方案详情文

智能文字提取功能测试中

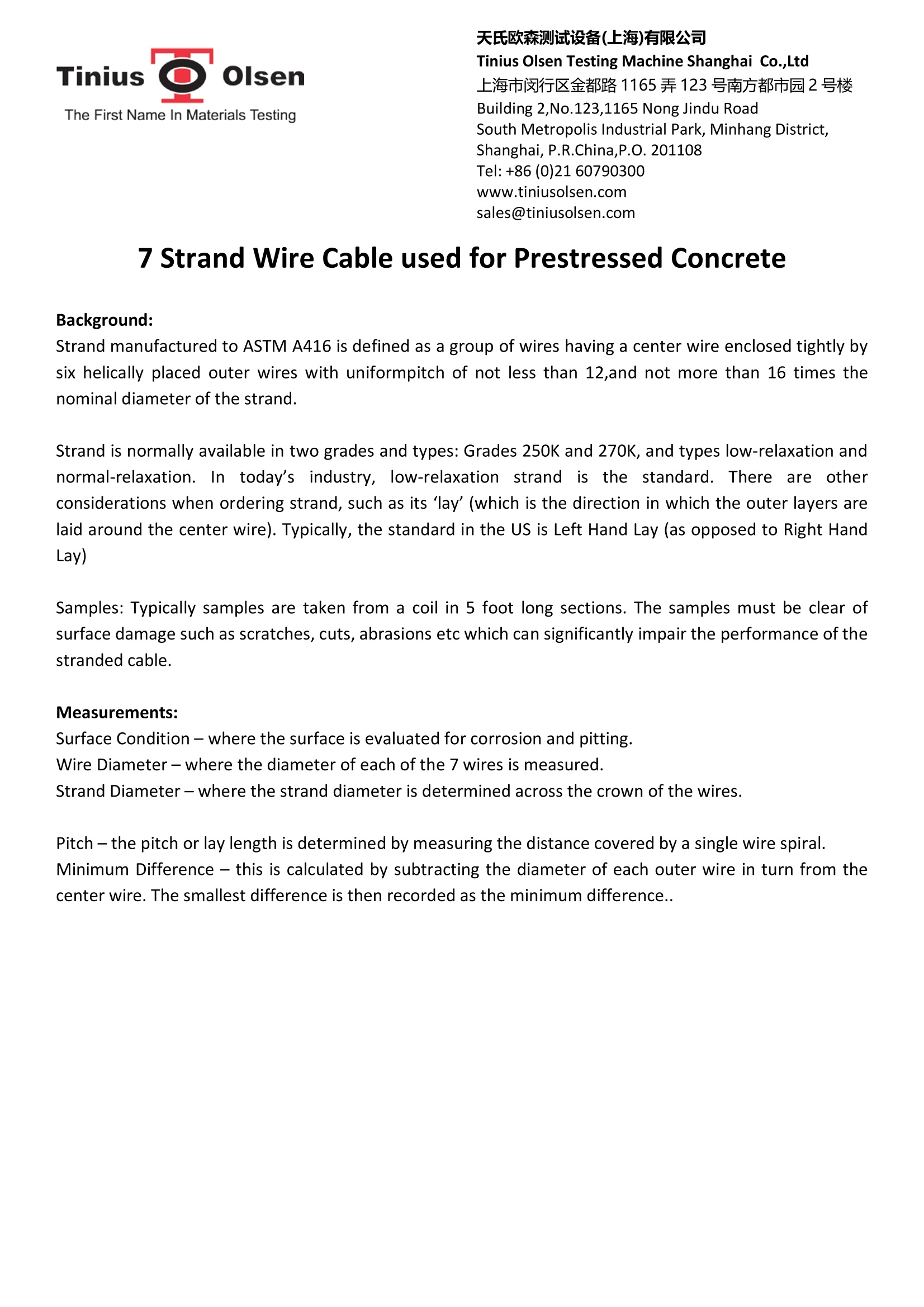

天氏欧森测试设备(上海)有限公司The First Name In Materials Testing The First Name In Materials Testing Tinius Olsen Testing Machine Shanghai Co.,Ltd 上海市闵行区金都路1165弄123号南方都市园2号楼 Building 2,No.123,1165 Nong Jindu Road South Metropolis Industrial Park, Minhang District, Shanghai, P.R.China,P.O. 201108 Tel: +86(0)21 60790300 www.tiniusolsen.com sales@tiniusolsen.com 7 Strand Wire Cable used for Prestressed Concrete Background: Strand manufactured to ASTM A416 is defined as a group of wires having a center wire enclosed tightly bysix helically placed outer wires with uniformpitch of not less than 12,and not more than 16 times thenominal diameter of the strand. Strand is normally available in two grades and types: Grades 250K and 270K, and types low-relaxation andnormal-relaxation. In today's industry, low-relaxation strand iiss the standard.There are otherconsiderations when ordering strand, such as its lay'(which is the direction in which the outer layers arelaid around the center wire).Typically, the standard in the US is Left Hand Lay (as opposed to Right HandLay) Samples: Typically samples are taken from a coil in 5 foot long sections. The samples must be clear ofsurface damage such as scratches, cuts, abrasions etc which can significantly impair the performance of thestranded cable. Measurements: Surface Condition-where the surface is evaluated for corrosion and pitting. Wire Diameter-where the diameter of each of the 7 wires is measured. Strand Diameter-where the strand diameter is determined across the crown of the wires. Pitch- the pitch or lay length is determined by measuring the distance covered by a single wire spiral.Minimum Difference - this is calculated by subtracting the diameter of each outer wire in turn from thecenter wire. The smallest difference is then recorded as the minimum difference.. 天氏欧森测试设备(上海)有限公司 Tinius Olsen Testing Machine Shanghai Co.,Ltd The First Name In Materials Testing 上海市闵行区金都路1165 弄123号南方都市园2号楼Building 2,No.123,1165 Nong Jindu RoadSouth Metropolis Industrial Park, Minhang District,Shanghai, P.R.China,P.O. 201108Tel:+86 (0)21 60790300www.tiniusolsen.com sales@tiniusolsen.com Typical Requirements of a Tensile Test Machine: Load capacity of 600kN/120,000 lbf Minimum free span test length of approx 610mm/24 inches Maximum free span test length of approx 965mm/38 inches.Open faced crossheads with hydraulically actuated grips Anti-rotational device on piston (see Fig. 2) Fig.2 Ruggedised levers Special 10inch long sample grips with replaceable inserts. 天氏欧森测试设备(上海)有限公司 Tinius Olsen Testing Machine Shanghai Co.,Ltd 上海市闵行区金都路1165弄123号南方都市园2号楼Building 2,No.123,1165 Nong Jindu RoadSouth Metropolis Industrial Park, Minhang District,Shanghai, P.R.China,P.O. 201108Tel:+86(0)21 60790300www.tiniusolsen.com sales@tiniusolsen.com Testing Procedure 1. Insert replaceable special inserts into the grip bodies. (See Fig3.). Note that these replaceable inserts aretypically made from asoft steel and are typically designed to be sacrificial. Fig.3 2. Take the sample and wet the ends (See Fig 4.) Fig.4 天氏欧森测试设备(上海)有限公司 sales@tiniusolsen.com 3.Roll the wet ends in a bath of alumina so that a paste is formed and covers the ends. This paste helpswith the adhesion of the sample in the replaceable insert. (See Fig5.) Fig.5 4.Place the sample in the grips,ensuring that there is no bowing of the sample when the grips are closed.(See Fig6. Fig.6 Tinius Olsen Testing Machine Shanghai Co.,Ltd 上海市闵行区金都路1165弄123号南方都市园2号楼 Building 2,No.123,1165 Nong Jindu RoadSouth Metropolis Industrial Park, Minhang District,Shanghai, P.R.China,P.O. 201108 Tel: +86 (0)21 60790300 www.tiniusolsen.com sales@tiniusolsen.com 5. Attach the special long gauge length (24 inch) extensometer which also has special clamps toaccommodate the shape of the cable. (See Fig 7 and Fig 8 for a close-up look at the clamps) Fig.7&8 6. Start the test. 7. Once the strain has reached 1%, the extensometer can be removed and the test allowed to continue. 8. Once the test is complete, the test sample should create what is affectionately referred to as 'a birdcage'shape. 天氏欧森测试设备(上海)有限公司 Tinius Olsen Testing Machine Shanghai Co.,Ltd The First Name In Materials Testing 上海市闵行区金都路1165 弄123号南方都市园2号楼Building 2,No.123,1165 Nong Jindu RoadSouth Metropolis Industrial Park, Minhang District,Shanghai, P.R.China,P.O. 201108Tel: +86(0)21 60790300www.tiniusolsen.com sales@tiniusolsen.com Tinius Olsen Testing Machine Shanghai Co.,Ltd 上海市闵行区金都路1165弄123号南方都市园2号楼 Tel:+86(0)21 60790300 www.tiniusolsen.com sales@tiniusolsen.com 用于预应力混凝土的七股钢绞线拉伸测试 背景: ASTM A416 所涉及的绞线定义为一组中心线被六个螺旋排列的外线紧密包围的绞线,其间距不小于12,且不会高于绞线公称直径的16倍。 绞线通常有两种等级和类型:等级250K和270K,以及低松弛和正常松弛类型。在当今的行业中,低松弛的绞线是标准。在订购绞线时,还有其他的考虑事项,比如它的“绞向”(这是中心绞线周围放置外层的方向)。通常情况下,美国的标准是左绞向(而不是右绞向)). 测量: 表面情况——表面被评估为腐蚀和凹陷。 绞线直径——测量每7根绞线的直径。 股直径——股直径是在绞线的顶部确定的。 节距——-节距或捻距是通过测量单个线螺旋所覆盖的距离来决定的。 最小差异——这是通过从中心绞线减去每根绞线的直径来计算的。最小的差异被记录为最小差异。 拉伸试验机的典型要求: 载荷能力达 600kN/120,000 lbf 最小自由跨度试验长度约610mm/24英寸 最大自由跨度试验长度约965mm/38 英寸 采用液压驱动的开放式横梁 活塞上反旋转装置(见图2) 坚固的杠杆 特殊的10英寸长度的试样夹具与可更换的插入附件。 天氏欧森测试设备(上海)有限公司 Tinius Olsen Testing Machine Shanghai Co.,Ltd 上海市闵行区金都路1165弄123号南方都市园2号楼 Building 2,No.123,1165 Nong Jindu RoadSouth Metropolis Industrial Park, Minhang District,Shanghai, P.R.China,P.O. 201108Tel:+86(0)21 60790300 www.tiniusolsen.com sales@tiniusolsen.com 测试七股钢绞线的典型机器配置图 图2.安装在测试平台上的防旋转装置,防止在绞线松开时活塞旋转。 天氏欧森测试设备(上海)有限公司 The First Name In Materials Testing Tel:+86 (0)21 60790300 www.tiniusolsen.com sales@tiniusolsen.com 测试流程 1.将可更换的特殊插入附件插入夹具内部。 (见图3)请注意,这些可替换的插入附件通常是由软钢制成的通常设计成牺牲层。 图3 2.取样品,把两端弄湿(参见图4). 图4 Tinius Olsen Testing Machine Shanghai Co.,Ltd sales@tiniusolsen.com 3.在氧化铝中把湿端卷起来,这样就形成了一层糊状物并覆盖末端。这种浆料有助于在可更换的管芯中粘附样品。(见图5) 图5 4.将试样放入夹具中,确保夹具闭合时样品不会弯曲。(见图6)。 图6 Tinius Olsen Testing Machine Shanghai Co.,Ltd www.tiniusolsen.com sales@tiniusolsen.com 5.粘附特殊的长标距(24英寸)引伸计,,它也有特殊的夹子以适应绞线的形状。(图7和图8所示) 图7图8 6、开始测试。 7、一旦应变达到1%,京就可以移除引伸计并继续进行试验。 天氏欧森测试设备(上海)有限公司 Tinius Olsen Testing Machine Shanghai Co.,Ltd 上海市闵行区金都路1165 弄123号南方都市园2号楼Building 2,No.123,1165 Nong Jindu RoadSouth Metropolis Industrial Park, Minhang District,Shanghai, P.R.China,P.O. 201108Tel: +86 (0)21 60790300www.tiniusolsen.com sales@tiniusolsen.com 8、一旦测试完成,测试试样会成为一个“鸟笼"形状。 用于预应力混凝土的七股钢绞线拉伸测试背景ASTM A416所涉及的绞线定义为一组中心线被六个螺旋排列的外线紧密包围的绞线,其间距不小于12,且不会高于绞线公称直径的16倍。绞线通常有两种等级和类型:等级250 K和270 K,以及低松弛和正常松弛类型。在当今的行业中,低松弛的绞线是标准。在订购绞线时,还有其他的考虑事项,比如它的“绞向”(这是中心绞线周围放置外层的方向)。通常情况下,美国的标准是左绞向(而不是右绞向)。 试样:通常试样从5英尺长的线圈中取出。试样必须清除表面的损坏,如刮痕、割伤、擦伤等,(这些损伤)严重损害电缆的性能。测量:表面情况——表面被评估为腐蚀和凹陷。绞线直径——测量每7根绞线的直径。股直径——股直径是在绞线的顶部确定的。节距 ——节距或捻距是通过测量单个线螺旋所覆盖的距离来决定的。最小差异——这是通过从中心绞线减去每根绞线的直径来计算的。最小的差异被记录为最小差异。拉伸试验机的典型要求:载荷能力达600kN/120,000 lbf最小自由跨度试验长度约610mm/24英寸最大自由跨度试验长度约965mm/38英寸采用液压驱动的开放式横梁活塞上反旋转装置 (见图2)坚固的杠杆特殊的10英寸长度的试样夹具与可更换的插入附件。 测试七股钢绞线的典型机器配置图图2.安装在测试平台上的防旋转装置,防止在绞线松开时活塞旋转。测试流程1.将可更换的特殊插入附件插入夹具内部。(见图3)请注意,这些可替换的插入附件通常是由软钢制成的,通常设计成牺牲层。图32. 取样品,把两端弄湿(参见图4)。图4 3.在氧化铝中把湿端卷起来,这样就形成了一层糊状物并覆盖末端。这种浆料有助于在可更换的管芯中粘附样品。(见图5)图5 4.将试样放入夹具中,确保夹具闭合时样品不会弯曲。(见图6)。图65.粘附特殊的长标距(24英寸)引伸计,它也有特殊的夹子以适应绞线的形状。(图7和图8所示)图7图86、开始测试。7、一旦应变达到1%,就可以移除引伸计并继续进行试验。8、一旦测试完成,测试试样会成为一个“鸟笼”形状。

关闭-

1/12

-

2/12

还剩10页未读,是否继续阅读?

继续免费阅读全文产品配置单

天氏欧森测试设备(上海)有限公司为您提供《七股钢绞线中拉伸试验检测方案(万能试验机)》,该方案主要用于钢材中机械性能检测,参考标准《暂无》,《七股钢绞线中拉伸试验检测方案(万能试验机)》用到的仪器有Tinius Olsen SL液压万能材料试验机。

我要纠错

相关方案

咨询

咨询