方案详情文

智能文字提取功能测试中

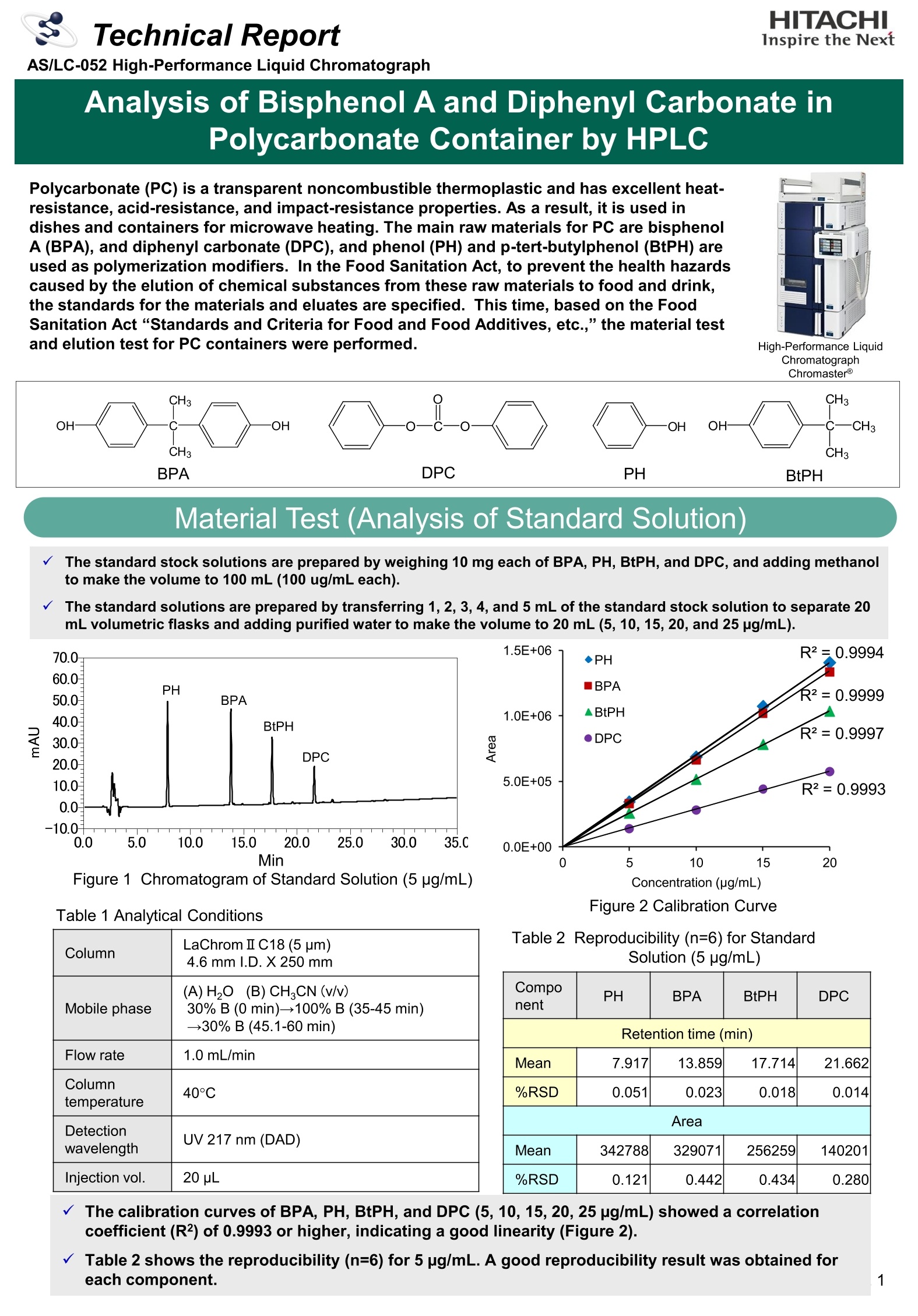

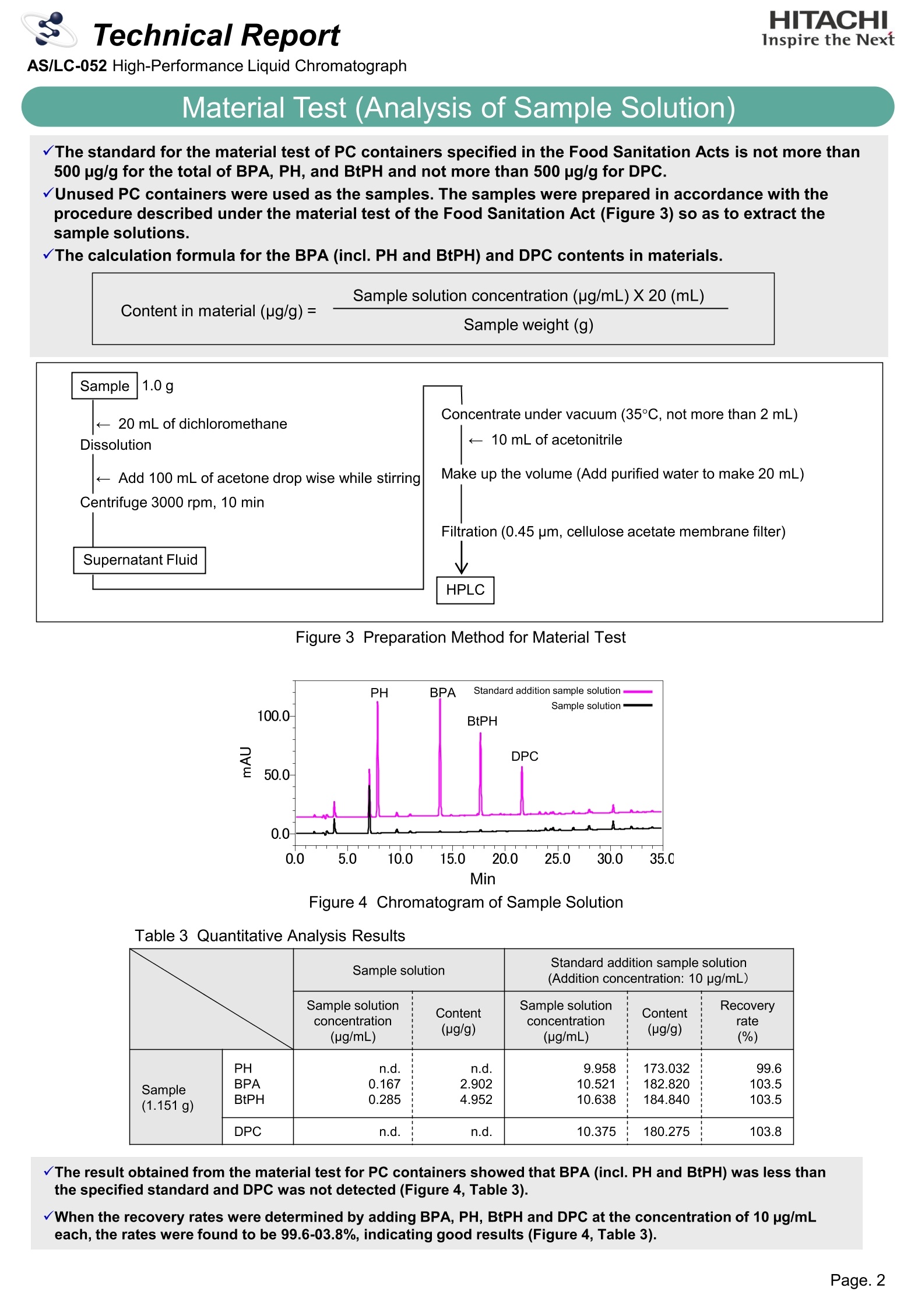

HITACHITechnical ReportInspire the NextAS/LC-052 High-Performance Liquid Chromatograph Analysis of Bisphenol A and Diphenyl Carbonate inPolycarbonate Container by HPLC Polycarbonate (PC) is a transparent noncombustible thermoplastic and has excellent heat-resistance,acid-resistance, and impact-resistance properties. As a result, it is used indishes and containers for microwave heating. The main raw materials for PC are bisphenolA (BPA), and diphenyl carbonate (DPC), and phenol (PH) and p-tert-butylphenol (BtPH) areused as polymerization modifiers. In the Food Sanitation Act, to prevent the health hazardscaused by the elution of chemical substances from these raw materials to food and drink,the standards for the materials and eluates are specified. This time, based on the FoodSanitation Act“Standards and Criteria for Food and Food Additives, etc.,” the material testand elution test for PC containers were performed. High-Performance LiquidChromatographChromaster@ Material Test (Analysis of Standard Solution) √The standard stock solutions are prepared by weighing 10 mg each of BPA, PH, BtPH,and DPC, and adding methanolto make the volume to 100 mL (100 ug/mL each). The standard solutions are prepared by transferring 1, 2, 3, 4, and 5 mL of the standard stock solution to separate 20mL volumetric flasks and adding purified water to make the volume to 20 mL (5,10, 15, 20, and 25 pg/mL). Figure 1 Chromatogram of Standard Solution (5 pg/mL) Figure 2 Calibration Curve Table 1 Analytical Conditions Column LaChromⅡC18 (5 pm)4.6 mm l.D. X250 mm Mobile phase (A) H20 (B) CH,CN (v/v) 30% B (0 min)→100%B (35-45 min) →30% B (45.1-60 min) Flow rate 1.0 mL/min Columntemperature 40°C Detectionwavelength UV 217 nm (DAD) Injection vol. 20 pL Table 2 Reproducibility (n=6) for StandardSolution (5 pg/mL) Component PH BPA BtPH DPC Retention time (min) Mean 7.917 13.859 17.714 21.662 %RSD 0.051 0.023 0.018 0.014 Area Mean 342788 329071 256259 140201 %RSD 0.121 0.442 0.434| 0.280 √The calibration curves of BPA, PH, BtPH, and DPC (5, 10, 15,20, 25 pg/mL) showed a correlationcoefficient (R) of 0.9993 or higher, indicating a good linearity (Figure 2). Table 2 shows the reproducibility (n=6) for 5 pg/mL. A good reproducibility result was obtained foreach component. Material Test (Analysis of Sample Solution) √The standard for the material test of PC containers specified in the Food Sanitation Acts is not more than500 pg/g for the total of BPA, PH, and BtPH and not more than 500 pg/g for DPC. √Unused PC containers were used as the samples. The samples were prepared in accordance with theprocedure described under the material test of the Food Sanitation Act (Figure 3) so as to extract thesample solutions. Sample solution concentration (ug/mL)X 20 (mL) Content in material (ug/g)= Sample weight (g) Figure 3 Preparation Method for Material Test Figure 4 Chromatogram of Sample Solution Table 3 Quantitative Analysis Results Sample solution Standard addition sample solution(Addition concentration: 10 pg/mL) Sample solutionconcentration(ug/mL) Content(ug/g) Sample solutionconcentration(ug/mL) Content(ug/g) Recoveryrate(%) Sample(1.151 g) PHBPABtPH n.d.0.1670.285 n.d.2.9024.952 9.95810.52110.638 173.032182.820184.840 99.6103.5103.5 DPC n.d. n.d. 10.375 180.275 103.8 √The result obtained from the material test for PC containers showed that BPA (incl. PH and BtPH) was less thanthe specified standard and DPC was not detected (Figure 4, Table 3). When the recovery rates were determined by adding BPA, PH, BtPH and DPC at the concentration of 10 pg/mLeach, the rates were found to be 99.6-03.8%, indicating good results (Figure 4, Table 3). Elution Test (Analysis of Standard Solution) The standard solutions are prepared by transferring 2 mL each of the material test standard solutions (5, 10,15, 20and 25 pg/mL) to separate 20 mL volumetric flasks and making the volume to 20 mL by adding purified water (0.5, 1,1.5, 2, 2.5 pg/mL). The target component for the elution test is BPA (incl. PH and BtPH). DPC is shown as a reference data. Figure 5 Chromatogram of Standard Solution(0.5 pg/mL) Figure 6 Absorption Spectrum of Standard Solution(0.5 ug/mL) Table 4 Reproducibility (n=6) for Standard Solution(0.5 ug/mL) Component PH BPA BtPH DPC Retention time ((min) Mean 7.952 13.886 17.736 21.682 %RSD 0.026 0.015 0.009 0.009 Area Mean 183755 161721 126865 62220 %RSD 0.342 0.421 0.379 0.255 Figure 7 Calibration Curve Table 5 Analytical Conditions Column LaChrom lI C18 (5 pm) 4.6 mm l.D. X250 mm Mobile phase (A)H,0 ((B) CH,CN (v/v) 30% B (0 min)→100% B (35-45 min) →30%B(45.1-60 min) Flow rate 1.0 mL/min Column temperature 40°C Detection wavelength UV 217 nm (DAD) Injection vol. 100 pL (200 pL sample loop was used) √Figure 6 shows the absorption spectrum of the standard solution (0.5 ug/mL). By using a diode allaydetector, the absorption spectrum of each component can be confirmed. The calibration curves for those components (0.5, 1, 1.5, 2, 2.5 pg/mL) showed correlation coefficients(R2) of 0.9996 or higher, indicating a good linearity (Figure 7) Elution Test (Analysis of Sample Solution) The standard for the elution test of PC containers specified in the Food Sanitation Acts is not more than 2.5 pg/g for the total of BPA, PH,and BtPH. The elution test was performed with reference to“lmplements or containers/packages that contact with food fats and oils or fat-rich foods." UnusedPC containers were used as the samples. For the sample preparation, the procedures of the solvent switch from heptane to acetonitrile andconcentration1) were added to the procedure conforming to the elution test described in the Food Sanitation Act (Figure 8). 1)2010 Method of Analysis in Health Science, Pharmaceutical Society of Japan, p. 622 Figure 8 Preparation Method for Elution Test Table 6 Quantitative Analysis Results Sample solution Standard addition sample solution(Addition concentration: 0.5 pg/mL) Sample solutionconcentration(pg/mL) Sample solution concentration (ug/mL) Recovery rate (%) Sample PHBPABtPH n.d.n.d.n.d. 0.4770.500 0.484 95.5100.096.8 DPC n.d. 0.505 101.0 Figure 9 Chromatogram of Sample Solution The result of the elution test for the PC containers indicated that BPH (incl. PH and BtPH) was not detected(Figure 9, Table 6). When the recovery rates were determined by adding BPA, PH, and BtPH at the concentration of 0.5 pg/mL each,good results were obtained with the rates of 95.5-100% (Figure 9, Table 6).

-

1/4

-

2/4

还剩2页未读,是否继续阅读?

继续免费阅读全文产品配置单

日立科学仪器(北京)有限公司为您提供《聚碳酸酯容器中碳酸二苯酯检测方案(液相色谱仪)》,该方案主要用于聚碳酸酯(PC)中含量分析检测,参考标准《暂无》,《聚碳酸酯容器中碳酸二苯酯检测方案(液相色谱仪)》用到的仪器有日立Chromaster高效液相色谱仪。

我要纠错

推荐专场

相关方案

咨询

咨询