方案详情文

智能文字提取功能测试中

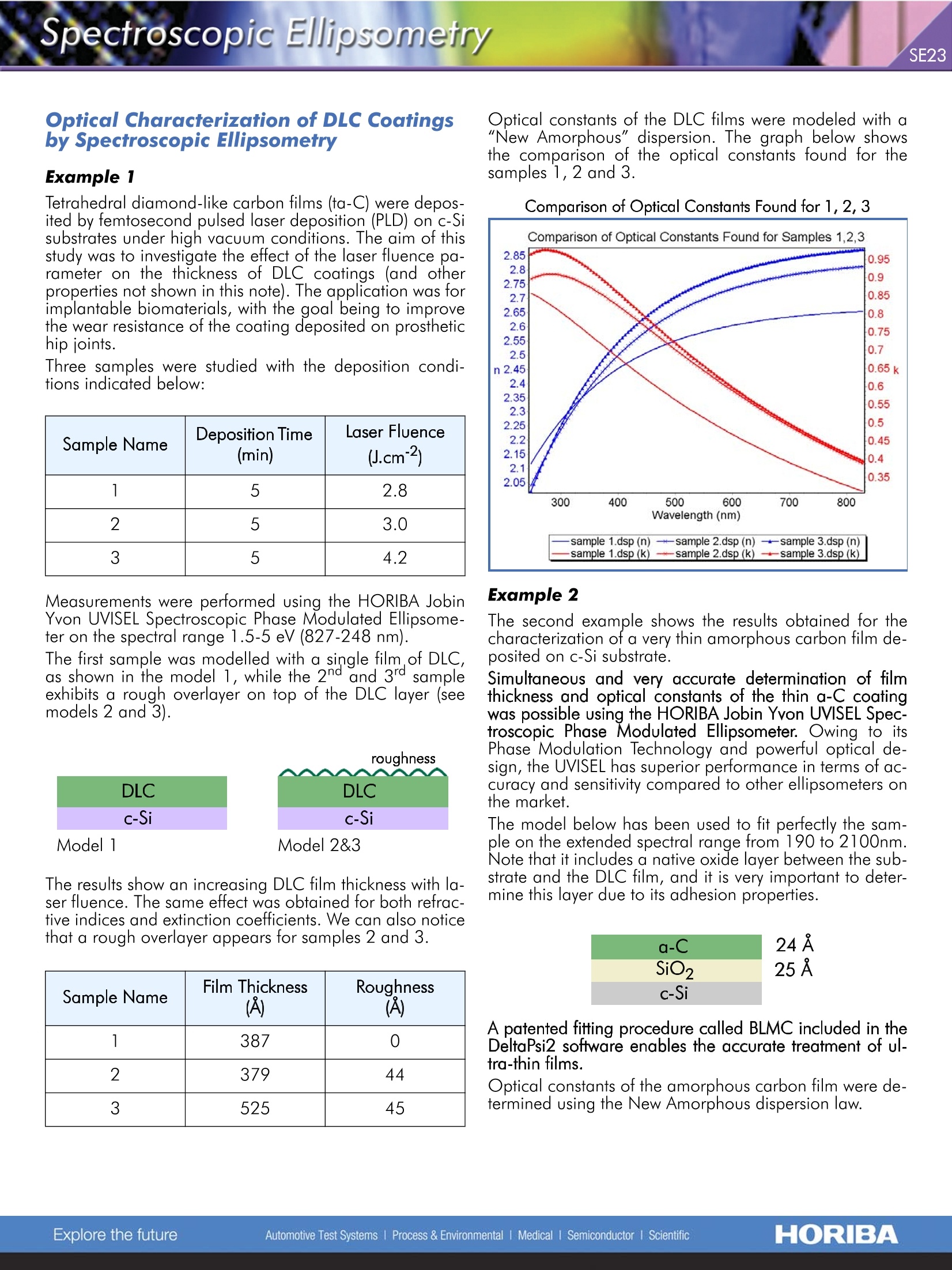

Telecommunications- BiotechnologyUVISELSpectroscopic Ellipsometry SE23Application Nofe Spectroscopic Ellipsometry Thickness and Optical Constants of Amorphous CarbonCoatings Measured by Spectroscopic Ellipsometry Celine Eypert, Melanie Gaillet, Application Scientists HORIBA Scientific Amorphous (a-C) and hydrogenated amorphous carbon (a-C:H) films have many useful physical prop-erties such as hardness, low friction, electrical insulation, chemical inertness, optical transparency, bio-logical compatibility, ability to absorb photons selectively, smoothness, and11resistance to wear. For anumber of years these technologically attractive properties have drawn tremendous interest towards thesecoatings. They are widely used to modify surfaces of materials and improve their tribological properties. Control of their layer thickness and optical constants are important properties for optimising the coatingsfor R&D and industrial purposes. The characterization of amorphous carbon coatings by spectroscopicellipsometry enables the simultaneous measurement ot these properties as welll as further informationabout surface roughness and the proportion of sp2and sp3 bonds in many cases. Furthermore the tech-nique can provide information about the adherence of the coating where an interface is found betweenthe substrate and the coating. Properties of diamond and DLC materials Carbon films with very high hardness, high resistivity anddielectric optical properties, are described as diamond-like carbon or DLC (table 1). A wide variety of objects are now being coated, rangingfrom small items, to large dies and moulds. The rapidlyexpanding uses of DLC films includes decorative/low fric-tion coatings, coating of tools for the high speed machin-ing of aluminium and copper alloys, ceramic washers inmixer taps, guides in textile processing machines, punch-es/dies, seals, cutting m9taps and many more. Most of thesuccess has been in applications tor magnetic storagemedia and optical coatings. Thin Film Bulk Property CVD dia a-C a-C:H Diamond Graphite Crystal Structure Cubica0=3.561A AmorphousMixed spand sp³bonds Amorphoussp/sp² Cubicao=3.567A Hexagonala=2.47 Form Facetedcrystals Smooth orrough Smooth Facetedcrystals Hardness (H) 3000-12000 1200-3000 900-3000 7000-10000 Density (g/cm) 2.8-3.5 1.6-2.2 1.2-2.6 3.51 2.26 Refractive Index 1.5-3.1 1.6-3.1 2.42 2.15 Electrical Resistivity (Q/cm) >1013 >1010 106-1014 >1016 0.4 Thermal Conductivity (W/m.K) 1100 - - 2000 3500 Chemical Stability Inert Inert Inert Inert Inert Hydrogen Content (H/C) - - 0.25-1 - 一- Growth Rate (um/hr) ~1 2 5 1000(Synthetic) - What is Spectroscopic Ellipsometry? Spectroscopic Ellipsometry (SE) isis an optical techniquemainly used to determine film thickness and optical con-stants (n,k) for structures composed of single layer or mul-tilayers. SE is based on the measurement of polarized light. It isnon destructive and requires no sample preparation. Thetechnique is very sensitive providing film thickness withangstrom resolution. The technique is information rich for layer stack descrip-tion and enables the determination of interface, rough-ness, film gradient, film anisotropy, etc... Main properties determined by Spectroscopic Ellipsometry*Maximal possible thickness for transparent layers O9p1tical Characterization of DLC Coatingsby Spectroscopic Ellipsometry Example 1 Tetrahedral diamond-like carbon films (ta-C) were depos-ited by femtosecond pulsed laser deposition (PLD) on c-Sisubstrates under high vacuum conditions. The aim of thisstudy was to investigate the effect of the laser fluence pa-rameter on the thickness of DLC coatings (and otherproperties not shown in this note). The application was forimplantable biomaterials, with the goal being to improvethe wear resistance of the coating deposited on prosthetichip joints. Three samples were studied with the deposition condi-tions indicated below: Sample Name Deposition Time(min) Laser Fluence(J.cm2) 1 5 2.8 5 3.0 3 5 4.2 Measurements were performed using the HORIBA JobinYvon UVISEL Spectroscopic Phase Modulated El:llipsome-ter on the spectral range 1.5-5 eV (827-248 nm). The first sample was modelled with a single film of DLC,as shown in the model 1, while the 2n and 3rsampleexhibits a rough overlayer on top of the DLC layer (seemodels 2 and 3). The results show an increasing DLC film thickness with la-ser fluence. The same effect was obtained for both retrac-tive indices and extinction coefficients. We can also noticethat a rough overlayer appears for samples 2 and 3. Sample Name Film Thickness Roughness (A 1 387 0 2 379 44 3 525 45 Optical constants of the DLC films were modeled with a"New Amorphous" dispersion. The graph below showsthe comparison of the optical constants found for thesamples 1, 2 and 3. Comparison of Optical Constants Found for 1, 2, 3 Example 2 The second example shows the results obtained for thecharacterization of a very thin amorphous carbon film de-posited on c-Si substrate. Simultaneous and very accurate determination of filmthickness and optical constants of the thin a-C coatingwas possible using the HORIBA Jobin Yvon UVISEL Spec-troscopic Phase Modulated Ellipsometer. Owing to itsPhase Modulation Technology and powerful optical de-sign, the UVISEL has superior performance in terms of ac-curacy and sensitivity compared to other ellipsometers onthe market. The model below has been used to fit perfectly the sam-ple on the extended spectral range from 190 to 2100nm.Note that it includes a native oxide layer between the sub-strate and the DLC film, and it is very important to deter-mine this layer due to its adhesion properties. tra-thin films. Optical constants of the amorphous carbon film were de-termined using the New Amorphous dispersion law. Conclusion The UVISEL Spectroscopic Ellipsometer is the ideal toolfor reliable film thickness and optical constants character-ization of amorphous carbon coatings, even in difficultcases where the film thickness is very thin. Roughness,and interface “adhesion" can also been determined. USA: +1-732 494 8660 France: +33 (0)1 64 54 13 00 Germany: +49 (0)89 462317-0 UK:+44(0) 20 8204 8142 ( J apan: + 81 ( 0 )3 3861 8231 I tal y : +3 9 0257603050 ) HORIBAExplore the futureAutomotive Test Systems Process & Environmental Medical SemiconductorScientific The UVISEL Spectroscopic Ellipsometer is the ideal tool for reliable film thickness and optical constants characterization of amorphous carbon coatings, even in difficult cases where the film thickness is very thin. Roughness, and interface “adhesion” can also been determined.

关闭-

1/3

-

2/3

还剩1页未读,是否继续阅读?

继续免费阅读全文产品配置单

HORIBA(中国)为您提供《非晶碳薄膜中厚度,光学常数检测方案(椭偏仪)》,该方案主要用于碳材料中厚度,光学常数检测,参考标准《暂无》,《非晶碳薄膜中厚度,光学常数检测方案(椭偏仪)》用到的仪器有HORIBA UVISEL Plus研究级经典型椭偏仪 。

我要纠错

推荐专场

相关方案

咨询

咨询