方案详情文

智能文字提取功能测试中

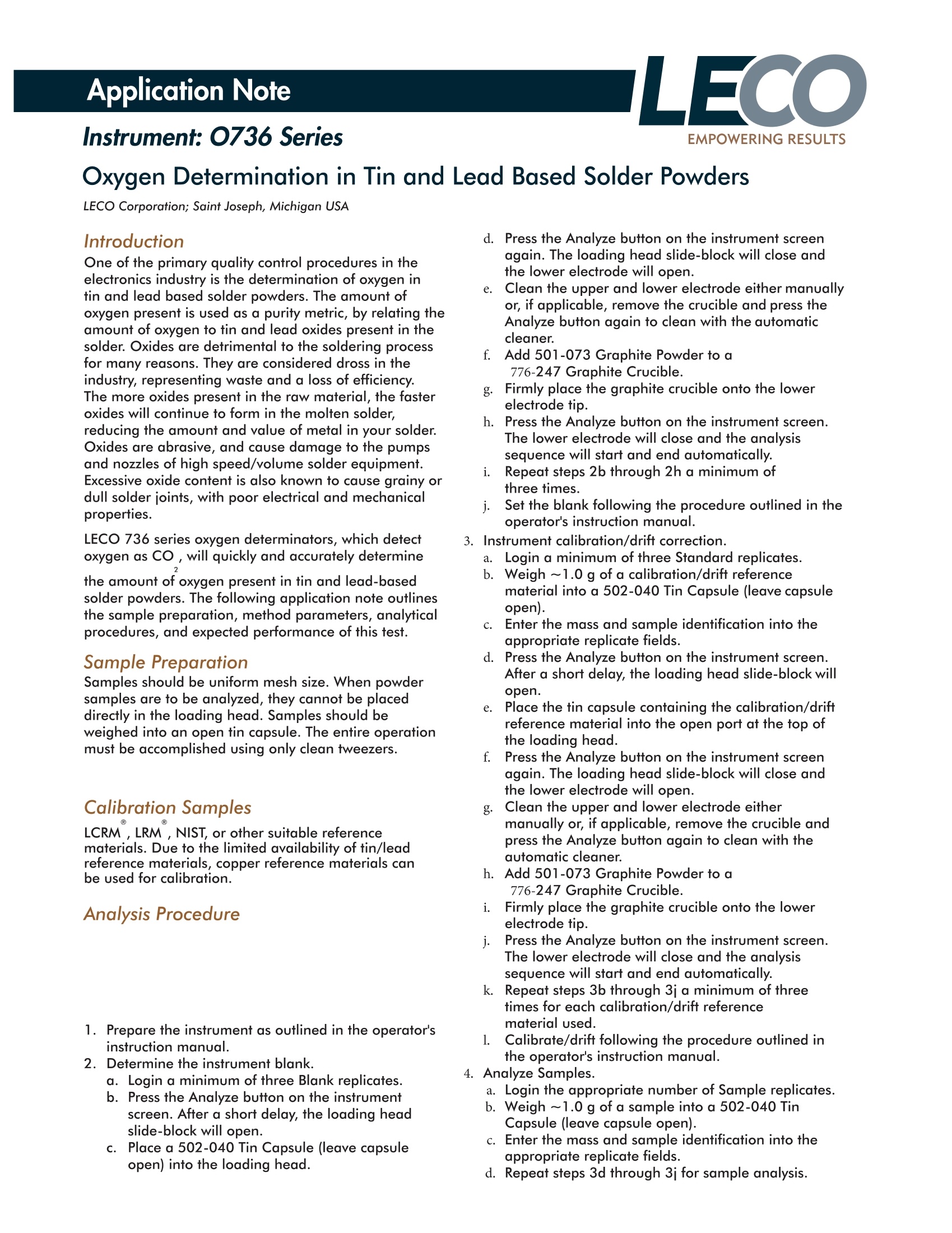

Application NoteEMPOWERING RESULTSForm No. 203-821-5632/19-REV0C 2019 LECO Corporation Instrument: O736 Series Oxygen Determination in Tin and Lead Based Solder Powders Introduction One of the primary quality control procedures in theelectronics industry is the determination of oxygen intin and lead based solder powders. The amount ofoxygen present is used as a purity metric, by relating theamount of oxygen to tin and lead oxides present in thesolder. Oxides are detrimental to the soldering processfor many reasons. They are considered dross in theindustry, representing waste and a loss of efficiency.The more oxides present in the raw material, the fasteroxides will continue to form in the molten solder,reducing the amount and value of metal in your solder.Oxides are abrasive, and cause damage to the pumpsand nozzles of high speed/volume solder equipment.Excessive oxide content is also known to cause grainy ordull solder joints, with poor electrical and mechanicalproperties. LECO 736 series oxygen determinators, which detectoxygen as CO, will quickly and accurately determine the amount of oxygen present in tin and lead-basedsolder powders. The following application note outlinesthe sample preparation, method parameters, analyticalprocedures, and expected performance of this test. Sample Preparation Samples should be uniform mesh size. When powdersamples are to be analyzed, they cannot be placeddirectly in the loading head. Samples should beweighed into an open tin capsule. The entire operationmust be accomplished using only clean tweezers. Calibration Samples LCRM , LRM,NIST, or other suitable referencematerials. Due to the limited availability of tin/leadreference materials, copper reference materials canbe used for calibration. Analysis Procedure 1. Prepare the instrument as outlined in the operator'sinstruction manual. 2.[Determine the instrument blank. a. Login a minimum of three Blank replicates. b. Press the Analyze button on the instrumentscreen. After a short delay, the loading headslide-block will open. C.Place a 502-040 Tin Capsule (leave capsuleopen) into the loading head. d.1.Press the Analyze button on the instrument screenagain. The loading head slide-block will close andthe lower electrode will open. e.Clean the upper and lower electrode either manuallyor, if applicable, remove the crucible and press theAnalyze button again to clean with the automaticcleaner. f. Add 501-073 Graphite Powder to a776-247 Graphite Crucible. g.Firmly place the graphite crucible onto the lowerelectrode tip. h.Press the Analyze button on the instrument screen.The lower electrode will close and the analysissequence will start and end automatically. i. Repeat steps 2b through 2h a minimum ofthree times. j. Set the blank following the procedure outlined in theoperator's instruction manual. 3.I1nstrument calibration/drift correction. 1.Login a minimum of three Standard replicates. abWeigh ~1.0 g of a calibration/drift referencematerial into a 502-040 Tin Capsule (leave capsuleopen). C.Enter the mass and sample identification into theappropriate replicate fields. d.1.Press the Analyze button on the instrument screen.After a short delay, the loading head slide-block willopen. e.Place the tin capsule containing the calibration/driftreference material into the open port at the top ofthe loading head. f. Press the Analyze button on the instrument screenagain. The loading head slide-block will close andthe lower electrode will open. g.Clean the upper and lower electrode eithermanually or, if applicable, remove the crucible andpress the Analyze button again to clean with theautomatic cleaner. h.Add 501-073 Graphite Powder to a776-247 Graphite Crucible. i.Firmly place the graphite crucible onto the lowerelectrode tip. j. Press the Analyze button on the instrument screen.The lower electrode will close and the analysissequence will start and end automatically. k.Repeat steps 3b through 3j a minimum of threetimes for each calibration/drift referencematerial used. l.Calibrate/drift following the procedure outlined inthe operator's instruction manual. 4.Analyze Samples. a. Login the appropriate number of Sample replicates.b. Weigh~1.0 g of a sample into a 502-040 TinCapsule (leave capsule open). C.Enter the mass and sample identification into theappropriate replicate fields. d.Repeat steps 3d through 3j for sample analysis. Typical Results Using Helium Carrier Gas Using Argon Carrier Gas Sample Mass (g) % Oxygen Sample Mass (g) % Oxygen Tin Alloy Powder 0.9937 0.0142 Tin Alloy Powder 1.0130 0.0143 1.0180 0.0142 1.0030 0.0144 1.0237 0.0141 1.0214 0.0144 1.0109 0.0141 1.0139 0.0144 1.0149 0.0143 1.0183 0.0143 Avg = 0.0142 Avg= 0.0144 S= 0.0001 S= 0.0001 Sn63-Pb37 Alloy 0.9833 0.0123 Sn63-Pb37 Alloy 1.0199 0.0127 Powder 1.0238 0.0123 Powder 1.0436 0.0125 0.9995 0.0123 1.0102 0.0124 0.9847 0.0125 1.0201 0.0124 1.0085 0.0127 1.0047 0.0127 Avg = 0.0124 Avg= 0.0126 S= 0.0001 S= 0.0001 Results based upon a linear, forced through origin calibration usingLECO 501-149 Lot:0577 Copper Pins LRM @ 0.0543%O. ( LECO Corporation| 300 0 Lak e view Avenue| St. Joseph, Ml 49085| P h one: 800-292-6141|2 6 9-985-5496 ) ( info@leco.com·www.leco.com|IS O -9001:2015 Q-994|LECO i s a registered trademark of LECO Corporation. ) ( L CRM = LECO Certified Reference Material; LRM= LECO Reference Material and are registered trademarks of LECO Corporation. ) 利用力可LECO ON736氧氮分析仪分析锡和铅基焊料粉中氧含量,获得如下结果,重复性和短期长期精度极好,详细方法请见附件:

关闭-

1/2

-

2/2

产品配置单

美国力可公司为您提供《锡和铅基焊料粉中氧含量检测方案(氧氮分析仪)》,该方案主要用于耐火耐腐材料中氧含量检测,参考标准《暂无》,《锡和铅基焊料粉中氧含量检测方案(氧氮分析仪)》用到的仪器有力可LECO ON736氧氮分析仪。

我要纠错

推荐专场

相关方案

咨询

咨询