黑种草籽含油率,黑种草籽粕蛋白质、脂肪、纤维含量的检测

检测样品 食用植物油

检测项目 营养成分

参考标准 GB 5009.5 食品安全国家标准 食品中蛋白质的测定

方案详情文

智能文字提取功能测试中

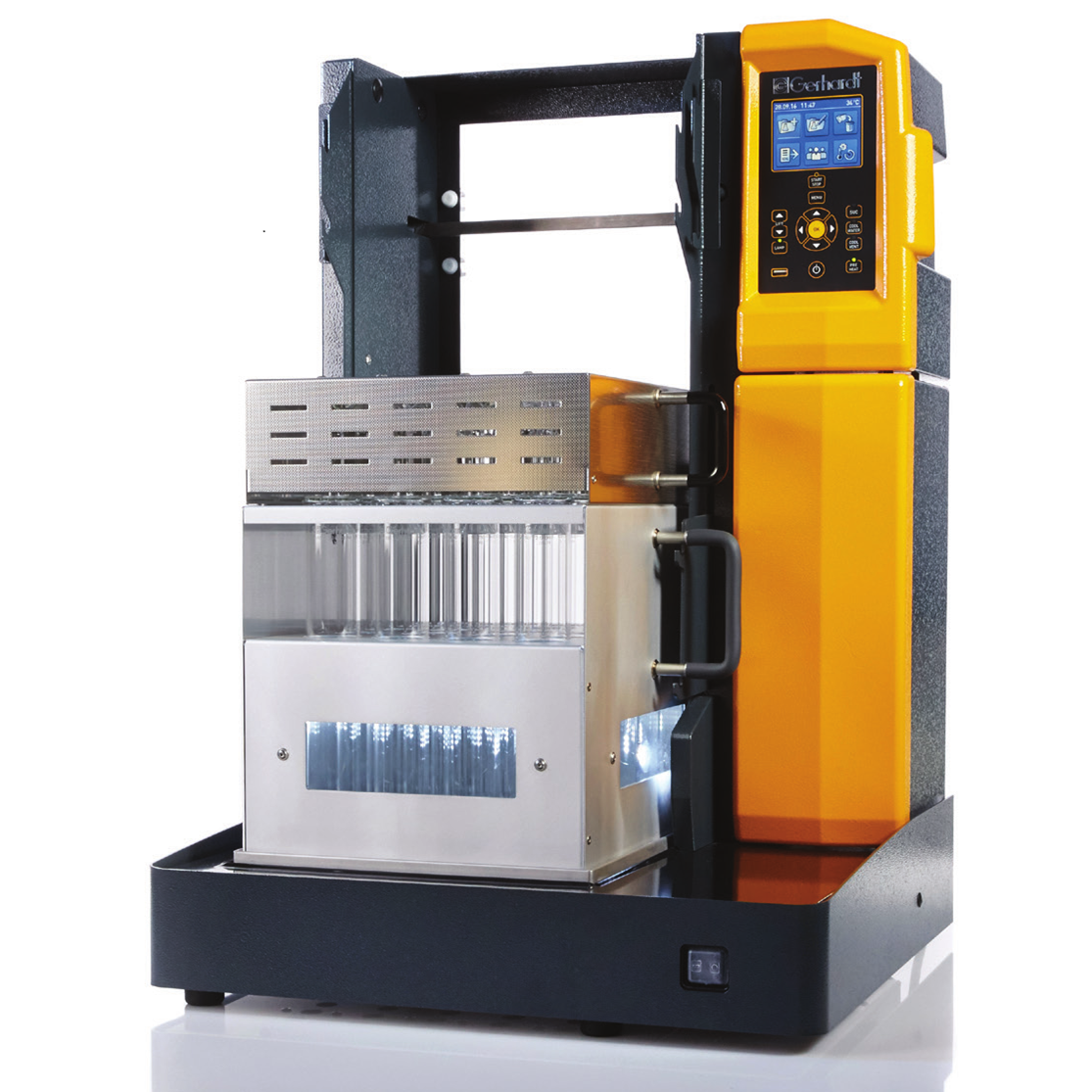

黑种草籽油的化学研究Chemical investigation of Nigella sativa L. seed oil produced in MoroccoJournal of the Saudi Society of Agricultural Sciences (2015) 14, 172–177Journal of the Saudi Society of Agricultural Scienceswww.ksu.edu.sa www.sciencedirect.coma icljjl pg Jol aigowiaooI SAUDI SOCIETY FOR AGRICULTURAL SCIENCES 173Nigella seed oil fromMorocco King Saud University FULLLENGTHARTICLE 摩洛哥黑种草籽油的化学研究 Chemical investigation of Nigella sativa L. seed oil Q CrossMark produced in Morocco Said Gharby a ,b , Hicham Harhar a ,*, Dominique Guillaume c , Aziza Roudani b , Samira Boulbaroud d , Mohamed Ibrahimi e , Mushtaq Ahmad f ,g , Shazia Sultana f ,g , Taibi Ben Hadda h , Imane Chafchaouni-Moussaoui i , Zoubida Charrouf a a Faculte´ des Sciences, Universite´ Mohammed V-Agdal, Rabat, Morocco b Etablissement Autonome de Controˆle et de Coordination des Exportations, Agadir, Morocco c UFRMe´decine-Pharmacie, CNRS, 51 rue Cognacq Jay, 51100 Reims, France d Faculty of Sciences, Ibn Tofail University, 14000 Kenitra, Morocco 伊本·托菲尔大学理学院 e Laboratoire Lesieur Cristal, Casablanca, Morocco f University Sains Malaysia, Penang, Malaysia 马来西亚理科大学 g Quaid-i-AzamUniversity, Islamabad 45320, Pakistan 巴基斯坦真纳大学 h Faculte´ des Sciences, Universite´ Mohammed 1er, Oujda 60000, Morocco i Universiapolis, Agadir, Morocco 摩洛哥阿加迪尔大学 Received 12 October 2013; accepted 4 December 2013Available online 11 December 2013 KEYWORDS Cold-press oil; Fatty acid; Nigella sativa ; Nutritive value; Morocco; Seed oil Abstract Seeds of Nigella sativa L. (black cumin or black seeds) are widely used in traditional Islamic medicine and for culinary purposes worldwide. Nigella seed oil is becoming popular in and out of the Islamic world. Composition of Nigella seed oil is known to be location-dependent. We investigated the composition ofNigella seed oil prepared by solvent- or cold press-extraction of Nigella seeds grown inMorocco.Oil extraction yieldwas 37% and 27%when solvent or cold press extraction methods were used, respectively. In terms of oil major components, composition of Nigella seed oil from Morocco is similar to that from other Mediterranean countries known for their Nigella seed-oil quality. ª 2013 Production and hosting by Elsevier B.V. on behalf of King Saud University. * Corresponding author. Tel.: +212 668799942. E-mail address: hichamoo79@yahoo.fr (H. Harhar). Peer review under responsibility of King Saud University. ELSEVIER Production and hosting by Elsevier 1. Introduction Nigella sativa L. (Ranunculaceae family) is an annual herba-ceous plant whose growth area extends from the countries of the southern- and eastern-rim of the Mediterranean basin to Iran, Pakistan, and India. In the ethnopharmacology of those countries,N. sativa seeds are used to cure gastro-intestinal dis-orders as well as skin or respiratory ailments (Riaz et al.,1996).Severalotherpharmacologicalpropertieshavebeen traditionally attributed to N. sativa seeds, simply as a crushed powder, or as an extract. Purified or as a mixture, metabolites of N. sativa seeds would present a potent and therapeutically interesting activity on the cardiovascular, respiratory, immune, and endocrine systems (Gilanie et al., 2004; El-Tahir et al.,2006; AitMbarek, 2007). Additional properties are frequently discovered (Al-Okbi et al., 2013).Most of these activities have already been attributed to thymoquinone, a major component of the essential oil of the seeds (Ali andBlunden, 2003). Addi-tionally, in its native range and far beyond,N. sativa seeds are also frequently used as spice and condiment in various recipes due to their characteristic aroma and bitter and peppery taste (Hedrick and Sturtevant, 1972). Finally, N. sativa seeds are used to prepare a highly prized nutritive oil. Although on the world scale Nigella seed oil does not really have a signifi-cant economic market share, yet, it nevertheless constitutes a niche market whose size is constantly growing due to its al-leged pharmacological properties, and to spirituous reasons resulting from its mention in sacred texts and reports of the presenceof Nigellaseedsin Tutankhamentomb (Padhye et al., 2008). In Morocco, large-scale production of Nigella seed oil is currentlyenvisioned asasupplementarysourceofincome for argan oil cooperatives. However, oil content of Nigella seed from Morocco has been reported to be low, compared to other regions (D’Antuono et al., 2002). Nevertheless, these results are questionable since for this study Nigella seeds were grown in Northern Italy. Because, previous investigations regarding N. sativa seed oil composition or yield have reported large variations (Cheikh-Rouhou et al., 2007), possibly result-ing from a different plant geographical origin, we decided to investigate the chemical composition of N. sativa seed oil cul-tivated in Morocco. The oil was prepared by solvent- or cold press-extraction. Thisstudyisaimed atprovidingsuitable tools for the resolution of twomatters: (1)Could N. sativa seed oil fromMorocco be used, alone or togetherwithNigella seed oil from a different origin, in the cosmetic, pharmacological or nutritious domains? and (2) Is Nigella seed oil fromMorocco different from Nigella seed oil from a different origin and, if so, can these differences be characterized in order to possibly detect adulterations that, regretfully, are quite frequent (Aitzetmuller et al., 1997). 2. Material and methods 2.1. Plant material and chemicals Cultivation of N. sativa was performed in the region ofGharb-Chrarda-BeniHssen (34°°150 0000North, 6°°350 0000West)where the year average temperature reported is 17.4 ℃℃C(average low:15.5 °°C, average high: 19.3 ℃℃C) and average precipitation is 600mmbetweenOctober andMay falls to nearly zero between May and October (Worldweatheronline, 2013). Seeds were harvested in June 2012 in the agricultural prov-ince of Had-Kourt (Region of Gharb-Chrarda-Beni Hssen, North-West of Morocco). After harvest, the seeds were stored at 4 °°C until processed. All the reagents were of analytical or HPLC grade. Iso-octane and isopropanol used as HPLCmobile phase and cyclohexane used for extinction coefficient determination were purchased from Professional Labo (Casablanca, Morocco). 2.2. Seed analysis Seed moisture content, expressed as percentage by mass, was determined using 5 g of seeds by adapting the AOACmethod 934.06 (AOAC, 1990). A Jouan Quality Systems oven regu-lated at 105 °C Cwas used. The difference between the results of two last determinations was 0.1 g of moisture per 100 g of sample. Oil yield was calculated following the DIN EN ISO 659 recommendation (ISO 659, 2009). Nutritional composition of the Nigella seed oil cake was determined using the recommendedmethods of the association of official analytical chemists (AOAC, 2005). Ash content was determined by incinerating 5 g of oil cake at 550 ℃℃Cin amuffle furnace. Crude protein content was calculated from the nitro-gen content measured by the Kjeldahl procedure with Ger-hardt model Vapodest20instrument,usingafactor6.25. Crude fiber was determined according to the gravimetric pro-cedure on defatted samples.The difference between dryweight and ash content of the residue was taken as an estimation of the crude fiber content (AOAC, 2005). All analyses were per-formed in triplicate. 2.2.1. Nigella oil analysis Oil extraction: Press-extractionwas carried out using screwless cold presses (IBG Monforts Oekotec GmbH, Mo¨ nchenglad-bach, Germany). Solvent-extraction was performed using 20 g of ground seeds placed in a Soxhlet apparatus and ex-tracted with hexane for 8 h. The organic phase was then con-centrated under vacuum and dried for 5min in an oven at 103± 2 ±2C. Oil samples were stored at 4 °°C and protected from sunlight prior analysis. Fatty acid composition : Fatty acid composition was deter-mined following regulation EEC/2568/91 (EEC/2568, 2003). Before analysis, fatty acids (FAs)were converted to fatty acid methyl esters (FAMEs) by shaking for 25min a solution of 60mg oil and 3mL of hexane with 0.3mL of 2Nmethanolic potassium hydroxide. FAMEs were analyzed by gas chromatography using a Varian CP-3800 (Varian Inc.) chro-matograph equipped with a FID. A split injector was used and the injected volume was 1 l l. The column used was a CP-Wax52CB column (30m · 0.25mm i.d.; VarianInc., Middelburg, The Netherlands). The carrier gas was helium and the total gas flow rate was 1mL/min. The initial and fi-nalcolumn temperature was 170and230 0 C, respectively, and the temperature was increased by steps of4 4C/min. The injector and detector temperature was 230 °°C.Data were processed using a Varian Star Workstation v 6.30 (Varian Inc., Walnut Creek, CA, USA). Results were expressed as the relative percentage of each individual FA present in the sample. Sterol composition: Sterol composition was determined using the NFT 60–254 method as previously described (Hilali et al., 2005). After trimethylsilylation of the crude sterol frac-tion, using aVarian 3800 instrument equippedwith aVF-1ms column (30m; 9 0.25mm i.d.) and helium (flow rate 1.6mL/mn) as carrier gas a splitless injector was used and the volume injected set at 1 l l. Column temperature was isothermal at 270 °°C, injector and detector temperaturewas 300 °°C. Injected quantitywas 1 l Lfor each analysis.Datawere processed using aVarian StarWorkstation v 6.30 (Varian Inc., WalnutCreek, CA,USA). 2.2.2. Physical and chemical oil parameters Free fatty acid content, peroxide value (PV), extinction coeffi-cients (K 232 and K 270), refractive index, and iodine value were determined according toAOCS recommended practicesCa 5a-40,Cd 8b-90,Ch 5-91,Cc 7-25,Cd 1c-85; respectively (AOCS,1998).Free fatty acid contentwas expressed as percent of oleic acid. PVwas expressed as milliequivalent of active oxygen per kilogram of oil (Meq O2/kg oil), and extinction coefficient (K 232 and K 270) was expressed as the specific extinction of a 1% (w/v) solutionofoilincyclohexanein1 cm cell path length, using a CARY 100 Varian UV spectrometer. 2.2.3. Oxidative stability of seed oils The oxidative stability of each sample was determined follow-ing theAOCS recommended practiceCd 12b-92 (AOCS, 1998) as the induction period (IP, h) recorded by a 743 Rancimat (Metrohm, Switzerland)apparatus using 3 gof oilsample. Samples placed in Rancimat standard tubes were tested by heating at 110 °C Cwith an air flow of 20 L/h. 2.2.4. Statistical analysis Values reported in tables and figures are the means± SE of three replications. The significance level was set at P =0.05. Separation of means was performed by the Tukey’s test at the 0.05 significance level. 3. Results and discussion 3.1. Chemical composition of dried Nigella sativa L. seeds Oil content inmostNigella seeds investigated, so far, is higher than 30% (Akram Khan et al., 1999; Mattha¨ us et al., 2011) and possibly up to 40% (Cheikh-Rouhou et al., 2007). How-ever, phenological events as water-stress or saline conditions, and eventually cool temperatures can reduce this yield to 13–23 (Al-Kayssi et al., 2011; Bourgou et al., 2010; Atta, 2003). Nigella seeds from Morocco afforded 37% and 27% of oil after hexane- or cold press-extraction, respectively (Table 1). These yields are very similar to those repeatedly reported for Nigella seeds cultivated in countries presentingweather condi-tions close to those encountered in Northwestern Morocco. Additionally,the reduced yieldobservedforcold press-ex-tracted Nigellaseedoil,compared tothesolvent-extracted oil has already been observed and explained the high solvent efficiency to extract oleoresins, compared to cold-pressing (Atta, 2003). A comparison of solvent-extracted Nigella seed oil yields, reported for various geographical origin is presented Table 1. Enzymatictriacylglyceride hydrolysis andsaponification reactions are responsible for free fatty acid (FFA) formation in vegetable oils. FFA determination is particularly important for industrial purposes since FFA can modify the oil organo-leptic or physicochemical properties. FFA content in Nigella seed oil was determined to be 2.3% and 0.9% for solvent-ex-tracted oil and cold-press extracted oil, respectively (Table 2). Similarly lowFFA values have already been reported for sol-vent extracted oil Nigella seed oil from Tunisia (Hamrouni-Sellami et al., 2003) or Pakistan (Sultan et al., 2009). Such low values must be opposed to the high values sometimes re-ported for Nigella seed oil (U¨ stun et al., 1990; Ramadan and Mo¨ rsel, 2002) and, the frequently alleged strong enzymatic hydrolysis of Nigella seeds during harvesting, handling or oil processing (U¨ stun et al., 1990) should be considered with cau-tion or, if true, can be easily prevented by seed storage at 4 °°C. Indeed, our results demonstrate that (1) if it exists, enzymatic triacyglyceride hydrolysis in Nigella seed oil fromMorocco is reduced at low temperature, and (2) solvent-extraction-associ-ated heat likely favors saponification reactions that are easily avoided by cold press-extraction. Cold press- and solvent-ex-tracted Nigella seed oil presented a similar iodine value (126–128 g of I 2/100 g) (Table 2) suggesting a similar unsaturated fatty acid (UFA) composition. Compared to Nigella seed oils from other geographical origin, this value is in the high range group together with Nigella seed oil fromEgypt (Atta, 2003). Such high value could suggest that Nigella seed oil fromMor-occo possesses a higher content in UFAs than most Nigella seed oils. Refractive index of solvent- and cold press-extracted oil was found to be very similar to each other and also similar to previously reported values (Cheikh-Rouhou et al., 2007). The oxidative state of any vegetable oil can be evaluated from the combined analysis of its PV, and its specific absorption at 232 (K 232) and 270 nm (K 270) which indicates the presence of primary and secondary oxidation products, respectively. Per-oxide values above 10 have been reported for Nigella seed oil (Bourgou et al., 2010; Ali et al., 2012) suggesting its high sensitivity toward oxidation. Interestingly,whereas solvent-ex-tracted Nigella seed oil from Morocco also presented a high PV (11.4 MeqO2/kg),cold press-extracted Nigellaseed oil PV was only 3.4 MeqO2/kg, a value even lower than that was reported for the oil from Pakistan (Sultan et al., 2009). Cold-press extraction is known to preserve oil integrity; there-fore it is very likely that the high PVs frequently observed for Nigella seed oil results from extraction-associated oxidative Country Yield (%) Reference Country Yield (%) References Morocco 37 This study Egypt 34.8 Ali and Blunden (2003) Italya 13–23 D’Antuono et al. (2002) Iran 40 Cheikh-Rouhou et al. (2007) Tunisia 28 Cheikh-Rouhou et al. (2007) Turkey 32 Nergiz and O¨ tles (1993) 31.7 Hamrouni-Sellami et al. (2003) 30–36 Mattha¨ us and O¨ zcan (2011) Pakistan 31.2 Sultan et al. (2009) Bangladesh 32 Ali et al. (2012) Turkey 29.4–29.7 U¨ stun et al. (1990) Saudi-Arabia 38.2 Al-Jassir (1992) Yemen 36.8–38.4 Al-Naqeep et al. (2009) a Moroccan seeds. Table 2 Physicochemical properties of the Moroccan Nigella seeds oil. Cold press-extracted Solvent-extracted Free fatty acids (as oleic %) 0.9± 0.2 2.3± 0.5 Iodine value (g of I2/100 g) 128± 2 126± 4 K232 1.585± 0.008 2.21± 0.01 K270 2.370± 0.003 2.771± 0.009 PV (MeqO2/kg) 3.4± 0.5 11.4± 2.5 Refractive index at 20 kgC 1.473± 0.002 1.468± 0.003 processes or from insufficient oxidation protection immedi-ately after extraction. Accordingly with PV, extinction coeffi-cients of solvent-extracted Nigella seed oil were found higher than those of press extracted oil confirming a higher oxidative state for solvent-extractedNigella seed oil, and, again, a better quality of the cold press extracted oil. 3.2. Fatty acid composition Fatty acid composition of Nigella seed oil from various geo-graphical origin has been extensively studied (Cheikh-Rouhou et al., 2007; Atta, 2003; Hamrouni-Sellami et al., 2003; Sultan et al., 2009; U¨ stun et al., 1990; Ali et al., 2012; Nergiz and O¨ tles, 1993; Harzallah et al., 2012). No significant differences were observed between the fatty acid compositions of our cold press- and solvent-extracted oils (Table 3). Fatty acid compo-sition of Nigella seed oil from Morocco was also found very similar to that of Nigella seed oils from different geographical origin with the major exceptions of Nigella seed oils from Egypt (Atta, 2003) and Tunisia (Hamrouni-Sellami et al.,2003).The composition of the former presented amyristic acid content ten times higher than that of Moroccan Nigella seed oil and reduced linolenic acid content (48% vs. 57%). Nigella seed oil fromTunisia presented a twice lower content in oleic acid, compared to Moroccan oil with a higher content in sat-urated fatty acids (myristic acid: 3.2% vs. average 1%, and stearic acid: 6.3% vs. average 3%). In Nigella seed oil from Morocco, linoleic and oleic acids represented the main unsaturated fatty acids and accounted for more than 80% of the total fatty acids and the high lino-leic/oleicacidratioevidencedthatsuch Nigellaoilshould not be used in fried food (Table 3). Thepresence of traces of other fatty acids inNigella seed oil as behenicoreicosenoicacidshasbeenreported(Atta,2003; Hamrouni-Sellami et al.,2003). Those fattyacids were not detected during our study or were possibly detected but in a so reduced amount that accurate quantification was impossible. Differences in fatty acid composition between different Nigella seed oils could be explained by various factors including seed ge-netic variations, oil processing differences, or different harvest dates. 3.3. Sterol composition Phytosterolsareimportant molecules endowed with potent biological properties (Awad and Fink 2000; Nickavar et al.,2003; Trautwein and Demonty, 2007). Total sterol content of solvent extracted Nigella seed oil was 2915mg/kg of oil (Table 4). As reported in previous studies (Cheikh-Rouhou et al., 2007; Atta, 2003; Hassanein et al., 2011; Salama,1973), b -sitosterol, stigmasterol, and campesterol were found to be themajor sterols ofNigella seed oil.No significant differ-encewas observed between cold press and solvent extracted oil (Table 4). Minor sterols were cholesterol,D 5-avenasterol, D 7-stigmasterol, and D 7-avenasterol. 3.4. Oxidative stability Oxidative stability is an important parameter to estimate vege-table oil susceptibility to oxidation, and consequently, its shelf life.Oxidative stability ofNigella seed oil has already been eval-uated to be satisfactory by UV absorption studies (Ramadan andMo¨ rsel, 2002).To get amore precise picture,we determined Nigella seed oil induction time by the Rancimat accelerated method (AOCS, 1998). An induction time of 13 and 9 h was found for cold press- and solvent-extracted Nigella seed oils, respectively. An induction time of 12 h has already been re-ported for Nigella seed oil from Tunisia(Cheikh-Rouhou et al., 2007)whileNigella seed oil from Iranwas said to present an impressive induction time of 50 h.Large variations inRanc-imat induction time have also been reported forNigella seed oil from Egypt (Edris, 2011). Content in volatile matters (Edris,2011) or in otherminor components as polyphenols or tocophe- Table 3 Moroccan Nigella seed oil fatty acid composition (%). Fatty acid Cold press-extracted Solvent-extracted Myristic acid (C14:0) 1± 0.1 0.2± 0.1 Palmitic acid (C16:0) 13.1± 0.2 11.9± 0.2 Palmitoleic acid (C16:1) 0.2± 0.1 0.2± 0.1 Stearic acid (C18:0) 2.3± 0.1 3.2± 0.1 Oleic acid (C18:1) 23.8± 0.1 24.9± 0.5 Linoleic acid (C18:2) 58.5± 0.1 56.5± 0.7 Linolenic acid (C18:3) 0.4± 0.1 0.2± 0.1 Arachidic acid (C20:0) 0.5± 0.1 0.2± 0.1 R Saturated fatty acids 16.8± 0.5 15.5± 0.5 RUnsaturated fatty acids 82.9± 0.5 82.1± 0.5 Sterols Cold press-extracted Solvent-extracted Cholesterol 0.9± 0.1 0.8± 0.4 Campesterol 13.1± 0.5 12.8± 0.5 Stigmasterol 17.8± 0.5 18± 1 b-Sitosterol 49.4± 1.5 51.3± 2.5 D5-Avenasterol 12.4± 0.5 8± 1 D7-Stigmasterol 0.6± 0.1 0.7± 0.1 D7-Avenasterol 2.1± 0.2 1.3± 0.5 Cold press-extracted Solvent-extracted Moisture 8.1± 0.5 11.6 Crude protein 23.3± 0.6 26.5± 0.5 Cellulose 6.8± 0.5 7.4± 1.2 Ash 9.6± 0.7 6.1± 0.5 rols (Ramadan et al., 2003) or phospholipids (Ramadan and Mo¨ rsel, 2004), whose primary importance has also been evi-denced for argan oil (Gharby et al., 2012) could explain such induction time variability. Finally, to determine the nutritional value of the oil extrac-tion residue, the proximate composition of oil cakes obtained after cold press- or solvent-extraction was determined (Table 5). Crude protein (23.3–26.5%), moisture (8.1–11.6%), andcellulose(6.8–7.4%) content were foundsimilartothat reported in other studies (Table 5) (Cheikh-Rouhou et al.,2007; Atta, 2003; Ali et al., 2012). Interestingly, ash content was found to be particularly high (6.1–9.6%). 4. Conclusion The present investigation indicates that the region of Gharb-Chrarda-BeniHssen is suitable to produce high qualityNigella seed oilwhose composition is comparablewith that of the best elsewhere-produced Nigella seed oils or other commonly used vegetable oils. It indeed constitutes rich source of many essen-tial nutrients that have a very positive effect on human health. The good shelf life presented by the cold-press extracted oil, as well as other desirable characteristics makes the Moroccan Nigellaseedoilasuitableingredientinthepharmaceutic, nutraceutic and cosmetic domains. Acknowledgment We thank the Higher Education Commission (HEC) of Morocco for their financial support. References Aitzetmuller, K., Werner, G., Ivanov, S.A., 1997. Seed oils of Nigella species and closely related genera. Oleag. Corps Gras Lipides 4,385–388. Akram Khan, M., 1999. Chemical composition and medicinal prop-erties of Nigella sativa Linn. Inflammopharmacology 7, 15–35. Ali, B.H., Blunden, G., 2003. Pharmacological and toxicological properties of Nigella sativa . Phytother. Res. 17, 299–305. Ali, M.A., Sayeed, M.A., Alam, M.S., Yeasmin, M.S., Khan, A.M., Muhamad, I.I., 2012. Characteristics of oils and nutrient contents of Nigella sativa Linn. and Trigonella foenum-graecum seeds. Bull. Chem. Soc. Ethiop. 26, 55–64. Al-Kayssi, A.W., Shihab, R.M., Mustafa, S.H., 2011. Impact of soil water stress on nigellone oil content of black cumin seeds grown in calcareous-gypsifereous soils. Agric. Water Manage. 100,46–57. Al-Okbi,S.Y., Mohamed, D.A., Hamed, T.E., Edris, A.E., 2013. Potential protective effect of Nigella sativa crude oils towards fatty liver in rats. Eur. J. Lipid Sci. Technol.. http://dx.doi.org/10.1002/ejlt201200256. AOAC, 1990. Official Methodof Analysisofthe Associationof Official Analytical Chemist. AOAC International, Arlington (USA), N ° 934.06. AOAC, 2005.AOACMethods-W. In:Horwitz (Ed.),OfficialMethods ofAnalysis ofAOACInternational, 18thEd.AOACInternational, Gaithersburg MD,USA . AOCS, 1998. Official Methods and Practices of the AOCS, fifth ed. AOCS Press, Champaign, USA . Atta, M.B., 2003. Some characteristics of nigella (Nigella sativa L.) seed cultivated in Egypt and its lipid profile. Food Chem. 83, 63–68. Awad, A.B., Fink, C.S.,2000.Phytosterols asanticancerdietary components:evidenceand mechanism of action.J. Nutr.130,2127–2130. Bourgou,S., Bettaieb,I.,Saidani, M., Marzouk, B., 2010. Fatty acids, essential oil, and phenolics modifications of black cumin fruit under NaCl stressconditions.J. Agric. Food Chem. 58,12399–12406. Cheikh-Rouhou, S.,Besbes, S.,Hentati,B.,Blecker,C.,Deroanne,C., Attia, H., 2007. Nigella sativa L. Chemical composition and phytochemical characteristics of lipid fraction. Food Chem. 101,673–681. D’Antuono, L.F.,Moretti, A.,Lovato, A.F.S., 2002. Seed yield, yield components, oil content and essential oil content and composition of Nigella sativa L. and Nigella damascena L. Ind. Crops Prod. 15,59–69. Edris, A.E., 2011. The chemicalcomposition andthe contentof volatile oil: Potential factors that can contribute to the oxidative stability of Nigella sativa L. crude oil. J. Diet. Suppl. 8, 1–9. EEC/2598, 2003. Commission of the European Communities. Regu-lation 2568/91 on the characteristics of olive oil and olive-residues and on relevant methods of analysis. Off. J. Eur. Commun. L248,1–109. El-Tahir,K.E.-L.H.,Bakeet,D.M., 2006.The black seed Nigella sativa Linnaeus-A mine for multi cures: a plea for urgent clinical evaluation of its volatile oil. J. T. U.Med. Sci. 1, 1–19. Gharby, S., Harhar, H., Guillaume, D., Haddad, A., Charrouf, Z.,2012. The originof virgin arganoil’shighoxidative stability unraveled. Nat. Prod. Commun. 7, 621–624. Gilani, A.H., Jabeen, A.,Khan, M.A.U., 2004. A review ofmedicinal uses and pharmacological activities of Nigella sativa . Pak. J. Biol. Sci. 7, 441–451. Hamrouni-Sellami, I., Kchouk, M.E., Marzouk, B., 2003. Lipid and aroma composition of black cumin (Nigella sativa L.) seeds from Tunisia. J. Food Biochem. 32, 335–352. Harzallah, H.J., Noumi, E., Bekir, K., Bakhrouf, A., Mahjoub, T.,2012. Chemical composition, antibacterial and antifungal proper-ties of Tunisian Nigella sativa fixed oil. Afr. J. Microbiol. Res. 6,4675–4679. Hassanein, M.M.M., El-Shami, S.M., El-Mallah, M.H., 2011. Inves-tigation of, lipids profiles of Nigella ,Lupin and artichoke seed oils to be used as healthy oils. J. Oleo. Sci. 60, 99–107. Hedrick,U.P., Sturtevant,E.L., 1972. Sturtevant’sEdible Plants of the World. Dover Publication Inc., NewYork, pp. 388–389. Hilali, M., Charrouf, Z., Soulhi, A.E.A.,Hachimi,L.,Guillaume, D.,2005.Influenceoforiginandextraction methodonarganoil physico-chemical characteristics and composition. J. Agric. Food Chem. 53, 2081–2087. ISO 659, Oilseeds – Determination of oil content (Reference method). EN ISO 659:2009. Mattha¨ us, B.,O¨ zcan, M.M., 2011. Fatty acids, tocopherol, and sterol contents of some Nigella species seed oil. Czech J. Food Sci. 29,145–150. Nergiz, C., O¨ tles, S., 1993. Chemical composition of Nigella sativa L. seeds. Food Chem. 48, 259–261. Nickavar,B.,Mojab,F., Javidnia,K.,Amoli,M.A.R., 2003.Chemical composition of the fixed and volatile oils of Nigella sativa L. from Iran. In: Z. Naturforsch. 58c, 629–631. Padhye, S., Banerjee, S., Ahmad, A., Mohammad, R., Sarkar, F.H.,2008. From here to eternity-the secret of pharaohs: therapeutic potential of black cumin seeds and beyond. Cancer Ther. 6, 495–510. Ramadan, M.F., Mo¨ rsel, J.-T., 2002. Neutral lipid classes of black cumin (Nigella sativa L.) seed oils. Eur. Food Res. Technol. 214,202–206. Ramadan, M.F., Mo¨ rsel,J.-T., 2004. Oxidative stability of black cumin (Nigella sativa L.), coriander (Coriandrum sativum L.) and niger (Guizotia abyssinica Cass.) crude seed oils upon stripping. Eur. J. Lipid Sci. Technol. 106, 35–43. Ramadan,M.F.,Kroh,L.W.,Mo¨ rsel, J.-T., 2003.Radical scavenging activity of black cumin (Nigella sativa L.), coriander (Coriandrum sativum L.), and niger (Guizotia abyssinica Cass.) crude seed oils and oil fractions. J. Agric. Food Chem. 51, 6961–6969. Riaz, M., Syed, M., Chaudhary, F.M., 1996. Chemistry of the medicinal plants of the genus Nigella .HamdardMedicus 39, 40–45. Salama, R.B., 1973. Sterols in the seed oil of Nigella sativa . Planta Med. 24, 375–377. Sultan, M.T., Butt, M.S., Anjum,F.M., Jamil, A., Akhtar, S., Nasir, M., 2009.Nutritional profile of indigenous cultivar of black cumin seeds and antioxidant potential of its fixed and essential oil. Pak. J. Bot. 41, 1321–1330. Trautwein,A.E.,Demonty, I., 2007. Phytosterols: natural compounds with establishedandemerginghealthbenefits. Ol. Corps Gras Lipides. 14, 259–266. U¨ stun,G.,Kent,L.,C¸ ekin,N.,Civelekoglu,H., 1990. Investigation of the technological properties of Nigella sativa (black cumin) seed oil. J. Am.Oil Chem. Soc. 67, 958–960. World weather online, (2013)

-

1/6

-

2/6

还剩4页未读,是否继续阅读?

继续免费阅读全文产品配置单

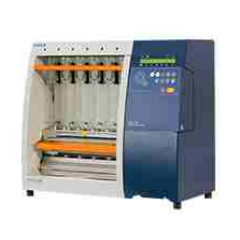

中国格哈特为您提供《黑种草籽含油率,黑种草籽粕蛋白质、脂肪、纤维含量的检测》,该方案主要用于食用植物油中营养成分检测,参考标准《GB 5009.5 食品安全国家标准 食品中蛋白质的测定》,《黑种草籽含油率,黑种草籽粕蛋白质、脂肪、纤维含量的检测》用到的仪器有格哈特带自动进样器凯氏定氮仪VAP500C、格哈特自动升降凯氏定氮电热消解仪KT-L 20s、格哈特全自动快速索氏提取SOXTHERM、格哈特全自动型纤维分析仪FT12、格哈特强力高重现振荡器LS500/RO500、德国移液器MM、凯氏定氮催化剂5.0g K2SO4+0.5g CuSO4 x 5H2O。

我要纠错

相关方案

咨询

咨询