方案详情文

智能文字提取功能测试中

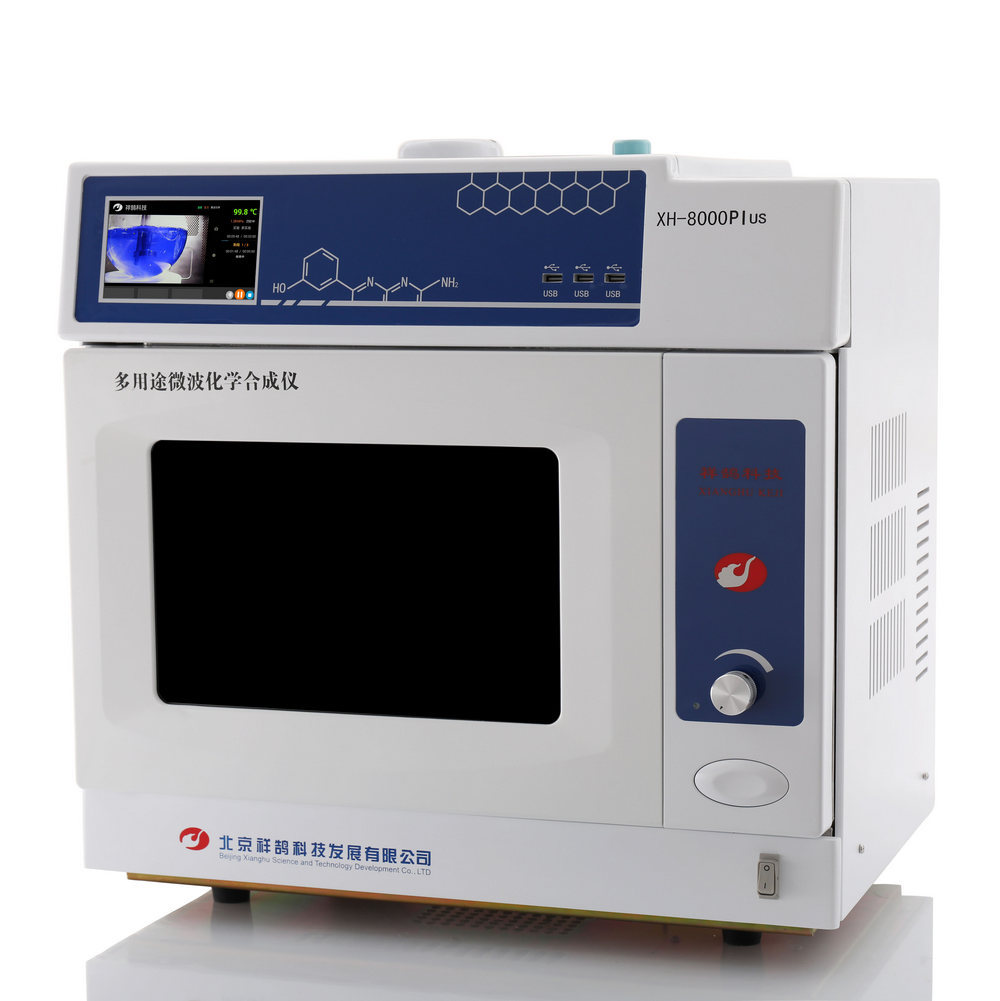

LWT-Food Science and Technology 152 (2021)112310 Y. Zhang et al.LWT 152 (2021)112310 Contents lists available at ScienceDirect LWT journal homepage: www.elsevier.com/locate/lwt Degradation of aflatoxin Bi by water-assisted microwave irradiation:Kinetics, products, and pathways Yaolei Zhang, Mengmeng Li, Yuanxiao Liu, Erqi Guan, Ke BianCollege of Food Science and Engineering, Henan University of Technology, Zhengzhou, 450001, China ARTICLEINFO A BSTRACT Keywords:Aflatoxin BWater-assisted microwave irradiationDegradation kineticsDegradation productsDegradation pathway The effect of aflatoxin B1 (AFBi) degradation by water-assisted microwave irradiation (WMI) and the identifi-cation of the degradation products of AFB1 are key issues in the feasibility study of WMI detoxification. In thisstudy,WMI was applied to degrade pure AFBi in aqueous medium, and the kinetics, products, and pathways ofthe degradation of AFBi were studied. The results showed that AFBi could be effectively degraded by WMI, andthe degradation process followed pseudo-first-order reaction kinetics. In addition, six new main degradationproducts were identified by ultra-high-performance liquid chromatography Q-Orbitrap mass spectrometry, and apossible degradation pathway was proposed. Furthermore, the variety and quantity of AFB1 degradation prod-ucts and the degradation pathway of AFB were affected by microwave heating temperature, time, and power.After WMI treatment, the double bond in the terminal furan ring or the lactone bond of AFBi was destroyed,which implied that the toxicity of the degradation product was significantly reduced. Therefore, WMI is deemedto be an effective method to degrade AFB1. 1. Introduction Aflatoxins are common mycotoxins in food and grains and are mainlyproduced by Aspergillus flavus and Aspergillus parasiticus. A recent studyreported that approximately 25% of agricultural products are contami-nated by aflatoxins worldwide (Yard et al., 2013). Aflatoxin B1 (AFB1) isone of the most common aflatoxins and is classified as a class 1 carcin-ogen by the International Agency for Research on Cancer as anextremely potent liver carcinogen (Jalili, 2016; Wogan, 1968). There-fore, finding appropriate methods to reduce AFB in food and grains is aglobal concern. and limitations. The ideal method of detoxification should be econom-ical, effective, safe, and non-destructive to food quality (Ellis, Smith,Simpson, & Oldham, 1991; Zhang, Li,Liu, Guan, & Bian, 2020). Water-assisted microwave irradiation (WMI) is expected to becomea new method for AFB1 degradation, because the water moleculescompletely alter the effect of microwave degradation on AFB1,resultingin new characteristics and properties. Its main feature is that watermolecules participate in the degradation of AFB1. The advantages anddetails of this processing method were described in a previous study andcan be briefly summarised as follows (Zhang et al., 2020): First, WMI canconcentrate the microwave irradiation energy on the parts with highAFB1 concentration (broken kernels, embryo tissue, and cortex of corn)and lower the decomposition temperature of AFBi to home cookingtemperature (95-100°C). Second, WMI can reduce AFB1 by 60% whileensuring that the temperature of corn kernels does not exceed 120 °C,which avoids the widespread generation of heat-damaged grain kernels.Third, WMI can effectively avoid the disadvantages of microwaveheating, such as the difficulty of temperature control and uneven heat-ing and improve the possibility of industrial application of microwaveirradiation to AFB1 degradation (Pankaj, Shi, & Keener, 2018). Inaddition, water is safe and harmless compared to other substances. It is ( W M I: water-assisted microwave irradiation. ) ( https: // doi.org / 10 . 1016/j . lwt.202 1 . 112310 ) ( Received 1 1 May 2021; R e ceived in revised form 1 2 A ugust 2021; Accepted 13 August 2 0 21 Available online 14 August 2 021 ) Fig. 1. Schematic view of the microwave equipment; (a) under high pressure and (b) under normal pressure. an important component in grains and food, a commonly used additivein food processing, and a good solvent in chemical reactions. Water isalso an excellent medium for absorbing microwave energy and gener-ating heat. Therefore, it might be a promising method to use WMI todegrade AFB in food and grains. However, the current research resultsremain insufficient to verify that WMI is a successful and feasibledetoxification method, because further critical information is lacking.For instance, the degradation pathway, the structures of degradationproducts, and the change in toxicity of AFBi treated with WMI remainunclear. In particular, the structural identification and analysis of thedegradation products of AFBi are crucial. This is a key issue in thefeasibility study of WMI detoxification (Liu et al., 2010; Wang et al.,2011). In this study, AFB was dissolved in ultrapure water and placed inmicrowave equipment for microwave irradiation. The effect of WMI onthe reduction of AFB and the degradation kinetics of AFBi at differenttemperatures, microwave powers, and initial AFBi concentrations werestudied preliminarily. Moreover, this study aimed to: i) analyse the va-riety of degradation products of AFBi under different WMI conditions,ii) identify the structure of the degradation products of AFB1, and iii)elucidate the degradation pathways of AFB and analyse the toxicity ofthe degradation products based on their chemical structures. This studyprovides a new reference for the degradation of AFBj in food and grains. 2. Materials and methods 2.1. Chemicals and reagents The AFB standard (purity=99.5%) was obtained from J&KChemical Ltd. (Beijing, China). Methanol and acetonitrile (LC-MS grade)were obtained from Thermo Fisher Scientific (Waltham, MA,USA). Ul-trapure water (resistivity =18.2 MQ cm,25℃) was obtained from aMilli-Q SP Reagent Water system (Millipore, Bedford, MA,USA). 2.2. Preparation of AFBi aqueous solution The AFB standard (5 mg powder) was dissolved in methanol (50mL) to obtain standard stock solutions (100 mg/L). Then, 0.5 mL of theprepared standard stock solution was transferred to glass tubes (orvolumetric flasks) and dried with nitrogen.Different initial concentra-tions of AFB1 aqueous solutions (0.05, 0.10, 0.50, and 5.00 mg/L) wereobtained by adding 1000, 500,100, and 10 mL of ultrapure water to theglass tube (or volumetric flask), respectively. 2.3. WMI treatment A water solution of pure AFB1 (20 mL) was transferred into a high-pressure reactor (100 mL), and then placed in a multi-function micro-wave chemical synthesiser (Beijing Xianghu Technology Co., Ltd., Bei-jing, China) (Fig. 1(a)). The temperature in the vessel was displayed onthe control panel in real time and detected by a temperature sensorinserted into the vessel. There were two different power output modes for thisisinstrument: constant output and proportional-integral-derivative adaptive power adjustment output. The latter could main-tain a constant microwave heating temperature. The basic principle andprocess of maintaining a constant temperature is that the microwaveequipment heats the samples close to the set temperature rapidly with aconstant power (500 W). Then, the system automatically switches to thesecond mode. The microwave computer automatically calculates andoutputs an appropriate low microwave power. Because the heat gener-ated by this low microwave power irradiation is equal to the heat lost bythe natural cooling of the samples, the temperature of the samples re-mains constant (±0.2 C). Then, the AFBi samples were treated fordifferent times by WMI at110°C, 120°C, 130 °C, and 140 °C. To determine the influence of microwave power on the degradationof AFB1, the following method was used. The high-pressure reactor wasreplaced by a triangular bottle (250 mL), and the bottleneck was con-nected with a ling condensing reflux device (Fig. 1(b)). The AFBi sam-ples were heated to the boiling temperature (100°C) with constantpower (500 W), and then they were treated for different times usingdifferent microwave powers (200, 300, 400, and 500 W). Consideringthat the water evaporated during the WMI treatment, it was necessary toadd an appropriate amount of ultrapure water to the triangle bottle aftertreatment. The quality (or volume) of the added water was equal to thequality (or volume) of the reduced water before and after treatment. 2.4. Ultra-high-performance liquid chromatography (UHPLC) Q-Orbitrapanalysis AFBi anddegradation products were qualitatively and quantitativelyanalysed using UHPLC Q-Orbitrap (Thermo Fisher Scientific). Chroma-tography was performed using a C18 column (100 x 2.1 mm, 1.7 umparticle size) (Thermo Fisher Scientific). After WMI treatment, 1 mL ofAFBi aqueous solution was removed for analysis. The analysis wasperformed according to the method reported by Liu, Li, Liu, and Bian(2019). The concentration of AFBi was quantified using the responsevalue of AFBi in the mass spectra. 2.5. Molecular formula proposition and structure identification The originaltl chromatography/massssspectrometry data werecollected using Xcalibur v. 3.0 (Thermo Fisher Scientific, Waltham, MA,USA), and then the data were imported into SIEVE v. 2.0 (Thermo FisherScientific) to screen out degradation products. Information on thedegradation products (such as retention times, proposed formulae, ac-curate experimental masses, double bond equivalent, and mass errors)could be acquired using these two software. The molecular formulas andstructures of the degradation products were proposed based on thefollowing information: the composition of elements and exact mass ofdegradation products, the structure of AFBi, and the principles ofchemical reaction mechanisms. Finally, the structure of the degradationproducts was identified and verified using Mass Frontier 7.0 (ThermoFisher Scientific). The operation of the above software was performedaccording to the method described by Li, Guan, and Bian (2019). (a) 1.0 0.8- II 0.6- 0.4 200 W 300 W 0.2 400 W :500 W 0.0- 0 5 10 15 20 25 30 Time (min) Fig. 2. Degradation curve and kinetics of aflatoxin B1 (AFBj) at (a) and (b) different initial concentrations of AFBi, (c) and (d) different temperatures of water-assisted microwave irradiation (WMI), and (e) and (f) different microwave powers of WMI. (Co and Ct are the concentrations of AFBi at times 0 and t, respec-tively, and t is the WMI processing time.) (b)0.0 2.6. Statistical analysis Each experiment was independently performed at least three times,and data are expressed as mean± standard deviation (SD). The statis-tical significance of the data was analysed using Duncan’s multiplerange post hoc tests using SPSS (version 16.0; SPSS Institute, Chicago, IL,USA) (p <0.05). 3. Results and discussion 3.1. Effect ofinitial concentration, temperature, and microwave power onthe degradation ofAFB1 The effect of initial concentration on the degradation of AFB1 byWMI is shown in Fig. 2(a). The temperature of the WMI was set to Parametric equations of degradation of aflatoxin B1 (AFBj) at different initialconcentrations, temperatures, and microwave powers in aqueous medium. Temperature (°C)/Microwave power (Ln(Ct/Co)=-A- B × t) (W) 0.05 mg/L Ln(Ct/Co)= -0.0394 - 0.9900 0.0188 t 0.10 mg/L Ln(Cz/Co)=-0.0012- 0.9974 0.0216t 0.50 mg/L Ln(Ct/Co)=-0.0427 - 0.9965 0.0462 t 5.00 mg/L Ln(Ct/Co)=-0.0149 - 0.9831 0.0076t 110°C Ln(Cr/Co)= -0.0034 - 0.9876 0.0063 t 120°C Ln(Ct/Co) = -00..0012 0.9974 0.0216t 130°C Ln(Ct/Co)=-0.0539- 0.9878 0.0342t 140°C Ln(Ct/Co)=-0.0832 · 0.9824 0.0433t 200 W Ln(Ct/Co)= 0.0085 0.9907 0.0081 t 300 W Ln(C:/Co)=0.0161 - 0.9692 0.0110t 400 W Ln(Ct/Co)= 0.0019 - 0.9831 0.0188t 500 W Ln(Ct/Co)=0.0026 0.9789 0.0232t The values of A and B are pseudo-first-order rate constants; Co and Ct are theconcentrations of AFB at times 0 and t, respectively, and t is the water-assistedmicrowave irradiation processing time. 120°C, and the initial AFBi concentrations were 0.05, 0.1,0.5, and 5mg/L. All four degradation curves showed a downward trend withprocessing, although there was a significant difference between thedegradation curves. This indicated that the initial concentration of AFBaffected the degradation effect of WMI on AFBj. The degradation rate ofAFB1 was calculated as (1-Ct/Co)% where Ct and Co are the concen-trations of AFB1 at times t and 0, respectively, and t is the WMI pro-cessing time. When the initial AFBi concentration was 0.05, 0.1, 0.5,and5 mg/L, the degradation rate was 50.0%, 56.3%,80.7%, and 21.6%,respectively, after 35 min. Within a certain concentration range,increasing the concentration of AFB also increased the degradation rateof AFB1. However, when the concentration of AFB was very high, thedegradation rate decreased. The same phenomenon has been reportedby Lee, Cucullu, Franz, and Pons (1969) and Arzandeh and Jinap (2011).The collision theory is useful to explain this phenomenon; when otherconditions remain constant, increasing the concentration of the reactantis equivalent to increasing the number of activated molecules per unitvolume and reducing the distance between the reactant molecules. Thiscould increase the number and frequency of effective collisions ofreactant molecules per unit time and unit volume, resulting in a fasterreaction rate per unit volume, which means an increase in the degra-dation rate of AFB1. However, the total energy output of the microwavesis limited. When the AFBi concentration was high, the energy receivedby a single molecule decreased,which was unfavourable for the occur-rence of the reaction. Therefore, the degradation rate of AFB began todecrease. The effect of different WMI temperatures on AFBi degradation isshown in Fig. 2(c). The initial concentration of AFBj was set as 0.1 mg/Land the WMI temperatures were 110°C, 120°C, 130°C, and 140 °C. Anincrease in the temperature of WMI was accompanied by a significantincrease in the degradation rate of AFB1 (p<0.05). High temperatureswere beneficial for the degradation of AFBi, consistent with findings of aprevious study (Farag, Rashed, & Hgger,1996). In our study, 17%, 46%, 62%, and 74% of AFBi was degraded after 30 min of processing by WMIat temperatures of 110 °C,120°C, 130°C, and 140 °C, respectively.Therefore, the degradation rate of AFB1 is strongly affected by thetemperature of the WMI. In addition, the results also indicated that AFBcould be efficiently degraded by WMI at temperatures less than 300°C,which was much lower than the dry thermal decomposition temperatureof AFB1. For the same processing time, the higher the microwave power, thehigher was the WMI temperature. Therefore, it is difficult to separate theeffect of microwave power from that of the WMI temperature on thedegradation of AFB1. However, the boiling temperature of water undernormal pressure remains stable under different microwave powers.Therefore, the effect of microwave power on the degradation of AFB1was studied under normal pressure conditions. Fig. 2(e) shows thedegradation curves of AFB at an initial concentration of 0.1 mg/L andtreated with different microwave powers. The results showed that anincrease in microwave power led to an increase in the degradation rateof AFB1. This demonstrated that the degradation rate of AFBi could beaffected by the microwave power. In addition, the difference betweenthe degradation rates of AFB1 at the same temperature implies that thereis a non-thermal effect in the process of degradation of AFB1 by WMI.Finally, the condensed water remaining in the condensing reflux devicewas collected and analysed. No AFBi could be detected in the condensedwater, which indicated that AFB was degraded instead of escaping withthe evaporated water. 3.2. Degradation kinetics of AFBi at different initial concentrations,temperatures, and microwave powers The graphs ofLn(Ct/Co)and processing time under different condi-tions are shown in Fig. 2(b), (d), and (f), and the fitting equations arepresented in Table 1. The degradation kinetics of AFB1 by WMI could bedescribed by a dynamic first-order kinetic model. According to the linearrelationship between Ln(Ct /Co)and processing time, the degradation ofAFB1 with different initial concentrations might fit a pseudo-first-orderkinetic model (R²>0.95). The equation was Ln(Ct/Co) = -A - B xt, and the values of A and B changed under different initial concen-trations of AFB1, which showed that the degradation reaction rate wasclosely related to the initial concentration of AFB1. In addition, thepseudo-first-order kinetic model indicated that water molecules not onlyacted as solvents but may also participate in the degradation reaction ofAFB1 as reactants. In addition, the values of A and B showed obvious changes underdifferent temperatures and microwave powers of WMI, illustrating thatthe degradation reaction rate also had a strong dependence on thetemperature and microwave power of WMI. As B is the first-order rateconstant of the parametric equation, it can be regarded as the chemicalreaction rate of AFB in unit concentration. In general, the larger the Bvalue, the larger is the degradation reaction rate of AFB1. Therefore, itcould be seen from the constant B that the AFBi degradation reactionrate (V) in unit concentration decreased in the following order: V(0.50 mg/L) >V(0.10 mg/L)>V(0.05 mg/L)> V(5.00 mg/L), V(140 ℃)>V(130℃)>V(120 ℃)>V(110℃) and V(500 W)> V(400 W)> V(300 W)> V(200 W). 3.3. Degradation products ofAFB1 The Orbitrap tandem mass spectrometry (MS/MS) is an efficientanalytical tool to identify trace chemical compounds (Gao et al., 2020;Sun, Li, & Jaisi,2019). To detect the main degradation products of AFB1,the concentration of AFBi was increased to 5 mg/L (Sangare et al.,2014). The chromatographic and mass spectral data of AFBi treatedwith WMI were collected by UHPLC-Q-Orbitrap and imported intoSIEVE v.2.0. This software is an efficient statistical auxiliary tool thatcan be used to analyse the significant differences between differentsamples. After the above data is imported into SIEVE v.2.0, the softwarecan automatically screen out compounds that are significantly different Table 2Hypothetical formulae for the aflatoxin B1 (AFBj) degradation products. Proposed Retention Hypothetical Determined Diff DBE Product Time Formula Mass (m/z) (ppm) (min) a P1 11.34 C15H1305 273.07584 0.42739 9.5 P2 7.34 C16H1706 305.10202 0.48215 8.5 P3 10.05 C16H150s 287.09152 0.31923 9.5 P4 6.99 C12H1304 221.08089 0.30174 6.5 P5 9.28 C13H1305 249.07599 0.20531 7.5 P6 7.50 C13H1105 247.06032 0.38854 8.5 AFB1 10.12 C17H1306 313.07065 0.14985 11.5 The m/z of [M + H]+. Diff =mass difference. DBE= double bond equivalent. from the control sample. If a compound is present in the WMI-treatedsamples but not in the WMI-untreated samples, it would most likelybe the degradation product. Finally, six new products were identified bythe software and denoted as P1', P2', ‘P3’,P4', P5', and ‘P6’. The information on P1 to P6 and AFB1 is shown in Table 2. Twoimportant pieces of information are required to propose the molecularformulas of degradation products: the accurate mass and composition ofthe elements. The accurate mass was detected by Q-Orbitrap, and themass error obtained was less than 5 ppm when compared with thetheoretical mass of the proposed molecular formula. Furthermore, asAFB1was treated with WMI in ultrapure water, the elemental composition of the degradation products of AFB1 would not exceed threeelements: C, H, and O. Therefore, the molecular formulas of P1 to P6were proposed using Xcalibur v.3.0, according to the exact masses andthe constituent elements of the compounds. For example, the m/z of P3was 287.09152, and the mass numbers of C, H, and O are 12.00000,1.00783, and 15.99492, respectively. Therefore, the molecular formulaof P3 was most likely to be C16H1505(287.09205), rather than C15H1106(287.05565). In addition, the effects of processing time, temperature,microwavepower, and initial concentration of AFB on the degradation products ofAFB were also studied. Fig.3(a) shows the change in the response valueof AFBi and degradation products (P1-P6) with the processing time ofWMI (the temperature of WMI was 140°C, and the initial concentrationof AFBi was 5 mg/L). With the extension in processing time, AFB1gradually decomposed and the content of P1-P6 continued to increase.The content of P3 was higher than that of the other degradation prod-ucts, which proved that P3 was the main degradation product. Fig.3(b)shows the change in P1-P6 content at different initial AFBi concentra-tions of 1, 5, and 10 mg/L (the condition of WMI was 140C and 20min). For example, as the initial concentration of AFBi increased from 1mg/L to 10 mg/L, the content of P1-P6 increased simultaneously. Thiswas favourable evidence to further show that P1-P6 were the maindegradation products of AFB1. Fig. 3(c) shows that the temperature hadsignificant effects on the type and quantity of degradation products ofAFB1 (the processing time was 20 min and the initial concentration ofAFBi was 5 mg/L). For example, the formation of P4 required the Fig. 3. Relative change in the responses value of degradation products (P1-P6) in water (a) with increasing water-assisted microwave irradiation (WMI) time, (b) atvarious initial aflatoxin B1 (AFB) concentrations, (c) at different temperatures, and (d) at different microwave powers. Fig. 4. Orbitrap MS-MS spectra and main proposed fragmentations (insets) ofaflatoxin B1 (AFBi) and the six degradation products. temperature of WMI to be higher than 130°C, and a temperature higherthan 120 °C was necessary for the formation of P5 and P6. The quantityof P1 was higher than that of P2 at 140 °C, but there was more P2produced than P1 when the temperature was lower than 140C. Fig. 3(d) shows the effect of microwave power on the degradation of AFB byWMI (the processing time was 20 min and the initial concentration ofAFB1 was 5 mg/L). The degradation products of AFBi were P1, P2, andP3. This might be related to the temperature being lower than 120 °C,because the temperature of WMI was only 100°C under normal pres-sure. However, these three products (P1, P2, and P3) were still affectedby the microwave power. For example, the generation of P2 requires amicrowave power at least 300 W. With the increase in microwave power, the generation of P1, P2, and P3 showed an overall increasingtrend. The above results indicate that the temperature, time, and powerof WMI are all important factors affecting the types and quantities ofAFBi degradation products. 3.4. Proposed structures of the AFB1 degradation products To illustrate the structure of P1 to P6, the exact masses of the frag-mentation ions of each degradation product were determined usingOrbitrap MS/MS. The MS/MS spectra of AFB and the six degradationproducts were obtained and are shown in Fig. 4. The structural formulasof P1 to P6 are proposed according to the molecular formula of theparention and the accurate mass of the fragments (Fig.5). Mass Frontier7.0 was used to verify the structural formulas (P1-P6). The principle ofthe software can be briefly described as follows: After importing theproposed degradation product structure into the software, the softwarewill present fragment ions and generation paths based on the theoreticalfragmentation law of this chemical structure and the mass spectrumfragment path database. The software automatically checks the degreeof matching between these fragment ions and the actual fragment ions.If they are consistent, the proposed structure is validated (Li et al.,2019). The main matching fragment ions and their generation pathwaysare shown in Fig. 4 as inserts. 3.5. Reaction pathway of AFBi and toxicity analysis of the degradationproducts Based on the structure of AFBi and degradation products, combinedwith the law of chemical reaction, the degradation pathways of AFB1 byWMI were proposed and are shown in Fig. 6. The first step was thehydrolysis and decarboxylation of the lactone ring, forming product P3.The quantity of P3 was the largest among the six degradation products.Then, the methoxy group of the side chain of the benzene ring of P3 wasconverted to a hydroxyl group to form P1. At the same time, the C(8)-C(9) double bond in the furan ring of P3 was hydrated to produce P2. Ifthe temperature of WMI was high enough(>130°C), it would promotethe hydrolysis of the furan ring of P3, P1,and AFB to generate P4, P5,and P6, respectively. The lactone ring was easily hydrolysed by wet heating because thewater molecule could serve as a base catalyst to open the lactone ring(Gomez-Bombarelli, Calle, & Casado, 2013; Shi, 2016). Several studieshave speculated that the lactone ring of AFBi is hydrolysed to formterminal carboxylic acid in the presence of moisture, and then undergoesheat-driven decarboxylation (Coomes, Crowther, Feuell, & Francis,1966; Samarajeewa, Sen, Cohen, &Wei, 1990). Our study alsoconfirmed that P3 was the most easily produced and the primarydegradation product. Furthermore, we found that the furan ring of AFBwas also hydrolysed after WMI treatment. The participation of waterwas also conducive to the opening and cracking of the furan ring. It hasbeen reported that under high temperature and high pressure, polarwater molecules are beneficial to the opening of the C-O bond of thefuran ring (Shinmi, Koso, Kubota, Nakagawa, & Tomishige, 2010;Zhang, Zhu, Ding, Zheng, & Li, 2012). The toxicology of AFBi has been widely studied. There are twoimportant sites for the toxicological activity of the AFB1 molecule(Guengerich, 2001; Hussein & Brasel, 2001; Samarajeewa et al., 1990).The first site is the C(8)-C(9) double bond in the furan ring. Manystudies have reported that the interaction of aflatoxin with DNA andprotein mainly occurs at this site (O’Brien, Moss, Judah, & Neal, 1983;Samarajeewa et al., 1990). For instance, AFB1 can be converted intoAFB1-8,9 epoxides by cytochrome P450-mediated oxidation, and itusually has deleterious effects on liver cells by altering the normalbiochemical functions of DNA and protein (Hsu, Metcalf, Sun Welsh, &Harris, 1991). The second site is the lactone ring of the coumarin moietyof AFB1. Several studies have highlighted that the lactone ring is proneto further reactions after being hydrolysed, thereby changing the Fig. 5. Proposed structure of the six degradation products of aflatoxin B1 (AFB1). Fig. 6. Proposed degradation pathways of aflatoxin B1 (AFBj) based on the results of this study. binding properties of the furan ring with DNA and protein (Samarajeewaet al., 1990). Thus, the removal of the C(8)-C(9) double bond of thefuran ring or the lactone ring of the coumarin moiety is a crucial step forthe detoxification of AFB1. In our study, the structure of the six degra-dation products (P1-P6) revealed that the C(8)-C(9) double bond or thelactone ring was destroyed. The destruction of any toxicity sites in-dicates a reduction in AFB toxicity, which has been shown previouslyby the results of the Ames & cytotoxicity tests (Liu et al., 2016).Therefore, the degradation products would have lower toxicity thanAFB1, according to the relationships between biological activity andchemical structure. Previous toxicity tests on day-old Khaki-Campbellducklings proved that the toxicity of AFBj-contaminated groundnutmeal was considerably reduced when treated with autoclaving (120°C)(Coomes et al., 1966). Considering that WMI and autoclaving have manysimilarities, it is a good indicator that WMI can also reduce the toxicityof AFB1. Owing to the complexity of the food matrix, the degradation prod-ucts of AFBi in food may be complex. Therefore, with the developmentof trace detection technology, the study of the degradation products ofAFB in food and grains may be a goal in the future. From theperspective of food safety, the next step will be to evaluate the safety ofthe AFB1 degradation product in food through animal experiments. 4. Conclusions In this study, the degradation kinetics, products, and pathways ofAFB1 by WMI were studied. The degradation of AFB1 by WMI was shownto follow pseudo-first-order reaction kinetics well (R²> 0.95), which indicated that water molecules not only act as solvents but also partic-ipate in chemical reactions during the degradation of AFB1. Six newdegradation products were identified by UHPLC-Orbitrap-MS, and apossible degradation pathway was proposed. In addition, the variety andquantity of AFB1 degradation products and the degradation path of AFB1were affected by the microwave heating temperature,time, and power.After WMI treatment, the double bond in the terminal furan ring and thelactone bond of AFB were destroyed, which indicates that the toxicityof the degradation products was significantly reduced. Therefore, WMIis expected to be a promising method for degrading AFB1. Funding This work was supported by the National Key Research and Devel-opment Program of China [grant number: 2018YFE0206000]; the Na-tional Natural Science Foundation of China (NSFC) [grant numbers:31801654]; and the Cultivation Programme for Young BackboneTeachers in Henan University of Technology. CRediT authorship contribution statement Yaolei Zhang: Conceptualization, Methodology, Software, Valida-tion, Formal analysis, Investigation, Data curation, Writing -originaldraft. Mengmeng Li: Methodology, Validation, Formal analysis,Writing - review & editing, Supervision, Project administration, Fund-ing acquisition. Yuanxiao Liu: Software, Formal analysis, Writing-review & editing. Erqi Guan:Methodology,Resources, Project admin-istration. Ke Bian: Conceptualization, Resources, Writing - review & editing, Supervision, Project administration, Funding acquisition. Declaration of competing interest No conflict of interest exists in the submission of this manuscript, andthe manuscript is approved by all authors for publication. I would like todeclare on behalf of my co-authors that the work described was originalresearch that has not been published previously, and not underconsideration for publication elsewhere, in whole or in part. All theauthors listed have approved the manuscript that is enclosed. Appendix A. Supplementary data Supplementary data to this article can be found online at https://doi.org/10.1016/j.lwt.2021.112310. References Arzandeh, S., & Jinap, S. (2011). Effect of initial aflatoxin concentration, heating timeand roasting temperature on aflatoxin reduction in contaminated peanuts andprocess optimisation using response surface modelling. International Journal ofFoodScience and Technology, 46(3), 485-491. Coomes, T.J., Crowther, P. C., Feuell, A. J., & Francis, B. J. (1966). Experimentaldetoxification of groundnut meals containing aflatoxin. Nature, 209(5021),406-407. ( E lli s, W. O . , S m i t h , J . P . , Si mpson, B . K ., & O ldham , J. H . ( 1 9 9 1). A f l at o xins in fo o d : O ccurr e n c e, b i os yn t h esi s , e ffec ts on or g anisms , dete c t i on, a nd m et h o ds o f control . C r itical R e vi e ws in F ood S cience and Nutrition , 30 ( 4) , 4 03 - 4 3 9. ) ( F ar ag , R . S. , R a s he d, M. M ., & H gg e r , A. A . A . ( 1 9 96). A fl at oxi n d estruc t ion b y mi cr o w a ve he a ting . Int e rna t ional Journ a l of Fo od Sc i e n ces & N u t r i tion, 4 7 (3 ) ,197 -2 08 . ) ( G ao, X . , L i , Y . , M en g ,M . , W a n g, P . , F e n g , Y. , J i a, J., e t a l . ( 2 020). Ex p l o rati o n of ch e m i c al c o m positi on a n d a b s orp t ion c h ara c t e r is t i c s of c h a ig ui gr a nule s b a sed on U H PLC - Q - o r bitr a p- M S/M S . J o urnal of P h armaceutical and Biomedical An a lysi s, 1 8 7, 1 1 32 9 3. ) Ghanem, I., Orfi, M., & Shamma, M.(2008). Effect of gamma radiation on the ( i nac t i v a ti o n o f af l at o xin b1 i n fo o d and fe e d c r o p s . B razi l ia n Jo u rnal o f M icrobiology, 39(4), 7 87- 7 91 . ) ( G omez- Bo mba r elli , R ., C a l l e, E . , & C a s a d o , J . ( 2 0 13) . M e ch an isms o f l a c to n e h y drolysis i n ne u t r al a n d a lk a line cond i ti o ns . J o ur n al o f Orga n i c Chem i stry , 78 ( 1 4),6868-687 9 . ) ( G uan, Y. , C h e n , J . , Nepovimova,E., L o n g, M . ,& Kuca, K. ( 2 021). Afl atoxin detoxification u si n g m i cr oor gan is m s a n d enzyme s . T o x ins, 1 3 ( 1), 4 6. ) ( Guenger i ch ,F . P . (2 001). C o m mon an d uncommon c y toc hr o m e P450 react i o n s r el a t ed t o m e tabolism a n d ch e m ical to x i c i ty . C h e mi c a l Rese a rch in T o xico l ogy, 14 ( 6 ) , 6 1 1- 6 5 0 . ) ( H su, I . C . , Met ca l f, R . , S u n, T . , Welsh, J . , & H a rr i s, C . C . ( 1 99 1 ) . Mu tation a l ho t s p ot i n ) the p53 gene in human hepatocellular carcinomas. Nature,350(6317),427-428. ( H usse i n , H . S . , & Bra se l , J . M . (2001 ) . Tox i c i ty , me t abol i sm , an d impac t of mycot o xins o n h umans and a n imals. T oxicology , 167(2) , 10 1- 134 . ) Inan, F., Pala, M., & Doymaz, I. (2007). Use of ozone in detoxification of aflatoxin b1 in red pepper. Journal of Stored Products Research, 43(4),425-429. Jalili, M. (2016). A review on aflatoxins reduction in food. Iranian Journal of Health,Safety and Environment, 3(1), 445-459. Jalili, M.,Jinap, S., & Noranizan, M. A. (2012). Aflatoxins and ochratoxin a reduction inblack and white pepper by gamma radiation. Radiation Physics and Chemistry, 81(11),1786-1788. Lee, L. S., Cucullu, A. F., Franz, A. O., & Pons, W.A. (1969). Destruction of aflatoxins inpeanuts during dry and oil roasting. Journal ofAgricultural and Food Chemistry, 17(3),451-453. Li, M., Guan, E., & Bian, K. (2019). Structure elucidation and toxicity analysis of thedegradation products of deoxynivalenol by gaseous ozone. Toxins, 11(8), 474. Liu, R., Jin, Q., Tao, G., Shan, L., Huang, J., Liu, Y., ... Wang, S. (2010). Photodegradation kinetics and byproducts identification of the aflatoxin b1 inaqueous medium by ultra-performance liquid chromatography-quadrupole time-of-flight mass spectrometry. Journal of Mass Spectrometry, 45(5), 553-559. Liu, Y., Li, M., Liu, Y., & Bian, K. (2019). Structures of reaction products and degradationpathways of aflatoxin b1 by ultrasound treatment. Toxins, 11(9),526. Liu, R., Wang, R., Lu, J., Chang, M., Jin, Q., Du, Z., ... Wang, X. (2016). Degradation ofafb1 in aqueous medium by electron beam irradiation: Kinetics, pathway andtoxicology. Food Control, 66, 151-157. Mendez-Albores, A.,Martinez-Bustos, F., Gaytan-Martinez, M., & Moreno-Martinez, E.(2010).Effect of lactic and citric acid on the stability of B-aflatoxins in extrusion-cooked sorghum. Letters in Applied Microbiology,47(1), 1-7. Mendez-Albores, A., Rio-Garcia, J. C. D.,& Moreno-Martinez, E.(2007).Decontamination of aflatoxin duckling feed with aqueous citric acid treatment.Animal Feedence and Technology, 135(3-4), 249-262. O'Brien, K., Moss, E., Judah, D., & Neal, G. (1983). Metabolic basis of the speciesdifference to aflatoxin b1 induced hepatotoxicity. Biochemical and BiophysicalResearch Communications, 114(2), 813-821. Pankaj, S. K., Shi, H., & Keener, K. M. (2018). A review of novel physical and chemicaldecontamination technologies for aflatoxin in food. Trends in Food Science &Technology, 71,73-83. Pearson, T.(2004). Reduction of aflatoxin and fumonisin contamination in yellow cornby high-speed dual-wavelength sorting. Cereal Chemistry, 81(4), 490-498. Samarajeewa, U., Sen, A. C., Cohen, M. D., & Wei, C. I. (1990). Detoxification ofaflatoxins in foods and feeds by physical and chemical methods. Journal of FoodProtection, 53(6),489-501. Sangare, L., Zhao, Y., Folly, E., Y M, Chang, J., Li, J.,et al. (2014). Aflatoxin b1degradation by a Pseudomonas strain. Toxins, 6(10), 3028. Shi, H. (2016). Investigation of methods for reducing aflatoxin contamination in distillersgrains. PhD, Purdue University. Shinmi, Y., Koso, S., Kubota, T., Nakagawa, Y.,& Tomishige, K. (2010). Modification ofRh/SiO2 catalyst for the hydrogenolysis of glycerol in water. Applied Catalysis B:Environmental, 94(3-4), 318-326. Sun, M., Li, H., & Jaisi, D. P. (2019). Degradation of glyphosate and bioavailability ofp1 16.hosphorus derived from glyphosate in a soil-water system. Water Research, 163,114840. Wang, F., Xie, F., Xue, X., Wang, Z., Bei, F., & Ha, Y. (2011). Structure elucidation andtoxicity analyses of the radiolytic products of aflatoxin b1 in methanol-watersolution. Journal of Hazardous Materials, 192(3), 1192-1202. Wogan, G. N. (1968). Aflatoxin risks and control measures. Federation Proceedings, 27(3),932-938. Yard, E. E., Daniel, J. H., Lewis, L. S., Rybak, M. E., Paliakov, E. M., Kim, A. A., ...Akhwale, W. (2013). Human aflatoxin exposure in Kenya, 2007: A cross-sectionalstudy. Food Additives & Contaminants: Part A, 30(7), 1311-1322. Yazdanpanah, H., Mohammadi, T., Abouhossain, G., & Cheraghali, A. M. (2005). Effectof roasting on degradation of aflatoxins in contaminated pistachio nuts. Food andChemical Toxicology, 43(7), 1135-1139. Zhang, Y., Li, M., Liu, Y., Guan, E., & Bian, K. (2020). Reduction of aflatoxin b1 in cornby water-assisted microwaves treatment and its effects on corn quality. Toxins, 12(9),605. Zhang, B., Zhu, Y., Ding, G., Zheng, H., & Li, Y. (2012). Selective conversion of furfurylalcohol to 1,2-pentanediol over a Ru/MnOx catalyst in aqueous phase. GreenChemistry, 14(12), 3402-3409. 水辅助微波照射对黄曲霉毒素B1的降解。动力学、产物和路径前言 水辅助微波辐照(WMI)降解黄曲霉毒素B1(AFB1)的效果和AFB1降解产物的鉴定是WMI解毒可行性研究的关键问题。在这个研究中,WMI被应用于在水介质中降解纯AFB1,以及动力学、产物和途径,结果表明AFB1可以被 WMI有效降解,并且降解过程遵循准一级反应动力学。此外,六个新的主要退化产品采用超高效液相色谱Q-Orbitrap质谱进行鉴定,提出了可能的降解途径。此外,AFB1降解产物的种类和数量以及AFB1的降解途径受微波加热温度、时间和功率的影响。WMI处理后,末端呋喃环中的双键或AFB1的内酯键被破坏,这意味着降解产物的毒性显着降低。因此,WMI被视为成为降解AFB1的有效方法。简介02黄曲霉毒素是食品和谷物中常见的霉菌毒素,主要存在于由黄曲霉和寄生曲霉产生。最近的一项研究报道,全球约有25%的农产品受到黄曲霉毒素的污染(Yard等,2013 年)。黄曲霉毒素 B1(AFB1)最常见的黄曲霉毒素之一,被国际癌症研究机构列为1类致癌物,极强的肝脏致癌物(Jalili,2016;Wogan,1968)。因此,寻找适当的方法来降低食品和谷物中的 AFB1 是一项重要的工作。近几十年来全球关注,许多类型的物理、化学和生物方法已被用于减少AFB1,包括排序(Pearson,2004),烘烤 (Yazdanpanah,Mohammadi,Abouhossain,& Cheraghali, 2005), 辐射 (Ghanem, Orf, & Shamm, 2008; Jalili, Jinap,& 诺拉尼赞,2012; Liu et al., 2016)、柠檬酸和乳酸(Mendez-Albores、Martinez-Bustos、Gaytan-Martinez和Moreno-Martinez,2010; Mendez-Albores,Rio-Garcia,&Moreno-Martinez, 2007),臭氧化和氨化(Inan,Pala,&Doymaz, 2007),以及微生物和酶促过程(Guan,Chen, Nepovimova, Long, &库卡,2021;Sangare 等人,2014 年)。每种方法都有自己的优势和限制。理想的解毒方法应该是经济、有效、安全且对食品质量无破坏性(Ellis,Smith,辛普森和奥尔德姆,1991;张、李、刘、关、卞,2020)。水辅助微波辐照(WMI1)有望成为一种降解 AFB1的新方法,因为水分子完全改变微波降解对AFB1的影响,导致在新的特性和属性。它的主要特点是水分子参与 AFB1 的降解。优点和这种处理方法的细节在之前的研究中有所描述,并且可以简单概括如下(Zhang et al., 2020):首先,WMI 可以将微波辐射能量集中在高强度部件上AFB1浓度(玉米碎粒、胚胎组织和皮层)并将AFB1的分解温度降低到家庭烹饪中温度(95–100°C)。其次,WMI可以将AFB1降低60%,同时确保玉米粒的温度不超过 120°C,这避免了热损伤谷粒的广泛产生。三、WMI可以有效避免微波的弊端加热,如温度控制困难和加热不均匀,提高微波工业应用的可能性AFB1 降解的辐照(Pankaj、Shi 和 Keener,2018 年)。在此外,与其他物质相比,水是安全无害的。它是谷物和食品中的重要成分,常用的添加剂用于食品加工,是化学反应的良好溶剂。水也是吸shou微波能量和产生热量的极好介质。因此,使用WMI可能是一种很有前途的方法降解食物和谷物中的 AFB1。然而,目前的研究结果仍然不足以验证WMI是成功且可行的解毒方法,因为缺乏进一步的关键信息。例如,降解途径、降解结构WMI处理的AFB1 的毒性变化仍然存在不清楚。特别是结构识别和分析AFB1 的降解产物至关重要。这是该领域的一个关键问题WMI 解毒可行性研究 (Liu et al., 2010; Wang et al.,2011)。在本研究中,将AFB1溶解在超纯水中并置于用于微波辐照的微波设备。WMI的影响AFB1的还原和AFB1在不同条件下的降解动力学温度、微波功率和初始AFB1浓度为初步研究。此外,本研究旨在:i)分析不同WMI条件下AFB1的各种降解产物,ii) 鉴定 AFB1 降解产物的结构,以及 iii)阐明AFB1的降解途径并分析其毒性基于其化学结构的降解产物。这项研究为食品和杂粮中AFB1的降解提供了新的参考。图1. 微波设备的示意图;(a)在高压下和(b)在正常压力下。祥鹄仪器在此文献中的使用过程03将纯AFB1(20mL)的水溶液转移到高压反应器(100mL)中,然后置于多功能微波化学合成仪XH-8000Plus(北京祥鹄科技有限公司,北京,中国)中(图1 )。容器内的温度显示在实时控制面板并由温度传感器检测插入容器中。本仪器有两种不同的功率输出方式:恒量输出和比例积分微分自适应功率调节输出。后者可以保持恒定的微波加热温度。基本原理和保持恒温的过程是微波设备将样品快速加热至接近设定温度恒定功率(500W)。然后系统自动切换到第二种模式。微波计算机自动计算并输出适当的低微波功率。因为这种低微波功率辐照产生的热量等于辐射损失的热量样品的自然冷却,样品的温度保持恒定(±0.2°C)。然后,对 AFB1样品进行处理WMI110°C、120°C、130°C和140°C下的不同时间。确定微波功率对降解的影响对于AFB1,使用以下方法。高压反应器是用一个三角形瓶(250mL)代替,瓶颈与一个冷凝回流装置连接(图 1)。将AFB1样品加热到沸腾温度(100°C)功率(500 W),然后使用不同的微波功率(200、300、400和 500 W)。考虑到水在WMI处理过程中蒸发,有必要三角瓶中加入适量超纯水治疗。添加的水的质量(或体积)等于处理前后还原水的质量(或体积)。结论06结论:在这项研究中,研究了WMI对AFB1的降解动力学、产物和途径。研究了WMI对AFB1的降解动力学、产物和途径。结果表明,WMI对AFB1的降解很好地遵循了伪前序反应动力学。遵循伪一阶反应动力学(R2>0.95)。这表明在AFB1的降解过程中,水分子不仅起到了溶剂的作用,而且还参与了化学反应。六种新的通过UHPLC-Orbitrap-MS鉴定了6种新的降解产物,并提出了一条可能的降解途径。此外,AFB1降解产物的种类和数量以及AFB1的降解路径受到微波加热温度、时间和功率的影响。经WMI处理后,AFB1末端呋喃环上的双键和呋喃末端环上的双键和AFB1的内酯键都被破坏了,这说明降解产物的毒性是显著的。这表明降解产物的毒性明显降低。因此,WMI预计是一种很有前途的降解AFB1的方法。

关闭-

1/8

-

2/8

还剩6页未读,是否继续阅读?

继续免费阅读全文产品配置单

北京祥鹄科技发展有限公司为您提供《黄曲霉毒素B1中微波辅助降解检测方案(微波合成仪)》,该方案主要用于其他中其他检测,参考标准《暂无》,《黄曲霉毒素B1中微波辅助降解检测方案(微波合成仪)》用到的仪器有多用途微波化学合成仪、Nanocube 多功能微波水热平行合成仪。

我要纠错

相关方案

咨询

咨询