方案详情文

智能文字提取功能测试中

烫漂对木薯干叶品质的影响Pretreatment of the Leaves of Ethiopian Cassava (Manihot esculenta Crantz) Varieties Effect of Blanching on the Quality of Dried Cassava Leaves食FFUUUappliedSCLsciencesMDPI 2 of 11Appl. Sci. 2022, 12,11231 check for updates Academic Editor: Roberto Anedda Received: 6 October 2022 Accepted: 3 November 2022 Published: 5 November 2022 Publisher's Note: MDPI stays neutralwith regard to jurisdictional claims inpublished maps and institutional affil-iations. Pretreatment of the Leaves of Ethiopian Cassava(Manihot esculenta Crantz) Varieties: Effect of Blanching on theQuality of Dried Cassava Leaves Haimanot Hailegiorgis Ayele *D, Sajid LatiffiicD:and Joachim MullerriDD Institute of Agricultural Engineering, Tropics and Subtropics Group, University of Hohenheim, 70599 Stuttgart, Germany * Correspondence: info440e@uni-hohenheim.de or haimanot.ayele@uni-hohenheim.de;Tel.: +49-(0)711-459-23112 Abstract: The aim of this work was to study the effect of blanching and drying on the quality of fourEthiopian cassava varieties (Chichu, Hawassa-4, Quelle,and Kello). Cassava leaves were subjectedto blanching at 100°C in plain water, 0.2% NaHCO3, and 0.4% NaHCO3 for five minutes. Cassavaleaves without blanching were considered as a control. The drying temperature was set at 60 °℃with a constant air velocity of 0.14 ms-1. A high reduction in vitamin C (95.6% in Chichu, 95.0% inHawassa-4, 94.9% in Quelle, and 94.4% in Kello) was noticed in leaves blanched in the 0.4%NaHCO3solution. After blanching, the reduction in the ash content was higher for those blanched in plainwater. The crude fiber and protein content were improved by blanching. Blanching in clear waterwas more effective among the different solutions in reducing the cyanide content in the leaves ofKello, Quelle, and Chichu by 51, 33, and 60%, respectively. While for Hawassa-4, the reduction washigher (47%) with the 0.2%NaHCOs solution. After blanching, the h° values decreased, while a*,b*, and c* increased. Plain water blanching resulted in a better nutritional quality, while Hawassa-4exhibited the best nutritional value among the four varieties. Keywords: cassava leaves; blanching; NaHCO3; nutrient; cyanide; vitamin C 1. Introduction In Ethiopia, cassava was introduced in the 1960s but was not considered as a foodcrop until 1984 [1]. It is locally known as the Yenchet Boye, Mita Boye, Mogo, and Furnotree, and has been mainly cultivated by small-scale farmers on small plots of land [2]. Itserves as a food security crop and a source of household income in different parts of thecountry; however, it is consumed more in the southern region of the country [3,4]. Eventhough the consumption of cassava leaves has been recognized in different parts of theworld for many decades, it is not used as a food in Ethiopia [5]. Cassava is mainly producedin Ethiopia for its t心110ubers, which are boiled for direct consumption or used to produce flour.The flour is used to produce composite flours for the preparation of bread and Injera [6,7].The use of leaves like cassava leaves as a vegetable has been limited due to the high levelof anti-nutritional factors (oxalates, nitrates, tannins, and phytates) and cyanide in theleaves [8]. In other countries, cassava leaves are traditionally prepared by pounding or chopping,fermentation for a day or two, or by boiling them for several hours to reduce the cyanidelevel [9]. Different experiments are also done to evaluate the different processing mech-anisms including cooking, fermentation [10], soaking [11] the addition of 0.4% sodiumbicarbonate (NaHCO3), enzymatic and ultrasonic treatments [12] and drying [13]. For vari-eties with a high initial cyanogen glucoside content, drying alone is not an efficient methodto detoxify cassava leaves [14]. To facilitate the detoxification process, cassava leaves canbe processed by drying combined with pounding [15], fermentation, blanching [16],and hot water cooking [17]. This also helps to reduce the anti-nutritional content and results ina better taste and texture of the end products. One of the most important pretreatment processes used in food preparation andpreservation is blanching [18]. It is used to inactivate enzymes, increase the dehydrationrate, and reduce the microbial load [19,20]. To select a suitable blanching method, it isimportant to understand the different temperatures, duration times, the physical andchemical properties of the products, and the effect of different technologies, as these have asignificant impact on the quality of the final products [18,19,21]. Due to the variations of theproperties among different vegetables, no single blanching technology can be effectivelyapplied to all products [19,21]. Blanching leads to a better retention of protein, dietaryfiber, and a higher fat content [22,23]. Green leafy vegetables are a rich source of vitamins,minerals, polyphenols, flavonoids, and antioxidants. Pre-treatment by blanching beforethe drying process helps to maintain the color quality of leaves with high chlorophyllcontents [24]. On the other hand, drying can cause an increase in the concentration ofnutrients [25]. Having a high nutritional and mineral value, cassava leaves can be usedas leafy vegetables after blanching [26]. For many leaves and vegetables, other blanchingsolutions besides pure water are used before drying, e.g.,NaHCO3 [27]. Adding NaHCO3in cassava leaf processing has been practiced in some countries [28]. This is believed tohave an impact on the pH content and facilitates the spontaneous decomposition of acetonecyanohydrin [12]. The blanching and drying of cassava leaves and the effect it has on the nutritionaland antinutritional content of the final product can play a role in their acceptance asa potential alternative food source. An additional study on the processing of cassavaleaves can play a great role to ensure the nutritional quality and safety of the products forhuman consumption. With this in mind, studies targeting the reduction of cyanide and themaintenance of the nutritional content of processed cassava leaves are needed [15]. Eventhough the consumption of cassava leaves as a vegetable has not yet been established inEthiopia, recent research focused on the effect of different processing methods, but onlytwo varieties were investigated [5,29]. The consumption of cassava leaves in Ethiopia canplay a role to close the malnutrition gap in the country. Therefore, this study investigatedthe differences in the nutrient and antinutrient composition of the dried leaves of fourEthiopian cassava cultivars released by research centers and how they are affected bydifferent blanching methods. 2. Materials and Methods 2.1. Material To cultivate cassava plants, stem cuttings of four varieties (Chichu, Hawassa-4, Quelle,and Kello) were brought from Hawassa Agricultural Research Center, in Hawassa, Ethiopia,in compliance with the applicable export and import regulations, and were planted in agreenhouse at the University of Hohenheim. Six months after planting, leaves with petioleswere harvested by hand from each variety. The leaves were brought to the laboratory onthe day of harvest and the petioles were removed. 2.2. Methods 2.2.1. Sample Preparation Cassava leaves (100 g for each sample run) were subjected to blanching at 100 °℃ with300 mL of plain water, 0.2% NaHCO3, and 0.4%NaHCO3 for five minutes and immediatelycooled down under running water to stop further cooking. These conditions were setbased on previous suggestions for cassava processing and blanching [9,12,30]. Cassavaleaves without blanching were considered as the control. The blanched leaves were leftat room temperature on the drying tray for 30 min to allow the excess water to dissipate.The cyanide, dry matter, color, and vitamin C content of the samples were measured beforeand after blanching. The drying temperature was set at 60°C with a constant air velocityof 0.14 m/s. The experiments were conducted in three independent runs. The dryer was preheated for 1 h to the set temperature before the sample trays were loaded. A 100 gsample was dispersed uniformly on the tray and the trays were placed in a cabinet drier(HT 15, Innotech Ingenieursgesellschaft mbH, Altdorf, Germany) in a randomized order.During drying, the samples were weighed over 30 min intervals to monitor water loss untila constant mass was obtained. The dried samples were triturated in a blender (ThermomixTM5, Vorwerk, Cloyes, France) and packed in aluminium foil bags. The samples werestored at -20°C until the chemical analyses were performed. 2.2.2. Chemical Analysis All chemical analyses were conducted in triplicate for each sample run. In the study,picric acid and linamarin (Sigma-Aldrich St. Louis, MO, USA), sodium carbonate, sodiumphosphate, sulfuric acid, sodium hydroxide, L-ascorbic acid (VWR chemicals, Leuven,Belgium), ammonium dihydrogen phosphate, metaphosphoric acid, orthophosphoricacid, and perchloric acid were purchased from Merck (Darmstadt, Germany). All chem-icals and reagents used were of analytical grade and were used following each methoddescribed below. Vitamin C analysis was determined after blanching and drying according to themethod of Valente, et al. [34] by using High-performance liquid chromatography HPLC(Shimadzu, Kyoto, Japan). Cassava leaf (1 g of fresh or 0.5 g of dried) samples were placedin a small mortar and 5 mL of extraction solution, 10%(w/u) perchloric acid with 1%(w/u)meta-phosphoric acid, were added. The samples were crushed for 2 min, then 15 mL ofextraction solution were added, and the mixture was left standing for 10 min. The sampleswere centrifuged (Sorvall RC6 superspeed centrifuge, Kendro Co., Hanau, Germany) for10 min at 4 °C at a speed of 15,000 rpm and were then filtered through a 0.45 um Nylonmembrane. The standard curve was prepared from L-ascorbic acid (Chem-supply PtyLtd., Port Adelaide Enfield, Australia) diluted with the mobile phase (Figure A1). TheHPLC peaks were separated by 250×4.6 mm columns Luna 5u C18(2) 100A (Phenomenex,Torrance, CA, USA). The mobile phase was 20 mM of ammonium dihydrogen phosphatemixed with 0.015%(w/u) m-phosphoric acid in HPLC water that was adjusted to a pHof 3.5 with 10 mol-1 L of NaOH. The mobile phase was set at a flow rate of 0.6 mL permin and ran constantly for 20 min. The quantification of the ascorbic acid components wasperformed at 254 nm. The crude protein content was analysed by the Kjeldahl analysis system (Vapodest500, C. Gerhardt GmbH & Co. KG, Konigswinter, Germany). The crude fiber content of thesamples was measured following the method described by the AOAC [31] official method962.09 using an automated fiber analysis system (FibreBag Analysis System FBS6, GerhardtGmbH & Co. KG., Konigswinter, Germany). The CIELAB values including darkness/lightness (L*), red-green color (a*), and yellow-blue color (b*) values of dried samples were measured using a color meter (CM-600dSpectrophotometer, Konica Minolta, Tokyo, Japan). The hue value (h) and chroma (C*)were calculated as described by Mclellan, et al. [35] as indicated below: The total color changes with respect to dried untreated leaves (^E) were calculated asdescribed by Sledz, et al. [36] as follows: 2.3. Statistical Analysis The analysis of variance and Tukey test were performed to compare means of valuesin fresh, blanched, and dried cassava leaves. The experiments were conducted in three in-dependent runs. The statistical analysis was conducted using statistical analysis software(SAS) (version 9.4, SAS Institute Inc., Cary, NC,USA). 3. Results and Discussion The initial moisture content of fresh cassava leaves before drying was 81.1 ±0.6%,77.8±0.9%,78.9±0.8%, and 78.3±0.1% for Chichu, Hawassa-4, Quelle, and Kello, re-spectively. After blanching, the moisture content of the leaves increased on average by 10%.During drying, the moisture content of the fresh leaves (control) reduced continuously untila constant moisture content was established for Chichu (5.3±0.2), Hawassa-4 (5.4±0.1),Quelle (5.9±0.3), and Kello (4.9 ±0.3). The moisture loss was initially very rapid, whilethe evaporation rate decreased with increasing drying time. It took 4 h for the controland 5 h for the blanched leaves to reach a constant moisture content. The initial moisturecontent of the samples had an impact on the time to reach a constant value. 3.1. Cyanide Content 3.2. Nutritional Content 3.2.1. Vitamin C Vitamin C is highly heat and pH-sensitive to different leaf processing methods, includ-ing blanching [46-48]. Due to the instability of vitamin C, one of the highest nutritionallosses in cassava leaf processing is that of vitamin C. In the current study, the control ofHawassa-4 had the highest amount in vitamin C among the four varieties used in thisstudy. The highest reduction (95.6% in Chichu, 95.0% in Hawassa-4,94.9% in Quelle, and94.4% in Kello) in vitamin C was noticed when the leaves were blanched in water with0.4% NaHCO3 (Figure 1c). The impact of drying after blanching on the vitamin C content was not significant in comparison to the blanching process (Figure 1d). The pH of the plainwater used for blanching was 6.2 whereas the levels for 0.2% NaHCO3 and 0.4%NaHCO3were 8.77 and 8.82, respectively. Due to the pH variation in the blanching solutions, thevitamin C loss in the leaves blanched with plain water was lower than for the other twoblanching solutions. The effect of blanching on the vitamin C content was similar to theblanching of sweet potato leaves for 2 min, which resulted in the total loss of vitamin C [49]while a loss of more than 50% was found in Moringa oleifera leaves [50]. The vitaminC content of all cassava leaf varieties in this study was higher than reported by da SilvaSantos,Requiao Silva, Minho, Brandao, Pinto dos Santos, Carvalho dos Santos, Lopes Silva,and Lopes dos Santos [10]. Hawassa-4 Qulle Kello Figure 1. Influence of blanching and drying on (a,b) cyanide, (c,d) vitamin C, (e,f) ash, (g) protein,and (h) crude fiber content of leaves from Ethiopian cassava varieties. Bars with the same letter arenot significantly different from other samples within the same variety. 3.2.2. Ash Content After blanching, the reduction in ash content was higher in the trials with plain waterfor all varieties used in this study. This was caused by the leaching process of the mineralsin the leaves [51]. Adding NaHCO3 to the blanching solution had a positive impact on the reduction of the ash content (Figure 1e,f). A similar trend was observed for the ash contentof beetroot leaves after drying [52]. The reduction in plain water was high and this wassimilar to previous research done for other cassava varieties [26]. 3.2.3. Protein Content From a preliminary experiment, it was found that the crude protein and fiber contentof cassava leaves during blanching before drying was insignificant. After drying theblanched leaves, the protein content of all the cassava varieties was not significantlyaffected by the different blanching solutions, but was improved by the blanching process(Figure 1g). Results from this study are similar to those reported by Awoyinka, Abegunde,and Adewusi [9] for cassava leaves and Pawase, et al. [53] for drumstick leaves. This mighthave been caused by the losses of sugars, minerals, and vitamins to the blanching water,resulting in the changes in the total solids and an increase in protein on a dry basis [54]. 3.2.4. Crude Fiber Content The crude fiber content in the leaves increased for all varieties after blanching (Figure 1h).This result is similar to that reported by other authors for cassava leaves and other leafyvegetables [52] and contrary to the report made by Udoetok and Uffia [26]. The loss of drymatter plays a role in the increase in crude fiber in the blanched dry leaves [55]. 3.3. Color The influence of color on fresh and dried food plays a significant role in the accept-ability of the product by consumers. The quality of a dried product is evaluated by peoplebased on their visual impression of the product. The negative values of a* coefficient,representing greenness, and the color saturation (chroma C) of the green leafy vegetablesare crucial factors describing the quality of the leaves [36]. The results of the current studyshow that the different leaf pigments were significantly affected by blanching and dryingcompared to the fresh leaves (p<0.05). From the four varieties, Chichu and Kello exhibiteda high value for L*, b*, C*, and a lower a* value. The h° value of Hawassa-4 was the highestamong the four varieties. After blanching, the h° values were reduced while those for a*, b*, and C* increased(Table 1). The a* value of the dried control leaves varied from -8.3 to -6.4. This indicatedthat the blanched leaves were less green than fresh cassava leaves. The L* value of thedried cassava leaves ranged from 45.2 to 32.7 and the b* value from 30.4 to 8.0 dependingon the variety and the blanching conditions. Higher L* and b* values were recorded in thecontrol of Kello, whereas lower values were recorded in the Hawassa-4 treated with 0.4%NaHCO3. In the current study, the color value L* was equal and a* values were lower thaneL”Vthose reported by Latif, et al. [56], which was caused by the different varieties used in thestudies. The impact of blanching and drying on the quality of the four cassava varietieswas lower than that recorded for leaves dried without blanching. These color qualitieswere better in all four varieties in the control group, and best in the Kello variety. Generally,a greater diversity of the a* coefficient was observed in samples dried after blanching. Forthese samples, blanching resulted in a greater change in leaf color, whereas the results forthe control cassava leaves were comparable to those of the untreated dried sample. It canbe concluded that blanching resulted in a darker color of the cassava leaf compared to thefresh one. When the total color difference (^E) value is higher than 2, it indicates a coloralteration visible for the consumers [36]. Based on this criterion, the color of most of thedried leaves changed in relation to the fresh ones (Table 1). Pre-treatment by blanchingbefore the drying process resulted in a better color quality than for fresh leaves, which wassimilar to what was reported for herbal tea [24]. The AE indicates the degree of changebetween the control and treated dried samples, not the direction of the changes. Addingsodium bicarbonate to the blanching process had an impact on the color change of theleaves after drying, while the change was the highest in the dried controls. This is similarto what was reported for other vegetable leaves [57]. Table 1. Effect of blanching and drying on the color quality of different cassava varieties. Blanched Dried Variety Treatment L* b* C* AE L* a* b* C* h* AE Chichu Control 33.0±0.6 -8.4±0.1占 11.8±1.1℃ 14.5±0.9D 125.4±2.6a 一 44.8±1.0a -10.4±0.4 23.3±0.6a 25.5±0.7a 114.0±0.4a Plain water 28.3±0.4D -4.2±0.2 14.3±0.6ab 14.9±0.7ab 106.4±0.1℃ 7.0±0.4 35.6±0.6D -4.7±0.24 11.9±0.6 12.8±0.6 111.4±0.8 4.2±0.2D 0.2%NaHCO3 28.1±0.9b -7.1±0.1b 15.3±1.0a 16.9±0.8 115.0±1.9b 6.6±1.0 35.1±0.8b -5.0±0.13 12.8±0.3 bc 13.8±0.3 bc 111.2±0.8 3.9±0.5D 0.4%NaHCO: 33.3±0.2a -4.0±0.1a 12.5±0.8 bc 13.1±0.7b 107.6±1.4 4.4±0.3b 33.7±0.6 -5.3±0.0a 13.3±0.3b 14.3±0.3b 111.6±0.6D 3.4±0.2 Hawassa-4 Control 30.0±0.5a -6.4±0.2 7.3±0.3b 9.7±0.3b 131.2±0.7a 一 42.6±0.0a -10.1±0.2 24.2±0.4a 26.3±0.4a 112.6±0.2b Plain water 28.5±1.2a -4.6±0.2ab 6.7±0.2D 8.2±0.2占 124.3±1.6b 2.6±0.6 33.1±1.0b -4.3±0.2a 10.7±0.7b 11.5±0.7b 111.7±0.5b 5.1±1.3b 0.2%NaHCO3 25.0±0.4b -4.8±0.5b 13.3±1.1a 14.2±1.0a 110.0±2.6 8.1±0.7b 33.5±0.1b -4.5±0.2a 8.5±0.3 9.6±0.2℃ 117.9±1.5a 4.1±0.5b 0.4%NaHCO3 23.7±0.3b -3.9±0.3 13.2±0.2a 13.8±0.3 106.7±0.9 9.0±0.1a 32.7±0.65 -4.4±0.1a 8.0±0.6 9.1±0.5℃ 119.0±2.0a 3.4±0.2℃ Quelle Control 31.9±0.7 -6.4±0.3 8.6±0.3 10.7±0.1℃ 126.7±2.0 44.6±0.7 -10.5±0.1 25.0±0.6 27.1±0.6 112.8±0.5 21.1±0.8 Plain water 27.5±0.5b -4.3±0.2ab 13.1±0.4b 13.7±0.4D 108.3±0.2D 6.6±0.9C 35.9±0.8b -4.4±0.2a 10.7±0.2C 11.5±0.2C 112.5±1.1a 5.0±1.3D 0.2%NaHCO3 25.8±0.2 -3.7±0.2a 14.6±1.2ab 15.1±1.2ab 104.3±1.0 9.0±0.3b 36.0±1.4b -4.6±0.2a 10.5±0.3 11.5±0.3 113.5±0.8a 5.0±1.6b 0.4%NaHCO3 24.7±0.6 -4.4±0.3b 16.0±0.9a 16.6±0.9a 105.2±0.2 10.6±0.4a 33.9±0.6b -4.8±0.0a 13.3±0.3b 14.1±0.2D 109.7±0.4b 5.4±0.6b Kello Control 33.0±0.8 -8.1±0.1℃ 11.0±0.4a 13.7±0.3ab 126.5±1.3b 45.2±1.3 -11.9±0.5b 30.4±1.9a 32.6±2.0 111.3±0.5b Plain water 32.9±0.1a -5.0±0.4a 11.3±0.4a 12.3±0.2b 114.1±2.4 3.3±0.5b 34.8±2.0b -6.3±0.3a 14.8±1.2 16.1±1.1b 113.2±2.2ab 5.1±0.7b 0.2%NaHCO3 30.7±0.6b -6.5±0.2 12.7±1.2a 14.3±1.1a 117.1±2.4 3.5±1.2D 35.6±0.2 -5.9±0.1a 12.5±0.2b 13.8±0.2D 115.2±0.2a 3.8±0.8℃ 0.4%NaHCO3 34.2±0.4 一-6.4±0.3D 6.8±0.5b 9.3±0.4 133.8±2.34 4.8±0.4 35.3±0.2b -5.9±0.1日 12.7±0.1 14.1±0.1D 114.9±0.4 3.7±0.7℃ * Values with the same super script letter are not significantly different from other samples within the same variety. L*—darkness/lightness,a*—red-green color, b*-yellow-blue color,h°—hue value, C*-chroma, and AE-total color change. 4. Conclusions This research investigated the effect of blanching on the nutritional and anti-nutritionalproperties of leaves from four cassava varieties. The results obtained have shown thatblanching can decrease both the nutritional and anti-nutritional properties of the samples.Even though the reduction of cyanide was high, it did not reach a safe level to be recom-mended for human consumption. Therefore, further methods should be introduced toprocess leaves from Ethiopian cassava varieties to reach a safe level. The dried cassavaleaves pre-treated by blanching prior to drying had a darker color, and the AE values werelower than the control after drying. Plain water blanching for 10 min resulted in better nu-tritional quality. Among the four varieties, Hawassa-4 exhibited a better nutritional value.While blanching was found to affect the nutritional properties of the samples, this did notaffect the potential of the leaves to be used as leafy vegetables. Cassava leaves can be usedas vegetables and in the preparation of snacks with appropriate processing methods. Author Contributions: Conceptualization, H.H.A.; methodology, H.H.A.; software, H.H.A.; formalanalysis,H.H.A.;investigation, H.H.A.; resources,J.M.and S.L.; data curation,H.H.A.; writing-originaldraft preparation, H.H.A.; writing-review and editing,H.H.A., J.M. and S.L.; supervision, J.M. andS.L.; project administration, S.L.; funding acquisition, J.M. and S.L. All authors have read and agreedto the published version of the manuscript. Funding: This publication is the result of a Ph.D. scholarship at the University of Hohenheim in theframework of the project "German-Ethiopian SDG Graduate School: Climate Change Effects on FoodSecurity (CLIFOOD)" between the University of Hohenheim (Germany) and the Hawassa University(Ethiopia), supported by the DAAD with funds from the Federal Ministry for Economic Cooperationand Development (BMZ)". The publication was prepared in cooperation with the Institute ofAgricultural Engineering, Tropics and Subtropics Group, at the University of Hohenheim, Germany. Data Availability Statement: The data presented in this study are available on request from thecorresponding author. The data are not publicly available due to privacy. Acknowledgments: The authors are appreciative of all the help from the lab team and colleaguesin the Institute of Agricultural Engineering, Tropics and Subtropics Group, at the University ofHohenheim, Germany. The authors are thankful to Sabine Nugent for language editing. Conflicts of Interest: The authors declare no conflict of interest. The funders had no role in the designof the study, collection, analyses, or interpretation of data; nor in the writing of the manuscript, or inthe decision to publish the results. Appendix A (a) Figure A1. Cont. 25 Figure A1. HPLC-chromatogram from the standard (L-ascorbic acid) (a) and cassava leaf sample (b). References 1. Kebede, A.; Teshome, B.; Wondimu, A.; Belay, A.; Wodajo, B.; Lakew, A. Detoxification and Consumption of Cassava Based Foodsin South West Ethiopia. Pak. J. Nutr. 2012, 11, 237-242. [CrossRef] 2. Misganaw,C.D.; Bayou, W.D. Tuber yield and yield component performance of cassava (Manihot esculenta) varieties in FafenDistrict, Ethiopia. Int. J. Agron. 2020,2020,5836452. [CrossRef] 3. Parmar, A.; Sturm, B.; Hensel, O. Crops that feed the world: Production and improvement of cassava for food, feed, and industrialuses. Food Secur. 2017, 9,907-927.[CrossRef] 4. Atnafua, B.; Tesfaye, T.; Asfaw, K.; Tewodros, M.; Getachew, E.; Neim. The Elite Cassava Genotypes with High Yield and Stabilityin Diverse Environmental Conditions of Ethiopia. Curr. Top. Agric. Sci. 2021,2,81-89. [CrossRef] 5. Parmar, A.; Fikre, A.; Sturm, B.; Hensel, O. Post-harvest management and associated food losses and by-products of cassava insouthern Ethiopia. Food Secur. 2018,10,419-435. [CrossRef] 6. Banti, M.; Atlaw, T.; Gebre, B. Injera Making Quality Evaluation of Tef and Cassava Composite Flour. Am. J. Biosci. Bioeng. 2020,8,99-104. [CrossRef] 7. Bayata, A. Review on nutritional value of cassava for use as a staple food. Sci. J. Anal. Chem. 2019, 7,83-91. [CrossRef] 8. Sarkar, T.; Salauddin, M.; Roy, S.; Chakraborty, R.; Rebezov, M.; Shariati, M.A.; Thiruvengadam, M.; Rengasamy, K.R.R. Underutilized green leafy vegetables: Frontier in fortified food development and nutrition. Crit. Rev. Food Sci. Nutr. 2022,62,1-55.[CrossRef| 9. Awoyinka, A.F; Abegunde, V.O.; Adewusi, S.R. Nutrient content of young cassava leaves and assessment of their acceptance as agreen vegetable in Nigeria. Plant Foods Hum. Nutr. 1995, 47,21-28. [CrossRef] 10. da Silva Santos, B.R.; Requiao Silva, E.F.;Minho, L.A.C.; Brandao, G.C.; Pinto dos Santos, A.M.; Carvalho dos Santos, W.P.; LopesSilva, M.V.; Lopes dos Santos, W.N. Evaluation of the nutritional composition in effect of processing cassava leaves (Manihotesculenta) using multivariate analysis techniques. Microchem. J. 2020,152,104271.[CrossRef] 11. Hawashi, M.; Sitania, C.; Caesy, C.; Aparamarta, H.W.; Widjaja, T; Gunawan, S. Kinetic data of extraction of cyanide during thesoaking process of cassava leaves. Data Brief 2019, 25,104279. [CrossRef] [PubMed] 12. Latif, S.; Zimmermann,S.; Barati, Z.;Muller, J. Detoxification of Cassava Leaves by Thermal, Sodium Bicarbonate, Enzymatic,and Ultrasonic Treatments. J. Food Sci. 2019,84,1986-1991.[CrossRef] [PubMed] 13. Laya, A.; Koubala, B.B. Changes in Vitamin E and B Carotene Contents in Various Edible Cassava Leaves (Manihot esculentaCrantz) of Different Ages across Multiple Seasons. Int. J. Agron. 2020,2020,4671018. [CrossRef] 14. Montagnac, J.A.; Davis, C.R.; Tanumihardjo, S.A. Processing Techniques to Reduce Toxicity and Antinutrients of Cassava for Useas a Staple Food. Compr. Rev. Food Sci. Food Saf. 2009,8, 17-27. [CrossRef] 15. Umuhozariho,M.; Shayo,N.; Sallah, P.; Msuya, J. Sensory evaluation of different preparations of cassava leaves from three speciesas a leafy vegetable. Afr. J. Biotechnol. 2013, 12, 6452-6459.[CrossRef] 16. Waluchio, C.N. Nutrient and Antinutrient Content in Leaves of Selected Coastal Kenya Cassava Varieties as Affected by MaturityStage, Leafage and Preparation Method. Master’s Thesis, University of Nairobi, Nairobi, Kenya, 2016. 17. Modesto Junior, E.N.; Chiste, R.C.; Pena, R.d.S. Oven drying and hot water cooking processes decrease HCN contents of cassavaleaves. Food Res. Int. 2019,119,517-523.[CrossRef] 18. Hamid,S.S.; Wakayama, M.; Ashino, Y.; Kadowaki,R.; Soga, T.; Tomita, M. Effect of blanching on the concentration of metabolitesin two parts of Undaria pinnatifida, Wakame (leaf) and Mekabu (sporophyll). Algal Res. 2020, 47,101829. [CrossRef] Trivedi, A.; Saraswat, S.; Yadav, P. Effect of blanching on greenvegetables. URRJ-JVWU 2018,1,218-225.28 Klungboonkrong, V;Phoungchandang, S.; Lamsal, B. Drying of Orthosiphon aristatus leaves: Mathematical modeling, dryingcharacteristics, and quality aspects. Chem. Eng. Commun. 2018, 205,1239-1251. [CrossRef] 21. Xiao, H.-W.; Pan, Z.;Deng, L.-Z.; El-Mashad, H.M.; Yang, X.-H.;Mujumdar, A.S.; Gao, Z.-J.; Zhang, Q. Recent developments andtrends in thermal blanching-A comprehensive review. Inf. Process. Agric. 2017,4,101-127.[CrossRef] 22. Kshirsagar, R.B.; Sawate, A.R.; Sadawate, S.K.; Patil, B.M.; Zaker, M.A. Effect of blanching and drying treatment on the proximatecomposition of Moringa oleifera leaves. Int. J. Agric. Eng. 2017, 10, 10-15.[CrossRef] 23. Mythili, S.; Rajeswari, N.; Bosco, S.J.D.; Kamatchi alias Rajalechumi, A. Impact of blanching treatments on the chemicalcomposition, total dietary fiber, physicochemical, functional, and structural properties of underutilized cauliflower leaves(Brassica oleracea var. botrytis). J. Food Process. Presero. 2021,45, e15910.[CrossRef] 24. Saetan, P.;Usawakesmanee, W.; Siripongvutikorn, S. Influence of hot water blanching process on nutritional content, microstruc-ture, antioxidant activity and phenolic profile of Cinnamomum porrectum herbal tea. Funct. Foods Health Dis. 2016, 6,836-854.[CrossRefl 25. Meena, S.; Agrawal, M.; Agrawal, K. Effect of blanching and drying on antioxidants and antioxidant activity of selected greenleafy vegetables. Int. J. Sci. Res. 2016,5,1811-1814. 26. Udoetok,I.; Uffia, I. Effect of blanching on nutrient and anti-nutrient level of leaves of some varieties of cassava (Manihot esculentaC.). J. At. Mol. 2012,2,387. 27. Bishnoi, S.; Chhikara, N.; Singhania, N.; Ray, A.B. Effect of cabinet drying on nutritional quality and drying kinetics of fenugreekleaves (Trigonella foenum-graecum L.). J. Agric. Food Res. 2020, 2,100072. [CrossRef] 28. Achidi, A.U.; Ajayi, O.A.; Maziya-Dixon, B.; Bokanga, M. The Effect of Processing on the Nutrient Content of Cassava (Manihotesculenta Crantz) Leaves. J. Food Process. Presero. 2008,32,486-502.[CrossRef] 29. Terefe, Z.K.; Omwamba,M.;Nduko, J.M. Effect of microbial fermentation on nutritional and antinutritional contents of cassavaleaf. J. Food Saf. 2022,42,e12969. [CrossRef] AOAC. Official Methods of Analysis of AOAC; Association of Official Analytical Chemists: Arlington, VA, USA, 2005. Bradbury, M.G.;Egan, S.V; Bradbury, J.H. Picrate paper kits for determination of total cyanogens in cassava roots and all forms ofcyanogens in cassava products. J. Sci. Food Agric. 1999,79,593-601. [CrossRef] 33. Haque,M.R.; Bradbury, J.H. Preparation of linamarase solution from cassava latex for use in the cassava cyanide kit. Food Chem.1999,67,305-309. [CrossRef] 34. Valente, A.; Albuquerque, T.G.; Sanches-Silva, A.; Costa,H.S. Ascorbic acid content in exotic fruits: A contribution to producequality data for food composition databases. Food Res. Int. 2011, 44, 2237-2242. [CrossRef] 35. Mclellan, M.R.; Lind, L.R.; Kime, R.W. Hue angle determinations and statistical analysis for multiquadrant hunter L,a,b data.J. Food Qual. 1995, 18,235-240.[CrossRef] 36. Sledz, M.; Wiktor, A.; Rybak, K.;Nowacka, M.; Witrowa-Rajchert, D. The impact of ultrasound and steam blanching pre-treatmentson the drying kinetics, energy consumption and selected properties of parsley leaves. Appl. Acoust. 2016,103,148-156.[CrossRef]37. Indrastuti, E.; Estiasih, T.;Zubaidah, E. Physicochemical characteristics and In vitro starch digestibility of spontaneously combinedsubmerged and solid state fermented cassava (Manihot esculenta Crantz) flour. Curr. Nutr. Food Sci. 2019,15,725-734.[CrossRef] 38. Fadahunsi, I.F.; Busari,N.K.; Fadahunsi, O.S. Effect of cultural conditions on the growth and linamarase production by a localspecies of Lactobacillus fermentum isolated from cassava effluent. Bull. Natl. Res. Cent. 2020, 44, 185.[CrossRef] 39. Kuliahsari, D.; Sari, I.;Estiasih, T. Cyanide detoxification methods in food: A review. In Proceedings of the IOP Conference Series:Earth and Environmental Science,Surakarta, Indonesia, 24-25 August 2021; p.012099. 40. Indrastuti, Y.; Estiasih, T.; Christanti, R.; Pulungan, M.; Zubaedah, E. Microbial and some chemical constituent changes of highcyanide cassava during simultant spontaneous submerged and solid state fermentation of "gadungan pohung". Int. Food Res.J.2018,25,487-498. 41. Lambebo, T.; Deme, T. Evaluation of Nutritional Potential and Effect of Processing on Improving Nutrient Content of Cassava(Mannihot esculenta crantz) Root and Leaves. bioRxiv 2022. [CrossRef] Ndubuisi, N.; Chidiebere, A. Cyanide in cassava a review. Int. J. Genom. Data Min. 2018, 2,118-227. [CrossRef]43 Leguizamon, A.J; Rompato, K.M.; Hoyos, R.E.; Audisio, M.C. Nutritional evaluation of three varieties of cassava leaves (Manihotesculenta Crantz) grown in Formosa, Argentina. J. Food Compos. Anal. 2021, 101,103986. [CrossRef] 44. Okoth, R.A.; Matofari, J.W.; Nduko, J.M. Effectiveness of Levilactobacillus brevis fermentation on antinutrients and proteinquality of leaves of selected cassava varieties. Appl. Food Res. 2022, 2,100134. [CrossRef] 45. Ospina, M.A.; Pizarro, M.; Tran, T.; Ricci,J.;Belalcazar, J.; Luna, J.L.; Londono, L.F.; Salazar, S.; Ceballos, H.; Dufour, D.; et al.Cyanogenic, carotenoids and protein composition in leaves and roots across seven diverse population found in the world cassavagermplasm collection at CIAT, Colombia. Int. J. Food Sci. Technol. 2021,56,1343-1353. [CrossRef] 46. Wickramasinghe, Y.W.H.; Wickramasinghe, I.; Wijesekara, I. Effect of Steam Blanching, Dehydration Temperature & Time, on theSensory and Nutritional Properties of a Herbal Tea Developed from Moringa oleifera Leaves. Int. J. Food Sci. 2020,2020,5376280.[CrossRef] [PubMed] 47.COwade,J.O.; Abong', G.; Okoth, M.;Mwang’ombe, A.W. A review of the contribution of cowpea leaves to food and nutritionsecurity in East Africa. Food Sci. Nutr. 2020, 8,36-47. [CrossRef] 48. Mondragon-Portocarrero, A.d.C.; Pena-Martinez, B.; Fernandez-Fernandez,E.;Romero-Rodriguez, A.; Vazquez-Oderiz, L. Effectsof different pre-freezing blanching procedures on the physicochemical properties of Brassica rapa leaves (Turnip Greens, Grelos).Int. J. Food Sci. Technol. 2006, 41,1067-1072. [CrossRef] 50. Arwani, M.; Wijana, S.; Kumalaningsih, S. Nutrient and saponin content of Moringa oleifera leaves under different blanchingmethods. IOP Conf. Ser. Earth Environ. Sci. 2019,230, 012042.[CrossRef] 51. Nobosse,P; Fombang, E.N.;Mbofung, C.M.F. The effect of steam blanching and drying method on nutrients, phytochemicals andantioxidant activity of Moringa (Moringa oleifera L.) leaves. Am. J. Food Sci. Technol. 2017,5,53-60. [CrossRef] 52. Kakade, S.B.; Hathan, B. Effect of blanching and drying air temperature on quality characteristics of beetroot (Beta vulgaris L.)leaves powder. Int. J. Eng. Manag. Res. (IJEMR) 2014,4,213-219. 53. Pawase, P.; Gaikwad, M.; Veer, S. Effect of processing techniques (Pretreatments and Drying) on physico-chemical profile ofdrumstick leaves powder. Int. J. Chem. Res. Dev. 2018,1,8-11. 54. Tanongkankit, Y.; Chiewchan, N.; Devahastin, S. Physicochemical property changes of cabbage outer leaves upon preparationinto functional dietary fiber powder. Food Bioprod. Process. 2012, 90, 541-548.[CrossRef] 55. Nilnakara, S.; Chiewchan, N.; Devahastin, S. Production of antioxidant dietary fibre powder from cabbage outer leaves.Food Bioprod. Process. 2009,87,301-307.[CrossRef]

关闭-

1/11

-

2/11

还剩9页未读,是否继续阅读?

继续免费阅读全文产品配置单

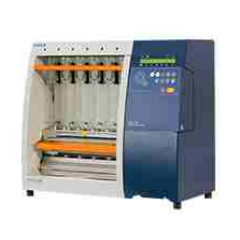

中国格哈特为您提供《木薯干叶蛋白质和粗纤维含量的检测》,该方案主要用于蔬菜中营养成分检测,参考标准《暂无》,《木薯干叶蛋白质和粗纤维含量的检测》用到的仪器有格哈特带自动进样器凯氏定氮仪VAP500C、格哈特凯氏消化系统KT8S、格哈特维克松废气实验室废物处理系统涤气VS、格哈特快速纤维测定器FBS6、德国加液器MM、凯氏消化管。

我要纠错

相关方案

咨询

咨询