方案详情文

智能文字提取功能测试中

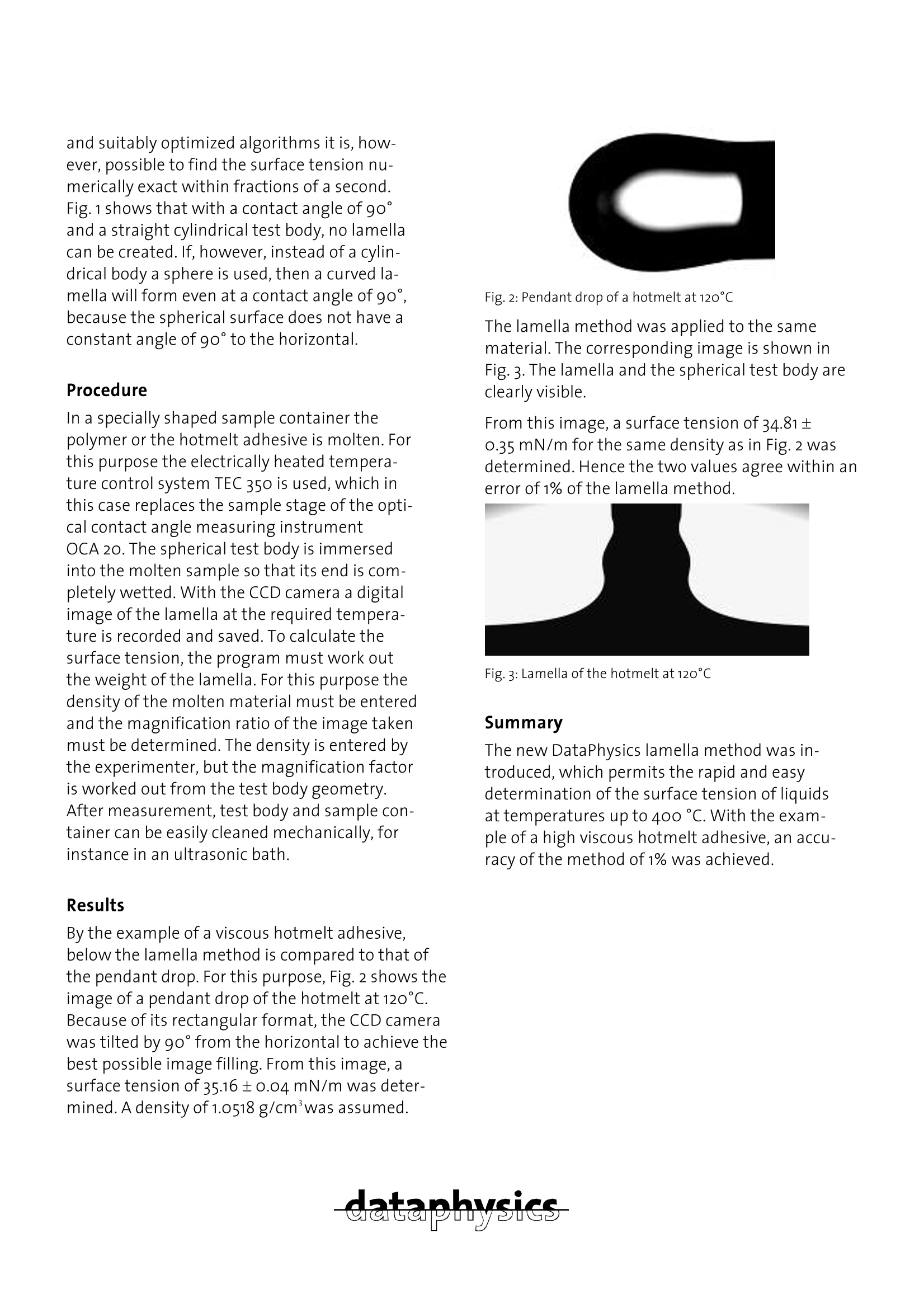

-dataphysics- DataPhysics Instruments GmbH·RaiffeisenstraBe 34· D-70794 Filderstadt phone++49 (o)711 770556-o·fax++49(o)711-770556-99 e-mail info@dataphysics.de·internet http://www.dataphysics.de Application Note 5 Surface tensions of molten polymers and hotmelts The DataPhysics lamella method, a newmethod of determining the surface tensionwith increased temperatures Problem So far,the determination of the surface tensionof molten polymers or hotmelt adhesives wasonly possible with considerable experimentalefforts. The contact lamella method introducedby DataPhysics permits a rapid, accurate meas-urement of the surface tension with a consid-erably smaller experimental expense,compared to conventional methods, even attemperatures up to 400C. Traditional methods of determining the sur-face tension with gravimetric tensiometers aremostly limited to a temperature range up tomax.10o°C. In suitable temperature controlsystems, the contour analysis of pendant drops(Pendant Drop Method) is also possible athigher temperatures.The problem here is thehandling of highly viscous molten polymers.The dosing with heated syringes is trouble-some, and especiallythe cleaning is difficultand takes a lot of time. Moreover problems areoften caused by the formation of gas bubblesin the syringe, which make the dosing of dropsof a defined size difficult or even impossible.The newly developed lamella method avoidsthese difficulties, because only easy to cleancomponents come into contact with the mol-ten polymer, and the sample container is openso that no gas bubbles can be trapped. Method Like the method of the pendant drop,the la-mella method is based on the equilibrium be-tween the weight and the surface tension. Fig.1shows schematically a liquid lamella, which willdevelop when a vertical test body is broughtinto contact with a liquid. With contact anglesbetween o° and 9o° the lamella is curved up-wards, whereas it is curved downwards forcontact angles between 9o°and 18o°. If thecontact angle is exactly 9o°, there is no curva-ture of the liquid surface. Fig. 1. Schematic illustration of the formation of a lamella The lamella develops from the effort of theliquid to wet the test body. In this process theeffect of the surface tension ensures that thenewly created surface is kept as small as possi-ble. At the same time, the weight tries tominimize the volume of a rising lamella.Atequilibrium, the effects of surface tension andweight just counterbalance each other. Whenthe weight is known, the surface te1:..:nsion of theliquid can be calculated from the exact knowl-edge of the lamella contour. The equation ofthe state of equilibrium forming the base ofthe calculation is the Young-Laplace differen-tial equation for which there is no closed ana-lytical solution under these boundaryconditions. With recent, high-speed PC systems and suitably optimized algorithms it is, how-ancever, possible to find the surface tension nu-merically exact within fractions of a second.Fig.1 shows that with a contact angle of 90°and a straight cylindrical test body, no lamellacan be created. If, however, instead of a cylin-drical body a sphere is used, then a curved la-mella will form even at a contact angle of 9o°,because the spherical surface does not have aconstant angle of 9o°to the horizontal. Procedure In a specially shaped sample container thepolymer or the hotmelt adhesive is molten. Forthis purpose the electrically heated tempera-ture control system TEC 350 is used, which inthis case replaces the sample stage of the opti-cal contact angle measuring instrumentOCA 20. The spherical test body is immersedinto the molten sample so that its end is com-pletely wetted. With the CCD camera a digitalimage of the lamella at the required tempera-ture is recorded and saved. To calculate thesurface tension, the program must work outthe weight of the lamella. For this purpose thedensity of the molten material must be enteredand the magnification ratio of the image takenmust be determined. The density is entered bythe experimenter, but the magnification factoris worked out from the test body geometry.After measurement, test body and sample con-tainer can be easily cleaned mechanically, forinstance in an ultrasonic bath. Results Fig. 2: Pendant drop of a hotmelt at 120℃ The lamella method was applied to the samematerial. The corresponding image is shown in Fig. 3. The lamella and the spherical test body areclearly visible. From this image, a surface tension of 34.81±0.35 mN/m for the same density as in Fig. 2 wasdetermined. Hence the two values agree within anerror of 1% of the lamella method. Fig.3 Lamella of the hotmelt at 12o℃ Summary The new DataPhysics lamella method was in-troduced,which permits the rapid and easydetermination of the surface tension of liquidsat temperatures up to 400°C. With the exam-ple of a high viscous hotmelt adhesive, an accu-racy of the method of 1% was achieved. By the example of a viscous hotmelt adhesive,below the lamella method is compared to that ofthe pendant drop. For this purpose, Fig.2 shows theimage of a pendant drop of the hotmelt at 120℃.Because of its rectangular format, the CCD camerawas tilted by 9o°from the horizontal to achieve thebest possible image filling. From this image, asurface tension of 35.16±0.04mN/m was deter-mined. A density of 1.0518 g/cm’was assumed.

关闭-

1/2

-

2/2

产品配置单

北京东方德菲仪器有限公司为您提供《不同样品中表面张力检测方案(接触角测量仪)》,该方案主要用于其他中表面张力检测,参考标准《暂无》,《不同样品中表面张力检测方案(接触角测量仪)》用到的仪器有null。

我要纠错

相关方案

咨询

咨询