方案详情文

智能文字提取功能测试中

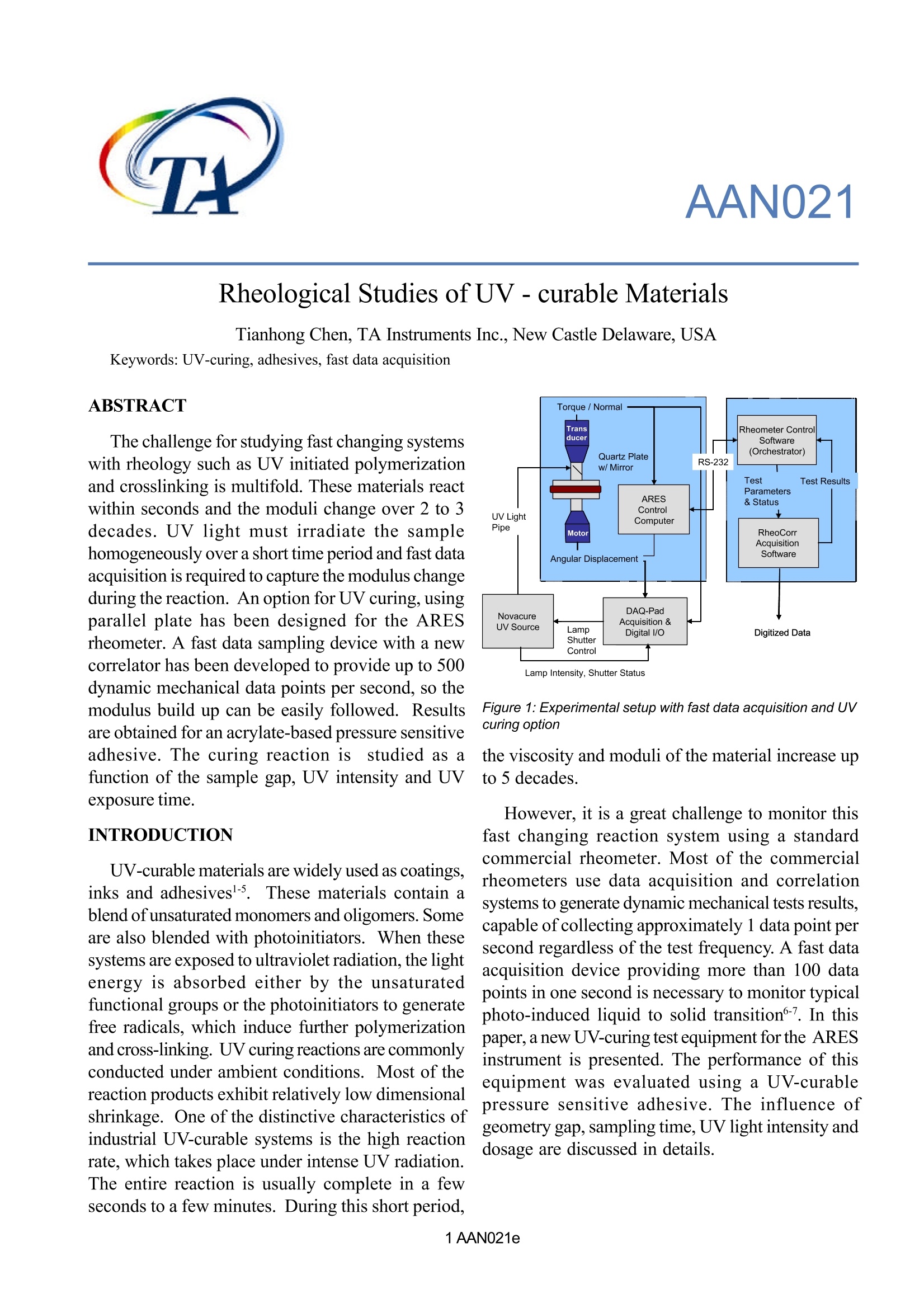

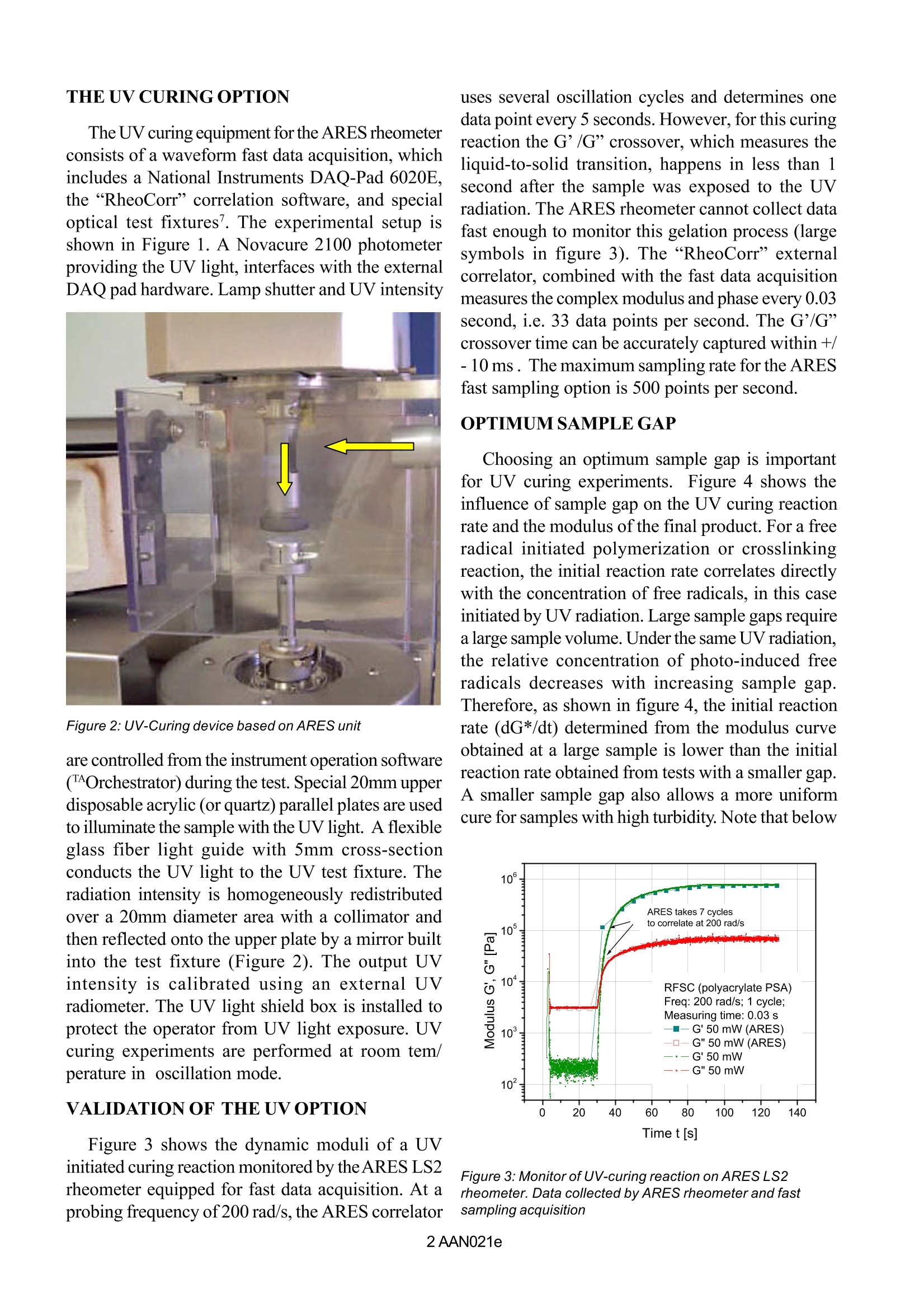

AAN021 Rheological Studies of UV - curable Materials Tianhong Chen, TA Instruments Inc., New Castle Delaware, USA ABSTRACT The challenge for studying fast changing systemswith rheology such as UV initiated polymerizationand crosslinking is multifold. These materials reactwithin seconds and the moduli change over 2 to 3decades. UV light must irradiate the samplehomogeneously over a short time period and fast dataacquisition is required to capture the modulus changeduring the reaction. An option for UV curing, usingparallel plate has been designed for the ARESrheometer. A fast data sampling device with a newcorrelator has been developed to provide up to 500dynamic mechanical data points per second, so themodulus build up can be easily followed. Resultsare obtained for an acrylate-based pressure sensitiveadhesive. The curing reaction is studied as afunction of the sample gap, UV intensity and UVexposure time. INTRODUCTION UV-curable materials are widely used as coatings,inks and adhesives1-5..T]hese materials contain ablend ofunsaturated monomers and oligomers. Someare also blended with photoinitiators. When thesesystems are exposed to ultraviolet radiation, the lightenergy is absorbed either by the unsaturatedfunctional groups or the photoinitiators to generatefree radicals, which induce further polymerizationand cross-linking. UV curing reactions are commonlyconducted under ambient conditions. Most of thereaction products exhibit relatively low dimensionalshrinkage. One of the distinctive characteristics ofindustrial UV-curable systems is the high reactionrate, which takes place under intense UV radiation.The entire reaction is usually complete in a fewseconds to a few minutes. During this short period, Figure 1:Experimental setup with fast data acquisition and UVcuring option the viscosity and moduli of the material increase upto 5 decades. However, it is a great challenge to monitor thisfast changing reaction system using a standardcommercial rheometer. Most of the commercialrheometers use data acquisition and correlationsystems to generate dynamic mechanical tests results,capable of collecting approximately 1 data point persecond regardless of the test frequency. A fast dataacquisition device providing more than 100 datapoints in one second is necessary to monitor typicalphoto-induced liquid to solid transition-7. In thispaper, a new UV-curing test equipment for the ARESinstrument is presented. The performance of thisequipment was evaluated using a UV-curablepressure sensitive adhesive. The influence ofgeometry gap, sampling time, UV light intensity anddosage are discussed in details. The UV curing equipment for the ARES rheometerconsists of a waveform fast data acquisition, whichincludes a National Instruments DAQ-Pad 6020E,the“RheoCorr”correlation software, and specialoptical test fixtures’. The experimental setup isshown in Figure 1. A Novacure 2100 photometerproviding the UV light, interfaces with the externalDAQ pad hardware. Lamp shutter and UV intensity Figure 2:UV-Curing device based on ARES unit are controlled from the instrument operation software(IAOrchestrator) during the test. Special 20mm upperdisposable acrylic (or quartz) parallel plates are usedto illuminate the sample with the UV light. A flexibleglass fiber light guide with 5mm cross-sectionconducts the UV light to the UV test fixture. Theradiation intensity is homogeneously redistributedover a 20mm diameter area with a collimator andthen reflected onto the upper plate by a mirror builtinto the test fixture (Figure 2). The output UVintensity is calibrated using an external UVradiometer. The UV light shield box is installed toprotect the operator from UV light exposure. UVcuring experiments are performed at room tem/perature in oscillation mode. VALIDATION OF THE UVOPTION Figure 3 shows the dynamic moduli of a UVinitiated curing reaction monitored by theARES LS2rheometer equipped for fast data acquisition. At aprobing frequency of 200 rad/s, the ARES correlator uses several oscillation cycles and determines onedata point every 5 seconds. However, for this curingreaction the G’/G”crossover, which measures theliquid-to-solid transition, happens in less than 1second after the sample was exposed to the UVradiation. The ARES rheometer cannot collect datafast enough to monitor this gelation process (largesymbols in figure 3). The “RheoCorr”externalcorrelator, combined with the fast data acquisitionmeasures the complex modulus and phase every 0.03second, i.e. 33 data points per second. The G’/G”crossover time can be accurately captured within +/-10 ms. The maximum sampling rate for the ARESfast sampling option is 500 points per second. OPTIMUMSAMPLE GAP Choosing an optimum sample gap is importantfor UV curing experiments. Figure 4 shows theinfluence of sample gap on the UV curing reactionrate and the modulus of the final product. For a freeradical initiated polymerization or crosslinkingreaction, the initial reaction rate correlates directlywith the concentration of free radicals, in this caseinitiated by UV radiation. Large sample gaps requirea large sample volume. Under the same UV radiation,the relative concentration of photo-induced freeradicals decreases with increasing sample gap.Therefore, as shown in figure 4, the initial reactionrate (dG*/dt) determined from the modulus curveobtained at a large sample is lower than the initialreaction rate obtained from tests with a smaller gap.A smaller sample gap also allows a more uniformcure for samples with high turbidity. Note that below Figure 3:Monitor of UV-curing reaction on ARES LS2rheometer. Data collected by ARES rheometer and fastsampling acquisition a critical gap the measured final modulus decreasesagain (see Table 1). This is an effect of the instrumentcompliance. In general a small sample gap benefits the UVcuring reaction. To avoid instrument complianceeffects, a large gap is preferred. As such the gapselection has to be a compromise and is differentfor each sample. For the specific sample used infigure 4, the optimum gap is 0.6 mm. dG*/dt [Pa/sec)] G* [Pa] 3.7×104 7.6×10° 3.6×104 9.1×10 3.2×104 9.4×10 2.6×10 9.3×10 Table 1: Effect of sample gap on the curing reaction EXPERIMENTAL An acrylate-based pressure sensitive adhesive isused in this study. The curing reaction is initiatedwithout any external photo-initiataotro.r. Dynamicrheological UV curing experiments were carried outusing a TA ARES LS2 rheometer equipped with a2KFRTN1 transducer, the waveform fast acquisition,and the UV curing option. An optical 20mmdisposable parallel plate was used as the uppergeometry. The intensity of the UV output wascalibrated using an external radiometer, insertedbetweenthe plates. Dynamic e sweepmeasurements were performed at 200 rad/s at roomtemperature with different UV light intensities. The UV light source was triggered on, 30 second afterthe test start by the software. RESULTSAND DISCUSSIONSEffect of UV intensity For UV-initiated polymerization and cross-linking, the reaction rate correlates with theconcentration of initiator: in this case the con-centration of free radicals. The number of freeradicals in the system depends on the UV radiationintensity. Figure 6 shows the influence of the UVlight intensity on the curing reaction rate. As the UVintensity increases, the initial reaction rate increases.The change of the initial modulus with time dG*/dtas a function of UV intensity follows a linearrelationship. For the same radiation dosage (dosage=intensity * exposure time) in figure 5, the complexmodulus reaches the same final value. Effect of UV dosage Figure 7 exhibits a series of cure traces for thesame adhesive as a function of UV exposure time.The results, here G’& G”show that for a UVradiation of 30mW, the adhesive does not reach themaximum modulus value after an exposure time of30 s. Since the radiation dosage represents the totalenergy applied to the sample by the UV light source,the sample did not receive enough energy to fullycomplete the cure; the final modulus G* was notobtained. Figure 8 shows the relationship betweenUV dosage and the final modulus G’of the material.To reach the maximum G’value or full cure for this Figure 5: Influence of ultra-violet light intensity to the curingreaction. Sample modulus vs reaction time at different UVintensities Figure 6: The reaction rate (dG*/dt) vs UV exposure intensity specific material a dosage of 6 Joules is required.Since the UV intensity was constant during the test,the initial rate of reaction is unaffected and the curecurves superpose during the start up. CONCLUSIONS The ARES Rheometer equipped with the fast dataacquisition and newly designed UV curing option isa powerful tool to study fast changing UV curingreactions. The fast sampling is capable of collectinga maximum of 500 data points per second. As suchit is possible to monitor fast changes of materialproperties during UV curing reactions. The testresults show high accuracy and reproducibility. TheUV curing fixtures enable uniform light intensitydistribution across the diameter of the plate. Resultsshow that the influence of the UV light intensity anddosage on the curing reaction rate and the photo- Figure 7: UV-initiated curing under 30mW intensity anddifferent exposure time Figure 8: The influence of UV exposure dosage to thematerial's final modulus induced changes in the mechanical properties canbe easily studied. REFERENCES 1. S. A. Khan, I.M.Plitz, R.A. Frantz.“In situtechnique for monitoring the gelation ofUVcurablepolymers”. Rheologica Acta, 31, 151(1992) 2. S.S. Lee, A. Luciani, JA. E.Manson.“Arheological characterization technique for fast UV-curable systems”. Progress in Organic Coatings38,193 (2000) 3. R.J.Geiger, C.A.Henderson.“UV-flexographicinks: correlation between rheology and pressperformance". Radtech Report July, 15,2001. 4. R.R.Eley.“Rheology in coating, Principles, andMethods”.Encyclopedia of Analytical Chemistry1-30,2001. 5. B.S. Chiou, S.R. Raghavan, S.A.Khan. “Effectof colloidal fillers on the cross-linking of a UV-curable polymer: gel point rheology and theWinter-Chambon Criterion”. Macromolecules.34, 13 (2001) 6. M. Grehlinger.“A technique for the rapidacquisition of rheological data, and its applicationto fast curing systems”. NATAS conferenceproceeding, 2003 7. A. Franck, M. Grehlinger.“Benefit of fast datasampling during rheological testing”, Proc. XIVthIntl. Congress on Rheology,Re 29,1, August 22-27,2004, Seoul, Korea AAN The challenge for studying fast changing systems with rheology such as UV initiated polymerization and crosslinking is multifold. These materials react within seconds and the moduli change over 2 to 3 decades. UV lights must irradiate the sample homogeneously over a short time period and fast data acquisition. An option for UV curing, using parallel plate has been designed for the ARES rheometer. A fast data sampling device with a new correlator has been developed to provide up to 500 dynamic mechanical data points per second, so the modulus build up can be easily followed. Results are obtained for an acrylate-based pressure sensitive adhesive. The curing reaction is studied as a function of the sample gap, UV intensity and UV exposure time.

关闭-

1/4

-

2/4

还剩2页未读,是否继续阅读?

继续免费阅读全文产品配置单

TA仪器为您提供《UV材料中流变检测方案(流变仪)》,该方案主要用于其他中流变检测,参考标准《暂无》,《UV材料中流变检测方案(流变仪)》用到的仪器有TA仪器ARES-G2 高级流变仪。

我要纠错

相关方案

咨询

咨询