方案详情文

智能文字提取功能测试中

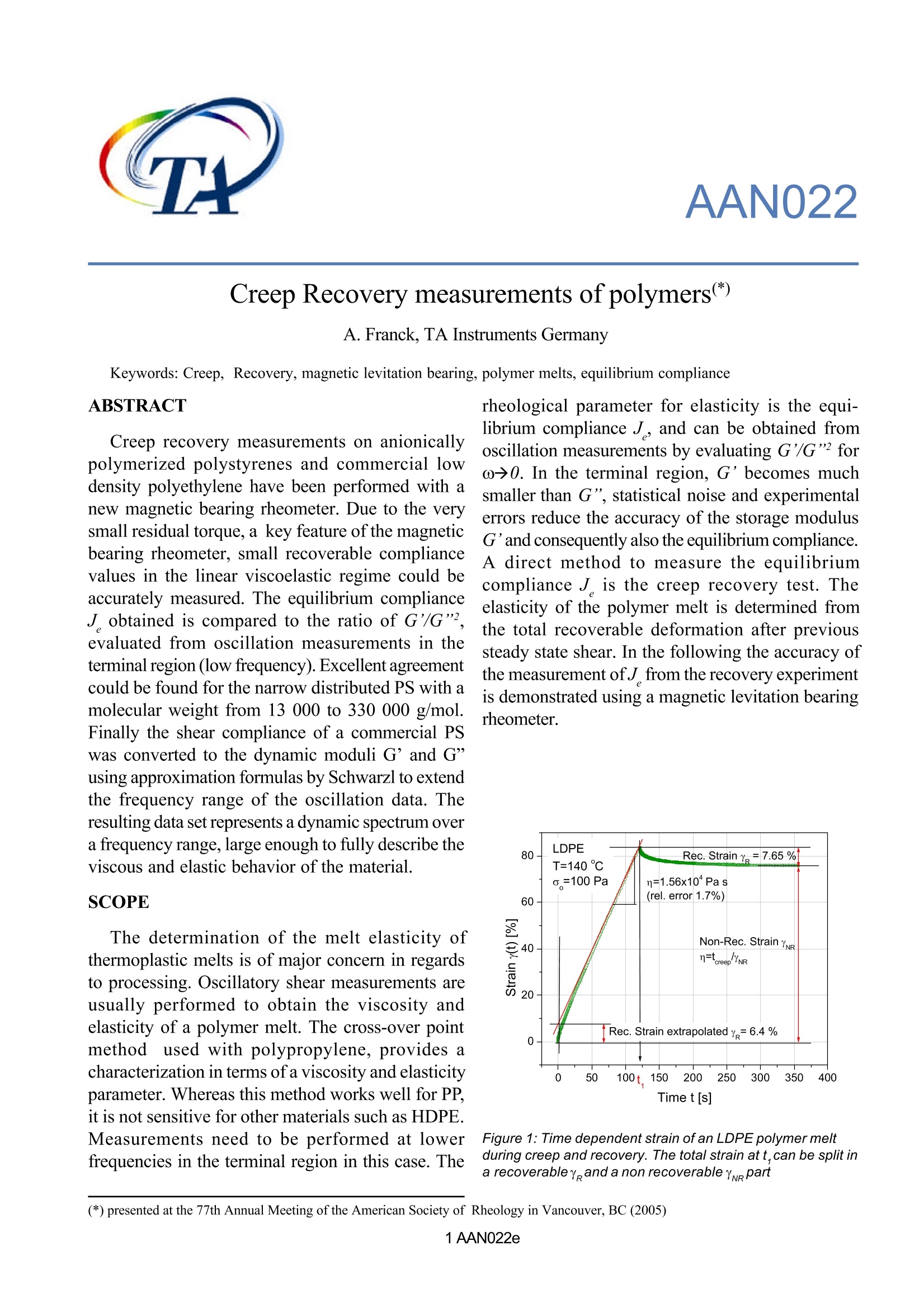

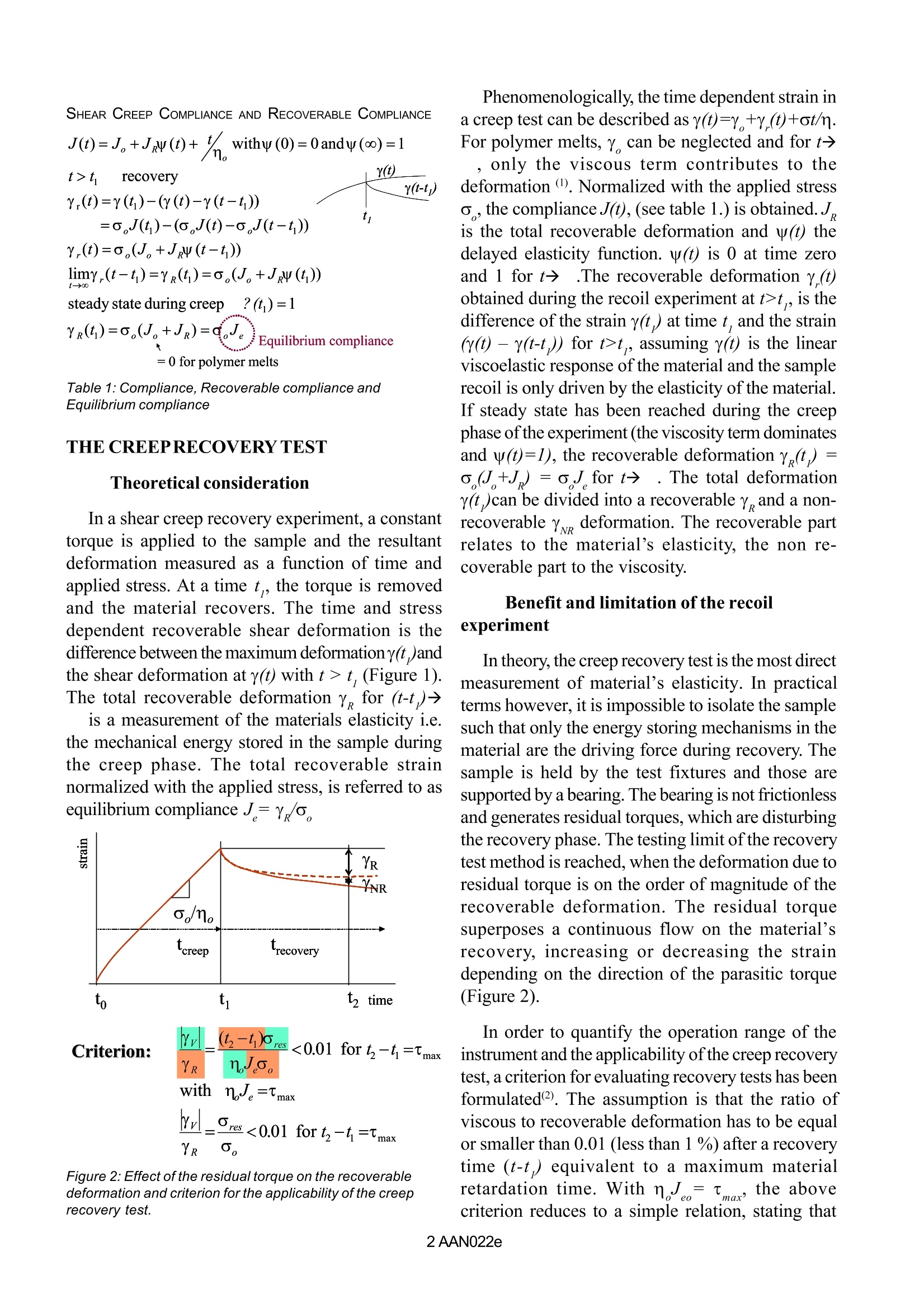

AAN022 Creep Recovery measurements of polymers(") A. Franck, TA Instruments Germany ABSTRACT Creep recovery measurements on anionicallypolymerized polystyrenes and commercial lowdensity polyethylene have been performed with anew magnetic bearing rheometer. Due to the verysmall residual torque, a key feature of the magneticbearing rheometer, small recoverable compliancevalues in the linear viscoelastic regime could beaccurately measured. The equilibrium complianceJ obtained is compared to the ratio of G/G”,evaluated from oscillation measurements in theterminal region (low frequency). Excellent agreementcould be found for the narrow distributed PS with amolecular weight from 13 000 to 330 000 g/mol.Finally the shear compliance of a commercial PSwas converted to the dynamic moduli G’and G"using approximation formulas by Schwarzl to extendthe frequency range of the oscillation data. Theresulting data set represents a dynamic spectrum overa frequency range, large enough to fully describe theviscous and elastic behavior of the material. SCOPE The determination of the melt elasticity ofthermoplastic melts is of major concern in regardsto processing. Oscillatory shear measurements areusually performed to obtain the viscosity andelasticity of a polymer melt. The cross-over pointmethod used with polypropylene, provides acharacterization in terms ofa viscosity and elasticityparameter. Whereas this method works well for PP,it is not sensitive for other materials such as HDPE.Measurements need to be performed at lowerfrequencies in the terminal region in this case. The rheological parameter for elasticity is the equi-librium compliance J, and can be obtained fromoscillation measurements by evaluating G'/G” fora→0. In the terminal region, G’becomes muchsmaller than G”, statistical noise and experimentalerrors reduce the accuracy of the storage modulusG'and consequently also the equilibrium compliance.A direct method to measure the equilibriumcompliance J is the creep recovery test. Theelasticity of the polymer melt is determined fromthe total recoverable deformation after previoussteady state shear. In the following the accuracy ofthe measurement ofJ from the recovery experimentis demonstrated using a magnetic levitation bearingrheometer. Figure 1:Time dependent strain of an LDPE polymer meltduring creep and recovery. The total strain at t, can be split ina recoverableyand a non recoverableypart SHEAR CREEP COMPLIANCE AND RECOVERABLE COMPLIANCE Table 1: Compliance, Recoverable compliance andEquilibrium compliance THE CREEPRECOVERY TEST Theoretical consideration In a shear creep recovery experiment, a constanttorque is applied to the sample and the resultantdeformation measured as a function of time andapplied stress. At a time t,, the torque is removedand the material recovers. The time and stressdependent recoverable shear deformation is thedifference between the maximum deformationy(t,)andthe shear deformation at y(t) with t> t, (Figure 1).The total recoverable deformation y, for (t-t,)→ is a measurement of the materials elasticity i.e.the mechanical energy stored in the sample duringthe creep phase. The total recoverable strainnormalized with the applied stress, is referred to asequilibrium compliance J=yo, Figure 2: Effect of the residual torque on the recoverabledeformation and criterion for the applicability of the creeprecovery test. Phenomenologically, the time dependent strain ina creep test can be described as y(t)=y +y(t)+ot/n.For polymer melts,y can be neglected and for t→, only the viscous term contributes to thedeformation (). Normalized with the applied stresso, the compliance J(t),(see table 1.) is obtained.Jis the total recoverable deformation and w(t) thedelayed elasticity function. w(t) is 0 at time zeroand 1 for t→ .The recoverable deformation y (t)obtained during the recoil experiment at t>t,, is thedifference of the strain y(t,) at time t, and the strain(Y(t) -Y(t-t,)) for t>t,,assuming y(t) is the linearviscoelastic response of the material and the samplerecoil is only driven by the elasticity of the material.If steady state has been reached during the creepphase of the experiment (the viscosity term dominatesand w(t)=1), the recoverable deformation y (t) =aJ+J)=oJfort .. The total deformationy(t,)can be divided into a recoverable y and a non-recoverable Y deformation. The recoverable partrelates to the material’s elasticity, the non re-coverable part to the viscosity. Benefit and limitation of the recoilexperiment In theory, the creep recovery test is the most directmeasurement of material's elasticity. In practicalterms however, it is impossible to isolate the samplesuch that only the energy storing mechanisms in thematerial are the driving force during recovery. Thesample is held by the test fixtures and those aresupported by a bearing. The bearing is not frictionlessand generates residual torques, which are disturbingthe recovery phase. The testing limit of the recoverytest method is reached, when the deformation due toresidual torque is on the order of magnitude of therecoverable deformation. The residual torquesuperposes a continuous flow on the material’srecovery, increasing or decreasing the straindepending on the direction of the parasitic torque(Figure 2). In order to quantify the operation range of theinstrument and the applicability of the creep recoverytest, a criterion for evaluating recovery tests has beenformulated2). The assumption is that the ratio ofviscous to recoverable deformation has to be equalor smaller than 0.01 (less than 1 %) after a recoverytime (t-t,) equivalent to a maximum materialretardation time. With n=, the abovecriterion reduces to a simple relation, stating that Figure 3: Residual torque of a typical AR-G2 bearing beforeand after mapping. the residual torque must be no grater than 0.01 timesthe torque applied during the creep phase (Figure2). Note that the equilibrium compliance can beobtained only,when the creep time is longer thanthe longest material's retardation time (w(t)=1). Therecovery test has to last double the time of the creep,so the effect of small residual torque contributionscan be measured and corrected for. For measurementswithin the linear viscoelastic region, the stress hasto be chosen such that a maximum shear of 1 is notexceeded during the creep phase. EXPERIMETAL CMT rheometer with magnetic levitationthrust bearing The creep recovery test is the native test for theCMT or stress controlled rheometers. In the earlyrheometers, a constant torque was applied duringcreep and removed during recovery in an open loop(no feedback). As such, no external forces exceptinertia and bearing friction were present. In order toimprove the operation range, in today's rheometersthe residual torque is actively compensated in aclosed loop control. The method to measure residualtorques in a bearing is referred to as“mapping”.The mapping is applied during the recovery phaseto correct for the imperfections ofthe support bearing,eliminating a substantial part of the residual torquecontributions and as such increasing the torque rangeand improving the lower torque performance. Atypical, good quality bearing generates a sinusoidalresidual torque curve, an example of which is shown in figure 3. Mapping removes this periodic variationofthe torque. The residual torque is a strong functionof the air pressure in the bearing and the imbalanceof the shaft and the test geometries. When mappingis applied, the residual torque is reduced to a valuein the order of +/- 4nN m, typical for the AR-G2rheometer featuring a magnetic levitation thrust andair supported radial bearings. Evaluation of residual torque The best approach to validate an instrument andcheck the residual torque after mapping is to run acreep recovery experiment on a low viscosityNewtonian fluid and measure the drift of the strainduring the recoil phase. Since the viscosity of thetest fluid is known, the residual torque can becalculated from the slope of the angular positionversus time (Figure 4). In the present example aresidual torque of 3.3 nN m was obtained. This is ingood agreement with what is expected from themapping results shown in figure 3. Note also that the residual is not a constant valueand varies with position, but on the average shouldnot be larger than the average residual torque aftermapping. Effect of instrument inertia At the start-up ofthe creep experiment, due to thefinite mass of the test fixture, a substantial part ofthe applied torque is used to overcome inertia. Witha constant torque applied, the equivalent stress todeform the sample is not available instantaneous,but approaches its final value exponentially, as shownin figure 5. As a consequence, the deformation rate Figure 4: Measurement of the residual torque from the drift ofthe recoverable compliance for a 12 mPa s silicone oil Figure 5: Influence of the instrument inertia on the systemresponse in the creep and recovery experiment increases slowly and the total deformation will belagging the expected strain y(t). The energy toovercome inertia is not dissipated, but stored in themomentum ofthe rotating motor shaft. When theapplied stress is removed at the end of the creeptest, the fixture momentum is dissipated by theviscous flow of the sample with time. If themomentum of the rotating mass is significant inn tcomparison to the elastic energy stored in thematerial and the energy dissipation capabilities of tthe viscous flow, the strain will continue to increaseinto the recovery zone. The measured recoverablestrain will be erroneous and the equilibrium1compliance not representative of the material'selasticity. In order to minimize the inertial effects on therecoverable strain, an inertia braking technique isused to eliminate the momentum of the rotating shaftinstantaneously at the beginning of the recoilexperiment. Since rotation speed and inertia of therotating mass are known, the momentum can becalculated and then compensated for by applying the Figure 6:Recoverable compliance for a 12 mPa s silicone oilwith and without braking full instrument torque in the opposite direction for agiven period of time (10-50 milliseconds) to stopthe motor shaft. This is demonstrated in figure 6 for 400 mPa ssilicone oil. Since a Newtonian oil has no elasticcomponent, the motor shaft is expected to stop deadimmediately at the end the creep experiment, ifbraking is enabled. Without braking, the shaftcontinues to rotate for approximately 20 strain unitsbefore stopping. Low viscous elastic fluids requireinertia braking, whereas for high viscosity polymermelts, the error on the recoverable deformation dueto inertia usually can be neglected. RESULTS FOR PE AND PS Creep recovery experiments were performed ona low density polyethylene LDPE in a stress rangefrom 10 to 5000 Pa at a temperature of 140 °C. Theduration of the recovery section did last twice thetime of the creep. For the LDPE under investigation,the total recovery is significant in comparison to thetotal deformation during creep (Figure 7). Theapplied stresses are ranging from 10 to 5000 Pa..Up to a stress of 1000 Pa, the creep compliance isindependent of the stress. At a stress of 5000 Pa, adeviation from linear behavior occurs. Deviationfrom linear behavior can be seen in the recoverablecompliance at a much lower stress of 500Pa. Therecoverable compliance is more sensitive and it isnecessary to operate at lower stress in order to staywithin the limits of the linear viscoelastic regime. Much more challenging is testing materials withsmall values of the equilibrium compliance, such asnarrow distributed polystyrene with low molecular PS 13K PS145K PS330K M.[g/mol} 13 200 145 000 330 000 M/M 1.06 1.03 1.1 T[°C] 124 170 170 Creep:noPas] 8.8x104 1.8x105 Recovery:eo[1/Pa] 2.2x10-6 1.1x10-5 1.9x10-5 Oscillation: n, [Pas] 9.05x104 2.2x10° Oscillation:J[1/Pa] 1.2x10-5 2.1x10-5 Table 2: Summary of molecular and rheological parametersfor the PS13K, PS145K and PS330K weight. Creep recovery measurements wereperformed on three narrow distributed PS and theresults compared to the properties in oscillation.Table 2 summarizes key molecular and rheologicalparameters of the three polystyrenes; PS145K and330K are samples with a MW above the entang-lement point, PS13K has an MW below theentanglementMW. Figure 8:Creep and recoverable compliance for the PS145Kat 170 °C in a stress range from 10 to 10 000 Pa. All experiments were conducted withoutexceeding a maximum strain of 1 and a recoverytime lasting at least twice the creep time. The figure8 shows the results for the PS145K with the appliedstress ranging from 10 to 10 000 Pa. The creep andrecoverable compliance are independent ofthe stresswithin the testing range. The equilibrium complianceextracted from the recovery experiment is 1.1x101/Pa. In order to verify this result, oscillationexperiments at small strain were performed atdifferent temperatures in a frequency range from 0.1to 100 rad/s . The data are represented as a mastercurve referenced to 170 C in figure 9. The elasticcomponent was determined from the ratio G/G” inthe terminal region (slope 2 for G’, slope 1 for G”)as a function of frequency and found to beapproximately 1.2x101/Pa. With ω→,G‘becomessmall compared to G”as the phase angle approaches90°. Under these conditions, G‘is noisy and the ratioof G/G”as well. A slope of 2 for G'cannot beobtained in an experimental acceptable frequency Time t [min] Figure 10: Creep and recoverable compliance for the PS330Kat 170°℃ in a stress range from 30 to 30 000 Pa. Figure 11: Mastercurve of G'and G"for the PS330K at 170℃ Figure 12: Creep and recoverable compliance for the PS13Kat 124°℃ for polymers with broader molecular weightdistribution. This fact and the uncertainty of the G'in the terminal zone are the main reasons, whyoscillation measurements are not best suited tomeasure the equilibrium compliance. The viscosity,calculated from G"/o reaches a plateau (zero shearviscosity) at higher frequency already and thereforeis experimentaly much easier accessible in anoscillation test. For the narrow distributed PS145, G'shows aslope of 2 versus frequency already at 0.3 rad/s at170℃-thus the G/G”ratio obtained at this pointcoincides very well with the result from the recoverytest at the same temperature. The same analysis has been performed with thePS330K. Whereas the creep compliance remains Figure 13:Oscillation data extended with the dynamic moduliG'and G"converted from the creep recovery results in figure independent of the stress in the range from 30 to30 000 Pa in figure 10, does the recoverablecompliance decrease above a stress of 300 Pa. Theequilibrium compliance at the low stress limit is2.1x105 1/Pa. The equilibrium compliance Jobtained from the dynamic moduli at a frequency of0.3 rad/in figure 11 is 1.9x10 1/Pa. Again goodagreement has been achieved between the creeprecovery and oscillation experiment. At lowerfrequency in figure 10, the ratio G/G” increase dueto experimental errors in the measurement ofG. The PS13K (13'000 g/mol) has a molecularweight below the entanglement molecular weight forPS and as such also very little elasticity. Therecoverable compliance determined in a recoveryexperiment (Figure 11) is found to be approximately2x1061/Pa, which is slightly higher than the literature Figure 14: Creep and recovery of ta commercial PS at170℃ values3). The reason for the discrepancies might bethe sample’s condition, as the amount of sampleavailable was limited and the preparation of a goodsample from powder difficult. Creep recovery and oscillation experimentscomplement each other. The oscillation measurementprovides the short time response of a material andthe creep recovery test the long time response,necessary to determine the equilibrium complianceJand the zero shear viscosity n. Within theframework of the linear viscoelasticity, the timedependent compliance can be converted into afrequency dependent compliance or modulus. Thishas been done and the results are shown in figure 13and 14 for a commercial PS. The compliance J(t)has been converted to G'and G"data using approxi-mation equations by Schwarzl4). The calculated dynamic moduli agree very well with the experi-mental loss and storage modulus and extend theddyynIamic spectrum to the low frequency. The valueofG'/G”(1.72x1041/Pa) determined at 2x10rad/s agrees well with the equilibrium compliance J(1.64x10-4 1/Pa), obtained from the recoveryexperiment. The combination of these two testsprovides a complete spectrum of relaxation timesfrom low to high frequency without the need toperform the less accurate and time consuming lowfrequency measurements or the scans for tempera-ture/frequency superposition. CONCLUSIONS Creep recovery measurements have beenperformed with narrow distributed polystyrenes todetermine the equilibrium compliance. The resultswere found to be in good agreement with theequilibrium compliances, calculated from thedynamic moduli G/G” at low frequency. In orderto obtain reliable compliance data in the recoveryexperiment, a magnetic levitation rheometer withminimum residual torque has been used. For the commercial PS polymers, the compliancedata obtained from the creep recovery experimentwere converted to dynamic moduli and combinedwith the experimental oscillation results. Theresulting composite curve describes the completerelaxation spectrum over a sufficient large frequencyrange to accurately extract the zero shear viscosityand the equilibrium compliance. REFERENCES 1. Leaderman, H., Smith,R.G.,J.Pol.Sci. 36, 233(1959) ( 2. F ranck, A. J. Rheol.29(6),8 3 3 (1985) ) ( 3 . Santangelo, P.G.,Roland C.M.,J.Rheol 45(2),583 (2001) ) ( 4. Schwarzl, F ., Rheol. Acta 14, 881 ( 1975) ) AAN Creep recovery measurements on anionically polymerized polystyrenes and commercial low density polyethylene have been performed with a new magnetic bearing rheometer. Due to the very small residual torque, a key feature of the magnetic bearing rheometer, small recoverable compliance values in the linear viscoelastic regime could be accurately measured. The equilibrium compliance Je obtained is compared to the ratio of G’/G’’2, evaluated from oscillation measurements in the terminal region (low frequency). Excellent agreement could be found for the narrow distributed PS with a molecular weight from 13,000 to 330,000 g/mol. Finally the shear compliance of a commercial PS was converted to the dynamic moduli G’ and G’’ using approximation formulas by Schwarzl to extend the frequency range, large enough to fully describe the viscous and elastic behavior of the material.

关闭-

1/7

-

2/7

还剩5页未读,是否继续阅读?

继续免费阅读全文产品配置单

TA仪器为您提供《高分子中高分子蠕变与回复检测方案(流变仪)》,该方案主要用于其他中高分子蠕变与回复检测,参考标准《暂无》,《高分子中高分子蠕变与回复检测方案(流变仪)》用到的仪器有TA仪器Discovery流变仪。

我要纠错

相关方案

咨询

咨询