spectroscopy(ICP-OES), it is a modern technique analytically capable of thisdetermination. There are several ASTM methods specifyingICP-OES for a variety of elements in similar matrices, such asD7151-0S, D7111-05, D5185-05, and D4951-06.(3-6) This paperwill demonstrate the measurement of sulfur using ICP-OES forbiodiesel. Experimental The Optima7000 (PerkinElmer, Inc., Shelton, CT, USA) wasused for all measurements. Samples were obtained from a biodieselproducer and run with the addition of yttrium (Conostan@,Ponca City, OK).“Sulfur in Diesel Fuel"series, blank, 5,10,and15 mg/kg calibration standards and multielement standardsConostan, Ponca City, OK) were combined to provide cali-bration standards. Instrument conditions are shown in Table 2. Table 2. Instrumental ICP-OES Conditions for Biodiesel Analysis. Instrument Optima 7000 ICP-OES RF Power 1500 W Nebulizer Flow 0.50 L/min Auxiliary Flow 0.8 L/min Plasma Flow 16.0 L/min Sample Pump Flow 0.5 mL/min Plasma Viewing Radial Processing Mode Area Auto Integration 2 sec min-5 sec max Read Delay 30 sec Rinse 30 sec Replicates 3 Background Correction one or two points Spray Chamber Cyclonic Nebulizer MicroMist Injector Ceramic 1.2 mm id Total Analysis Time per Sample ~2 minutes The radial mode of viewing the plasma was used for all elementsbecause of sufficient sensitivity. Because the sample is an organicliquid, little improvement in detection limit is seen using axialviewing because of the enhancement of the organic structure.Yttrium was chosen as an internal standard because it is not usuallyobserved in biodiesel samples, has a clean spectrum with nointerferences and does not interfere with the analytes of interest.Other elements, such as cobalt, may also be a suitable internalstandard element. The MicroMist nebulizer (Glass Expansion@,USA) was chosen because of the low uptake rate and excellentprecision. No overlaps are observed on the wavelength of interest and arugged location was identified for a background correction pointas shown by the small cross on the baseline at a slightly higherwavelength. Results and discussion To ensure the accuracy of the method developed, NIST 2723Sulfur in Diesel Oil, was prepared in duplicate. Table 3 showsthe results for the analysis. Two wavelengths were evaluated for determination of sulfur inbiodiesel. The wavelengths selected and the resulting profiles areshown in Figure 1 for the suite of blank and calibration standardsin the radial mode. The standard deviation and relative standard deviation of the threereplicate measurements was very good. The relative percent differ-ence between the two duplicate preparations and measurementswas 3.5% which is well below the 20% usually deemed acceptablefor environmental programs. The reference value of the standardwas recovered within the tolerance of the certified value. Although both wavelengths demonstrate a baseline free fromstructure, the S 180.669 nm wavelength is more sensitive. Thiswavelength was further evaluated for issues arising from typicalsamples of diesel and biodiesel, shown in Figure 2. Figure 1. Evaluation oftwo wavelengths for sulfur determination, 180.669 nm and 181.975 nm. Table 3. Results for Sulfur (180.669 nm) from Measurement of aNIST Standard Reference Material. Sample ID Mean (mg/kg) SD (mg/kg) %RSD RPD NIST 27231 11.3 0.10 0.89 NIST 2723 10.9 0.07 0.61 Mean of Duplicates 11.1 3.5 NIST CertifiedValue 11.0±1.1 Figure 2. Calibration standards, NIST material and samples at 180.669 nm. Several biodiesel samples from different batches were measuredin the same fashion and the results are shown in Table 4. Thestarting material for the samples is most likely soybeans, but thesampling point in the manufacturing process (whether completelycleaned) is unknown. Table 4. Biodiesel Sulfur Results. Sample ID Mean (mg/kg) SD (mg/kg) %RSD B8-10-1 17.5 0.059 0.33 B8-10-2 1.56 0.11 7.13 Lot 95081 4.9 0.096 1.95 The results show measurements for a variety of concentrations,with good precision, even at the 1.5-mg/kg concentration level.The detection limit for sulfur was measured to be 0.01 mg/kg inthe original fuel. The most efficient analysis would be to measure all necessaryelements in biodiesel samples at the same time.ICP-OES is amultielement technique, suited for this purpose and elementswere added to the existing sulfur method. After optimization thedetection limits were measured using blank oil and calculatedfor the original starting material (method detection limits).Detection limits are shown in Table 5 and show that we candetect far below the compliance limit, ensuring confidence athigher concentrations. Table 5. Method Detection Limits for Biodiesel Analysis. Element Biodiesel Detection Limit (mg/kg) S 180.669 0.01 P 178.221 0.09 Na 589.592 0.1 K 766.490 0.1 Ca 317.029 0.05 Mg 285.213 0.01 Table 6 shows the results for the entire suite of elements neces-sary to meet the U.S. and European requirements, measured in asingle run for duplicate samples. Table 6. Results for Duplicate ICP-OES Measurement of the Full Suite of Elements in Biodiesel. Element Sample 1 (mg/kg) Sample 1 Dup(mg/kg) Relative PercentDifference S 180.669 0.64 0.60 9 P 178.221 6.9 6.8 1 Na 589.592 3.0 2.7 10 K 766.490

-

1/5

-

2/5

还剩3页未读,是否继续阅读?

继续免费阅读全文产品配置单

珀金埃尔默企业管理(上海)有限公司为您提供《生物柴油中无机污染物(含硫化物)的ICP-OES分析》,该方案主要用于生物能源中null检测,参考标准《暂无》,《生物柴油中无机污染物(含硫化物)的ICP-OES分析》用到的仪器有null。

我要纠错

相关方案

咨询

咨询