方案详情文

智能文字提取功能测试中

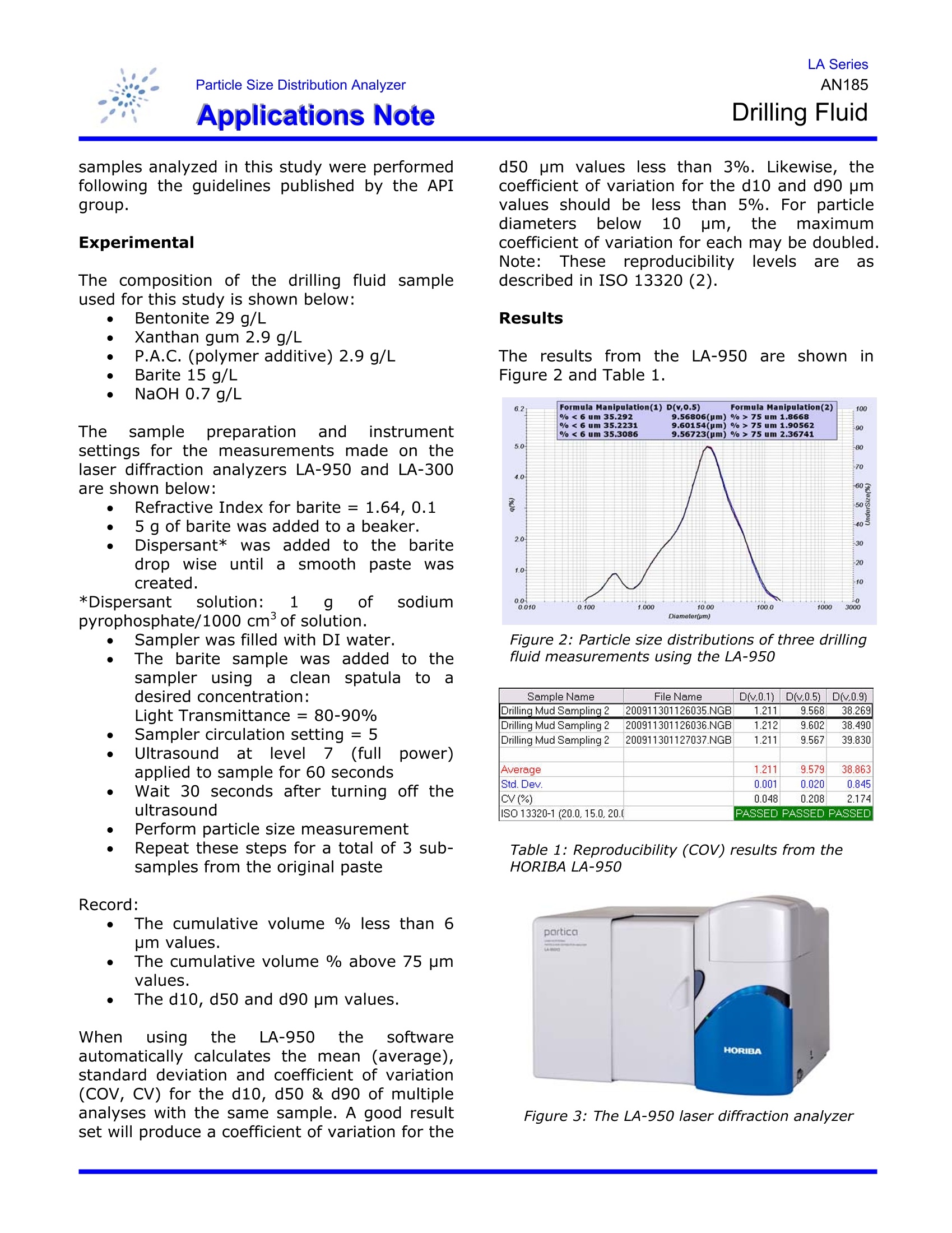

LA SeriesAN185Particle Size Distribution AnalyzerDrilling FluidApplications Note PARTICLE SIZE ANALYSIS OF DRILLING FLUID The particle size distribution of drilling fluid is an important physical parameter along withother properties such as density and rheology. Although particle size is recognized asbeing a critical parameter, older techniques such as sieving and sedimentation have longbeen used in this industry. Laser diffraction is now becoming more popular due to theincreased amount of information generated by this analysis technique which is quick andeasy to use. This application note explains why particle size distribution is critical andhowI HORIBA laser diffraction analyzers can bee used to measure the particle sizedistribution of drilling fluids. Two diffraction analyzers were used in the study, the LA-950and the more portable LA-300. Both models offer unique advantages for these samples. Drilling fluids (or muds) are often used whendrilling oil and natural gas wells. The drillingfluid is pumped from the mud pit through thedrill string and out of the nozzle of the drill bit.The fluid is continuously re-circulated wettingthe drill bit interaction with the formation andcarrying the cuttings up the annular spacebetween the drill string and hole being drilled.Drilling fluids fulfill many functions including: Remove cuttings from the well Control formation pressures Maintain wellbore stability Seal permeable formations ● Lubricate, cool, and support the drill bitand drilling assembly Typical water based drilling fluids are oftensuspensionss ofbentoniteCclay (gel)withadditives suchi as barium :sulfate i(barite),calciumn carbonate (chalk) orrhematite.Thickeners such as xanthan gum can be addedto iincrease the viscosity of the fluid. Theparticle size distribution of the solids in thedrilling fluid is an important physicalcharacteristic affecting the interaction with thewell formation and the rheological properties ofthe fluid itself. Testing the Particle Size of Drilling Fluids Onehistoricc approach for· specifying theparticle size of drilling fluids is described in ISO13500 "Petroleum and natural gas industries -Drillinigfluidmaterials-Specificationsandtests" (1). This standard includes two tests forparticle size: Figure 1: Drill bit in drilling fluid Using a 200 mesh sieve to determinethe sample residue greater than 75 pmwhere the maximum allowable massfraction is 3.0%. Measuringi particlessllessthan16umusing sedimentation where themaximumallowablemassffractionis30%. These two tests provide single point resultswithout any information on the full particle sizedistribution of the sample. Laser diffraction isani easyytouse, quickand reproducibletechnique capable of measuring the entiredistribution of particles in almost any drillingfluid., For thisreason laser diffractionisbecoming a more popular technique for drillingfluids both in the laboratory and in the field. The API, TG03 group has investigated the laserdiffraction method through committee workand round-robin tests of typical samples. The samples analyzed in this study were performedfollowing the guidelines published by the APIgroup. Experimental The composition of the drilling fluid sampleused for this study is shown below: Bentonite 29 g/L Xanthan gum 2.9 g/L P.A.C. (polymer additive) 2.9 g/L Barite 15 g/L NaOH 0.7 g/L Thesampleepreparation and instrumentsettings for the measurements made on thelaser diffraction analyzers LA-950 and LA-300are shown below: Refractive Index for barite = 1.64, 0.1 5 g of barite was added to a beaker. . Dispersant*was;added to the baritedrop wise untililaa smoothpaste wascreated. *Dispersant solution: 1 g of sodiumpyrophosphate/1000 cm’of solution. Sampler was filled with DI water. The barite sample was added to thesampler usingj a clean spatulantoadesired concentration: Light Transmittance =80-90% Sampler circulation setting = 5 Ultrasound at level 7(fullpower)applied to sample for 60 seconds Wait 30 seconds after turning off theultrasound Perform particle size measurement Repeat these steps for a total of 3 sub-samples from the original paste Record: The cumulative volume%less than 6um values. . The cumulative volume % above 75 pmvalues. The d10, d50 and d90 um values. When ising the LA-950 the softwareautomatically calculates the mean (average),standard deviation and coefficient of variation(COV, CV) for the d10, d50 & d90 of multipleanalyses with the same sample. A good resultset will produce a coefficient of variation for the d50 pm values less than 3%. Likewise, thecoefficient of variation for the d10 and d90 pmvalues should be less than 5%. For particlediameterstbelowi10um,, the maximumcoefficient of variation for each may be doubled.Note: These: reproducibility levels are asdescribed in ISO 13320(2). Results The results from the LA-950are showninFigure 2 and Table 1. 62 Formula Manipulation(1) D(v,0.5)Formula Manipulation(2)n3 %o<6 um 35.292 9.56806(pm)%>75 um1.86680/o<6 um35.2231 9.60154(pm) %/o>75 um 1.90562%<6 um 35.3086 9.56723((pm1)%/o> 75 um 2.36741 100 -90 -80 -70 .60 -50 -40 5 -30 -20 -10 Figure 2: Particle size distributions of three drillingfluid measurements using the LA-950 Sample Name File Name D(v0.1) D(v,0.5) D(v0.9) Drilling Mud Sampling 2 200911301126035.NGB 1.211 9.568 38.269 Drilling Mud Sampling 2 200911301126036.NGB 1.212 9.602 38.490 Drilling Mud Sampling 2 200911301127037.NGB 1.211 9.567 39.830 Average 1.211 9.579 38.863 Std. Dev. 0.001 0.020 0.845 CV(%) 0.048 0.208 2.174 ISO 13320-1 (20.0,15.0,20.0 Table 1: Reproducibility (COV) results from theHORIBA LA-950 Figure 3: The LA-950 laser diffraction analyzer The averaged results from the LA-300areshown in Figure 4 and Table 2. Figure 4: Averaged particle size distribution ofdrilling fluid measurements using the LA-300 Table 2: d10, d50, and d90 values from theaveraged LA-300 measurements. Figure 5: The HORIBA LA-300 laser diffractionparticle size analyzer Conclusions It was easy to perform these measurementsand achieve the desired CoV values usingeither the LA-950 or LA-300. The two systemsgave slightly different results for the samesample. This is not uncommon in the field ofparticle characterization. Two different modelssystems will not typically generate the exactsame results. The LA-950 is a newer designand is more automated. The LA-950l is theinstrument of choice in the laboratory settingwhen the broadest possible size range and capability is required. The LA-300 is a smaller,more portable system,making it the idealsystem when these measurements are made inthe field. HORIBAInstruments delivers theadvanced measurement technologies and worldwide expertise and support requiredby thedrilling fluids and exploration industries. Figure 6: Photomicrograph of drilling fluidusing the HORIBA PSA300 image analyzer References 1. ISO 13500, Petroleum and natural gasindustries - Drilling fluid materials -Specifications and tests 2. ISO 13320, Particle size analysis- Laserdiffraction methods -Part 1: Generalprinciples It was easy to perform these measurements and achieve the desired COV values using either the LA-950 or LA-300. The two systems gave slightly different results for the same sample. This is not uncommon in the field of particle characterization. Two different models systems will not typically generate the exact same results. The LA-950 is a newer design and is more automated. The LA-950 is the instrument of choice in the laboratory setting when the broadest possible size range and capability is required. The LA-300 is a smaller, more portable system, making it the ideal system when these measurements are made in the field. HORIBA Instruments delivers the advanced measurement technologies and world wide expertise and support required by the drilling fluids and exploration industries.

关闭-

1/3

-

2/3

还剩1页未读,是否继续阅读?

继续免费阅读全文产品配置单

HORIBA(中国)为您提供《钻井液中粒径大小,粒度分布,COV值检测方案(激光粒度仪)》,该方案主要用于其他中粒径大小,粒度分布,COV值检测,参考标准《暂无》,《钻井液中粒径大小,粒度分布,COV值检测方案(激光粒度仪)》用到的仪器有Partica mini LA-350-紧凑型激光粒度仪。

我要纠错

相关方案

咨询

咨询